Professional Documents

Culture Documents

CAJ1427

CAJ1427

Uploaded by

mr. mydCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAJ1427

CAJ1427

Uploaded by

mr. mydCopyright:

Available Formats

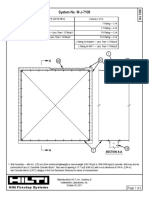

System No.

C-AJ-1427

Through Penetrations

March 05, 2007

F Rating – 3 Hr

T Rating – 0 Hr

W Rating – Class 1 (See Item 3)

Metallic Pipes

1. Floor or Wall Assembly – Min 2-1/2 in. (64 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600 - 2400 kg/m3) concrete

floors or min 3 in. (76 mm) thick reinforced lightweight or normal weight concrete walls. Floor assembly may also be constructed of any

min 6 in.(152 mm) thick UL Classified hollow-core Precast Concrete Units*. Wall may also be constructed of any UL Classified Concrete

Blocks*. Max diam of opening 12-3/4 in. (324 mm). Max diam of opening in floors constructed of hollow-core concrete is 7 in. (78 mm).

See Concrete Blocks (CAZT) and Precast Concrete Units (CFTV) categories in Fire Resistance Directory for names of manufacturers.

1A. Steel Sleeve – (Optional) - Nom 12 in. (305 mm) diam (or smaller) Schedule 10 (or heavier) steel sleeve cast or grouted into floor or wall

assembly. Steel sleeve may be installed flush or may project max 2 in. (51 mm) beyond the floor or wall surfaces. As an alternate, nom 12 in.

(305 mm) diam (or smaller) sleeve fabricated from nom 0.019 in. (0.48 mm) thick galv steel cast or grouted into floor or wall assembly flush

with floor or wall surfaces.

1000 Series

2. Through Penetrant – One metallic pipe, conduit, tubing or flexible metal piping installed concentrically or eccentrically within opening.

Annular space between penetrant and periphery of opening or sleeve shall be min of 0 in. (0 mm) (point contact) to max 2 in. (51 mm).

Penetrant to be rigidly supported on both sides of floor or wall assembly. The following types and sizes of penetrants may be used:

A. Steel Pipe – Nom 10 in. (254 mm) diam (or smaller) Schedule 10 (or heavier) steel pipe.

B. Iron Pipe – Nom 10 in. (254 mm) diam (or smaller) cast or ductile iron pipe.

C. Conduit – Nom 6 in. (152 mm) diam (or smaller) steel conduit or nom 4 in. (102 mm) diam (or smaller) steel electrical metallic tubing.

D. Copper Tubing – Nom 4 in. (102 mm) diam (or smaller) Type L (or heavier) copper tubing.

E. Copper Pipe – Nom 4 in. (102 mm) diam (or smaller) Regular (or heavier) copper pipe.

F. Through Penetrating Product* – Flexible Metal Piping – The following types of steel flexible metal gas piping may be used:

1.) Nom 2 in. (51 mm) diam (or smaller) steel flexible metal gas piping. Plastic covering on piping may or may not be removed on

both sides of floor or wall assembly.

OMEGA FLEX INC

2.) Nom 1 in. (25 mm) diam (or smaller) steel flexible metal gas piping. Plastic covering on piping may or may not be removed on

both sides of floor or wall assembly.

GASTITE, DIV OF TITEFLEX

3.) Nom 1 in. (25 mm) diam (or smaller) steel flexible metal gas piping. Plastic covering on piping may or may not be removed on

Concrete

both sides of floor or wall assembly.

WARD MFG INC

3. Firestop System – The details of the firestop system shall be as follows:

A. Packing Material – Min 2 in. (51 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into opening

as a permanent form. Packing material to be recessed from top surface of floor or top edge of sleeve or from both surfaces of wall or

both ends of sleeve as required to accommodate the required thickness of fill material. In floors constructed of hollow-core concrete,

packing material to be recessed from top and bottom surfaces of floor or sleeve as required to accommodate the required thickness of

fill material.

B. Fill, Void or Cavity Materials* – Caulk or Sealant – Min 1/2 in. (13 mm) thickness of caulk applied within the annulus, flush with top

surface of floor or top edge of sleeve or with both surfaces of wall or both ends of sleeves. In floors constructed of hollow-core concrete,

min 1/2 in. (13 mm) thickness of caulk applied within the annulus, flush with top and bottom surfaces of floor or sleeve. Min 1/4 in.

(6 mm) diam bead of caulk applied to the penetrant/concrete or penetrant/sleeve interface at the point contact location on the top surface

of floor or both surfaces of wall or hollow-core.

CAJ

3M COMPANY – IC 15WB+, CP 25WB+ caulk or FB-3000 WT sealant

(Note: W Rating applies only when FB-3000 WT is used.)

*Bearing the UL Classification Mark

This material was extracted and drawn by 3M Fire Protection Products from the 2007 edition of the UL Fire Resistance Directory.

3Fire Protection Products Product Support Line: 1-800-328-1687

60 www.3m.com/firestop C-AJ-1427 • 1 of 1 Choose option 4 for FAX ON DEMAND

You might also like

- Pre Pouring Inspection ChecklistDocument2 pagesPre Pouring Inspection Checklistvarunstuff75% (4)

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- U412 - 2 HourDocument4 pagesU412 - 2 Hourmaher58No ratings yet

- NMAC 14.7.4 New Mexico Earthen Building Materials CodeDocument16 pagesNMAC 14.7.4 New Mexico Earthen Building Materials CodeAlejandro Jiménez100% (1)

- System No. C-AJ-8175: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-8175: F Rating - 2 HR T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- System No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRArulNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- CAJ1317Document1 pageCAJ1317Luis AlbertoNo ratings yet

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviNo ratings yet

- HW D 0187Document2 pagesHW D 0187Luiggi Zuñiga BarahonaNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- System No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRArulNo ratings yet

- CAJ1353Document1 pageCAJ1353Anonymous PCsoNCt0mFNo ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- Firestopping System Applications AND Standard Application - Ul ListedDocument5 pagesFirestopping System Applications AND Standard Application - Ul ListedAry TubagusNo ratings yet

- System No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Document2 pagesSystem No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Lea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- System No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRDocument2 pagesSystem No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersDocument2 pagesDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlNo ratings yet

- WL1167Document1 pageWL1167Juvenal GutierrezNo ratings yet

- System No. C-AJ-2898Document2 pagesSystem No. C-AJ-2898darwish.hiltiNo ratings yet

- W L 1054Document2 pagesW L 1054shama093No ratings yet

- System No. W-J-5116: F Rating - 2 HR T Rating - 1 HRDocument2 pagesSystem No. W-J-5116: F Rating - 2 HR T Rating - 1 HRArulNo ratings yet

- FM Design 628 (FB-4003)Document2 pagesFM Design 628 (FB-4003)raviNo ratings yet

- System No. W-L-2199Document2 pagesSystem No. W-L-2199DatNo ratings yet

- Rev DrainDocument6 pagesRev DrainRaj RahulNo ratings yet

- CAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626Document8 pagesCAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626shama093No ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- Bandeja - Concreto - W-J-4031Document2 pagesBandeja - Concreto - W-J-4031cesar walter salazar garciaNo ratings yet

- W L 1176Document1 pageW L 1176shama093No ratings yet

- w-j-2094 - PVC CPVC, ABS 2 Hr.Document2 pagesw-j-2094 - PVC CPVC, ABS 2 Hr.DatNo ratings yet

- Rockwool Intumescent PillowsDocument3 pagesRockwool Intumescent PillowsBobana AdamovicNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj8113 - DLDocument4 pagesSystem PDF Files - 1. UL and cUL Systems - Caj8113 - DLEmanuel PastlNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- C Aj 2294Document2 pagesC Aj 2294vhin84No ratings yet

- TECH SPECS For Cabin For Jail - FINALDocument8 pagesTECH SPECS For Cabin For Jail - FINALmanzarsamanposNo ratings yet

- M2 - Manual PDFDocument0 pagesM2 - Manual PDFFlorinHanu100% (1)

- Retain: Spare PartsDocument1 pageRetain: Spare PartsAhmed Mohamed Abd ElhakamNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- Ul HWD 0209Document2 pagesUl HWD 0209jlledwinestebanNo ratings yet

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- CEJ114PDocument2 pagesCEJ114PGauri Calderon TrujilloNo ratings yet

- CAJ1066 Multiples MTDocument1 pageCAJ1066 Multiples MTEdwin G Garcia ChNo ratings yet

- Design of Self Supported Steel ChimneyDocument27 pagesDesign of Self Supported Steel ChimneyAlok JhaNo ratings yet

- Suspended Ceilings Construction GuideDocument4 pagesSuspended Ceilings Construction GuideHassan RahilNo ratings yet

- Section 082808hs High Security Perimeter Spec PDFDocument7 pagesSection 082808hs High Security Perimeter Spec PDFمحمد عبد السلام الصوافNo ratings yet

- 0421 Roofing - CombinedDocument6 pages0421 Roofing - CombinedRiski SuhardinataNo ratings yet

- W L 1297Document1 pageW L 1297shama093No ratings yet

- FL - Sleeves and Sleeve Seals For Plumbing Piping - BudDocument5 pagesFL - Sleeves and Sleeve Seals For Plumbing Piping - BudAntonius HarrisNo ratings yet

- ASME B31.4 Design Minimum Wall ThicknessDocument6 pagesASME B31.4 Design Minimum Wall ThicknessAlfredo BravoNo ratings yet

- Fire Barrier & Cavity Systems Stop Fires!: KillerDocument4 pagesFire Barrier & Cavity Systems Stop Fires!: KillerMedhat ElhagrasiNo ratings yet

- System No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDocument2 pagesSystem No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDatNo ratings yet

- FRP Ceiling Panel Roof Deck - Data Sheet - FINAL - 03 01 18Document2 pagesFRP Ceiling Panel Roof Deck - Data Sheet - FINAL - 03 01 18Research DevelopmentNo ratings yet

- Design No. R705: BXUVC.R705 Fire-Resistance RatingsDocument3 pagesDesign No. R705: BXUVC.R705 Fire-Resistance RatingsSimon BeaudoinNo ratings yet

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- ProSTUD UL V477Document8 pagesProSTUD UL V477K PreitoNo ratings yet

- System No. W-L-2276: F Rating - 2 HR T Rating - 2 HRDocument2 pagesSystem No. W-L-2276: F Rating - 2 HR T Rating - 2 HRDatNo ratings yet

- Proposed Staff House Plan Technical DrawingsDocument10 pagesProposed Staff House Plan Technical DrawingsLawrence TingNo ratings yet

- Therapeutic ArchitectureDocument35 pagesTherapeutic Architecturehiral70% (10)

- Acoustics 7 Residential BuildingsDocument20 pagesAcoustics 7 Residential BuildingsNaveen Kumar NilNo ratings yet

- Activity 7Document2 pagesActivity 7Kyle CortezNo ratings yet

- 2ND Floor Cracking WidthDocument13 pages2ND Floor Cracking WidthJade Paul D. BesanaNo ratings yet

- 2-Storey Residence 14th St. Sto. NiñoDocument4 pages2-Storey Residence 14th St. Sto. NiñoIsmael De Leon100% (1)

- AUSTROADS - Bridge Manual - Part 2 - Materials - AGBT02-09 PDFDocument144 pagesAUSTROADS - Bridge Manual - Part 2 - Materials - AGBT02-09 PDFmiddlepermianNo ratings yet

- African Architects That Use Vernacular ArchitectureDocument4 pagesAfrican Architects That Use Vernacular Architecturebeakal chanyalewNo ratings yet

- XXXXXXXXXXXX ARCHITECTURALDocument1 pageXXXXXXXXXXXX ARCHITECTURALeiman bataNo ratings yet

- Construction of New Road Phase 3Document10 pagesConstruction of New Road Phase 3mustafeNo ratings yet

- Demolition Method Statement 394 Camden Road, London N7: Project Number 5588 Document Reference 5588.D006 P1 Revision P1Document11 pagesDemolition Method Statement 394 Camden Road, London N7: Project Number 5588 Document Reference 5588.D006 P1 Revision P1AdeNo ratings yet

- Cantilever MethodDocument10 pagesCantilever MethodNorfahmi Abd RahmanNo ratings yet

- Minoru Yamasaki: Grace Henry S1S2 B.Arch Roll No 61017Document32 pagesMinoru Yamasaki: Grace Henry S1S2 B.Arch Roll No 61017Grace HenryNo ratings yet

- Dqs363 Assignment 2 Concrete Work Mar 2022 FinalDocument5 pagesDqs363 Assignment 2 Concrete Work Mar 2022 FinalSoncubby s.cNo ratings yet

- L 1.5 W A 1.5W (W) 1.5 W D 600 75 525 MM: One-Way Shear/ Beam ShearDocument4 pagesL 1.5 W A 1.5W (W) 1.5 W D 600 75 525 MM: One-Way Shear/ Beam ShearYedda M IlaganNo ratings yet

- Structure II: Course Code: ARCH 209Document29 pagesStructure II: Course Code: ARCH 209layaljamal2No ratings yet

- Tanaka Design Group-Landscape Architecture & Arboricultural ServicesDocument18 pagesTanaka Design Group-Landscape Architecture & Arboricultural ServicesL. A. PatersonNo ratings yet

- Simulation of IBS Formation For Housing Construction PDFDocument111 pagesSimulation of IBS Formation For Housing Construction PDFHani HusainiNo ratings yet

- Capital GateDocument18 pagesCapital GatePranayita MyadamNo ratings yet

- Frank Gehry PDFDocument2 pagesFrank Gehry PDFZulkifli LasakaNo ratings yet

- Residential Elevator - Hoistway Pit DetailDocument1 pageResidential Elevator - Hoistway Pit DetailbalagulliNo ratings yet

- GFRCDocument15 pagesGFRCNitinSenNo ratings yet

- Civil Works BoqDocument2 pagesCivil Works BoqShuvo Shaha0% (1)

- Method Statement For Shaft ConstructionDocument1 pageMethod Statement For Shaft ConstructionjoranyeinNo ratings yet

- Building Construction: (Ceng3093)Document22 pagesBuilding Construction: (Ceng3093)natnaelNo ratings yet

- Boundary Wall Design - Final For RFCDocument10 pagesBoundary Wall Design - Final For RFCShubham Khare100% (1)

- EC NoidaDocument12 pagesEC NoidaMUHAMMED SHAHID100% (1)