Professional Documents

Culture Documents

FT 2 1 4A MR MK 201601 Ang

FT 2 1 4A MR MK 201601 Ang

Uploaded by

Juan Jose GomezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FT 2 1 4A MR MK 201601 Ang

FT 2 1 4A MR MK 201601 Ang

Uploaded by

Juan Jose GomezCopyright:

Available Formats

2.1.4A.

1

INDUSTRIAL DAMPER

MRO - MRG - MRS / MKO - MKG - MKS

VOLUME CONTROL

Industrial dampers series MR and MK are developped to resist important aeraulic constraints (high pressure,

high speed or high temperature). They are appropriate for industrial applications such as furnaces, chemical

industries, tunnels,...

CODIFICATION

MR X

Range MR – Industrial Reinforced

O – Non classified

Range MK – Industrial Hight pressure

G – Class 1

Information and data can not be considered as contractual. Design and data changes may occur without notice during F2A’s continuous product development.

S – Class 3

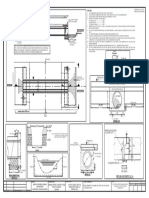

CONSTRUCTION

Frame

MR MK Blade

Galvanized steel thickness: 3 mm MR MK

Options: Stainless, painted steel or aluminium 4 mm

Galvanised steel

Drilling Ø12 in each angle or standard drilling Options : Stainless, painted steel or aluminium

with a step of 165 mm Thickness :

Special drilling on request Thickness :

2 x 1,5 mm

2 x 1,5 mm

Width : 185 mm + reinforced tube

Flanges : 55 mm Pitch: 165 mm

Bearings: cast iron cage + high temperature grease

Options: Stainless cage, Insert bronze, Teflon, Ertalyte

Zinc-coated steel shafts

Option : stainless steel

Ø 15 mm Ø 20 mm

Control

MR MK

Manual : Smooth shaft - length 150 mm

Shaft Ø16 - reinforced Linkage

Shaft Ø16

locking device

Zinc-coated-linkage with opposed blade operation

Motorised : Smooth shaft - length 150 mm Options : stainless steel, parrallel operation

Electric or pneumatic actuator supplied on request

1

2015/11

F2A - 70 Impasse des Barmettes - Parc d’activités des 2B - F 01360 BELIGNEUX

Tel. +33 (0) 4 78 06 54 72 - Fax +33 (0) 4 78 06 53 45 - E-mail : export@f2a.fr

2.1.4A.1 INDUSTRIAL DAMPER

MRO - MRG - MRS / MKO - MKG - MKS

VOLUME CONTROL

CONSTRUCTION

Volume control Antifrost Shut-off

MRO MKO MRG MKG MRS MKS

Lateral stainless steel lateral stainless steel

Seals None

seal EPDM seal on the blades

Class 1 according to EN

Non classified Class 3 according to EN 1751

Airtightness 1751

Option: frame’s airtightness classe C according to EN 1751

Acceptable pressure (L=1m) 4 000 Pa 6 000 Pa 4 000 Pa 6 000 Pa 4 000 Pa 6 000 Pa

Acceptable velocity 20 m/s 25 m/s 20 m/s 25 m/s 20 m/s 25 m/s

- 20°C to + 100°C EPDM seal in

standard version

Temperature - 20 to + 300°C - 20 to + 300°C

-20 to + 250°C with silicone seal

Information and data can not be considered as contractual. Design and data changes may occur without notice during F2A’s continuous product development.

in option

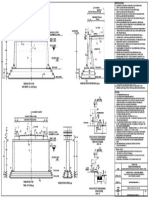

DIMENSIONS

• Height H from 180 to 2 490 mm with a pitch of 165 mm

• Length L from 200 to 2 500 mm with a pitch of 100 mm

Other dimension on request

WEIGHT (kg)

L

H 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2500

345 24 30 36 42 48 64 70 76 82 88 94 100 103

510 30 37 43 50 57 78 84 91 98 105 111 118 121

840 41 49 57 66 74 105 113 121 130 138 147 155 159

1170 51 61 72 82 92 131 142 152 162 172 182 192 197

1500 62 74 86 97 109 158 170 182 194 206 217 229 235

1830 73 86 100 113 127 185 199 212 226 239 253 266 273

2160 83 99 114 129 144 212 227 242 258 273 288 303 311

2325 89 105 121 137 153 225 241 258 274 290 306 322 330

2490 94 111 128 145 162 239 256 273 290 307 324 341 349

2

2015/11

F2A - 70 Impasse des Barmettes - Parc d’activités des 2B - F 01360 BELIGNEUX

Tel. +33 (0) 4 78 06 54 72 - Fax +33 (0) 4 78 06 53 45 - E-mail : export@f2a.fr

INDUSTRIAL DAMPER 2.1.4A.1

MRO - MRG - MRS / MKO - MKG - MKS

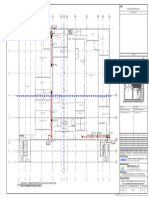

USE LIMITS

VOLUME CONTROL

The acceptable pressure of the damper, closed blades, must be higher than the accidental maximum

pressure of the network.

MRO / MRG / MRS Dampers MKO / MKG / MKS Dampers

Information and data can not be considered as contractual. Design and data changes may occur without notice during F2A’s continuous product development.

Accidental operating zone Accidental operating zone

Maximum operating zone Maximum operating zone

Recommended operating zone Recommended operating zone

MOTOR TORQUE

Consider the accidental maximal pressure to determine the minimum motor torque.

The design must include a safety coefficient.

Motor torque for a type of damper MRO or MKO.

For the dampers MRS and MKS, apply a 1.3-coefficient to the result.

1400 1800 2100 2500 345 510 675 840 1005

1200

1170

1000

1335

Height (mm)

Length (mm)

800

1500

1665

600 1830

1995

2160

400 2325

2490

200

4000

4000 3000

3000 2000

2000 1000

1000 55 10

10 15 20 2425 30 35 40

40 45

45 50

50

∆P (Pa) Motor torque (Nm)

3

2015/11

F2A - 70 Impasse des Barmettes - Parc d’activités des 2B - F 01360 BELIGNEUX

Tel. +33 (0) 4 78 06 54 72 - Fax +33 (0) 4 78 06 53 45 - E-mail : export@f2a.fr

2.1.4A.1 INDUSTRIAL DAMPER

MRO - MRG - MRS / MKO - MKG - MKS

LEAKAGE RATE (MRS / MKS version)

VOLUME CONTROL

The upstream-downstream leakage rate is proportional to the damper section and the pressure level.

Leakeage rate

Information and data can not be considered as contractual. Design and data changes may occur without notice during F2A’s continuous product development.

Duct pressure ( Pa)

Tests carried out according to EN 1751 standard.

PRESSURE LOSS

Pressure loss generated by a damper according to its blades opening:

0° = fully open

90° = fully closed

4

2015/11

F2A - 70 Impasse des Barmettes - Parc d’activités des 2B - F 01360 BELIGNEUX

Tel. +33 (0) 4 78 06 54 72 - Fax +33 (0) 4 78 06 53 45 - E-mail : export@f2a.fr

You might also like

- Volvo C70 S70 V70 1999 Wiring DiagramsDocument133 pagesVolvo C70 S70 V70 1999 Wiring DiagramsJarek Pietras75% (8)

- CS35 Service Manual (En)Document1,978 pagesCS35 Service Manual (En)huawei huawei0% (1)

- The Leading Edge by Goro Tamai - Complete IndexDocument8 pagesThe Leading Edge by Goro Tamai - Complete IndexBentley PublishersNo ratings yet

- Tesla CybertruckDocument24 pagesTesla CybertruckDeekshant RekhiNo ratings yet

- System Description LP3-CS4000 NHP2&4Document9 pagesSystem Description LP3-CS4000 NHP2&4AlexDorNo ratings yet

- 0900P Shocks Absorber Parker-IndustrialDocument50 pages0900P Shocks Absorber Parker-IndustrialRenato AlvesNo ratings yet

- A1 Side A2 Side: Longitudinal Sectional Elevational On 'Xyz'Document1 pageA1 Side A2 Side: Longitudinal Sectional Elevational On 'Xyz'sheikNo ratings yet

- Magnetic Work Light RecargableDocument1 pageMagnetic Work Light RecargableAlicia AltamiranoNo ratings yet

- Single Dead End, Terminal Pole, Dead End Riser Pole: Saudi Arabian Oil CompanyDocument1 pageSingle Dead End, Terminal Pole, Dead End Riser Pole: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Consolidated List of Civil, Structural, Technological Structures, Roads & Piles - 2.0 MTPY Iron Ore Pelletization Plant, NMDC, NagarnarDocument4 pagesConsolidated List of Civil, Structural, Technological Structures, Roads & Piles - 2.0 MTPY Iron Ore Pelletization Plant, NMDC, NagarnarVenkatesh HebbarNo ratings yet

- GDC Layout Updated 14.06.2023Document1 pageGDC Layout Updated 14.06.2023PradneshNo ratings yet

- JB MC STR CA 203 r0Document1 pageJB MC STR CA 203 r0Fatih ArıkanNo ratings yet

- General Notes: (Roads, Drainage and Structures) I. at SpecificationsDocument1 pageGeneral Notes: (Roads, Drainage and Structures) I. at SpecificationsDarren ValienteNo ratings yet

- Amar Factory To Jail Road Culvert-555Document1 pageAmar Factory To Jail Road Culvert-555AATVIK SHRIVASTAVANo ratings yet

- For Construction Drawing - FCD: General Structural Notes & SpecificationsDocument1 pageFor Construction Drawing - FCD: General Structural Notes & SpecificationsJossell De AlaNo ratings yet

- ZIBAGWE Offices UPDATEDocument1 pageZIBAGWE Offices UPDATEdereramichaelNo ratings yet

- APPROVAL DRAWING-ModelDocument1 pageAPPROVAL DRAWING-Modelnandkishormore1112No ratings yet

- PC110R-1 Wess001201 0902Document2 pagesPC110R-1 Wess001201 0902prajjwal patidarNo ratings yet

- Guide To Small Tools: Section OrganizationDocument48 pagesGuide To Small Tools: Section OrganizationKasia MazurNo ratings yet

- Yash Harde....Document1 pageYash Harde....jawareprathmesh02No ratings yet

- DWG Aaa SWG Dist Aispd 1102 01Document1 pageDWG Aaa SWG Dist Aispd 1102 01Wael OthmanNo ratings yet

- Fourth Floor Plan: NBCC (India) LimitedDocument1 pageFourth Floor Plan: NBCC (India) LimitedBindu BollempalliNo ratings yet

- Bato-Cogon Pertcpm (Final)Document1 pageBato-Cogon Pertcpm (Final)MANNY CARAJAYNo ratings yet

- 02 Podium&BasementDocument32 pages02 Podium&BasementMAGED ELSADIGNo ratings yet

- BSC - RGOrtigas - WD-AI 2.0Document1 pageBSC - RGOrtigas - WD-AI 2.0Ramon AngNo ratings yet

- Cube Test Result As Per Is: 456 & 516: Requisitioning Agency: M/S Ingeo Contractor PVT LTD AuthorityDocument21 pagesCube Test Result As Per Is: 456 & 516: Requisitioning Agency: M/S Ingeo Contractor PVT LTD AuthorityBinayalal PatraNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- Si - 02 - Figura 1 - Cuencas - AnalizadasDocument1 pageSi - 02 - Figura 1 - Cuencas - AnalizadasSantiago Forero ZuluagaNo ratings yet

- Flat Slab ModelDocument1 pageFlat Slab ModelMinaNo ratings yet

- Elite Extrusion BrochureDocument13 pagesElite Extrusion BrochureSultana Khanum0% (1)

- SRD - 111 - S CWDT 01 02.05.2022Document1 pageSRD - 111 - S CWDT 01 02.05.2022Nishant KarthikeyanNo ratings yet

- Slab Design SheetDocument8 pagesSlab Design SheetMano CivilengineerNo ratings yet

- Architecture: Construction Notes Design and Management ServicesDocument1 pageArchitecture: Construction Notes Design and Management ServicesChristian ReyesNo ratings yet

- 01 StructuralDocument39 pages01 StructuralSaifullahNo ratings yet

- RMR CcotaDocument4 pagesRMR CcotaFranco Olivera MartínezNo ratings yet

- Ar Ged 04 001 01Document1 pageAr Ged 04 001 01Bahaa MohamedNo ratings yet

- Made Easy!: 25Mm Square RangeDocument2 pagesMade Easy!: 25Mm Square RangeTonyNo ratings yet

- Inec314 Approved ElectricalDocument26 pagesInec314 Approved ElectricalUmer RashidNo ratings yet

- AD SHENDE SLAB BEAM RC 01 CEAD R0 25-02-2022-Model1Document1 pageAD SHENDE SLAB BEAM RC 01 CEAD R0 25-02-2022-Model1swapnil bokadeNo ratings yet

- 32 Gfc-P2c3-Tu02-Crp-Dr-Btn-73106-01-ADocument1 page32 Gfc-P2c3-Tu02-Crp-Dr-Btn-73106-01-ASUBHASH KUMARNo ratings yet

- S5-00A - WOOD WALL SCHEDULE AND DETAILS Rev.2 MarkupDocument1 pageS5-00A - WOOD WALL SCHEDULE AND DETAILS Rev.2 MarkupjhamiralexNo ratings yet

- Land Use and Zoning District / City / Municipal: Vicinity Map ScaleDocument18 pagesLand Use and Zoning District / City / Municipal: Vicinity Map ScaleGeraldine Araneta GalingNo ratings yet

- Thana To Anaj MandiDocument9 pagesThana To Anaj MandiAATVIK SHRIVASTAVANo ratings yet

- Details "B" BD 110: - Cadd Designer'SDocument1 pageDetails "B" BD 110: - Cadd Designer'SDileep K MahadevaiahNo ratings yet

- No. Despription Amount (USD) Remarks Architechture: Total #REF!Document63 pagesNo. Despription Amount (USD) Remarks Architechture: Total #REF!tianhe zhaoNo ratings yet

- Sa-0224311 0001 0000Document1 pageSa-0224311 0001 0000Bilal ChohanNo ratings yet

- HDS 120mm SystemDocument2 pagesHDS 120mm Systemrahavom20No ratings yet

- 01-EL-116 - LOCATION OF LUMINAIRES - KEY PLAN - UBICACIN DE LUMINARIAS - PLANO LLAVE - Revision 21Document1 page01-EL-116 - LOCATION OF LUMINAIRES - KEY PLAN - UBICACIN DE LUMINARIAS - PLANO LLAVE - Revision 21Maria Fernanda Trujillo ArizagaNo ratings yet

- 03.DET 2 Layout1Document1 page03.DET 2 Layout1division4 designsNo ratings yet

- Ysc-ms-769-Dw-0005 SHT 3 of 3 Rev-CDocument1 pageYsc-ms-769-Dw-0005 SHT 3 of 3 Rev-CbalamuralinakshatraNo ratings yet

- 2 Structure Design Outline Outline Perencanaan Struktur: 3 Special Specification Persyaratan KhususDocument1 page2 Structure Design Outline Outline Perencanaan Struktur: 3 Special Specification Persyaratan KhususbelmontRidwanNo ratings yet

- Spray Master: 250 Amp MIG GunDocument1 pageSpray Master: 250 Amp MIG GunLeonardo Martínez LópezNo ratings yet

- Building 02 - Corridor Smoke Extraction Layout For 3RD FloorDocument1 pageBuilding 02 - Corridor Smoke Extraction Layout For 3RD FloorMTT VIETPRONo ratings yet

- 62 Defence ExportsDocument1 page62 Defence Exportsganesh sonkarNo ratings yet

- FTRS Threaded Rod AnchorDocument2 pagesFTRS Threaded Rod AnchorariefNo ratings yet

- Wa-0636860 0001 0001Document1 pageWa-0636860 0001 0001Bilal ChohanNo ratings yet

- CD - BrgyMalaga - CalbayogCity - WesternSamarDocument18 pagesCD - BrgyMalaga - CalbayogCity - WesternSamarGeraldine Araneta GalingNo ratings yet

- Ajv DPW 10 525 CL DWG 0695 03 R03Document1 pageAjv DPW 10 525 CL DWG 0695 03 R03sivagnanamNo ratings yet

- AjthDocument1 pageAjthAA070 ShivaniNo ratings yet

- Final BeamsDocument1 pageFinal Beamsmudenda henryNo ratings yet

- Edge Series 2.0 Regulators: High Capacity, Single Stage RegulatorsDocument2 pagesEdge Series 2.0 Regulators: High Capacity, Single Stage Regulatorsdedy setiawanNo ratings yet

- Common Service Panel SLDDocument1 pageCommon Service Panel SLDVikasNehraNo ratings yet

- Schedule of Loads: LegendDocument1 pageSchedule of Loads: Legenddan PioquintoNo ratings yet

- GSMB Vanity Drawing - 02Document1 pageGSMB Vanity Drawing - 02rushdiNo ratings yet

- Caught-In or BetweenDocument6 pagesCaught-In or BetweenCiandeb GracianoNo ratings yet

- Mechanical Engineering Department: Lab ReportDocument13 pagesMechanical Engineering Department: Lab ReportLukman HadiNo ratings yet

- 2da Parte Cent - Tech 60694Document67 pages2da Parte Cent - Tech 60694Toni VazquezNo ratings yet

- ZW 310-6 MaintenanceDocument141 pagesZW 310-6 MaintenanceDragan100% (1)

- Swot AnalysisDocument6 pagesSwot AnalysisSneha SinhaNo ratings yet

- Lawsuit Against Shelby County Over Records SystemDocument27 pagesLawsuit Against Shelby County Over Records SystemKatherine Fretland100% (1)

- 213-4539 Control Gp-Transmission HydDocument2 pages213-4539 Control Gp-Transmission HydEdsw Riv ́sNo ratings yet

- Caravan Travel and Tours International, Inc. v. AbejarDocument3 pagesCaravan Travel and Tours International, Inc. v. AbejarCarlota Nicolas Villaroman100% (1)

- L1204C Plus - Section 4 - PowertrainDocument60 pagesL1204C Plus - Section 4 - PowertrainPeetNo ratings yet

- Advanced Tuning of A Delco ECM - V1.02Document23 pagesAdvanced Tuning of A Delco ECM - V1.02Leiden O'SullivanNo ratings yet

- Hero MotoCorp-AR-FY19 PDFDocument283 pagesHero MotoCorp-AR-FY19 PDFRishabh RanaNo ratings yet

- Output 1Document20 pagesOutput 1ahmedNo ratings yet

- Basic 2 Stroke T UnningDocument6 pagesBasic 2 Stroke T UnningCodaNorm S DevNo ratings yet

- Customer Information Pack: E70 TAGM Marine Auxiliary EngineDocument17 pagesCustomer Information Pack: E70 TAGM Marine Auxiliary EngineAlfonso RivasNo ratings yet

- AC72 Technical Data: AOSIF Cummins SeriesDocument9 pagesAC72 Technical Data: AOSIF Cummins SeriesfasdfsdNo ratings yet

- Task 14 - Engine and Motors - WorksheetDocument7 pagesTask 14 - Engine and Motors - WorksheetDenis DavidNo ratings yet

- A Study On Customer Satisfaction Towards Two WheelersDocument3 pagesA Study On Customer Satisfaction Towards Two WheelersMS editzz100% (1)

- Armstrong Pads Application Guide UsaDocument112 pagesArmstrong Pads Application Guide UsaselsoulNo ratings yet

- AS NZS 4680-2006 Hot-Dip Galvanized (Zinc) Coatings On FabriDocument33 pagesAS NZS 4680-2006 Hot-Dip Galvanized (Zinc) Coatings On FabriDang Thanh TuanNo ratings yet

- T400,450,500 LeafletDocument2 pagesT400,450,500 LeafletOsmar Alvites YachachinNo ratings yet

- Tdi Sdi MotorDocument25 pagesTdi Sdi Motordodo40100% (2)

- Gasoline Powered Generator Owner's Manual: Max Tool Customer ServiceDocument28 pagesGasoline Powered Generator Owner's Manual: Max Tool Customer ServiceErika LozadaNo ratings yet

- AE 323 Airbreathing Propulsion Assignment 1Document1 pageAE 323 Airbreathing Propulsion Assignment 1Ravi Kiran JanaNo ratings yet

- Route Used For Collection and Transportation of Solid Waste of The CityDocument11 pagesRoute Used For Collection and Transportation of Solid Waste of The CityBro Patil100% (1)

- The Static and Mobile Pressure Vessels 2016Document85 pagesThe Static and Mobile Pressure Vessels 2016Ravi Prakash BhartiNo ratings yet