Professional Documents

Culture Documents

Basic Level 3 Part A - II

Basic Level 3 Part A - II

Uploaded by

fadli hei0 ratings0% found this document useful (0 votes)

1 views3 pagesOriginal Title

Basic Level 3 Part a- II

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views3 pagesBasic Level 3 Part A - II

Basic Level 3 Part A - II

Uploaded by

fadli heiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

1.

A blast furnace converts iron ore into what product

B) Pig iron

2. Two basic types of steel ingot are

A) Big end up and big end down

3. Hot tears, cold shuts and blowholes are defects typically found in what form of product?

D) Casting

4. Which of the following processes would reduce grain structure and thus improve strength

and ductility

D) Rolling

5. Excess penetration, spatter and undercut are typically due to

A) Excessive amperage

6. Too low amperage would give rise to

B) Poor penetration and lack of fusion

7. Which of the following welding processes utilizes a non-consumable electrode

C) TIG

8. Direct and indirect are two forms of what process

A) Extrusion

9. A forging defect caused by working at too low a temperature or working excessively is

B) Bursts

10. The formation of atom to atom by the application of heat and pressure describes which

process

D) Welding

11. Which of the following welding processes utilize inert gas to shield the molten weld pool

as it solidifies

A) MIG

12. Which are the following defects are typical of the casting process

D) Cold shuts, hot tears and shrinkage

13. A forging defect caused by working at too low temperature or working excessively is

B) Bursts

14. Shielding of the weld pool in MMA welding is provided by

C) Decomposition of flux coating

15. Small droplets of electrode material which have strayed away from the arc and which

may or may not have fused to the parent plate describe which of the following

A) Spatter

16. Which of the following is not a wrought production method

D) Welding

17. Fatigue cracking will occur under which conditions

D) Cyclic loading

18. A forging defect caused by working at too low temperature or working excessively is

A) Bursts

19. A temporary backing bar is used to:

B) Control root penetration

20. In casting, cold shuts are caused by

D) The meeting of two streams of metal at different temperatures

21. Crater cracking in the weld run has the appearance of:

D) Star shaped indications

22. Hot tears, shrinkage and blowholes are defects typically found in what form of product?

A) Casting

23. Solidification cracks occur most commonly in which part of a weld

C) Weld center line

24. Fatigue cracks in welds are most likely to be found:

C) At a stress riser

25. The defect which can occur during the solidification of cast part

A) Hot tear

26. The point D on the Stress Strain diagram as given in figure below is

D) Ultimate Stress point

27. The steel which has lack of magnetic attraction is

B) 18-8 steel

28. The variables to be controlled in heat treatment is

A) Heating Rate

B) Temperature attained

C) Cooling rate

D) All of the above

29. Annealing is a process

A) Heat to above 910 deg C and cool very slowly till 680 deg C and cool in air

30. Normalizing is a process

B) Heat to above 901 deg C and cool in air

You might also like

- Fmea For Injection MoldingDocument4 pagesFmea For Injection Moldingsuresh kumar80% (15)

- Cswip 3.2 MCQ-004Document5 pagesCswip 3.2 MCQ-004Moses_Jakkala80% (5)

- 9 14 Pages MCQS CSWIP 3.1 Question Answers Solved Past Papers Cswip 3.1Document14 pages9 14 Pages MCQS CSWIP 3.1 Question Answers Solved Past Papers Cswip 3.1Mohammed Amjad Ali86% (21)

- Welding QADocument40 pagesWelding QAsskiitbNo ratings yet

- Knowladge Question CSWIP 3.1Document25 pagesKnowladge Question CSWIP 3.1larusi100% (5)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Ntu MethodDocument11 pagesNtu MethodPradyumna DhamangaonkarNo ratings yet

- Basic 3 Part ADocument3 pagesBasic 3 Part Afadli heiNo ratings yet

- Final Assesment Multiple Choice Question Cswip Welding Inspector Course Mfy Oo4 All Question To Be AttemptedDocument4 pagesFinal Assesment Multiple Choice Question Cswip Welding Inspector Course Mfy Oo4 All Question To Be AttemptedLe TuanNo ratings yet

- General 3Document4 pagesGeneral 3Anum Zara (Zaari)No ratings yet

- Weld QuestionsDocument9 pagesWeld QuestionsdselvakuuNo ratings yet

- General 2Document4 pagesGeneral 2Sobia KalsoomNo ratings yet

- Welding Inspector Question Rew290Document45 pagesWelding Inspector Question Rew290dhasdj0% (2)

- Question WI..Document42 pagesQuestion WI..Indra MansyahNo ratings yet

- MP May2021 Quiz 4 KeyDocument4 pagesMP May2021 Quiz 4 KeyRuthNo ratings yet

- Tech 1Document9 pagesTech 1PraviBeetlesNo ratings yet

- Cswip Wi-5Document10 pagesCswip Wi-5Thirumalesu ChowdamNo ratings yet

- Cswip3.1 Question 1Document9 pagesCswip3.1 Question 1mohammed dallyNo ratings yet

- General 3Document4 pagesGeneral 3Sobia KalsoomNo ratings yet

- Cwi QuestionsDocument6 pagesCwi QuestionsGokul Thangam75% (4)

- Paper 6Document14 pagesPaper 6UmaibalanNo ratings yet

- D) Both (B) & (C) Are CorrectDocument8 pagesD) Both (B) & (C) Are CorrectPritamjit RoutNo ratings yet

- Welding Insp QuestionsDocument10 pagesWelding Insp QuestionsdselvakuuNo ratings yet

- Cswip 3 1 Welding Inspector Multiple Choice Question Dec 7 2007Document43 pagesCswip 3 1 Welding Inspector Multiple Choice Question Dec 7 2007sri.majji8937100% (1)

- Unit 1 AmpDocument7 pagesUnit 1 AmpAstle RebelloNo ratings yet

- CSWIP 3.1 QuestionsDocument43 pagesCSWIP 3.1 QuestionsMichael Albuquerque100% (2)

- Cswip 3.1 Welding Inspector - Multiple Choice Question, Dec 7, 2007Document18 pagesCswip 3.1 Welding Inspector - Multiple Choice Question, Dec 7, 2007Nagaya PushpaharaDoss50% (2)

- MCQ (Awt) Unit-3Document6 pagesMCQ (Awt) Unit-3So nuNo ratings yet

- Cswip Qa 1 - 300 QaDocument64 pagesCswip Qa 1 - 300 QaIyappan BaluNo ratings yet

- Cswip 3 1-300 - Multiple Choice QuestionDocument43 pagesCswip 3 1-300 - Multiple Choice QuestionTrương Ngọc SơnNo ratings yet

- Welding Inspector Question and Answer According CSWIP 3.1-1Document76 pagesWelding Inspector Question and Answer According CSWIP 3.1-1Mahmoud HagagNo ratings yet

- CSWIP Question 200 QDocument45 pagesCSWIP Question 200 Qakif aliNo ratings yet

- Multichoice Paper FiveDocument4 pagesMultichoice Paper FiveAhmed ShakirNo ratings yet

- Basic Question Bank Asnt Level IiiDocument7 pagesBasic Question Bank Asnt Level Iiiabhi100% (10)

- General All SolvedDocument25 pagesGeneral All SolvedAndiappan Pillai67% (3)

- (D) A Transformer or Alternator and A Means To Change The CurrentDocument19 pages(D) A Transformer or Alternator and A Means To Change The Currentmohammed dallyNo ratings yet

- Product Technology ASNT Module 4Document8 pagesProduct Technology ASNT Module 4mujjamilNo ratings yet

- ME Qs 3Document2 pagesME Qs 3Abhishek MishraNo ratings yet

- Metal Forming Processes Classification Questions and Answers - SanfoundryDocument3 pagesMetal Forming Processes Classification Questions and Answers - SanfoundryrahmaNo ratings yet

- Paper 5Document14 pagesPaper 5UmaibalanNo ratings yet

- 17.weldability - McqsDocument5 pages17.weldability - McqsJawed AkhterNo ratings yet

- General 2Document6 pagesGeneral 2skynyrd75No ratings yet

- Multiple Choice Paper A8Document3 pagesMultiple Choice Paper A8Chinni KrishnaNo ratings yet

- Question Paper For Snr. WeldingDocument3 pagesQuestion Paper For Snr. WeldingThulasi Ram100% (1)

- General Multi Choice Paper - 3Document4 pagesGeneral Multi Choice Paper - 3Chinni KrishnaNo ratings yet

- Cswip Paper 3.1Document5 pagesCswip Paper 3.1Fran Bakkara100% (1)

- Welding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsFrom EverandWelding Terminology: A Guide to MIG, TIG, Stick, Gas, and Spot Welding TermsNo ratings yet

- Metallurgy and Mechanics of Welding: Processes and Industrial ApplicationsFrom EverandMetallurgy and Mechanics of Welding: Processes and Industrial ApplicationsRegis BlondeauNo ratings yet

- Challenges in Corrosion: Costs, Causes, Consequences, and ControlFrom EverandChallenges in Corrosion: Costs, Causes, Consequences, and ControlNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Corrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionFrom EverandCorrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionNo ratings yet

- PT Level 2 Welds CW 1Document1 pagePT Level 2 Welds CW 1fadli heiNo ratings yet

- Basic 3 (PT) - Part CDocument1 pageBasic 3 (PT) - Part Cfadli heiNo ratings yet

- Basic 3 (Ut) - Part CDocument1 pageBasic 3 (Ut) - Part Cfadli heiNo ratings yet

- Basic 3 (MT) - Part CDocument1 pageBasic 3 (MT) - Part Cfadli heiNo ratings yet

- Basic 3 (RT) - Part CDocument1 pageBasic 3 (RT) - Part Cfadli heiNo ratings yet

- Basic 3 - Part A.Document1 pageBasic 3 - Part A.fadli heiNo ratings yet

- ASME B31.3 - Practice QuestionDocument18 pagesASME B31.3 - Practice QuestionPravin Vispute100% (1)

- SubsoilerDocument19 pagesSubsoilerElma BorinagaNo ratings yet

- 155-01ppr - MAN Alpha CPPDocument16 pages155-01ppr - MAN Alpha CPPhpss77No ratings yet

- Midea Ventilokonvektori 2016Document32 pagesMidea Ventilokonvektori 2016bzvzNo ratings yet

- Sample 4 PDFDocument34 pagesSample 4 PDFEmmanuelNo ratings yet

- Roller Cutters & Cutting ToolsDocument9 pagesRoller Cutters & Cutting ToolsDiego CalderonNo ratings yet

- Cimberio Valve CatalogueDocument16 pagesCimberio Valve CatalogueQuynh NguyenNo ratings yet

- Variable Refrigerant Flow (VRF) Systems: Ir. Dr. Sam C. M. HuiDocument54 pagesVariable Refrigerant Flow (VRF) Systems: Ir. Dr. Sam C. M. HuiS Amit Rao100% (1)

- State of The Art On Methods For Reducing Rising D - 2018 - Journal of Cultural HDocument7 pagesState of The Art On Methods For Reducing Rising D - 2018 - Journal of Cultural HGabriela DraghiciNo ratings yet

- Avon Sb122 - Gas Generator Lubricating Oil SpecificationDocument9 pagesAvon Sb122 - Gas Generator Lubricating Oil Specificationpeach5No ratings yet

- 05 Fiber - Reinforced Polymers Processes and ApplicationsDocument470 pages05 Fiber - Reinforced Polymers Processes and ApplicationsarivumaniNo ratings yet

- Distillation Column Design Lab ReportDocument31 pagesDistillation Column Design Lab ReportGracylla RoseNo ratings yet

- Assignment Unit IV BMEDocument2 pagesAssignment Unit IV BMERoop LalNo ratings yet

- 1K09309Document2 pages1K09309threwawayNo ratings yet

- Cooli Additive Maintenance GuideDocument8 pagesCooli Additive Maintenance GuideJavi AmadoNo ratings yet

- Polytronics PresentationDocument21 pagesPolytronics PresentationPrince AnudeepNo ratings yet

- Quotation # SO889: Invoicing AddressDocument5 pagesQuotation # SO889: Invoicing Addressmurali036No ratings yet

- Concrete Lec 7Document10 pagesConcrete Lec 7Owais Khan100% (1)

- Washing Machine: User's ManualDocument13 pagesWashing Machine: User's ManualAnna Lissa PilapilNo ratings yet

- Dynamic Analysis of Steel Frame Using Manufactured Viscous DamperDocument3 pagesDynamic Analysis of Steel Frame Using Manufactured Viscous DamperInnovative Research PublicationsNo ratings yet

- Sulzer OHH OHHL FeaturesDocument6 pagesSulzer OHH OHHL FeaturesScott TorgussonNo ratings yet

- TDS Fosroc Polyurea WH 200 IndiaDocument4 pagesTDS Fosroc Polyurea WH 200 Indiaprem prakash mishraNo ratings yet

- Elecon Scoop Coupling Installation Maintenance ManualDocument21 pagesElecon Scoop Coupling Installation Maintenance ManualVignesh VenkatasubramanianNo ratings yet

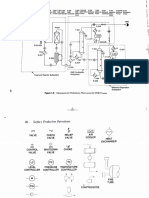

- PFD ISA Standard PDFDocument4 pagesPFD ISA Standard PDFRodolfo Solano SilvaNo ratings yet

- Darryl L Ulrich - Association For Finishing Processes of SME - User's Guide To Powder Coating-Society of Manufacturing Engineers (1993)Document132 pagesDarryl L Ulrich - Association For Finishing Processes of SME - User's Guide To Powder Coating-Society of Manufacturing Engineers (1993)PhucNo ratings yet

- Brake Fluid What You Should KnowDocument7 pagesBrake Fluid What You Should Knowmikael bezerra cotias dos santosNo ratings yet

- High Torque Timing Pulleys - S5MDocument1 pageHigh Torque Timing Pulleys - S5MdangmiuNo ratings yet

- Product Catalogue - Jakson PDFDocument2 pagesProduct Catalogue - Jakson PDFhiralalnhpc100% (2)