Professional Documents

Culture Documents

LP HP Dosing Calculation - PDF - Physical Sciences - Chemical Substances

LP HP Dosing Calculation - PDF - Physical Sciences - Chemical Substances

Uploaded by

V U P RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LP HP Dosing Calculation - PDF - Physical Sciences - Chemical Substances

LP HP Dosing Calculation - PDF - Physical Sciences - Chemical Substances

Uploaded by

V U P RaoCopyright:

Available Formats

1 of 1 Search document

Related titles

All dosage equation are based on C1Q1=C2Q2

Where C= concentration of chemical, Q= Flow rate

Or, Chemical feed solution (mg/l) X feed pump output(gallon/day) = Desired chemical dose(mg/l) X plant

flow rate

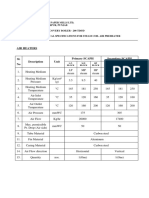

HP dosing calculation

Steam tph=10000 kgh

TDS in feed water=.1

TDS permitted in boiler= 25 ppm

Percentage blow down = 100X.1/(25-0.1)=0.4%

Actual blow down rate = 10000X 0.4/1000kgr=40kgr

PPM PO4 dose=4ppm

Loss of PO4 in BD=4X40/1000g/h=0.16 gm/hr

Loss of TSP in blowdown=0.16X4=0.64g/hr

TSP consumption/day=0.64X24/1000 kg/day=0.1536

LP dosing calculation

Steam tph=10000 kgh

0

O2 in feed water after deaeration @ 105 C=0.02ppm

Required oxygen level in feed water = 0.002 ppm

Oxygen to be removed = 0.02 – 0.002 ppm =0.018

N2H4 rqrd(30times) = 30 X 0.018 ppm=0.54 ppm

Residual N2H4 to be kept = 0.02 ppm

Total N2H4 rqrd = 0.54 + 0.02=0.56 ppm

Total N2H4 rqrd in Kg/Kg of evaporation = 0.56 X 0.000001 kg/kg = 0.00000056 kg/kg

N2H4 rqrd/hr = 10000 X 0.00000056 = 0.0056 kg/hr

Conc. Of N2H4 soln = 35%

N2H4 to be dosed @ 35 % conc = .0056 X 100/35 kg/hr=0.016 kg /hr

N2H4 Consumption/day = 0.016 X 24 Kg/day = 0.384 kg/day

You might also like

- LP HP Dosing CalculationDocument1 pageLP HP Dosing Calculationvikas_be1750% (4)

- Regular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsDocument23 pagesRegular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsYogaAnandNo ratings yet

- Felder Soalrecycle Arsya 3335170030Document9 pagesFelder Soalrecycle Arsya 3335170030Arsya AdityaNo ratings yet

- Chem131notes EnthalpyDocument10 pagesChem131notes EnthalpyCherry Embate0% (1)

- Environmental ChemistryDocument33 pagesEnvironmental ChemistryIbrahim HussainNo ratings yet

- HP Dosing CalculationDocument1 pageHP Dosing CalculationJegannathan NambukumarNo ratings yet

- Jar Testing of Chemical DosagesDocument32 pagesJar Testing of Chemical DosagesRolando CortazarNo ratings yet

- 5.6 DisinfectionDocument23 pages5.6 DisinfectionZul Imi100% (1)

- Anaerobic Treatment of Municipal Wastewater (10,000 Liter/Day) With A Staged Anaerobic Fluidized Membrane Bioreactor (Saf-Mbr) SystemDocument11 pagesAnaerobic Treatment of Municipal Wastewater (10,000 Liter/Day) With A Staged Anaerobic Fluidized Membrane Bioreactor (Saf-Mbr) SystemAzam HussainNo ratings yet

- Chem 1070 LabDocument9 pagesChem 1070 LabAcalaNo ratings yet

- Water CalculationDocument6 pagesWater CalculationRamkiNo ratings yet

- 05-Chem Eng Tools 2016Document11 pages05-Chem Eng Tools 2016arif thoha bariklanaNo ratings yet

- Solved Problems in Chemical Process CalculationsDocument19 pagesSolved Problems in Chemical Process CalculationsPrincess Janine CatralNo ratings yet

- 05-Chem Eng Tools 2016Document11 pages05-Chem Eng Tools 2016Hazel Raditya MizumareruNo ratings yet

- Topic IIDocument20 pagesTopic IIEmmarehBucolNo ratings yet

- Project: Subject: Date: Selection 1: Use Sodium Hypochlorite (Naocl) (Solution)Document2 pagesProject: Subject: Date: Selection 1: Use Sodium Hypochlorite (Naocl) (Solution)fiddy_ftNo ratings yet

- Material Balance: Reactor: From The Above ReactionDocument3 pagesMaterial Balance: Reactor: From The Above ReactionHoucine BendaoudNo ratings yet

- Useful Formulas in Fluid TherapyDocument2 pagesUseful Formulas in Fluid TherapySharmela BrijmohanNo ratings yet

- BEV2036 EV414 Exercises On Energy and Materials BalanceDocument4 pagesBEV2036 EV414 Exercises On Energy and Materials BalanceSam KhorNo ratings yet

- Chemistry Lab 6Document5 pagesChemistry Lab 6KayenNo ratings yet

- Jambucha ENVT715 HW 1Document4 pagesJambucha ENVT715 HW 1api-19993919No ratings yet

- Improvement of PH of RO Product Water: BasisDocument3 pagesImprovement of PH of RO Product Water: BasisPraneeth KoppineniNo ratings yet

- Nursery PathogensDocument2 pagesNursery PathogensVictor Hugo HinojosaNo ratings yet

- Exam PredictionDocument24 pagesExam PredictionTesfay K HaileNo ratings yet

- Chemical Engineering Tools: 1. Mass Balance (Neraca Massa)Document11 pagesChemical Engineering Tools: 1. Mass Balance (Neraca Massa)muhammad tohaNo ratings yet

- Disinfection Chlorination 7 TopicDocument42 pagesDisinfection Chlorination 7 TopicShivam KumarNo ratings yet

- Understanding Units of MeasurementDocument2 pagesUnderstanding Units of Measurementahmadubir4443No ratings yet

- Converting Occupational Exposure Limits From MGDocument6 pagesConverting Occupational Exposure Limits From MGmajedzNo ratings yet

- Concentration Units: Chemicals in Liquid SampleDocument9 pagesConcentration Units: Chemicals in Liquid Samplethuaiyaalhinai0% (1)

- Sample Problems of Chromium Hexa and CyanideDocument3 pagesSample Problems of Chromium Hexa and CyanideMichelle HutamaresNo ratings yet

- WRD Ot Pounds FormulaDocument21 pagesWRD Ot Pounds FormulaFredi Cari CarreraNo ratings yet

- Mass and Energy Balances Chapter 4.5Document24 pagesMass and Energy Balances Chapter 4.5Ferat BotNo ratings yet

- Conversion Examples CorrectedDocument2 pagesConversion Examples Correctedgusfika ayu wandariNo ratings yet

- 19 CH 005 - Residual ChlorineDocument8 pages19 CH 005 - Residual ChlorineMohamed RinasNo ratings yet

- WW Abcd Formula - 0Document6 pagesWW Abcd Formula - 0Ahmad Usman TahirNo ratings yet

- HVAC Useful FormulasDocument1 pageHVAC Useful Formulasnareshbv749No ratings yet

- PPM To MG - Nm3Document11 pagesPPM To MG - Nm3Chengkc2014100% (1)

- 10.8) Estimation of Oxidant-Antioxidant Status in Diabetic RatsDocument5 pages10.8) Estimation of Oxidant-Antioxidant Status in Diabetic Ratsratendra1No ratings yet

- Coagulation Flocculation CalculationDocument2 pagesCoagulation Flocculation CalculationDŨNG HUỲNH TẤNNo ratings yet

- Metode Analisis TitrimetriDocument28 pagesMetode Analisis TitrimetriDeki TamonobNo ratings yet

- Determination of Orgenic MatterDocument9 pagesDetermination of Orgenic MatterAjay KrishnanvNo ratings yet

- ChlorinationDocument10 pagesChlorinationAliNo ratings yet

- Chemical Dosing CalculationDocument3 pagesChemical Dosing CalculationAJU JOYNo ratings yet

- PPM DefineXXDocument2 pagesPPM DefineXXElias ChānNo ratings yet

- Parts Per MillionDocument1 pageParts Per MilliontskumarphdNo ratings yet

- Problem of The Day 1Document9 pagesProblem of The Day 1bakosua141No ratings yet

- Chapter 13 Properties of Solutions Exercise 1Document26 pagesChapter 13 Properties of Solutions Exercise 1janeNo ratings yet

- Understanding Units of Measurement: Environmental Science and Technology Briefs For CitizensDocument2 pagesUnderstanding Units of Measurement: Environmental Science and Technology Briefs For CitizensChintya AurelyaaNo ratings yet

- MATERIAL BALANCE Distillation ColumnDocument9 pagesMATERIAL BALANCE Distillation ColumnRajeev Kumar DohareNo ratings yet

- Environmental MeasurementsDocument5 pagesEnvironmental MeasurementsVincent OrianaNo ratings yet

- Units of Measure: SolidsDocument3 pagesUnits of Measure: SolidsHka Ismail100% (1)

- Design & Sizing WWTPDocument30 pagesDesign & Sizing WWTPRavishankar ANo ratings yet

- Pounds Formula: Prepared by Michigan Department of Environmental Quality Operator Training and Certification UnitDocument21 pagesPounds Formula: Prepared by Michigan Department of Environmental Quality Operator Training and Certification UnitAl Patrick Dela CalzadaNo ratings yet

- Concentrations and Other Units of Measure: (Nazaroff & Alvarez-Cohen, Section 1.C.1)Document7 pagesConcentrations and Other Units of Measure: (Nazaroff & Alvarez-Cohen, Section 1.C.1)Vivian SolangonNo ratings yet

- M&E BalanceDocument20 pagesM&E BalanceAhmed MustafaNo ratings yet

- Epitome of the Pharmacopeia of the United States and the National Formulary: With CommentsFrom EverandEpitome of the Pharmacopeia of the United States and the National Formulary: With CommentsNo ratings yet

- QUOTESDocument11 pagesQUOTESV U P RaoNo ratings yet

- TS Curve RPHDocument2 pagesTS Curve RPHV U P RaoNo ratings yet

- Screenshot 2023-10-08 at 9.41.21 AMDocument8 pagesScreenshot 2023-10-08 at 9.41.21 AMV U P RaoNo ratings yet

- Draft Award Letter - GlobalDocument2 pagesDraft Award Letter - GlobalV U P RaoNo ratings yet

- Scaph SpecnDocument3 pagesScaph SpecnV U P RaoNo ratings yet

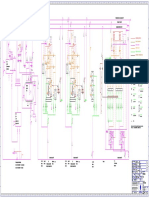

- Steam Scheme 851140169-0-00Document1 pageSteam Scheme 851140169-0-00V U P RaoNo ratings yet

- 13.specification Steam and Condensate SystemDocument2 pages13.specification Steam and Condensate SystemV U P RaoNo ratings yet

- Steam Consumption: Example For A Single-Corrugator Work Width 2200mmDocument2 pagesSteam Consumption: Example For A Single-Corrugator Work Width 2200mmV U P RaoNo ratings yet

- Pzi148df01-30000 - Foundation Load DataDocument1 pagePzi148df01-30000 - Foundation Load DataV U P RaoNo ratings yet

- Project: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedDocument2 pagesProject: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedV U P RaoNo ratings yet

- Safety Data Sheet TGX-2209: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument16 pagesSafety Data Sheet TGX-2209: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingV U P RaoNo ratings yet

- Stuffing Box: SR No DescriptionDocument2 pagesStuffing Box: SR No DescriptionV U P RaoNo ratings yet

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocument1 pageMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNo ratings yet

- Data Sheet For L.P Dosing SystemDocument2 pagesData Sheet For L.P Dosing SystemV U P RaoNo ratings yet

- Power Plant and Calculations - Safety Valves and Its Basic ConceptsDocument4 pagesPower Plant and Calculations - Safety Valves and Its Basic ConceptsV U P RaoNo ratings yet

- TG-X308L TG-X309L TG-X316L TG-X347 TG-X2209: Description and ApplicationDocument1 pageTG-X308L TG-X309L TG-X316L TG-X347 TG-X2209: Description and ApplicationV U P RaoNo ratings yet

- BHG Actvie CahtDocument6 pagesBHG Actvie CahtV U P RaoNo ratings yet