Professional Documents

Culture Documents

Welding Test Procedure Sheet

Welding Test Procedure Sheet

Uploaded by

Moch_adiganjarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Test Procedure Sheet

Welding Test Procedure Sheet

Uploaded by

Moch_adiganjarCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

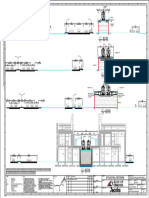

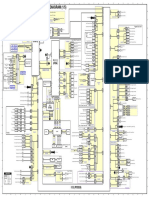

A A

Typical Detail -A

Typical Detail -B

B B

1053 - M16x50 - 8.8

1053 - M16x50 - 8.8

Na2W - EN ISO 4017

Na2W - EN ISO 4017

1053 - M16x50 - 8.8

conveyor

Na2W - EN ISO 4017

PC400

Side View

CL Pipe

Elevation View conveying direction 1054 - M16x80 - 8.8

C Na2W - EN ISO 4017 C

Isometric View

n

ctio

ire

gd

yin

nve

co

D D

Typical Detail -C

E SN1 SN1 E

Top Plan View

SN1

8xø22

F F

1055 - M20x100 - 8.8

1055 - M20x100 - 8.8

Na2W - EN ISO 4017 Na2W - EN ISO 4017

C SN2

2x SN5

G G

2x SN5 2x SN6

2x SN6

2x SN8 2x SN8

H H

Foundation Plan View

2x SN5

Typical Detail -D

2x SN5

J J

2x Pl 10 SN5

2x SN10 2x SN10

1052 - M12x40 - 8.8

Na2W - EN ISO 4017

2x SN5 A

2x SN5 1052 - M12x40 - 8.8

Na2W - EN ISO 4017

K B K

SN5 2x SN12

L D L

Pl 10 SN5 SN2

SN2 2x SN2

2x SN12

8x SN3

4x SN3

4x Pl 10 SN5

M M

4x SN3 4x SN4

2x SN4

2x SN4

No Painting No Painting No Painting No Painting

N N

WELDING TEST PROCEDURE SHEET

Frame: - - -

DrawNo.: - - -

Protection against corrosion: coated General quality requirements of weldings: Component: - - -

P Color of steel strcture: according client

P

Color of railing: according client All welding seam welded continously. Technical knowledge of welding inspection personnel: B acc. EN ISO 14731

Additional information see the contract! Acceptance criteria according review group: C acc. EN ISO 5817

Preparation for welding acc. to EN ISO 9692-1

Indicative of assembly preload and tightening torque

of assemblies according EN 15048 (preload chart for SB systems) Workshop welds grade C acc. EN ISO 5817 weldseam type VT RT or UT MT or PT

assembly R butt welds in frame corners

bolt tightening torque [Nm] Work classification of approved welders acc. EN ISO 9606-1 A 100% 50 ---

preload [kN] All edges rounded and at bridge ends

Fp,C M1 = 0.75 * Mr ( M2 = Mr ) All undefined welding seams have to be in acc. with the

All plates and all profiles longitudinal joints and seams

thread ASP instructions below: B 100% 10 ---

8.8 10.9 8.8 10.9 8.8 10.9 welded ribs

M10 58 26.0 36.5 25 36 34 48 fillet- and HV-fillet welds

a C without ribs 100% --- 10 Make preassembly and check in workshop when fabricated

M12 84.3 37.8 53.1 44 62 59 83 Size fillet welds

Q Execution Specifications: Q

BILL OF MATERIAL of identical number

a

M14 115 51.5 72.5 70 99 94 132

Surface characteristics: D extension of beams 100% 100% ---

M16 157 70.3 98.9 110 154 146 206

Plates and flats acc. EN10163-2: Class A1 Execution class : EXC2 acc. EN1090-2 t

Tagging number.: <3044>

M18 192 86.0 121 151 212 201 283 Preparation grade : P2 acc. ISO 8501-3 num. of seams weld by checked seams checked by

Profiles acc. EN10163-3: Class C1

M20 245 110 154 214 301 285 401

a

Basical tolerances : acc. EN1090-2 Double fillet weld: a=0,6t

Guidelines for bolt preload "structural boltings" ASSEMBLY ARRANGEMENT Additional conditions see contract. A

M22 303 136 191 291 409 388 546

for all bolt connections Welding - general tolerances : acc. EN13920 Customer

The specifications of EN 1090-2 for "structural boltings" must be observed. M24 353 158 222 370 520 493 694 Length/angle : A ; form/position : E B

bolt TUBAN

M27 459 206 289 541 761 722 1015 t

The preload takes place according to the system of reduced preload as a bolt washer

All specifications and tags are valid for all

ISO 9013 - 4 4 1 C

Size of welds M30 561 251 353 735 1034 980 1378 sheets with the drawing number. All thermal cuts according :

quality assurance measure with 70% of the yield strength. Fillet weld: a=0,7t s=t

The preload must be applied in two steps using the torque method. M33 694 311 437 1000 1407 1334 1876 D Name Date Project. no.: 622-150001 Designation

a

As well as bill of material of identical number. HV fillet weld: a=0,7t s=t

nut washer s Support Type 11.4 H=10914

a

M36 817 366 515 1285 1807 1713 2409 Vijay Kr. 11.11.2022 Issued Pos. no.:

a t

The tightening torques for the 1st step and 2nd step can be found in the * (thickness under-run of the welding seams is not permissible) Pipe Conveyor 400

nut Fp,C,y = preload with 70% of the yield strength (0.7*fy) Becvardi 11-11-2022 Checked Contact:

R a "Preload chart for SB systems".

Mr = reference torque = km * d * Fp,C,y with km = 0.13

Division into shares / extension of the beams

should be avoided as possible! The requirements of EN 1090-2 must be observed. Min. check length 900mm. Document no. Version Type Format

<0 Bending edges as possible

s

Tightening must be done by turning the nut. If this is not possible, the tightening .5 M1 = tightening torque for step 1 = 0.75 * Mr 40002789541

t

° leveling under AA DRW A0

If necessary, butt weld continously! A corresponding welding plan has to be prepared and be submitted in case of need.

procedure should be calibrated acc. to EN1090-2 Annex H and any additional

washer edition

M2 = tightening torque for step 2 = Mr in normal direction of rolling. Butt weld: s=t

Mat. no. Cust. drw. no.

washers should be inserted on the side of the nut. If the delivery is not made as a assemblie, the tightening torque Doubling checks have to be done in case of surface improvements.

Calculation of cold bendings acc. DIN6935:2011-10 Weld check 100%

must be determined in accordance with EN 1090-2 Annex H. This document and all data contained herein are confidential and exclusive

Scale 1:20,1:25,1:5

property of the BEUMER Group. Any reproduction, transmission, modification, etc.

Author

or any kind of supply to others is strictly forbidden without express prior written

Date

Index

Description

consent. Refer to Protection Notice ISO 16016.

ISO 14405 E Ind Modification Sheet/of 1 / 4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 ISO 13920-AE BIPO BAAN/ENX

AS2018-Version

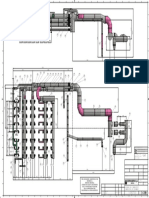

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

1x H 350x175x7x4088 SN1 SN1 D - D

SS 400 - 1:10

A A Typical Detail 6

SN2 B - B A

6 6

2 Scale: 1:5

SN1 A - A 6

PL 10

1021 4

4

4

B 5 B

5

1013 4

4

4

2x H 350x175x7x6573 SN2

5

SS 400 - 1:20

5 1019

SN2 A - A A

4

1004 6

6

1016

C 1016 C

1016

B 1023 1023

B

SN1 C - C 1016 1028

C SN1 B - B 2x H 350x175x7x6573 SN2

A A 1021 1028 SS 400 - 1:20

B

2x 1013 1021 1024

D D

1021 2x 1013 1013 1013 1010 SN2 C - C

1019 2x 1010 1024

2x 1003 1019 1019 1010

1020 1018 7

1022

7

7

7 1025

4

2x 1003 4

4

4

4

4 1020 4

1025

E 4 2x 1009 1020 1011 E

2x 1009 1010

1018 1024

1012 DETAIL A 4 1024

1012 2

1025 4

1010 2x 1002 1010

1008 1024

1022 1022

F F

1004 1004 2x 1010 1023 1010

1011 4

4 4

4

1008

2x 1009 4 2x 1009

4

1025

1014 1010 D 1025

1014 1015 1024 SN2 D - D

C C1024

G 1015 G

2x 1010

1023 1025

1010 4

4

1011

2x 1002

1007

1022 5

5

D 1022

H 1010 1011 H

1007 4

4

1014

1014 1031

4 2x 1001

4

1024

J J

2x 1009 1027

2x 1009 1027

2x 1001 1010 E E

4 1030

1012 4

1010 1012 1006

1011 2x 1026 SN2 E - E

1030

A

1029 2x 1026

K K

1006 4

4

F F

4

1014

1027

1014

L L

4

2x 1009

2x 1000 2x 1009

1x H 350x175x7x4088 SN1

1012 2x 1000 1010 SS 400 - 1:20

4

1010 4

M 1005 M

1030

1011 1023

D 4

1012

4

1017 SN2 F - F

D 1005

N

1016 1016 1004 N

1017

1016

C B

1029

5

5

P 7

1030 P

2x 1026

Q Q

Customer

TUBAN

Name Date Project. no.: 622-150001 Designation

Vijay Kr. 11.11.2022 Issued Pos. no.: Support Type 11.4 H=10914

Pipe Conveyor 400

Becvardi 11-11-2022 Checked Contact:

R Document no. Version Type Format

40002789541 AA DRW A0

Mat. no. Cust. drw. no.

This document and all data contained herein are confidential and exclusive

Scale 1:10,1:20,1:5

property of the BEUMER Group. Any reproduction, transmission, modification, etc.

Author

or any kind of supply to others is strictly forbidden without express prior written

Date

Index

Description

consent. Refer to Protection Notice ISO 16016.

ISO 14405 E Ind Modification Sheet/of 2 / 4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 ISO 13920-AE BIPO BAAN/ENX

AS2018-Version

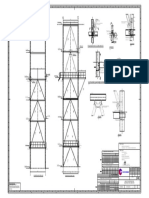

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

4x PL 20x300x60 SN4

4x L 70x70x7x1564 SN8 1x C 200x80x7.5x1803 SN11

SS 400 - 1:10 SS 400 - 1:10

8x PL 20x70x70 SN3 SS 400 - 1:10

A SS 400 - 1:10 A

SN4 = 1 set of Balancing plates:

Do not paint! (bare metal)

Do not weld this sheets!

5x 1033 1024 1045

1032 1024

1040

2x 1034

B B

1035

1036

1043

1032 1040

A B C

C 20x PL 10x150x80 SN5 C

SS 400 - 1:10

1x C 200x80x7.5x1495 SN9 4

4

SS 400 - 1:10

1037

1045 1024

D 1024 1043 D

1017 A B C

1024 1024

5

SN11 A - A 1024 SN11 B - B SN11 C - C

1037 5

E

1043 E

4

1041 4

4x L 70x70x7x1329 SN6 1045

SS 400 - 1:10

A B C

F F

1043

1024

4

4

1038

G G

1024

1024 1041

1017

A B C

4x L 70x70x7x2297 SN12

1038 SS 400 - 1:10

H SN9 C - C H

SN9 A - A 5

5

1024 SN9 B - B 1044

1041

6

J 1x C 200x80x7.5x1225 SN7 6

J

SS 400 - 1:10

1017

1024 1044

1017 1041

1024 1024

K K

1039

4x L 70x70x7x1834 SN10

SS 400 - 1:10

L L

A C B

4

4

M 1042 M

1024 1039 1024

1017

A C B

N N

SN7 A - A 1042

SN7 B - B

5 1024 5

P P

1039 1024

Q SN7 C - C Q

1039

Customer

1017 4 TUBAN

4

Name Date Project. no.: 622-150001 Designation

Vijay Kr. 11.11.2022 Issued Pos. no.: Support Type 11.4 H=10914

Pipe Conveyor 400

Becvardi 10-11-2022 Checked Contact:

R Document no. Version Type Format

40002789541 AA DRW A0

Mat. no. Cust. drw. no.

This document and all data contained herein are confidential and exclusive

Scale 1:10,1:5

property of the BEUMER Group. Any reproduction, transmission, modification, etc.

Author

or any kind of supply to others is strictly forbidden without express prior written

Date

Index

Description

consent. Refer to Protection Notice ISO 16016.

ISO 14405 E Ind Modification Sheet/of 3 / 4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 ISO 13920-AE BIPO BAAN/ENX

AS2018-Version

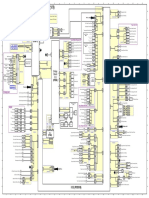

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

4x L 70x70x7x1122 1000 1x C 200x80x7.5x1256 1007 3x PL 10x430.7x272.38 1014 1x PL 15x1250x700 1021 8x PL 20x70x70 1032

SS 400 - 1:5 SS 400 - 1:5 SS 400 - 1:5 SS 400 - 1:5 SS 400 - 1:1 1x C 200x80x7.5x1803 1043 4x L 70x70x7x2297 1044

A SS 400 - 1:5 A

SS 400 - 1:5

4xø22 4xø22

4x L 70x70x7x942 1001 2xø14 2xø14

B SS 400 - 1:5 B

2xø18

1xø32

2xø18

2x PL 10x270.19x233.84 1015

C SS 400 - 1:5 2xø14 2xø14 C

4x L 70x70x7x786 1002 8x PL 5x300x60 1034

SS 400 - 1:5 SS 400 - 1:5

1x C 200x80x7.5x1098 1008

SS 400 - 1:5

1x PL 10x483.59x330.04 1045

D SS 400 - 1:5 D

4x PL 10x320.26x268.82 1025

4x L 70x70x7x583 1003 4x PL 10x300x60 1035 SS 400 - 1:5

SS 400 - 1:5 6x C 200x80x7.5x276 1022 SS 400 - 1:5

SS 400 - 1:5

E

2x PL 10x373.45x264.51 1027 E

SS 400 - 1:5 4xø18

4x PL 35x380x260 1016 4xø18

SS 400 - 1:5

12xø22 4xø18

2x H 350x175x7x4088 1004 4x PL 20x300x60 1036

F SS 400 - 1:5 F

SS 400 - 1:5

4xø18

16x PL 10x130x80 1009 4xø20

SS 400 - 1:5

G G

20x PL 10x150x80 1037

SS 400 - 1:5

2x PL 10x319.55x268.32 1028

3x PL 10x499.35x321.64 1017 SS 400 - 1:5

SS 400 - 1:5

H 28x PL 10x80x63 1010 H

SS 400 - 1:5 2x H 350x175x7x6573 1023 4xø14

SS 400 - 1:5

4xø18

4xø18

J 4xø18 J

14x PL 10x326x80 1011

4x L 70x70x7x1329 1038

SS 400 - 1:5

SS 400 - 1:5

1x C 200x80x7.5x1642 1005

K SS 400 - 1:5 K

2x PL 12x250x90 1029 2xø14

SS 400 - 1:5

1x PL 10x502.88x209.85 1018

SS 400 - 1:5 4xø18

6x PL 10x271.31x234.56 1012

L SS 400 - 1:5 2xø14 L

2x PL 40x430x310 1030 1x C 200x80x7.5x1225 1039

SS 400 - 1:5 SS 400 - 1:5

M

4x L 70x70x7x1564 1040 M

SS 400 - 1:5

12x PL 25x220x100 1024

1x PL 15x1250x400 1020 SS 400 - 1:5

2xø52

SS 400 - 1:5

1x C 200x80x7.5x1436 1006 2xø14

SS 400 - 1:5

N 2xø52 N

3xø18

4x PL 15x332x170 1013 4xø18

SS 400 - 1:5

2xø14

1x C 200x80x7.5x1495 1041

P 2x PL 4x100x80 1031 SS 400 - 1:5 P

1.4571 - 1:1 Do not paint

1xø13 4x PL 10x320.32x268.82 1025 4x L 70x70x7x1834 1042

SS 400 - 1:5 SS 400 - 1:5

1LL ø4-22

Q 1LL ø4-54 Q

1x PL 15x1230x170 1019 4x PL 15x250x120 1026 2xø14

SS 400 - 1:5 2xø10

SS 400 - 1:5 Customer

TUBAN

20x PL 2x300x60 1033 4xø18

1LL ø4-37 4xø18

SS 400 - 1:5 Name Date Project. no.: 622-150001 Designation

1LL ø4-20 2xø14 Vijay Kr. 11.11.2022 Issued Pos. no.: Support Type 11.4 H=10914

Pipe Conveyor 400

Becvardi 10-11-2022 Checked Contact:

R Document no. Version Type Format

40002789541 AA DRW A0

Mat. no. Cust. drw. no.

This document and all data contained herein are confidential and exclusive

Scale 1:1,1:5

property of the BEUMER Group. Any reproduction, transmission, modification, etc.

Author

or any kind of supply to others is strictly forbidden without express prior written

Date

Index

Description

consent. Refer to Protection Notice ISO 16016.

ISO 14405 E Ind Modification Sheet/of 4 / 4

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 ISO 13920-AE BIPO BAAN/ENX

AS2018-Version

You might also like

- SHARP RUNTKA857WJQZ Delta DPS-222BP-A SCHDocument2 pagesSHARP RUNTKA857WJQZ Delta DPS-222BP-A SCHdbwelectronicsNo ratings yet

- ICTAD Procurement of Work ICTAD SBD 01-2007Document80 pagesICTAD Procurement of Work ICTAD SBD 01-2007Wickramathilaka198196% (147)

- Effect of PH On FlotationDocument10 pagesEffect of PH On FlotationInnocent Achaye100% (1)

- Panel Type (Dm1-A) 24Kv Switchgear Sm6: Scale: NTSDocument19 pagesPanel Type (Dm1-A) 24Kv Switchgear Sm6: Scale: NTSFadly Fachrul RozyNo ratings yet

- Panel Type (Dm1-A) 24Kv Switchgear Sm6: Scale: NTSDocument18 pagesPanel Type (Dm1-A) 24Kv Switchgear Sm6: Scale: NTSAris Habbil100% (1)

- TH255C - CAT - Elec Schem PDFDocument9 pagesTH255C - CAT - Elec Schem PDFKevine KhaledNo ratings yet

- Coil Tubing OperationsDocument157 pagesCoil Tubing Operationsasset_kulmagambetov86% (7)

- Grating Handrails Removal PTW FormDocument1 pageGrating Handrails Removal PTW Formsarish84No ratings yet

- Vu 1202 070822Document1 pageVu 1202 070822api-3698996No ratings yet

- Note:: Scaleplate DescriptionDocument1 pageNote:: Scaleplate DescriptionAlbet MulyonoNo ratings yet

- P4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2011Document1 pageP4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2011ManojNo ratings yet

- DR-CST-800-0003 - Rev ADocument1 pageDR-CST-800-0003 - Rev APinak ProjectsNo ratings yet

- Upc6gx RC11 B0600 DD030 - 001 - 00Document1 pageUpc6gx RC11 B0600 DD030 - 001 - 00Viet NguyenNo ratings yet

- P4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2010Document1 pageP4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2010ManojNo ratings yet

- Ar PRM TDR Phase 02 Dse 0006Document1 pageAr PRM TDR Phase 02 Dse 0006Thota NageshNo ratings yet

- T - DO1013 - Rev2Document9 pagesT - DO1013 - Rev2jorgekarlosprNo ratings yet

- Typical PIPE 8" 6 M Max Support Span: Cross Country F Water Manifold A0Document5 pagesTypical PIPE 8" 6 M Max Support Span: Cross Country F Water Manifold A0cristianNo ratings yet

- Isometric View: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetDocument1 pageIsometric View: All Fabrication Drawing Shall Be in Accordance With RDSO Drg. B-10408 SetParikh DhavalNo ratings yet

- DNP DNP DNP: Proto - Area Proto - AreaDocument14 pagesDNP DNP DNP: Proto - Area Proto - AreaAinis ŠtelemėkasNo ratings yet

- B011 000 16 50 01205 - Rev 2Document1 pageB011 000 16 50 01205 - Rev 2GLOBUS ENGINEERSNo ratings yet

- 06 - Appendix E - Technical Reports and DrawingsDocument617 pages06 - Appendix E - Technical Reports and Drawingsmartin solarNo ratings yet

- Kitchen SpecDocument1 pageKitchen SpecabebaNo ratings yet

- Fire Alarm Lantai 3 MezzanineDocument1 pageFire Alarm Lantai 3 MezzanineIlham AdiNo ratings yet

- Existing - Earthing - Layout For Bogra 230kV SubstationDocument1 pageExisting - Earthing - Layout For Bogra 230kV SubstationRashad SarwarNo ratings yet

- X0231 PDW Ecb DG 20003 AaDocument1 pageX0231 PDW Ecb DG 20003 AajianranrenNo ratings yet

- Workplot: Not For ProductionDocument1 pageWorkplot: Not For ProductionOmkar TodkarNo ratings yet

- 0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelDocument1 page0320289-TE-DAD-6410-006-00 SEPARATOR 10HHA30AT001-ModelVivek VinayakumarNo ratings yet

- 001 00 PDFDocument1 page001 00 PDFGerman GomezNo ratings yet

- Right View: Proposed Office BuildingDocument1 pageRight View: Proposed Office BuildingJhon SabinoNo ratings yet

- Bp2021-C026s-Jwn03-A01-Drain System-Fp-1001-Ground and Roof Floor Plans - Sport HallDocument1 pageBp2021-C026s-Jwn03-A01-Drain System-Fp-1001-Ground and Roof Floor Plans - Sport HallMohammad IsmailNo ratings yet

- BP2021-C026S-JWN01 - A01-Drainage System-Fp-1003-Roof Floor Plan - Main BuildingDocument1 pageBP2021-C026S-JWN01 - A01-Drainage System-Fp-1003-Roof Floor Plan - Main BuildingMohammad IsmailNo ratings yet

- Vu 1205 070822Document1 pageVu 1205 070822api-3698996No ratings yet

- Ar PRM TDR Phase 02 Dde 0002Document1 pageAr PRM TDR Phase 02 Dde 0002Thota NageshNo ratings yet

- Toilet Detail To Send 19-1-2018 A 0 WD LandDocument1 pageToilet Detail To Send 19-1-2018 A 0 WD LandRaj GuptaNo ratings yet

- Limita Zona Protectie Autostrada 50m Fata de Axul Drumului (Conf. OG43/1997-Anexa1, Lit. B)Document1 pageLimita Zona Protectie Autostrada 50m Fata de Axul Drumului (Conf. OG43/1997-Anexa1, Lit. B)ciciNo ratings yet

- DR-CST-800-0012 - Rev ADocument1 pageDR-CST-800-0012 - Rev APinak ProjectsNo ratings yet

- Control Board - Schematic v626Document1 pageControl Board - Schematic v626XuNo ratings yet

- Campus Map 8 5x11Document2 pagesCampus Map 8 5x11MeiNo ratings yet

- PPD 0600-00 2DRT2 2018-EN 4367.076.00M Rev.1Document1 pagePPD 0600-00 2DRT2 2018-EN 4367.076.00M Rev.1Mujahidin AhmadNo ratings yet

- Point To Toint DiagramDocument23 pagesPoint To Toint DiagramApenas MaxNo ratings yet

- Ricoh C4502 D143 D144 and OPTIONS Point 2 Point Diagrams PDFDocument29 pagesRicoh C4502 D143 D144 and OPTIONS Point 2 Point Diagrams PDFDawood AhmedNo ratings yet

- Vu 1803 070822Document1 pageVu 1803 070822api-3698996No ratings yet

- Panel Type (Dm1-A) 24Kv Switchgear Sm6: DM1 - A Mot CO2S-CT 100-200 VT-48VDC W L1Document19 pagesPanel Type (Dm1-A) 24Kv Switchgear Sm6: DM1 - A Mot CO2S-CT 100-200 VT-48VDC W L1teguhalmelicNo ratings yet

- Panel Type (CM) 24 KV Switchgear Sm6: Scale: NTSDocument12 pagesPanel Type (CM) 24 KV Switchgear Sm6: Scale: NTSteguhalmelicNo ratings yet

- WiRing Tegangan ACOSDocument22 pagesWiRing Tegangan ACOSAnan NasutionNo ratings yet

- A5157494860-106 CMDocument12 pagesA5157494860-106 CMFahmi Idrs100% (1)

- MMS Project MGMT QP00036461 1Document3 pagesMMS Project MGMT QP00036461 1mms a19No ratings yet

- Panel Type (Im) 24 KV Switchgear Sm6: Scale: NTSDocument10 pagesPanel Type (Im) 24 KV Switchgear Sm6: Scale: NTSDaniNo ratings yet

- A2 Km. 186+580 ST PDFDocument1 pageA2 Km. 186+580 ST PDFciciNo ratings yet

- For Official Use Only: First Floor Plan Site Plan AREA 1862.72sq - FTDocument1 pageFor Official Use Only: First Floor Plan Site Plan AREA 1862.72sq - FTAnish NeupaneNo ratings yet

- Ab-By Bang RonieDocument1 pageAb-By Bang Ronieronie lastriNo ratings yet

- Proposed Office Building: Ground Floor Plan 1 Second Floor Plan 2 Roof Plan 3Document1 pageProposed Office Building: Ground Floor Plan 1 Second Floor Plan 2 Roof Plan 3Jhon SabinoNo ratings yet

- Data Extraction and Multileaders Sample-Layout2Document1 pageData Extraction and Multileaders Sample-Layout2Sunem Rios YañacNo ratings yet

- Diagrama ZT315Document26 pagesDiagrama ZT315percyctba FilhoNo ratings yet

- September SongDocument1 pageSeptember SongDanielle MurrayNo ratings yet

- Potkonstrukcija U Osi 9Document1 pagePotkonstrukcija U Osi 9HarisKaricNo ratings yet

- Va 1302 070822Document1 pageVa 1302 070822api-3698996No ratings yet

- TMX5BP Electrical SchematicsDocument16 pagesTMX5BP Electrical SchematicsSergioNo ratings yet

- M10 Class H Power Amp.Document10 pagesM10 Class H Power Amp.alanbermeo058No ratings yet

- Plan 1-2Document1 pagePlan 1-2amine allamNo ratings yet

- Fire Alarm Lantai 3Document1 pageFire Alarm Lantai 3Ilham AdiNo ratings yet

- FP-04 Upper Ground Floor Sprinkler LayoutDocument1 pageFP-04 Upper Ground Floor Sprinkler LayoutBerlin Andrew SionNo ratings yet

- Electrical Equipment LayoutDocument1 pageElectrical Equipment Layoutmohdtakrimi100% (1)

- Defect Sizing Using Non-Destructive Ultrasonic Testing: Wolf KleinertDocument13 pagesDefect Sizing Using Non-Destructive Ultrasonic Testing: Wolf KleinertMoch_adiganjarNo ratings yet

- Esential For WPS - FCAW (QW-255) PDFDocument2 pagesEsential For WPS - FCAW (QW-255) PDFMoch_adiganjarNo ratings yet

- Status Procedures Atau Dokumen - Rev. 3Document1 pageStatus Procedures Atau Dokumen - Rev. 3Moch_adiganjarNo ratings yet

- Master List WelderDocument2 pagesMaster List WelderMoch_adiganjarNo ratings yet

- Polsab Katalog Automatyzacja Esab 2020Document84 pagesPolsab Katalog Automatyzacja Esab 2020Moch_adiganjarNo ratings yet

- Pipe Body of Seamless and Welded Pipes Weld Seam of EW, LW, Saw and Cow Pipes Yield Strength Tensile Strength Elongation Tensile StrengthDocument2 pagesPipe Body of Seamless and Welded Pipes Weld Seam of EW, LW, Saw and Cow Pipes Yield Strength Tensile Strength Elongation Tensile StrengthMoch_adiganjarNo ratings yet

- Pinnacle Alloys E11018 MDocument2 pagesPinnacle Alloys E11018 MMoch_adiganjarNo ratings yet

- XA00048720 Stainless HandbookDocument92 pagesXA00048720 Stainless HandbookThanis SurapapwongNo ratings yet

- Book 1Document1 pageBook 1Moch_adiganjarNo ratings yet

- Trends in Product Design and DevelopmentDocument611 pagesTrends in Product Design and Developmentdr ps100% (1)

- Carolyn Reid ResumeDocument3 pagesCarolyn Reid Resumecsreid1coxnetNo ratings yet

- Prognostic Health Management For Car Service: Click To Edit Master Title StyleDocument12 pagesPrognostic Health Management For Car Service: Click To Edit Master Title StyleAriyanNo ratings yet

- Rework in Production Planning: ScenarioDocument4 pagesRework in Production Planning: ScenarioMinal TripathiNo ratings yet

- Electrical DevicesDocument123 pagesElectrical Devicesnavidelec100% (1)

- Repararea Turbinelor Cu Abur Remont Parovie Turbin ENGDocument324 pagesRepararea Turbinelor Cu Abur Remont Parovie Turbin ENGnueste100% (1)

- Garry Thuer & Hendrik VocksDocument12 pagesGarry Thuer & Hendrik VocksAsturoSuprojoNo ratings yet

- World Bank BOQ's UpdatedDocument41 pagesWorld Bank BOQ's Updatedgtarun22guptaNo ratings yet

- Bhel Pipe Color Code-Aa10630 1Document7 pagesBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniNo ratings yet

- Viewtenddoc AspDocument127 pagesViewtenddoc AspukalNo ratings yet

- Ansi-Cema 300-2003Document38 pagesAnsi-Cema 300-2003Ferney Alvarez NiñoNo ratings yet

- Manufacturing SystemDocument28 pagesManufacturing SystemAndra Diah Rachmawati100% (1)

- EI-1599 - Dirt Defence FiltersDocument19 pagesEI-1599 - Dirt Defence FiltersfuelcombNo ratings yet

- Tools: Constructi0N Material and TestingDocument43 pagesTools: Constructi0N Material and TestingKemuel TabamoNo ratings yet

- CPU Scheduling AlgorithmsDocument17 pagesCPU Scheduling AlgorithmsYianna Danidou100% (3)

- Photorealistic RenderingDocument593 pagesPhotorealistic Rendering27b7m2100% (2)

- Fort Washington Way 2000: A Project Managed by The City of Cincinnati With The Cooperation of ThousandsDocument59 pagesFort Washington Way 2000: A Project Managed by The City of Cincinnati With The Cooperation of ThousandsGranicus CivicIdeasNo ratings yet

- Good Morning: Me 711 Manufacturing Planning and ControlDocument7 pagesGood Morning: Me 711 Manufacturing Planning and ControlPurav ShahNo ratings yet

- Model Bills of Quantities: Federation of Piling SpecialistsDocument9 pagesModel Bills of Quantities: Federation of Piling SpecialistsEVONNENo ratings yet

- Steps To Create An ODATA Service For A BW Query - SAP NetWeaver Business Warehouse - SCN WikiDocument8 pagesSteps To Create An ODATA Service For A BW Query - SAP NetWeaver Business Warehouse - SCN WikiLiQiangNo ratings yet

- 02 Fundamental of SimulationDocument39 pages02 Fundamental of SimulationAshilaNurulHudaNo ratings yet

- Custom Woodworking Business - July 2013Document89 pagesCustom Woodworking Business - July 2013sergio100% (2)

- Draft Z Ways Technologies Corporation Company ProfileDocument8 pagesDraft Z Ways Technologies Corporation Company ProfileJaime Bolivar RoblesNo ratings yet

- H2 in AircraftDocument12 pagesH2 in AircraftAnvesh KadimiNo ratings yet

- Understanding Centrifugal Compressor Capacity ControlsDocument5 pagesUnderstanding Centrifugal Compressor Capacity Controlsjuancgr77100% (2)

- SR RNO Engineer - Job DescriptionDocument3 pagesSR RNO Engineer - Job DescriptionMuhammed AfsalNo ratings yet