Professional Documents

Culture Documents

Indium6.3 Water-Soluble Solder Paste

Indium6.3 Water-Soluble Solder Paste

Uploaded by

brunizzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indium6.3 Water-Soluble Solder Paste

Indium6.3 Water-Soluble Solder Paste

Uploaded by

brunizzaCopyright:

Available Formats

Product Data Sheet

Indium6.3 Water-Soluble

Solder Paste

Benefits Storage and Handling Procedures

• Excellent wetting and solder joint appearance Refrigerated storage will prolong the shelf life of

• Exceptional printing and response to pause solder paste. The shelf life of Indium6.3 is 4 months

• Wide reflow profile window when stored at <10°C. When storing solder paste

• Outstanding slump resistance contained in syringes and cartridges, the packages should

• Low voiding be stored with tip down.

• Halogen-Free

Solder paste should be allowed to reach ambient working

Alloys temperature prior to use. Generally, paste should be

Indium Corporation manufactures low oxide spherical removed from refrigeration at least two hours before use.

powder composed of eutectic Sn/Pb and Sn/Pb/Ag in Actual time to reach thermal equilibrium will vary with

the industry standard type 3 mesh size (J-STD-006). container size. Paste temperature should be verified

Other non-standard mesh sizes are available upon before use. Jars and cartridges should be labeled with

request. The weight ratio of the flux/vehicle to the date and time of opening.

solder powder is referred to as the metal load and

is typically in the range of 80-92% for standard alloy Material Safety Data Sheets

compositions. The MSDS for this product can be found online at

http://www.indium.com/techlibrary/msds.php

Standard Product Specifications

Alloy Metal Load Particle Size Placement

Sn63/Pb37 Printing Dispensing 25-45 µm The high tack value of Indium6.3 assures consistent

Sn62/Pb36/Ag2 89.5% (Type 3) 80-86% (Type 3) 0.001-0.0018” component holding power. It allows high speed

component placement operation, including use of tall

Packaging components. Tack remains adequate for over 24 hours

Standard packaging for stencil printing applications over a wide humidity range.

includes wide-mouth 500g jars and 700g cartridges. For

dispensing applications, 10cc and 30cc syringes are

standard. Other packaging options may be

available upon request.

OVER—>

B ELLC O R E AN D J- STD TE STS & RE SULTS

Test Result Test Result

J-STD-004 (IPC-TM-650) J-STD-005 (IPC-TM-650)

• Flux Type Classification ORH0 • Typical Solder Paste Viscosity

• Halide Content (F, Cl, Br) 0.0% (Sn63, 89.5%, Type 3

• SIR Pass Malcom (10 rpm), 1700 poise*

• Wetting Test Pass • Typical Tackiness 40g*

• Slump Test Pass

• Solder Ball Test Pass

*Pending statistical validation

All information is for reference only. Not to be used as incoming product specifications.

Form No. 98472 R2

www.indium.com askus@indium.com

ASIA: Singapore, Cheongju: +65 6268 8678

CHINA: Suzhou, Shenzhen, Liuzhou: +86 (0)512 628 34900

EUROPE: Milton Keynes, Torino: +44 (0) 1908 580400

USA: Utica, Clinton, Chicago: +1 315 853 4900

©2008 Indium Corporation

Indium6.3 Water-Soluble Solder Paste

Printing Reflow

Stencil Design: Recommended Profile:

Electroformed and laser cut/electropolished stencils produce

the best printing characteristics among stencil types. Stencil

aperture design is a crucial step in optimizing the print

process. The following are a few general recommendations:

• Discrete components — A 10-20% reduction of stencil

aperture has significantly reduced or eliminated the

occurrence of mid-chip solder beads. The “home plate”

design is a common method for achieving this reduction.

• Fine pitch components — A surface area reduction is

recommended for apertures of 20 mil pitch and finer. This

reduction will help minimize solder balling and bridging

that can lead to electrical shorts. The amount of reduction The profile shown here is designed for Indium6.3 with

necessary is process dependent (5-15% is common). Sn63/Pb37 and Sn62/Pb36/Ag2 under both air and

• For optimum transfer efficiency and release of the solder nitrogen reflow atmosphere. It serves as a general

paste from the stencil apertures, industry standard guideline in establishing a reflow profile for these alloys.

aperture and aspect ratios should be adhered to.

Printer Operation: Heating Stage:

The following are general recommendations for stencil A linear ramp rate of 0.5°- 2.0°C/second allows gradual

printer optimization for Indium6.3. Adjustments may be evaporation of volatile flux constituents and helps minimize

necessary based on specific process requirements: defects such as solder balling and/or beading and bridging

resulting from hot slump. It also prevents unnecessary

• Solder Paste Bead Size: 20-25mm diameter depletion of fluxing capacity when a high peak temperature

• Print Speed: 25-150mm/sec and extended time above liquidus is used.

• Squeegee Pressure: 0.018-0.027kg/mm of

blade length Liquidus Stage:

• Underside Stencil Wipe: Once every 10-25 prints A peak temperature of 25°- 45°C (215°C shown) above

or as necessary (dry the melting point of the solder alloy is needed to form

wipe recommended) a quality solder joint and achieve acceptable wetting due

• Solder Paste Stencil Life: >8 hrs. @ 20 to at to the formation of an intermetallic layer. If the peak

least 70% R.H. & 22-28°C temperature is excessive, or the time above liquidus

Wetting greater than the recommended 45-90 seconds, flux

Indium6.3 exhibits excellent wetting on a wide variety of charring, excessive intermetallic formation and damage

surface finishes, such as immersion tin, immersion to the board and components can occur.

silver, nickel/gold, palladium, alloy 42, HASL, and OSP,

under both air and nitrogen reflow atmosphere. The Cooling Stage:

solder joints yielded are very shiny and smooth, including A rapid cool down is desired to form a fine grain structure.

those of ultra-fine-pitch components. Indium6.3 has Slow cooling will form a large grain structure, which typically

ultra-low voiding performance. Minimal voiding can be exhibits poor fatigue resistance. The acceptable cooling

achieved with optimal process conditions. range is 0.5°C-6.0°C/second (2.0°-6.0°C/second is ideal).

Cleaning

Residue Cleaning: Indium6.3 flux residue is cleanable

up to at least 72 hours after reflow and is best cleaned

using DI water with a spray pressure of at least 60 psi

and a temperature of at least 55°C. These parameters

are a function of board complexity and cleaner efficency.

Stencil Cleaning: This is best performed using an

automated stencil cleaning system for both stencil and

misprint cleaning to prevent extraneous solder particles.

Most commercially available stencil cleaners and

isopropyl alcohol (IPA) work well.

This product data sheet is provided for general information only. It is not intended, described which are sold subject exclusively to written warranties and limitations

and shall not be construed, to warrant or guarantee the performance of the products thereon included in product packaging and invoices.

www.indium.com askus@indium.com

ASIA: Singapore, Cheongju: +65 6268 8678

CHINA: Suzhou, Shenzhen, Liuzhou: +86 (0)512 628 34900

EUROPE: Milton Keynes, Torino: +44 (0) 1908 580400

USA: Utica, Clinton, Chicago: +1 315 853 4900

©2008 Indium Corporation

You might also like

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Indium5.5LT Solder Paste: Product Data SheetDocument2 pagesIndium5.5LT Solder Paste: Product Data SheetluismcmcNo ratings yet

- ncsmq92 SolderDocument2 pagesncsmq92 SolderSergio MoyaNo ratings yet

- Indium10.8hf Pbfree Solder Paste 99040 A4 r9Document2 pagesIndium10.8hf Pbfree Solder Paste 99040 A4 r9rigoberto solNo ratings yet

- Durafuse LT Lowtemperature Indium10.8hf 99797 A4 r6Document2 pagesDurafuse LT Lowtemperature Indium10.8hf 99797 A4 r6Karthik ManiNo ratings yet

- Indium10.1HF Ultra-Low Voiding: Pb-Free Solder PasteDocument2 pagesIndium10.1HF Ultra-Low Voiding: Pb-Free Solder PasteBeto CRNo ratings yet

- ncsmq230 Pbfree Solder Paste 97722 r18Document2 pagesncsmq230 Pbfree Solder Paste 97722 r18deepak cNo ratings yet

- Indium8.9HFA 98549 R10Document2 pagesIndium8.9HFA 98549 R10José Antonio CuberoNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- NC-SMQ81: Solder PasteDocument2 pagesNC-SMQ81: Solder Pastealireza221369No ratings yet

- Indium5.1 Pbfree Solder Paste 97901 r8Document2 pagesIndium5.1 Pbfree Solder Paste 97901 r8Gustavo Kubo LacerdaNo ratings yet

- NC-SMQ®92J-UV Solder PasteDocument2 pagesNC-SMQ®92J-UV Solder PastebrunizzaNo ratings yet

- Amtech - RMA-223 Rev 0510Document2 pagesAmtech - RMA-223 Rev 0510Mohammed AbbariNo ratings yet

- Indium8.9hf Pbfree Solder Paste Pds 98485 r26Document2 pagesIndium8.9hf Pbfree Solder Paste Pds 98485 r26deepak cNo ratings yet

- Indium8 9HF-TDSDocument2 pagesIndium8 9HF-TDSSlavisa VeljkovicNo ratings yet

- Indium10.1 Pbfree Solder Paste 98881 r7Document2 pagesIndium10.1 Pbfree Solder Paste 98881 r7instagk99No ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- NC-SMQ®90 Solder Paste: Product Data SheetDocument2 pagesNC-SMQ®90 Solder Paste: Product Data SheetbrunizzaNo ratings yet

- Indium10.2hf Pbfree Solder Paste 99018 A4 r4Document2 pagesIndium10.2hf Pbfree Solder Paste 99018 A4 r4deepak cNo ratings yet

- ncsmq92j Solder Paste 97703 r13Document2 pagesncsmq92j Solder Paste 97703 r13Beto CRNo ratings yet

- Indium6.4R: Water-Soluble Pb-Free and SNPB Solder PasteDocument6 pagesIndium6.4R: Water-Soluble Pb-Free and SNPB Solder PasteKenn Jaspher QuinitNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Document3 pagesMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- TDS SV3 SV3 240325Document2 pagesTDS SV3 SV3 240325barritojaiNo ratings yet

- ContinueDocument2 pagesContinueTANNo ratings yet

- Carboguard 891: Selection & Specification DataDocument4 pagesCarboguard 891: Selection & Specification DataPrakashNo ratings yet

- Chipbonder BasicsDocument53 pagesChipbonder Basicsekasurya2012No ratings yet

- Sigmacover 380Document18 pagesSigmacover 380eitan-dalia4971No ratings yet

- 3289310Document2 pages3289310Philippe VelhaNo ratings yet

- Rma 223Document2 pagesRma 223Sergio ChicNo ratings yet

- Carboguard 893 SG MIO PDSDocument4 pagesCarboguard 893 SG MIO PDSMuthuKumarNo ratings yet

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiNo ratings yet

- NC-559-ASM, No-Clean Solder Paste: Product Data SheetDocument2 pagesNC-559-ASM, No-Clean Solder Paste: Product Data SheetAkhmad MukhsinNo ratings yet

- Apcoguard SF 725Document3 pagesApcoguard SF 725kiran vargheseNo ratings yet

- 02.hand Soldering (0.10 MB)Document6 pages02.hand Soldering (0.10 MB)essen999No ratings yet

- Carbozinc 858 PDSDocument4 pagesCarbozinc 858 PDShuycongvuNo ratings yet

- Carbocoat 8239: Selection & Specification DataDocument4 pagesCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Alpha Om-338 Teknisk DatabladDocument3 pagesAlpha Om-338 Teknisk Databladnormans00No ratings yet

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetDocument7 pagesAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasingheNo ratings yet

- Shell S4 OGT + SolidDocument2 pagesShell S4 OGT + SolidMuhammad SaputraNo ratings yet

- 3048421Document2 pages3048421Philippe VelhaNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Solder Paste SC Blf03: Lead-FreeDocument2 pagesSolder Paste SC Blf03: Lead-FreeluismcmcNo ratings yet

- Amercoat 370Document3 pagesAmercoat 370Victor Hugo Bustos Beltran100% (1)

- Solder Paste SC 170: Physical PropertiesDocument2 pagesSolder Paste SC 170: Physical PropertiesluismcmcNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- Henkel Loctite Engineering Manual Loctite GC 10 Solder Paste PDFDocument51 pagesHenkel Loctite Engineering Manual Loctite GC 10 Solder Paste PDFVICTOR MARCOSNo ratings yet

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraNo ratings yet

- Interplate 317: Zinc Silicate Shop PrimerDocument4 pagesInterplate 317: Zinc Silicate Shop PrimerMohamed NouzerNo ratings yet

- Amtech: LF-4300 Lead-Free Water Washable No-Clean Solder PasteDocument2 pagesAmtech: LF-4300 Lead-Free Water Washable No-Clean Solder PastebehzadNo ratings yet

- AN5963Document7 pagesAN5963Smriti SNo ratings yet

- 186 Soldering Flux Data SheetDocument2 pages186 Soldering Flux Data SheetBéla BődiNo ratings yet

- Sigmaprime 700Document7 pagesSigmaprime 700Trịnh Minh KhoaNo ratings yet

- Fujifilm Finepix s9000 s9500 SM ET 1Document147 pagesFujifilm Finepix s9000 s9500 SM ET 1newionNo ratings yet

- Technical Data Sheet Jazeera Selfmastic JI-66009: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Selfmastic JI-66009: Descriptionsalam nazarNo ratings yet

- Sigma Marine Coatings Manual - Part41Document2 pagesSigma Marine Coatings Manual - Part41EngTamerNo ratings yet

- 4010 TDS EnglishDocument1 page4010 TDS EnglishJose Luis Ramirez RamirezNo ratings yet

- R276 Global (03oct07)Document2 pagesR276 Global (03oct07)Dave GershawNo ratings yet

- Oxford Alloy 420 (ER420)Document1 pageOxford Alloy 420 (ER420)brunizzaNo ratings yet

- OK Grain 21.85Document1 pageOK Grain 21.85brunizzaNo ratings yet

- Oxford Alloy 182 (ENiCrFe-3)Document1 pageOxford Alloy 182 (ENiCrFe-3)brunizzaNo ratings yet

- Bar SolderDocument1 pageBar SolderbrunizzaNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- Oxford Alloy 385-16 (E385)Document1 pageOxford Alloy 385-16 (E385)brunizzaNo ratings yet

- Usw Alloy Designation AND Description Issued Data Sheet: Revision No. ADocument1 pageUsw Alloy Designation AND Description Issued Data Sheet: Revision No. AbrunizzaNo ratings yet

- Oxford Alloy A (ENiCrFe-2)Document1 pageOxford Alloy A (ENiCrFe-2)brunizzaNo ratings yet

- Oxford Alloy 625T-1 (ENiCrMo3T1-1)Document1 pageOxford Alloy 625T-1 (ENiCrMo3T1-1)brunizzaNo ratings yet

- Hobart Maxal 4943Document2 pagesHobart Maxal 4943brunizzaNo ratings yet

- SK Tool Alloy C-S (Up 23-Gf-200-Ckz)Document1 pageSK Tool Alloy C-S (Up 23-Gf-200-Ckz)brunizzaNo ratings yet

- SK 322-O (MF 3-GF-55-T)Document1 pageSK 322-O (MF 3-GF-55-T)brunizzaNo ratings yet

- Fluxofil 41 (T 55 6 1nimo B M, C 3 h5)Document1 pageFluxofil 41 (T 55 6 1nimo B M, C 3 h5)brunizzaNo ratings yet

- Thermanit Mts 3 (G Crmo91, Er90s-B9)Document1 pageThermanit Mts 3 (G Crmo91, Er90s-B9)brunizzaNo ratings yet

- AFM Bronze AlloysDocument15 pagesAFM Bronze AlloysbrunizzaNo ratings yet

- Nicrobraz Cement 680Document1 pageNicrobraz Cement 680brunizzaNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- Uv 421 TT (Sa FB 1 65 DC h5)Document4 pagesUv 421 TT (Sa FB 1 65 DC h5)brunizzaNo ratings yet

- The World Specialist in Nickel Based Alloy Wire: Phyweld 82Document1 pageThe World Specialist in Nickel Based Alloy Wire: Phyweld 82brunizzaNo ratings yet

- Carbofil Crmo9 (G Crmo9)Document1 pageCarbofil Crmo9 (G Crmo9)brunizzaNo ratings yet

- NC-SMQ®90 Solder Paste: Product Data SheetDocument2 pagesNC-SMQ®90 Solder Paste: Product Data SheetbrunizzaNo ratings yet

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Citoflux r82 SR (T 46 6 Ni1 P M 1 h5)Document1 pageCitoflux r82 SR (T 46 6 Ni1 P M 1 h5)brunizzaNo ratings yet

- Basinox 318: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageBasinox 318: MMA Electrodes Stainless and Heat Resistant SteelsbrunizzaNo ratings yet

- Jurnal Biologi, Volume 6 No 4, Oktober 2017 Hal. 106-114Document11 pagesJurnal Biologi, Volume 6 No 4, Oktober 2017 Hal. 106-114Moch NafilaNo ratings yet

- Liste Des FiltresDocument6 pagesListe Des FiltresYacine MokhtariNo ratings yet

- Different Interpretation Approaches To Acid Base Disturbances Mohamad Atef Radwan 2011Document54 pagesDifferent Interpretation Approaches To Acid Base Disturbances Mohamad Atef Radwan 2011nicky_lauw5885No ratings yet

- Constancy Testing Services: Research &Document6 pagesConstancy Testing Services: Research &SaJedur RahmanNo ratings yet

- 6 Coal Tar Epoxy CTE 110Document2 pages6 Coal Tar Epoxy CTE 110shrikrishna rathodNo ratings yet

- Answer Key - Andhra Pradesh - Ntse - Stage 1 - 2020-21 - SatDocument15 pagesAnswer Key - Andhra Pradesh - Ntse - Stage 1 - 2020-21 - SatVikas PassiNo ratings yet

- SC7620 Mini Sputter Coater Operating Manual: For Technical and Applications Advice Plus Our On-Line Shop For Spares andDocument33 pagesSC7620 Mini Sputter Coater Operating Manual: For Technical and Applications Advice Plus Our On-Line Shop For Spares andatul nalavadeNo ratings yet

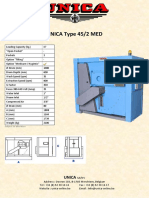

- UNICA Type 45/2 MEDDocument13 pagesUNICA Type 45/2 MEDkikokiko KarimNo ratings yet

- Halogen Oxidizing PowersDocument8 pagesHalogen Oxidizing PowersUkko PulkkinenNo ratings yet

- Determination of Dissolved Oxygen in Water by Winkler's Method-1Document8 pagesDetermination of Dissolved Oxygen in Water by Winkler's Method-1AJAY VISHNU M S100% (1)

- Biochem 101 LaboratoryDocument7 pagesBiochem 101 LaboratoryAiza MadroneroNo ratings yet

- Test Bank For Principles of General Organic and Biological Chemistry 2nd Edition Smith 0073511196 9780073511191Document36 pagesTest Bank For Principles of General Organic and Biological Chemistry 2nd Edition Smith 0073511196 9780073511191andrewgutierrezxtycopqfrd100% (21)

- InhibitionDocument17 pagesInhibitionLong Nhật PhanNo ratings yet

- United States Geological Survey Certificate of Analysis: Andesite, AGV-2Document3 pagesUnited States Geological Survey Certificate of Analysis: Andesite, AGV-2GimpsNo ratings yet

- Periodic Table Exam Questions (Chapter 2) : 131 Minutes 131 MarksDocument35 pagesPeriodic Table Exam Questions (Chapter 2) : 131 Minutes 131 MarksrejymolNo ratings yet

- AdatinaDocument1 pageAdatinaCRISTIELI IZABEL FOGUESATTONo ratings yet

- Dike Wall DesignDocument4 pagesDike Wall Designdantevarias100% (2)

- Materials and Design: - Ilker Bekir Topçu, Ahmet Raif Bog ADocument8 pagesMaterials and Design: - Ilker Bekir Topçu, Ahmet Raif Bog AJHON WILMAR CARDENAS PULIDONo ratings yet

- Dropping Point of Lubricating Grease: Standard Test Method ForDocument5 pagesDropping Point of Lubricating Grease: Standard Test Method ForPyone Ei ZinNo ratings yet

- Thermal Conductivity of Plastics by Means of A Transient Line-Source TechniqueDocument5 pagesThermal Conductivity of Plastics by Means of A Transient Line-Source TechniqueProvocateur SamaraNo ratings yet

- Longitudinal Tensile Properties of "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and TubeDocument6 pagesLongitudinal Tensile Properties of "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and TubeShaker QaidiNo ratings yet

- Buffers Green2018Document5 pagesBuffers Green2018pratibhauohanibtNo ratings yet

- Chromatography Higher QDocument2 pagesChromatography Higher QKhadijahNo ratings yet

- Manual of Fumigation For Insect Control PDFDocument333 pagesManual of Fumigation For Insect Control PDFThanh Tâm TrầnNo ratings yet

- Articulo #2Document6 pagesArticulo #2Lizana AdielNo ratings yet

- Structural Bolts, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthDocument8 pagesStructural Bolts, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthSendi Dwi OktaviandiNo ratings yet

- BS en 13820-2003Document12 pagesBS en 13820-2003محمد قديشيNo ratings yet

- Electrical Conductivity and Density of CoSO4H2SO4 Solutions in The Range of Modern Cobalt Electrowinning ElectrolytesDocument7 pagesElectrical Conductivity and Density of CoSO4H2SO4 Solutions in The Range of Modern Cobalt Electrowinning ElectrolytesEXELON_1No ratings yet

- How Do I Prepare For Inorganic Chemistry For The JEE AdvancedDocument5 pagesHow Do I Prepare For Inorganic Chemistry For The JEE Advancedbibhas_samantaNo ratings yet

- (Comprehensive Bioactive Natural Products 8) V K Gupta, S C Taneja, B D Gupta - Comprehensive Bioactive Natural Products, Volume 8 - Quality Control & Standardization - Studium Press LLC (2010) PDFDocument363 pages(Comprehensive Bioactive Natural Products 8) V K Gupta, S C Taneja, B D Gupta - Comprehensive Bioactive Natural Products, Volume 8 - Quality Control & Standardization - Studium Press LLC (2010) PDFrukwavuNo ratings yet