Professional Documents

Culture Documents

Tension Spring Method Statement

Tension Spring Method Statement

Uploaded by

kimdasilva187Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tension Spring Method Statement

Tension Spring Method Statement

Uploaded by

kimdasilva187Copyright:

Available Formats

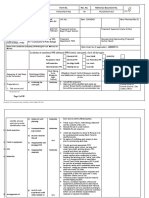

Safe Work Method Statement

(Small Projects)

Description of the Task / Replace Tension Spring on Rollershutter Work Order or

Activity to be performed Door Purchase Order PO4500721652

Number

Standard Bank

Contract / Project Name Project Number

Standard Bank

MIS505080

Service Provider Name Vendor Number

Mushi Integrated Systems

3 Simmonds Street Start Date / Time 11/04/2022

Site Location /Address

Finish Date / Time 11/04/2022

Name and Surname of the Peet Prinsloo Telephone Number 073 725 6323

Company Appointed Section Office:

16. 1 – Owner or Section Cell Phone:

16.2

Name and Surname of the Darren Pigden Telephone Number 061 400 9899

Manager or Supervisor Office:

overseeing the work to be Cell Phone:

performed on site

Name and Surname of the Telephone Number 073 725 6323

SHE Officer / Specialist Peet Prinsloo Office:

Cell Phone:

Personnel Involved Name and ID No. Role / Trade Name and ID No. Role / Trade

(Copy of the ID No. to be Manager

attached, if required for Peet

Access to site permit) 6204065049084

Darren Technician

9612095046085

Document No.: Bidvest Facilities Company Restricted

SharePoint Ver.: Management (Pty) Ltd Document No.: GOV0-4-504

Date: SharePoint Ver.: 1.0

Page 1 of 9

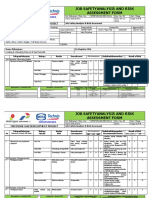

Safe Work Method Statement

(Small Projects)

Risk Rating Property /

Health, Safety Environmental Matrix

Methodology Business Lost

Catastrophic, Fatality, Loss limb 80% of the damage is 1 day or more 3

3 6 9

irreversible

Severity Lost Time Injury 60% of the damage is 1 day or less 2

2 4 6

irreversible

First Aid Treatment / Near Miss Fully reversible 1 Hour or less 1 1 2 3

Acceptable Risk High Risk (4-9) – Supervision, Competent Workers, Safe Working Procedure, 1 Unlikely 2 Likely 3Certain

Control Level Medium Risk (2-3)– Supervision, Competent Workers and Awareness Probability

Low Risk (1) – Tool Box Talk

Sequence of events (included sketches if required)

Potential Hazard Appropriate Controls

Probability (P)

Risk Rating (S

Sequence No:

Activity / Task

Severity (S)

Job Step/Task Against each step list the [Engineering, Administrative, PPE /

PPW and Training]

Describe the steps required to potential hazards that could Responsibility

List the control measure required to

perform the task in the cause injury/damage to

eliminate or minimise the risk of injury

sequence they are carried out property when the task step

arising from the identified hazard

is performed.

Close the door None 0 0 0 None Darren

1

2 Remove dust and protection Sharp edges- fingers can 2 1 2 Wear Gloves Darren

cover get cut Wear dust mask

Disengage Motordrive Rollershutter door can 9 5 4 Make sure no one is standing under Darren

3 collapse and injur people 5 the rollershutter door whilst

standing underneath it. disengaging the motordrive

Release doormat from shaft Sharp edges fingers can 2 1 2 Wear gloves Darren

4 get cut

Document No.: Bidvest Facilities Company Restricted

SharePoint Ver.: Management (Pty) Ltd Document No.: GOV0-4-504

Date: SharePoint Ver.: 1.0

Page 2 of 9

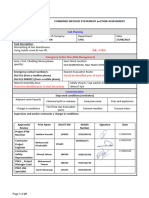

Safe Work Method Statement

(Small Projects)

Undo mounting brackets on Sharp edges- fingers can 2 1 2 Wear Gloves Darren

5 shaft get cut

Remove shaft from bracket Heavy weight- can fall onto 2 1 2 Wear safety Boots Darren

6 feet Make sure 2 or more people are

removing shaft

Pre-Requests before work

Document No.: Bidvest Facilities Company Restricted

SharePoint Ver.: Management (Pty) Ltd Document No.: GOV0-4-504

Date: SharePoint Ver.: 1.0

Page 3 of 9

Safe Work Method Statement

(Small Projects)

commences on site

Permit Required (Mark the item x Hot Work Working at Heights Confined Electrical/ Excavations

with an “X” if applicable) Space Mechanical

Lockout

Vehicles and mobile plant

(Registration Numbers)

Key Materials to be used

Tension spring

Key Equipment to be used

(Access platforms / winches / ladders, ladders

MEWP’s, etc.)

Key Hand Tools & Electrical Drill (if necessary)

Tools to be used Screw driver

Key Personnel Protective Safety boots

Equipment to be worn / Gloves

utilised Dust mask

Incident Management (Mark x First Aid Kit available on site Spillage Kit available on site

the item with an “X” if applicable)

Hazardous Substances to be N/A

used (Attach MSDS)

Safety signage and (i.e. Scaffolding Safe to Use Sign, Unauthorised Entry, Men at work, Orange Netting or Barricading tape, Hording, etc.)

Barricading to be used

Men at work Sign

Statutory required Training (i.e. Scaffolding Erectors & Inspectors, MEWP Operators, Rope Access and Fall Prevention, etc.)

Certificates (Attach records)

Method of Access and (i.e. Ladders, Scaffold, Trestles, MEWP, Rope Access, etc.)

Egress to the area:

(i.e. Fall Protection Systems / Guard Rails / Toe Boards / Safety Mesh, Life Lines; etc.)

Fall Protection Measures

(Where work at height cannot be

eliminated – consider both Personnel

and materials)

Attached the following items Contractual Scope of Work (Technical Specification) X Yes No N/A Available on SHE File

Document No.: Bidvest Facilities Company Restricted

SharePoint Ver.: Management (Pty) Ltd Document No.: GOV0-4-504

Date: SharePoint Ver.: 1.0

Page 4 of 9

Safe Work Method Statement

(Small Projects)

(“X” – Compulsory / Notification of Construction Work (Construction Regulation x Yes No N/A Available on SHE File

Mandatory item) 4)

Mandatory Agreement Signed (Section 37.2 Agreement) X Yes No N/A Available in SHE File

Public Liability Insurance Cover X Yes No N/A Verified at Site

Handover. Recorded in

Site Handover Meeting

Minutes

Valid Letter of Good Standing X Yes No N/A Available in SHE File

Task Based Risk Assessment approved by the Project X Yes No N/A Method Statement &

Risk Assessment

Manager Document

Safe Working Procedures e.g. LOTO, Hot Work, Working at X Yes No N/A Available in SHE File

Heights, Mast Recovery, etc.)

SHE Induction X Yes No N/A Method Statement &

Risk Assessment

Document

Legal Appointments (Section 16,2; Construction Supervisor / X Yes No N/A Available in SHE File

Manager; Risk Assessor; Fall Protection Planner; First Aider etc.,)

Technical Staff Competency Records e.g. HVAC, X Yes No N/A Available in SHE File

Electrical, Fire & Access, Plumbing, Carpentry, Welding, etc.

Statutory Training Certificates E.g. Erectors, Yes No N/A Available in SHE File

Inspectors, MEWP Operators, Fall prevention and fall

arrest equipment certificates, etc.

Fall Protection Plan (Construction Regulation 10) Yes No N/A Available in SHE File

Rescue Plan (Construction Regulation 10) Yes No N/A Available in SHE File

Fall prevention and fall arrest equipment Inspection Yes No N/A Available in SHE File

Registers (Include unique numbering)

Material Safety Data Sheets and Training Records Yes No N/A Available in SHE File

Waste Management Register Yes No N/A Available in SHE File

Sketches Yes No N/A Available in SHE File

Certificates of specialised equipment (e.g. Lifting Yes No N/A Available in SHE File

devices, Slings, etc.

Copies of ID’s / Passport for security access to site Yes No N/A Available in SHE File

Medical Certificates of fitness (Construction Regulation 7, 10, Yes No N/A Available in SHE File

22, 23, Annexure 3, Hazardous Chemical Substances, etc.)

Document No.: Bidvest Facilities Company Restricted

SharePoint Ver.: Management (Pty) Ltd Document No.: GOV0-4-504

Date: SharePoint Ver.: 1.0

Page 5 of 9

Safe Work Method Statement

(Small Projects)

Masts Recovery: Comply with Construction Regulation 7, 8, 9, Yes No N/A Available in SHE File

10, 11, 12, 14, 16, 18, 22, 23, 24, 27, 29, 30, 33, etc .

Other:

DOCUMENT APPROVAL

Contractor Authorised Person Role / Title Date Signature Revision

Technician 11/04/22

Darren Pigden

Approval Bidvest Facilities Management Authority Name Role / Title Date Signature

Approval Bidvest Facilities Management Authority Name Role / Title Date Signature

Document No.: Bidvest Facilities Company Restricted

SharePoint Ver.: Management (Pty) Ltd Document No.: GOV0-4-504

Date: SharePoint Ver.: 1.0

Page 6 of 9

Safe Work Method Statement

(Small Projects)

SAFE WORK METHOD STATEMENT BRIEFING AND INSPECTION RECORD

Heading Replace tension spring Work Order or Purchase PO4500721658

(Description of the Activity / Task) Order Number

Date 11/04/2022 Start Time

End Tame

Authorised Person on site Darren Position Technician

Briefing delivered by Position

We (the undersigned) have read and understood the attached Method Statement / Risk Assessment and will comply with the specific

requirements and control measures. If the work activity changes or deviates from that originally envisaged, we will seek further advice and

request an amended Method Statement / Risk Assessment.

Name (Print) Signature Name (Print) Signature

Darren

Register and Inspection of Hand Tools, Ladders, Portable Electrical Equipment and PPE

Legend: Yes – Safe to use, No- Unsafe to use (Prohibited)

Tools, Ladders & Equipment Personal Protective Equipment (PPE)

Description ID Nr. Yes No Name Description Yes No

Document No.: Bidvest Facilities Company Restricted

SharePoint Ver.: Management (Pty) Ltd Document No.: GOV0-4-504

Date: SharePoint Ver.: 1.0

Page 7 of 9

Safe Work Method Statement

(Small Projects)

Company Authority Name

I confirm that I understand the risks described above and that I am familiar with the health, safety and environmental precautions in place

Name Designation Signature Date

Document No.: Bidvest Facilities Company Restricted

SharePoint Ver.: Management (Pty) Ltd Document No.: GOV0-4-504

Date: SharePoint Ver.: 1.0

Page 8 of 9

Safe Work Method Statement

(Small Projects)

Bidvest Facilities Management Authority Name

Comments:

I confirm to the best of my knowledge, that the above information is correct and that all the health, safety and environmental precautions have

been taken as indicated

Name Designation Signature Date

Bidvest Facilities Management or Customer Sign-off

Comments:

I, the undersigned, do hereby confirm to the best of my knowledge, that the work was completed satisfactory

Name Designation Signature Date

Document No.: Bidvest Facilities Company Restricted

SharePoint Ver.: Management (Pty) Ltd Document No.: GOV0-4-504

Date: SharePoint Ver.: 1.0

Page 9 of 9

You might also like

- Being The Principal Powerpoint Ead 501Document15 pagesBeing The Principal Powerpoint Ead 501api-337555351100% (9)

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Document15 pagesJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanNo ratings yet

- Yautja: Case File No. WY-8790-2004Document18 pagesYautja: Case File No. WY-8790-2004MorkizgaNo ratings yet

- RAMS For Confined Space Activities in Underground Water TankDocument13 pagesRAMS For Confined Space Activities in Underground Water TankEm NiaxNo ratings yet

- Risk Assessment For ExcavatorDocument12 pagesRisk Assessment For ExcavatorCiaraNo ratings yet

- 69.JSA Loading & Unloading MaterialDocument9 pages69.JSA Loading & Unloading MaterialKidung pamungkas Pamungkas100% (2)

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument4 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriNo ratings yet

- Unit 6 Achievement TestDocument9 pagesUnit 6 Achievement TestPablo Silva AriasNo ratings yet

- Strategic Planning & Budget Essentials Part - 2 by GartnerDocument26 pagesStrategic Planning & Budget Essentials Part - 2 by GartnerRavi Teja ChillaraNo ratings yet

- ABSA Bidvest FM Safe Work Method Statement Template - May 2023Document7 pagesABSA Bidvest FM Safe Work Method Statement Template - May 2023manuel010478No ratings yet

- Safe Work Method Statement (York Street EC) 2023.06.23Document8 pagesSafe Work Method Statement (York Street EC) 2023.06.23manuel010478No ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- GTA - MGDP - JSA - Inland TransportDocument5 pagesGTA - MGDP - JSA - Inland TransportKidung pamungkas Pamungkas100% (1)

- Hirac of GutDocument34 pagesHirac of GutRandy Adisyah100% (1)

- Risk Assessment For 44 VilasDocument13 pagesRisk Assessment For 44 Vilasfarhanhussain852No ratings yet

- Front Page RAMS-Loading, Unloading and Shifting of MaterialDocument7 pagesFront Page RAMS-Loading, Unloading and Shifting of MaterialEm NiaxNo ratings yet

- Smp Risk Assessment - BlankDocument10 pagesSmp Risk Assessment - BlankAdele PheifferNo ratings yet

- RAMS - PR#7727, Dismanteling of Warehouse (Updated)Document20 pagesRAMS - PR#7727, Dismanteling of Warehouse (Updated)Muhammad niazNo ratings yet

- INDU - NOV2023 - 0043 - Anchoring Hooks FixingDocument3 pagesINDU - NOV2023 - 0043 - Anchoring Hooks FixingvaletgNo ratings yet

- Information Security BDCR Plan DRAFT Nov 2019Document11 pagesInformation Security BDCR Plan DRAFT Nov 2019Brian ThelwellNo ratings yet

- 23) R A For Installation of Kerbstone and Paving BlocksDocument6 pages23) R A For Installation of Kerbstone and Paving Blocksabubakrelsaid90No ratings yet

- Risk Assessment / Method Statement Form: (Please)Document5 pagesRisk Assessment / Method Statement Form: (Please)Sham AranNo ratings yet

- JSA Communication Tower Painting Foundation Repairs at WR - 501 WR - 617) - 6-20-21Document23 pagesJSA Communication Tower Painting Foundation Repairs at WR - 501 WR - 617) - 6-20-21Shaikh Abu bakarNo ratings yet

- ADAC - Asphalt Paving WorksDocument13 pagesADAC - Asphalt Paving Worksabubakrelsaid90No ratings yet

- Health, Safety & Environment Induction Record: Topics Covered in The InductionDocument1 pageHealth, Safety & Environment Induction Record: Topics Covered in The InductionEsauNo ratings yet

- TRA - Amine System Degreasing - October 14, 2018Document9 pagesTRA - Amine System Degreasing - October 14, 2018Ijaz HussainNo ratings yet

- Work Permit Approval_3Document9 pagesWork Permit Approval_3Dani Dwi AdityaNo ratings yet

- Screeding WorksDocument2 pagesScreeding WorksSaleem Basha100% (1)

- Baseline Risk Assessment FSDocument17 pagesBaseline Risk Assessment FSStephenNo ratings yet

- Adac Ra NightDocument3 pagesAdac Ra Nightabubakrelsaid90No ratings yet

- 017R Level 3 Risk Assessment 3Document1 page017R Level 3 Risk Assessment 3Jibbin JamesNo ratings yet

- JSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentDocument10 pagesJSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentAbdul Rasheed Mangrio50% (2)

- RA - Hard LandscapeDocument11 pagesRA - Hard Landscapeabubakrelsaid90No ratings yet

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- JSA-578 Underground Duct CleaningDocument9 pagesJSA-578 Underground Duct CleaningHabib ur rahmanNo ratings yet

- Weekly Report - 06 (14.12.2020)Document27 pagesWeekly Report - 06 (14.12.2020)Anisa FebrianaNo ratings yet

- Health, Safety & Environment Induction Record: Topics Covered in The InductionDocument1 pageHealth, Safety & Environment Induction Record: Topics Covered in The InductionElvisNo ratings yet

- Induction PDFDocument1 pageInduction PDFElvisNo ratings yet

- FMS BIA TemplateDocument16 pagesFMS BIA TemplatemurtijaletaNo ratings yet

- Construction Project Safe System of Work TemplateDocument16 pagesConstruction Project Safe System of Work Templater2mgt28ssvNo ratings yet

- Hsse Department: (Solar Alert SDN BHD)Document2 pagesHsse Department: (Solar Alert SDN BHD)syafiq firdausNo ratings yet

- JHA Example Installation of Underfloor Plumbing and DrainsDocument15 pagesJHA Example Installation of Underfloor Plumbing and DrainsShamel Jen FacundoNo ratings yet

- 334 - Manual Handling of GRP PipingDocument7 pages334 - Manual Handling of GRP Pipingcontrax8No ratings yet

- 20) Risk Assessment For Excavation WorksDocument13 pages20) Risk Assessment For Excavation Worksabubakrelsaid90No ratings yet

- PMS Risk AssessmentDocument5 pagesPMS Risk Assessmentmohandes06No ratings yet

- Risk Assessment For Site SurveyDocument9 pagesRisk Assessment For Site Surveyabubakrelsaid90No ratings yet

- 210 On and Off Loading of Vehicles and TrucksDocument15 pages210 On and Off Loading of Vehicles and TrucksgrantNo ratings yet

- 008 SWMS General Onsite Activities and RepairsDocument13 pages008 SWMS General Onsite Activities and Repairssiame festusNo ratings yet

- 42 (A) R A For Painting WorksDocument10 pages42 (A) R A For Painting Worksabubakrelsaid90No ratings yet

- Risk Assessment and Method Statement Coronavirus Pandemic Control MeasuresDocument8 pagesRisk Assessment and Method Statement Coronavirus Pandemic Control MeasuresSubin JoseNo ratings yet

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument6 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz Nouisri100% (1)

- 002-JSA RoW Opening and Marking FinalDocument6 pages002-JSA RoW Opening and Marking FinalMoaatazz NouisriNo ratings yet

- SOM 1.1 D Job - Hazard - Analysis - FormDocument3 pagesSOM 1.1 D Job - Hazard - Analysis - FormAmit BhadauriaNo ratings yet

- PTWDocument22 pagesPTWaliabdallah20232023No ratings yet

- Concrete Preparation GeneralDocument14 pagesConcrete Preparation GeneralTahar Berrachedi100% (1)

- Weekly Report - 05Document24 pagesWeekly Report - 05Anisa FebrianaNo ratings yet

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- OSH Plan FencingDocument20 pagesOSH Plan Fencingshamsul.widespectrumNo ratings yet

- 003 SWMS - ExcavationDocument11 pages003 SWMS - Excavationsasi kumar50% (2)

- Ra Fps-008-WeldingDocument11 pagesRa Fps-008-WeldinggrantNo ratings yet

- (SWMS - 04) Carpentry Work Temporary & PermanentDocument6 pages(SWMS - 04) Carpentry Work Temporary & PermanentPRATEEK SINGHNo ratings yet

- Business Impact Analysis ExampleDocument10 pagesBusiness Impact Analysis ExampleGülden KisaNo ratings yet

- HIRARC-MFG-36 Cleaning Raw Mill 2 Inlet Chute BlockageDocument2 pagesHIRARC-MFG-36 Cleaning Raw Mill 2 Inlet Chute Blockagekhairul japriNo ratings yet

- Introduction To Entrepreneurship: Bruce R. Barringer R. Duane IrelandDocument27 pagesIntroduction To Entrepreneurship: Bruce R. Barringer R. Duane IrelandAbu Bakar YousafNo ratings yet

- Melanie Tse - SR Project Final EssayDocument9 pagesMelanie Tse - SR Project Final Essayapi-551673459No ratings yet

- Stock Screener, Technical Analysis ScannerDocument82 pagesStock Screener, Technical Analysis Scannerravi kumarNo ratings yet

- Acumen West Africa One PagerDocument2 pagesAcumen West Africa One PagertobointNo ratings yet

- Ch. 2 The Enduring VisionDocument29 pagesCh. 2 The Enduring VisionDiar16No ratings yet

- VPN Owners Unveiled 97 VPN Products Run by Just 23 Companies InfographicDocument1 pageVPN Owners Unveiled 97 VPN Products Run by Just 23 Companies InfographicPeter PanNo ratings yet

- Leptos Estates Indicative Price Lists May GreeceDocument12 pagesLeptos Estates Indicative Price Lists May GreeceMansiNo ratings yet

- How To Grow Your Business Using BaZi PDFDocument18 pagesHow To Grow Your Business Using BaZi PDFanudora100% (1)

- Arts 10 4th QuarterDocument37 pagesArts 10 4th QuarterSamantha DelaraNo ratings yet

- Vegan News - Issue 1 (1944)Document4 pagesVegan News - Issue 1 (1944)Vegan FutureNo ratings yet

- ShowfileDocument179 pagesShowfileSukumar NayakNo ratings yet

- Pound-Jefferson and or MussoliniDocument125 pagesPound-Jefferson and or MussoliniTrad AnonNo ratings yet

- Lesson B Unit 4Document2 pagesLesson B Unit 4Beatriz ReyesNo ratings yet

- Laboratory Exercise No. 18 Urinary System I. Assessment Answer Each Item Guided by The Specific Instructions For Each Question Set. A. True/FalseDocument2 pagesLaboratory Exercise No. 18 Urinary System I. Assessment Answer Each Item Guided by The Specific Instructions For Each Question Set. A. True/FalseGalerose MalvarNo ratings yet

- Spruance Course 2016 SyllabusDocument316 pagesSpruance Course 2016 SyllabusKalyan Kumar SarkarNo ratings yet

- Hindu Marriage ActDocument13 pagesHindu Marriage ActAshok GautamNo ratings yet

- Yemen Pandemic Preparedness Plan doc-MK - Doc - 1Document27 pagesYemen Pandemic Preparedness Plan doc-MK - Doc - 1Mohammed Ahmed NasherNo ratings yet

- Quran and PhysicsDocument2 pagesQuran and PhysicsShahzad Shameem50% (2)

- Intellectual Property NotesDocument6 pagesIntellectual Property NotesJane ManantanNo ratings yet

- Enrico de Leus Froilan San JuanDocument16 pagesEnrico de Leus Froilan San JuanBryan Cesar V. AsiaticoNo ratings yet

- DevelopingamarketingplanDocument25 pagesDevelopingamarketingplanSitta RosdaniahNo ratings yet

- Answer - Tutorial - Record Business TransactionDocument10 pagesAnswer - Tutorial - Record Business TransactiondenixngNo ratings yet

- Vis The Ruffianly Bitch and A Pair of Grim Shaggy Sheep-Dogs, Who SharedDocument10 pagesVis The Ruffianly Bitch and A Pair of Grim Shaggy Sheep-Dogs, Who SharedChris BartlettNo ratings yet

- John Read Middle School - Class of 2011Document1 pageJohn Read Middle School - Class of 2011Hersam AcornNo ratings yet

- PH Map-Regions-Province-FestivesDocument10 pagesPH Map-Regions-Province-FestivesishavlncrnaNo ratings yet

- CCJ Issue 54 PDFDocument100 pagesCCJ Issue 54 PDFMariano Salomon PaniaguaNo ratings yet