Professional Documents

Culture Documents

Bolt Entering and Tightening Clearances

Bolt Entering and Tightening Clearances

Uploaded by

jason IOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolt Entering and Tightening Clearances

Bolt Entering and Tightening Clearances

Uploaded by

jason ICopyright:

Available Formats

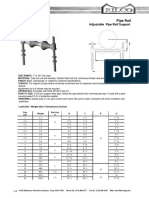

BOLTED CONSTRUCTION 8 - 13

Table 8-4.

Entering and Tightening Clearances, in.

Conventional ASTM A325 and A490 Bolts

Aligned Bolts

Nominal

Bolt Dia., Socket C3

socket

H1 H2 in. Dia., in. H1 H2 C1 C2 Circular Clipped

C1 C1 5⁄ 13 ⁄4 25 ⁄ 11 ⁄4 1 11⁄ 11⁄ 9⁄

8 64 16 16 16

C2 C1 3⁄

H2 4 21 ⁄4 15 ⁄

32 13 ⁄8 11 ⁄4 3⁄

4

3⁄

4

11⁄

16

7⁄ 21 ⁄2 35 ⁄ 11 ⁄2 13 ⁄8 7⁄ 7⁄ 13 ⁄

8 64 8 8 16

1 25 ⁄8 39 ⁄

64 15 ⁄8 17 ⁄16 15 ⁄

16 1 7⁄

8

11⁄ 8 27 ⁄8 11⁄

16 17 ⁄8 19 ⁄16 1 ⁄16

1 11 ⁄8 1

fillet

C3 11⁄ 4 31 ⁄8 25 ⁄

32 2 111⁄16 1 ⁄8

1 11 ⁄4 11 ⁄8

1 3 ⁄8 31 ⁄4 27 ⁄

32 21 ⁄8 13 ⁄4 11 ⁄4 13 ⁄8 11 ⁄4

1 1 ⁄2 31 ⁄2 15 ⁄

16 21 ⁄4 15 ⁄16 15 ⁄16 11 ⁄2 15 ⁄16

Staggered Bolts

Stagger P, in.

Nominal Bolt Diameter, in.

F 5⁄ 3⁄ 7⁄ 1 11⁄8 11⁄4 1 3 ⁄8 1 1 ⁄2

8 4 8

1 15 ⁄8

1 1 ⁄8 11 ⁄2

1 1 ⁄4 11 ⁄2 115 ⁄16

1 3 ⁄8 17 ⁄16 17 ⁄8 23 ⁄16

11⁄ 2 11 ⁄ 4 113 ⁄ 16 21 ⁄8 25 ⁄16

C1 1 5 ⁄8 11 ⁄4 13 ⁄4 21 ⁄16 25 ⁄16 29 ⁄16

1 3 ⁄4 13 ⁄16 111⁄16 2 21 ⁄4 29 ⁄16 213 ⁄16 3

P 1 7 ⁄8 11 ⁄8 19 ⁄16 115 ⁄16 23 ⁄16 21 ⁄2 23 ⁄4 3 33 ⁄4

2 1 11 ⁄ 2 113 ⁄ 16 21 ⁄ 8 27 ⁄ 16 23 ⁄ 4 215 ⁄ 16 31 ⁄4

2 1 ⁄8 13 ⁄

16 13 ⁄8 111⁄16 2 23 ⁄8 211⁄16 215 ⁄16 33 ⁄16

2 1 ⁄4 11 ⁄4 19 ⁄16 17 ⁄8 21 ⁄4 25 ⁄8 27 ⁄8 33 ⁄16

2 3 ⁄8 11 ⁄8 11 ⁄2 13 ⁄4 21 ⁄8 21 ⁄2 213 ⁄16 31 ⁄8

2 1 ⁄2 7⁄

8 13 ⁄8 15 ⁄8 2 27 ⁄16 23 ⁄4 31 ⁄16

2 5 ⁄8 13 ⁄16 11 ⁄2 115 ⁄16 25 ⁄16 27 ⁄8 3

F 2 3 ⁄4 15 ⁄

16 13 ⁄8 17 ⁄8 21 ⁄8 21 ⁄2 27 ⁄8

2 7 ⁄8 13 ⁄16 13 ⁄4 21 ⁄16 23 ⁄8 213 ⁄16

3 7⁄ 15 ⁄8 2 21 ⁄4 211⁄16

8

C1 = tightening

3 1 ⁄8 11 ⁄2 17 ⁄8 21 ⁄8 21 ⁄2

clearance 3 1 ⁄4 11 ⁄4 13 ⁄4 2 23 ⁄8

3 3 ⁄8 15 ⁄

16 15 ⁄8 115 ⁄16 21 ⁄4

31⁄ 2 13 ⁄8 13 ⁄4 21 ⁄8

standard

3 5 ⁄8 11 ⁄16 19 ⁄16 2

socket 3 3 ⁄4 15 ⁄16 17 ⁄8

3 7 ⁄8 1 ⁄16

11

4 13 ⁄8

Notes:

H1 = height of head, in.

H2 = maximum shank extension,* in.

C1 = clearance for tightening, in.

C2 = clearance for entering, in.

C3 = clearance for fillet,* in.

P = bolt stagger, in.

F = clearance for tightening staggered bolts, in.

*Based on one standard hardened washer.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

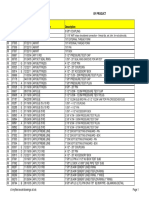

8 - 14 BOLTS, WELDS, AND CONNECTED ELEMENTS

Table 8-5.

Entering and Tightening Clearances, in.

Tension-Control ASTM A325 and A490 Bolts

Aligned Bolts

Nominal C3

Bolt

Tools Dia, in. H1 H2 C1 C2 Circular Clipped

Large Tools 3 3 ⁄8-in. Diameter Critical

3⁄ 1⁄ 13 ⁄8 17 ⁄8 7⁄ 3⁄ —

4 2 8 4

7⁄ 9⁄ 11 ⁄2 17 ⁄8 1 7⁄ —

33/8 8 16 8

1 5⁄ 13 ⁄4 17 ⁄8 11 ⁄8 1 —

H1 H2 8

1 /2 3 /8

1

2 /2

1

C1 C1

2 2 1 ⁄2-in. Diameter Critical

1

C2 C1

H2 3⁄ 1⁄ 13 ⁄8 13 ⁄8 7⁄ 3⁄ —

4 2 8 4

7⁄ 9⁄ 11 ⁄2 13 ⁄8 1 7⁄ —

8 16 8

1 5⁄ 13 ⁄4 13 ⁄8 11 ⁄8 1 —

8

fillet Small Tools 3-in. Diameter Critical

C3

5⁄ 7⁄ 11 ⁄4 15 ⁄8 13 ⁄ 11⁄ —

8 16 16 16

3⁄ 1⁄ 13 ⁄8 15 ⁄8 7⁄ 3⁄ —

4 2 8 4

7⁄ 9⁄ 11 ⁄2 15 ⁄8 1 7⁄ —

3 8 16 8

3

2 /16 2 3 ⁄16-in. Diameter Critical

21/2 2

2 5⁄ 7⁄ 11 ⁄4 11 ⁄8 13 ⁄ 11⁄ —

8 16 16 16

3⁄ 1⁄ 13 ⁄8 11 ⁄8 7⁄ 3⁄ —

4 2 8 4

7⁄ 9⁄ 11 ⁄2 11 ⁄8 1 7⁄ —

8 16 8

Staggered Bolts

Stagger P, in.

Nominal Bolt Diameter, in.

F 5⁄ 3⁄ 7⁄ 1

8 4 8

C1 11⁄ 4 113 ⁄ 16

1 3 ⁄8 13 ⁄4 21 ⁄16 21 ⁄4 27 ⁄16

P 11⁄ 2 111⁄ 16 2 23 ⁄ 16 23 ⁄8

1 5 ⁄8 19 ⁄16 17 ⁄8 21 ⁄16 21 ⁄4

1 3 ⁄4 11 ⁄2 1 ⁄16

13 2 23 ⁄16

1 7 ⁄8 17 ⁄16 13 ⁄4 17 ⁄8 21 ⁄8

2 15 ⁄16 15 ⁄8 13 ⁄4 2

2 1 ⁄8 11 ⁄4 19 ⁄16 111⁄16 115 ⁄16

2 1 ⁄4 13 ⁄16 11 ⁄2 19 ⁄16 17 ⁄8

2 3 ⁄8 11 ⁄8 13 ⁄8 11 ⁄2 13 ⁄4

F

2 1 ⁄2 1 15 ⁄16 13 ⁄8 111⁄16

2 5 ⁄8 13 ⁄16 15 ⁄16 19 ⁄16

2 3 ⁄4 11 ⁄8 13 ⁄16 11 ⁄2

C1 = tightening 2 7 ⁄8 11 ⁄8 13 ⁄8

installation

clearance tool 3 15 ⁄16

3 3 ⁄8 15 ⁄16

Notes:

H1 = height of head, in.

H2 = maximum shank extension,* in.

C1 = clearance for tightening, in.

C2 = clearance of entering, in.

C3 = clearance for fillet,* in.

P = bolt stagger, in.

F = clearance for tightening staggered

bolts, in.

*Based on one standard hardened washer.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

You might also like

- HVAC Performance Test Quality Control and Inspection Report FormDocument6 pagesHVAC Performance Test Quality Control and Inspection Report Formhasan_676489616100% (1)

- EIGA Doc 07 03 EDocument25 pagesEIGA Doc 07 03 EFrancisco Campos ParadaNo ratings yet

- #532-027 - Metering Pump Handbook PDFDocument2 pages#532-027 - Metering Pump Handbook PDFTuesou Machere100% (1)

- Bosch - RBIC PC Braking Components Catalogue-Vol 1 2020Document40 pagesBosch - RBIC PC Braking Components Catalogue-Vol 1 2020JB ThusthehirNo ratings yet

- Llustrated Arts Anual: Transmatic Lawn Tractor - Model Series 700Document48 pagesLlustrated Arts Anual: Transmatic Lawn Tractor - Model Series 700BoM36040100% (1)

- Fig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsDocument1 pageFig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsMarco AntonioNo ratings yet

- Steering System Service ManualDocument36 pagesSteering System Service Manualmybdt1691No ratings yet

- ANSI Standard Keys and Keyseats.-American National Standard, B17.1 Keys andDocument30 pagesANSI Standard Keys and Keyseats.-American National Standard, B17.1 Keys andCarmen GonzalezNo ratings yet

- SS SUB 181 v01Document1 pageSS SUB 181 v01mcohen LCINo ratings yet

- Filetages NPT - BSP - Sae+++Document3 pagesFiletages NPT - BSP - Sae+++SylvainJasonNo ratings yet

- Swiss Diamond International All-Clad Newell Rubbermaid Meyer Corporation Cross-Linked Electron Beam ProcessingDocument4 pagesSwiss Diamond International All-Clad Newell Rubbermaid Meyer Corporation Cross-Linked Electron Beam ProcessingguslohNo ratings yet

- Anvil Fig137 U-Bolt PDFDocument1 pageAnvil Fig137 U-Bolt PDFAin AzmiNo ratings yet

- BSPT & BSPP Threads Dimensions: Read: Putin's Priceless World Cup MomentDocument3 pagesBSPT & BSPP Threads Dimensions: Read: Putin's Priceless World Cup MomentguslohNo ratings yet

- Clevis Hangers Combined PDFDocument1 pageClevis Hangers Combined PDFSaleem BashaNo ratings yet

- Part 540 Adjustable Pipe Roll SupportDocument1 pagePart 540 Adjustable Pipe Roll Supportpenyuka tembalangNo ratings yet

- Pocket Bolt Reference Chart: Sealing Global - Servicing LocalDocument2 pagesPocket Bolt Reference Chart: Sealing Global - Servicing LocalMazhar MahadzirNo ratings yet

- Chatham Steel StructshapesDocument21 pagesChatham Steel Structshapesjalv.mendoza25No ratings yet

- BSPT & BSPP Size & PitchDocument3 pagesBSPT & BSPP Size & PitchguslohNo ratings yet

- Ark Boss Battle Theme Rockwell April 7 EditDocument1 pageArk Boss Battle Theme Rockwell April 7 EditGitano Lanza MusicNo ratings yet

- Solfeggietto: Carl Philipp Emanuel BachDocument5 pagesSolfeggietto: Carl Philipp Emanuel BachCris MaidanaNo ratings yet

- LB 49448Document1 pageLB 49448saidNo ratings yet

- Table 13 Permitted Variations From A Flat Surface For Carbon Steel PlatesDocument1 pageTable 13 Permitted Variations From A Flat Surface For Carbon Steel PlatesamevaluacionesNo ratings yet

- Fluid Flow Velocity Steel Pipe Schedule 40Document1 pageFluid Flow Velocity Steel Pipe Schedule 40Said FerdjallahNo ratings yet

- SS SUB 171 v01Document1 pageSS SUB 171 v01mcohen LCINo ratings yet

- A Minor Scale Ascending Across StringsDocument1 pageA Minor Scale Ascending Across StringsjollygerberNo ratings yet

- Hardware & Equipment: Freeman Lok-In Pattern LettersDocument1 pageHardware & Equipment: Freeman Lok-In Pattern LettersiocephNo ratings yet

- Watch CabinetDocument29 pagesWatch CabinetBán ZoltánNo ratings yet

- Xcelite Catalog 5506Document100 pagesXcelite Catalog 5506Ruben MontelongoNo ratings yet

- Flange Dimensions Based On Tables D and E of BS 10: 1962Document6 pagesFlange Dimensions Based On Tables D and E of BS 10: 1962윤규섭No ratings yet

- Triadas Menores - Drop 2Document1 pageTriadas Menores - Drop 2leguzman86No ratings yet

- Milbank MFG Co - U7490 RL TG - 78457214148 - CutDocument1 pageMilbank MFG Co - U7490 RL TG - 78457214148 - CutRod ReedNo ratings yet

- Bolt of ACI StandardDocument1 pageBolt of ACI StandardDani SaputraNo ratings yet

- Automatic Backflush Valve LeafletDocument2 pagesAutomatic Backflush Valve LeafletSajane MassadaNo ratings yet

- Flange SupportDocument1 pageFlange SupportvijayanmksNo ratings yet

- BSPP & BSPT Thread Identification TableDocument5 pagesBSPP & BSPT Thread Identification TableguslohNo ratings yet

- Asmeflanged PDFDocument1 pageAsmeflanged PDFrudi rockerNo ratings yet

- Asme FlangedDocument1 pageAsme Flangedmohammad zareiNo ratings yet

- Stainless Steel Heads and CapsDocument1 pageStainless Steel Heads and CapsAnonymous 9ixSOaQ5PPNo ratings yet

- Zap Screwlok® Data SheetDocument2 pagesZap Screwlok® Data SheetLeomariniNo ratings yet

- Gasket Installation: DurlonDocument3 pagesGasket Installation: Durlonlorenzo100% (1)

- Fluid Flow Velocity Steel Pipe Schedule 40 Metric UnitsDocument1 pageFluid Flow Velocity Steel Pipe Schedule 40 Metric UnitsRobert ThanhNo ratings yet

- Manual Rus-20190408084940Document32 pagesManual Rus-20190408084940comf002376No ratings yet

- SS SUB 175 v01Document1 pageSS SUB 175 v01mcohen LCINo ratings yet

- Classical Colonial Dimensioned WindsorONE PrintDocument1 pageClassical Colonial Dimensioned WindsorONE PrintMIGUEL MENDOZANo ratings yet

- World Cup Countdown: Sorting Wheat From The Chaff: Share On Facebook Share On Twitter Send Via EmailDocument5 pagesWorld Cup Countdown: Sorting Wheat From The Chaff: Share On Facebook Share On Twitter Send Via EmailguslohNo ratings yet

- 5 Storey Mixed Use BLDGDocument16 pages5 Storey Mixed Use BLDGElaine AsisNo ratings yet

- Round Washer DimsDocument1 pageRound Washer DimsBaoNo ratings yet

- BSG1018 - Rev 3Document1 pageBSG1018 - Rev 3Xu DuaNo ratings yet

- Carl Minor Lick: Standard TuningDocument1 pageCarl Minor Lick: Standard Tuningshing6man6kwokNo ratings yet

- Eaton Rtlo 11610b t2 Transmission Illustrated Parts List en UsDocument46 pagesEaton Rtlo 11610b t2 Transmission Illustrated Parts List en UsJavier Estrada ColindresNo ratings yet

- Tolerances Except As Noted: Job# Ustom Ngineering &Document1 pageTolerances Except As Noted: Job# Ustom Ngineering &Anbazhagan AnnaduraiNo ratings yet

- Diminished Augmented CAGEDDocument1 pageDiminished Augmented CAGEDLuna MaarNo ratings yet

- 30 Riffs 2 Strings 1918-2017Document5 pages30 Riffs 2 Strings 1918-2017FellipeNo ratings yet

- CBX II PestanaDocument1 pageCBX II PestanaZack BackNo ratings yet

- Polishing AccessoriesDocument1 pagePolishing AccessoriesEder guarneros zarateNo ratings yet

- Fastener Catalog: Product Groups - Page 1Document690 pagesFastener Catalog: Product Groups - Page 1zuluntando182No ratings yet

- Clevis Hangers CombinedDocument4 pagesClevis Hangers CombinedSaleem BashaNo ratings yet

- Straight Razor RulerDocument1 pageStraight Razor RulerEdson GordianoNo ratings yet

- Plug Switch 2D PDFDocument5 pagesPlug Switch 2D PDFAdy PurnamaNo ratings yet

- A608402 - 0 Sheet1Document1 pageA608402 - 0 Sheet1Brayand Colonia MarquinaNo ratings yet

- CBX I PestanaDocument1 pageCBX I PestanaZack BackNo ratings yet

- Lincoln Centromatic Inyectores AceiteDocument4 pagesLincoln Centromatic Inyectores Aceitejuan montufarNo ratings yet

- Weiss. Sonata Nr. 3 in G MollDocument9 pagesWeiss. Sonata Nr. 3 in G MollerueruerufuNo ratings yet

- Abracadeira Gota - 287 1Document1 pageAbracadeira Gota - 287 1Robson CustódioNo ratings yet

- One Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialFrom EverandOne Bold Move a Day: Meaningful Actions Women Can Take to Fulfill Their Leadership and Career PotentialNo ratings yet

- 38CKC Product DataDocument26 pages38CKC Product DataCarlos Enrique Godoy Sifontes0% (1)

- 390-Duke My-17Document71 pages390-Duke My-17XSHAFT MOTOGARAGENo ratings yet

- BUELL X1 Teile CatalogDocument79 pagesBUELL X1 Teile CatalogMoander SmithNo ratings yet

- An 525 Was Her Head Machine ScrewsDocument2 pagesAn 525 Was Her Head Machine ScrewshuriNo ratings yet

- CRS3 3Document18 pagesCRS3 3prueba100% (1)

- Nov Dec 2018 Som Question Paper SPPUDocument6 pagesNov Dec 2018 Som Question Paper SPPUaniket wadheNo ratings yet

- Structural Behavior of Deep Reinforced Concrete Beams Under Indirect Loading ConditionDocument20 pagesStructural Behavior of Deep Reinforced Concrete Beams Under Indirect Loading ConditionTJPRC PublicationsNo ratings yet

- ACADEMIC MANUAL For DistributionDocument58 pagesACADEMIC MANUAL For DistributionCamilo DominguezNo ratings yet

- Computation Exercise No. 1: GeotechDocument4 pagesComputation Exercise No. 1: GeotechAngelo BautistaNo ratings yet

- Module 5 - Fall 2023Document64 pagesModule 5 - Fall 2023Adnan ullahNo ratings yet

- Drawings All - 2017-06-23Document118 pagesDrawings All - 2017-06-23Syed IrtazaNo ratings yet

- 9 Cast Aluminum Alloys - EXEMPLO 20Document7 pages9 Cast Aluminum Alloys - EXEMPLO 20AlexandreinspetorNo ratings yet

- BWM 0000004 01Document54 pagesBWM 0000004 01stefanovicana1No ratings yet

- Two Stroke Piston DiagnosisDocument5 pagesTwo Stroke Piston Diagnosisnebnik100% (2)

- Design of Pile Caps FinalDocument50 pagesDesign of Pile Caps FinalImam Shakil100% (2)

- Owen Siebold Paper Airplane SimulationDocument9 pagesOwen Siebold Paper Airplane SimulationVíctor QuezadaNo ratings yet

- Die Maintenance. Die Repair.Document9 pagesDie Maintenance. Die Repair.zfrlNo ratings yet

- Two Phase Flow in PipeDocument27 pagesTwo Phase Flow in PipeHassanKMNo ratings yet

- Submittal: Job Title: Elevation: (FT) Date: Submitted By: John DoeDocument35 pagesSubmittal: Job Title: Elevation: (FT) Date: Submitted By: John Doejfher87No ratings yet

- IMS Crane Inspection Guide 1Document43 pagesIMS Crane Inspection Guide 1moahamed ahmed100% (1)

- ML 1500 Product ManualDocument9 pagesML 1500 Product Manualhector castellanos rNo ratings yet

- Screw Air Compressors: SCR Belt DriveDocument2 pagesScrew Air Compressors: SCR Belt DriveDelwin Jose Hernandez100% (1)

- Imo ACGDocument16 pagesImo ACGMiguel Ponce100% (1)

- 01 10 0001 enDocument4 pages01 10 0001 enFernando SabinoNo ratings yet

- Design of Safety Valves: Design Standard: ASME VIII / API 520Document26 pagesDesign of Safety Valves: Design Standard: ASME VIII / API 520JoyNo ratings yet