Professional Documents

Culture Documents

RDC - Mix Design

RDC - Mix Design

Uploaded by

keshavaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RDC - Mix Design

RDC - Mix Design

Uploaded by

keshavaCopyright:

Available Formats

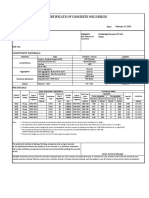

RDC CONCRETE (INDIA) PRIVATE LIMITED

CERTIFICATE OF CONCRETE MIX DESIGN

DATE: 17.04.2024

TO: PROJECT: (For

delivery of concrete):

Muneshwara associates Begur

CONSTITUENT MATERIALS:

Material Type Product / Source Supplier

Ordinary Portland Cement (OPC-53) Dalmia Kadapa

Cementitious

GGBS JSW Bellary.

Coarse Aggregate. Bidadi Various.

Aggregates

Fine Aggregates Bidadi Various.

MPCE Supafla PC260 Don construction products

Chemical Admixture

HPCE Auramix 450 Fosroc

MIX DESIGN DETAILS:

Project Requirement / IS CODE Specifications Mix Design Details

Aggregates

Total

Minimum Maximum Fine

Type of Average Cemen- Admixture

Grade Of Cemen-titious Maximum Size of Type of Coarse Aggregate.

Aggregates

Mode of Supply Cementitious Free W/C Slump/Flow Cementitious titious W/C Ratio Dosage in (%)

Concrete Content Aggregate

Material Ratio Material Content 20MM 12.5MM C.S.S.

Kg/Cum mm mm Kg/Cum Kg/Cum Kg/Cum Kg/Cum (%)

M20 Pump/Manual OPC 300 0.55 20MM 125±25 OPC+GGBS 240+60 661 437 830 0.52 0.3 to 1%

M25 Pump/Manual OPC 320 0.50 20MM 125±25 OPC+GGBS 256+64 664 439 806 0.49 0.3 to 1%

M30 Pump/Manual OPC 360 0.45 20MM 125±25 OPC+GGBS 288+72 670 443 769 0.43 0.3 to 1%

M35 Pump/Manual OPC 380 0.45 20MM 125±25 OPC+GGBS 304+76 671 444 748 0.41 0.3 to 1%

M40 Pump/Manual OPC 410 0.45 20MM 125±25 OPC+GGBS 328+82 674 446 718 0.38 0.3 to 1%

Note: 1. The above mix proportions are based on concrete performance observed at the time of submission of this Certificate of Mix Design.

2. The proportions & the quantities of constituent materials may change in future based on the performance, observations and/or routine revisions in mix designs.

3. The above concrete mixes are designed to confirm with acceptance criteria for compressive strength of concrete as per IS 456-2000 (Amendment no. 3, August 2007).

4. The sampling and testing of concrete specimens shall be as per guidelines of IS 4926-2003, IS 1199-1959 (Reaffirmed 1999) & IS 516-1959 (Reaffirmed 1999).

The methods of placing, finishing, compaction and curing of

RDC CONCRETE (INDIA) PVT.LTD.

Survey No.149/1, Kengeri Hobli,

Mysore Road, Kumbalgodu, concrete adopted at site significantly influence the quality of

Bangalore – 560074 in-situ concrete. It is, therefore, imperative that proper methods, PREETHU K J

www.rdcconcrete.com procedures and controls are exercised while handling the Technical Officer

concrete at site. 9739990245

To avoid harm to skin, minimize contact with wet concrete and wear suitable protective clothing. Whenever contact occurs

You might also like

- Price Comparisson - Bored Piling JCDC, Rev.02Document2 pagesPrice Comparisson - Bored Piling JCDC, Rev.02Zain AbidiNo ratings yet

- AGRT02 21 Guide To Road Tunnels Part 2 Planning Design CommissioningDocument176 pagesAGRT02 21 Guide To Road Tunnels Part 2 Planning Design CommissioningALDO IDROGONo ratings yet

- A Persuasive Speech On Limiting The Production and Use of PlasticDocument2 pagesA Persuasive Speech On Limiting The Production and Use of PlasticKemberly Semaña Penton100% (1)

- Imprintcrete Design m30-m40Document1 pageImprintcrete Design m30-m40Amol AwateNo ratings yet

- Mix Design 45 & 55Document1 pageMix Design 45 & 55syed AffanNo ratings yet

- APR Design Mix M10, M25, M30,&M35 For (Gar)Document1 pageAPR Design Mix M10, M25, M30,&M35 For (Gar)Pradeep ReddyNo ratings yet

- RDC Concrete (India) Private Limited: Certificate of Concrete Mix DesignDocument1 pageRDC Concrete (India) Private Limited: Certificate of Concrete Mix DesignAkashDashNo ratings yet

- Certificate of Concrete Mix Design: Strength - Performance - PassionDocument1 pageCertificate of Concrete Mix Design: Strength - Performance - PassionRamesh F SinghNo ratings yet

- RDC - M25 Mix Design With Flyash.Document1 pageRDC - M25 Mix Design With Flyash.Naresh CharyNo ratings yet

- Mix Design - Madhukar RaiDocument1 pageMix Design - Madhukar RaiGujjar Monu BhatiNo ratings yet

- ABHIJEET TALMARE Mix Design PDFDocument1 pageABHIJEET TALMARE Mix Design PDFImran KhanNo ratings yet

- Concrete Mix DesignDocument5 pagesConcrete Mix DesignshafeekNo ratings yet

- M-25 Mix DesignDocument2 pagesM-25 Mix DesignSharath RMNo ratings yet

- Concrete Mix Design C40/20-400 KG MSRC: Combined GradingDocument1 pageConcrete Mix Design C40/20-400 KG MSRC: Combined GradingkamakshiNo ratings yet

- Railway - M30 PSC Design MixDocument2 pagesRailway - M30 PSC Design MixAmit Ranjan SharmaNo ratings yet

- Summary of Concrete Mix DesignsDocument1 pageSummary of Concrete Mix DesignsKaran KumarNo ratings yet

- E - Painel 4 - 4o - Fórum - Sul - de - Biogás - 2022Document23 pagesE - Painel 4 - 4o - Fórum - Sul - de - Biogás - 2022y.goldoflaNo ratings yet

- m-50 Mix DesignDocument13 pagesm-50 Mix DesignProsenjit RoyNo ratings yet

- @aggregate For Students - Jun 23Document9 pages@aggregate For Students - Jun 23Asif Mahmud ArponNo ratings yet

- m-45 Mix DesignDocument13 pagesm-45 Mix DesignProsenjit RoyNo ratings yet

- Mix Design 5Document1 pageMix Design 5Rhizki SajaNo ratings yet

- Mastic Asphalt Source DetailsDocument3 pagesMastic Asphalt Source Detailsjitendra0% (1)

- (With Flyash) : M-20 KERBDocument8 pages(With Flyash) : M-20 KERBNaveen SinghNo ratings yet

- Kingdom of Saudi Arabia: Soils and AggregatesDocument1 pageKingdom of Saudi Arabia: Soils and AggregatesHamza AldaeefNo ratings yet

- BS1881 116 PDFDocument11 pagesBS1881 116 PDFjunqiangdongNo ratings yet

- M25 - Fluidic Mix Design With Trial MixDocument3 pagesM25 - Fluidic Mix Design With Trial Mixabir senguptaNo ratings yet

- Mix DesignDocument1 pageMix DesignjegadishNo ratings yet

- Cellular Concrete Mix Design: Agency ContactDocument1 pageCellular Concrete Mix Design: Agency ContactDilhara WickramaarachchiNo ratings yet

- M-20 MIX DESIGN - PCC (Subject To - Confirmation at Aite) : DistrictDocument3 pagesM-20 MIX DESIGN - PCC (Subject To - Confirmation at Aite) : DistrictAnuraazNo ratings yet

- Material Approval Submission: Jazz City KulimDocument28 pagesMaterial Approval Submission: Jazz City KulimMuhamad Yazid Bin Md YatinNo ratings yet

- Compound & Chemical Change Trial ReportDocument1 pageCompound & Chemical Change Trial ReportRS MANIKANDANNo ratings yet

- Concrete Mix Design STFA 09 06 2009Document20 pagesConcrete Mix Design STFA 09 06 2009Ahmet ÖzdenNo ratings yet

- Mix Design M - 30 NEWDocument6 pagesMix Design M - 30 NEWRajeev ReddyNo ratings yet

- Approved Mix Design Summary As On 14.02.2017 (Crushing & Washing)Document4 pagesApproved Mix Design Summary As On 14.02.2017 (Crushing & Washing)Manas Kumar SamalNo ratings yet

- Marshall Test SDBC-1 NEWDocument2 pagesMarshall Test SDBC-1 NEWSoumadip BhuniaNo ratings yet

- Approved SabieDocument1 pageApproved SabieMohammad DanishNo ratings yet

- BV-AGG-006 All in AggregateDocument4 pagesBV-AGG-006 All in AggregateLakshithaGonapinuwalaWithanageNo ratings yet

- 161115-00-S-DCL-4-241 Rev 0Document149 pages161115-00-S-DCL-4-241 Rev 0Amresh KumarNo ratings yet

- 04 Compressive Strength (Mix Design)Document1 page04 Compressive Strength (Mix Design)jitendraNo ratings yet

- 01 - GeosyntheticClayLiners - 2019Document3 pages01 - GeosyntheticClayLiners - 2019reshan champikaNo ratings yet

- Concrete Mix Design For Grade M - 30Document8 pagesConcrete Mix Design For Grade M - 30AswIni PadhiNo ratings yet

- Acc Concrete, Acc Limited: M/S.SSTP Expansion ProjectDocument1 pageAcc Concrete, Acc Limited: M/S.SSTP Expansion ProjectAmol Awate100% (1)

- M 35 PS Basf UltDocument2 pagesM 35 PS Basf UltSudarsanan KNo ratings yet

- Backfilling & Compaction Productive RateDocument4 pagesBackfilling & Compaction Productive RateIshan AththanayakeNo ratings yet

- C38 Mpa Type-IDocument17 pagesC38 Mpa Type-IshahulNo ratings yet

- BS 1881-119 1983 - Testing Concrete - Determination of Compressive StrengthDocument8 pagesBS 1881-119 1983 - Testing Concrete - Determination of Compressive Strengthmykel_dpNo ratings yet

- 16 Bitumen Invoice RegisterDocument2 pages16 Bitumen Invoice Registerakash dhamNo ratings yet

- Nuvoco TRDocument2 pagesNuvoco TRTricon Fortis noida projectNo ratings yet

- Approved List of BrandsDocument18 pagesApproved List of BrandsAishwarya KumarNo ratings yet

- BS 1881 101 1983 Testing Concrete. Method of Sampling Fresh Concrete On Site PDFDocument10 pagesBS 1881 101 1983 Testing Concrete. Method of Sampling Fresh Concrete On Site PDFaqyanNo ratings yet

- M40 With Fly AshDocument1 pageM40 With Fly Ashscribdfree anytimeNo ratings yet

- Likproof M10-M60Document21 pagesLikproof M10-M60likproofinfraprabhatNo ratings yet

- M30 With Fly AshDocument1 pageM30 With Fly AsharuthyannathuraiNo ratings yet

- MgCO3 Naikai Japan - Brocure & TDSDocument1 pageMgCO3 Naikai Japan - Brocure & TDSAreIf Cron BmxStreetNo ratings yet

- Analyzing KBC in Malaysia Bitumen IndustryDocument12 pagesAnalyzing KBC in Malaysia Bitumen IndustryMohd Noor AdamNo ratings yet

- List of NABL Accredited Labs PDFDocument47 pagesList of NABL Accredited Labs PDFAdarsh Kumar ManwalNo ratings yet

- Earthcon 2019 - Floor Plan NameDocument1 pageEarthcon 2019 - Floor Plan NameElement 5 expo SwatiNo ratings yet

- MSRC Cfa - 20230622 - 0001Document3 pagesMSRC Cfa - 20230622 - 0001Saad MuzaffarNo ratings yet

- Project:: Type of Concrete: RCC Concrete Confirms To: IS456 Concrete Mix For: Pump / ManualDocument2 pagesProject:: Type of Concrete: RCC Concrete Confirms To: IS456 Concrete Mix For: Pump / ManualKrishnaraj Cnt.No ratings yet

- Type - A Manhole BBS FileDocument1 pageType - A Manhole BBS FilefbdfNo ratings yet

- PPF Soil 1Document73 pagesPPF Soil 1Binayalal PatraNo ratings yet

- Case 3.1: "Ethical Selling at Perfect Solutions: The Case of The Delayed Product"Document3 pagesCase 3.1: "Ethical Selling at Perfect Solutions: The Case of The Delayed Product"Shan Danielle MortejoNo ratings yet

- Lab 06: Arrays & Functions Objective(s) :: ExercisesDocument4 pagesLab 06: Arrays & Functions Objective(s) :: ExercisesAhsan Ali GopangNo ratings yet

- Numerical Study On Application of CuO-Water NanoflDocument7 pagesNumerical Study On Application of CuO-Water NanoflvinodNo ratings yet

- Tutorial 2 EOPDocument3 pagesTutorial 2 EOPammarNo ratings yet

- Controller FIS134 19-22 EN PDFDocument4 pagesController FIS134 19-22 EN PDFrimce77No ratings yet

- S2 Chemistry 1Document42 pagesS2 Chemistry 1Jerry Jason100% (1)

- Ingress Protection-IP66-IEC60529Document12 pagesIngress Protection-IP66-IEC60529tushar2.khandelwalNo ratings yet

- Đề Thi Vào 10 - Bến TreDocument5 pagesĐề Thi Vào 10 - Bến TreMinh NguyễnNo ratings yet

- Tecsis P3276Document4 pagesTecsis P3276benNo ratings yet

- Academic Writing b2Document30 pagesAcademic Writing b2s.gouri100% (1)

- How To Be A SpeakerDocument6 pagesHow To Be A SpeakerGabor KovacsNo ratings yet

- Electron Scattering For Nuclear and Nucleon Structure John Dirk Walecka Full ChapterDocument51 pagesElectron Scattering For Nuclear and Nucleon Structure John Dirk Walecka Full Chapterwilliam.mcguire766100% (6)

- NDRP For Hydro-Met 2018Document117 pagesNDRP For Hydro-Met 2018Yusuf Al Rasheed SamijonNo ratings yet

- Kapita Selekta Modul MKKP PDFDocument74 pagesKapita Selekta Modul MKKP PDFDIKE NOVELLA -No ratings yet

- Lesson 6 Minerals and Rocks S11 12ES Ia 9Document8 pagesLesson 6 Minerals and Rocks S11 12ES Ia 9Christine CayosaNo ratings yet

- Test Erm T The Second:: MarkDocument2 pagesTest Erm T The Second:: Markkaimero changNo ratings yet

- Sumitomo Chemical Alumina (ENG)Document16 pagesSumitomo Chemical Alumina (ENG)Lawrence LauNo ratings yet

- Ethics Portfolio Miranda PierceDocument21 pagesEthics Portfolio Miranda Pierceapi-583731746No ratings yet

- 00 SP01 PDFDocument148 pages00 SP01 PDFAble KuriakoseNo ratings yet

- Flexible Coupling AssemblyDocument1 pageFlexible Coupling AssemblybluebirdNo ratings yet

- Com Eng ReviewerDocument132 pagesCom Eng ReviewerItsClarenceNo ratings yet

- DraimadDocument4 pagesDraimadAgustin VarelaNo ratings yet

- MiddleMagdalena Ramon&CrossDocument30 pagesMiddleMagdalena Ramon&CrossLaura Melendez RuedaNo ratings yet

- Qday7: CastorDocument1 pageQday7: CastorLiteratura esotericaNo ratings yet

- Ryna Du PlooyDocument8 pagesRyna Du PlooyRosel.RamosNo ratings yet

- Proc No 548 Multimodal TransportDocument19 pagesProc No 548 Multimodal TransportasdfNo ratings yet

- Prof Ed 109Document3 pagesProf Ed 109Nadnad DomingoNo ratings yet

- T 87 PG 101-102 PDFDocument2 pagesT 87 PG 101-102 PDFJossimar PerezNo ratings yet