Professional Documents

Culture Documents

Field Fab Lug W Chkplates

Field Fab Lug W Chkplates

Uploaded by

Logistica VGOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Fab Lug W Chkplates

Field Fab Lug W Chkplates

Uploaded by

Logistica VGCopyright:

Available Formats

1-----

I

- - - - -I - - - - - -

8

I

- - - - -... - - - - - -

I

- - - - -I - - - - - -

7

I

----l II 5 4 3 2 1

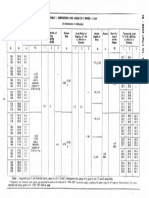

ALLOWABLE SHACKLE LUG LUG DIAMffiR DIA. LUG WELD SHELL PAD PAD PAD

LUG SIZE THICKNESS ECCENTRICITY LUG SHACKLE RADIUS SIZE THICKNESS THICKNESS DIA. WELD

LOAD HOLE PIN (~IN.) (MIN.)

D F T E D R w s t d w

Te Kips Ton in. in. in. in. in. in. in. in. in. in.

F D

_. ~ F

1 2.2 2 .38 1.25 .75 .63 1.25 3/16 .25 0 0 0

T I 2 4.4 3 1/4 .50 1.50 .88 .75 1.75 3/16 .25 0 0 0

R

?fr;

w LUG I 4 8.8 4 3/4 .75 1.50 1.00 .88 2.00 5/16 .38 0 0 0

- ~ 6 13.2 8 1/2 1.0 2.00 1.25 1.13 2.75 3/8 .38 0 0 0

8 17.6 9 1/2 .75 2.50 1.38 1.25 3.25 7/16 .50 .25 3.5 3/16

""" 10 22.0 12 1.00 2.50 1.50 1.38 3.50 7/16 .50 .25 3.5 3/16

I F 15 33.0 17 1.00 3.25 1.75 1.63 4.50 1/2 .50 .38 4.5 3/16

-

~()

20 44.0 25 1.25 3.25 2.13 2.00 5.50 1/2 .50 .50 4.5 3/16

~

25 55.0 35 1.50 4.00 2.38 2.25 6.25 .63 .50 6.0 3/16

,.. LIJ

30 66.0 35 1.50 4.25 2.38 2.25 6.25

5/8

3/4 .75 .50 6.5 3/16

35 77.0 55 1.63 4.25 2.88 2.75 6.50 3/4 .75 .50 6.5 3/16

~ ~ ~ ~

c 40 88.0 55 1.63 4.50 2.88 2.75 7.25 3/4 .75 .75 7.0 3/16

:Z

(/)

:iE 45 99.0 55 1.75 4.75 2.88 2.75 8.00 3/4 .75 .75 7.5 3/16

50 110.0 85 2.00 4.75 3.38 3.25 8.25 7/8 .88 .75 7.5 3/16

&

2R

GUSSET

• F ...

- MAx.

5' T

GUSSET

I

I. F

NOTES:

R 1. LUG DESIGN CONFOR~S TO AS~E B30.20 &: AISC 9th EDITION.

-t

PAD

- - -

r; 2.

3.

4.

LUG ~ATERIAL IS 32 KSI MINIMUM, WELDING ROD IS E-70.

LUG DESIGN IS BASED ON ZERO SIDE LOAD AS SHOWN.

5 DEGREES OF SIDE LOAD IS ALLOWED IF A GUSSET IS WELDED TO THE END OF THE

~-:_)

d LUG OPPOSITE THE FORCE F AND TO THE SHELL. THE GUSSET MUST BE 2R LONG

B Wr-.. AND CENTERED ON THE LUG, MUST BE E+R HIGH, T THICK, AND WELDED ALL

wv ~

LIJ

<

~ > ~ ~

5.

AROUND WITH WELD W. SEE DETAILS AT LEFT.

~INIMUM SHELL OR PLATE THICKNESS •s• IS SHOWN TO INSURE THAT A THICK ENOUGH

PLATE WILL BE USED FOR THE WELD SIZE SHOWN. THE SHELL HAS NOT BEEN ANALYlED FOR

(/)

:Z OVERSTRESSING DUE TO LUG FORCES. THE USER IS RESPONSIBLE FOR HAVING A RIGGING

:iE

ENGINEER ANALYlE THE SHELL STRESSES.

6. EACH LUG AND CORRESPONDING WELD HAS BEEN DESIGNED USING A FORCE •r- THAT IS CONSTANT

IN VALUE FOR A~ ANGLE IN THE 90 DEGREE RANGE FROM HORIZONTAL TO THE VERTICAL AS SHOWN,

- i.e. •F• HAS THE SAME MAXI~UM VALUE AT 45 DEGREES AS IT DOES IN THE HORIZONTAL OR VERTICAL

7. A PARTICULAR CO~BINATION OF LUG AND PADS CAN BE REPLACED WITH A SINGLE LUG AS LONG AS IT

IS EQUAL IN TOTAL WIDTH TO THE LUG AND PADS.

B. 1Kip = 1000 lbs.&

" - lllllt:

-- -w - -

..,!!'!.

;;

lllllt:

-- --

..,!!'!. .... 110.

-- fJ - --

-~

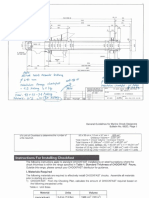

11.- DETAILS OF LUGS

1 fWt EXPANDED TABLE AND NOTES

2 1ft REVISED TABLE AND ADDED NOTE 8

____,.........____

FLUOR DANIEL

,---.--.,..-·--·--- ..........

-.-..... 1HI-- -- --

-~

II.PIWI

FOR FIELD FABRICATION

....____ __......... -·- --

.... _ . _ _ _ .,.llti.L ______

-.--..---~~~-

...._ .._.

--. u.r• ..-: ~· _,.. ~

--

L__________________________________________

12

j CAD 9CALE F - . SF A ~lE: f'LDI1W"E I - - CIWIGES - - YES c MDC CAD FU: ll'llol<l!D - YES C MDC IIIIDEl. ll'llol<l!D - YES C

NONE

MDC

I --- ~ --

ST-A3-9466

CAD FU: IWIE: 1HlflD

You might also like

- Manual Alstom S2DADocument50 pagesManual Alstom S2DABagla100% (2)

- Franki Piling SystemDocument3 pagesFranki Piling SystemAhmad Amanu SuryaNo ratings yet

- CHAPTER 1 Substructure PDFDocument139 pagesCHAPTER 1 Substructure PDFsayqa100% (6)

- Building Materials Construction Rangwala PDFDocument4 pagesBuilding Materials Construction Rangwala PDFDhanushya Myneni50% (6)

- Is 8422-4 - 1977 - 2Document1 pageIs 8422-4 - 1977 - 2Svapnesh ParikhNo ratings yet

- Potyethytene: ' TsffiffiDocument4 pagesPotyethytene: ' TsffiffiAlexander VedyNo ratings yet

- ?mc:e. lEE: I I K.ekDocument1 page?mc:e. lEE: I I K.ekFrancisco FariasNo ratings yet

- Brosur Hdpe Stempel - 220512 - 124732Document4 pagesBrosur Hdpe Stempel - 220512 - 124732Gary IrawanNo ratings yet

- Brosur Hdpe StempelDocument4 pagesBrosur Hdpe Stempelburhanuddin shNo ratings yet

- Is 8422-5 - 1977 - 4Document1 pageIs 8422-5 - 1977 - 4Svapnesh ParikhNo ratings yet

- Seein RedDocument5 pagesSeein RedFrédéric TotaNo ratings yet

- Properties and Strength Data of Tubulars and Casing PipesDocument1 pageProperties and Strength Data of Tubulars and Casing PipesPartha Sarathi ChatterjeeNo ratings yet

- T-20 AlfaLavalDocument1 pageT-20 AlfaLavalAdilson Paulo de Miranda juniorNo ratings yet

- Nindqi Ggs Tqi. Islznianagemen''L' Xmax'T: Ongc Distribution List 1 Rev Date:5/1/06Document1 pageNindqi Ggs Tqi. Islznianagemen''L' Xmax'T: Ongc Distribution List 1 Rev Date:5/1/06satya_dohareNo ratings yet

- Chockfast Stern TubeDocument2 pagesChockfast Stern Tubeakhmad harisNo ratings yet

- Img 0010Document1 pageImg 0010Krishna PrasadNo ratings yet

- Is 8422-2 - 1977 - 2Document1 pageIs 8422-2 - 1977 - 2Svapnesh ParikhNo ratings yet

- NEW AIRPORT SSA Final - Recover (3) - Layout1Document1 pageNEW AIRPORT SSA Final - Recover (3) - Layout1Nicole LayganNo ratings yet

- Vibrac o es+-+Melodia+-+Partitura+e+TablaturaDocument2 pagesVibrac o es+-+Melodia+-+Partitura+e+TablaturaGustavo Zysman NascimentoNo ratings yet

- Datsun 180b Model 610 Series Service ManualDocument20 pagesDatsun 180b Model 610 Series Service ManualMaria100% (60)

- Ifr2 - 030413-Matyc Automation SacDocument3 pagesIfr2 - 030413-Matyc Automation SacJoel PalaciosNo ratings yet

- TERMINAL LUG - Comply With IEC61238-1: Copper Cables OnlyDocument4 pagesTERMINAL LUG - Comply With IEC61238-1: Copper Cables OnlyJustice KNo ratings yet

- Screenshot 2023-10-22 at 2.51.52 PMDocument16 pagesScreenshot 2023-10-22 at 2.51.52 PMxkm8zj2mh6No ratings yet

- 2 Storey PropertyDocument1 page2 Storey PropertyKarl Anne DomingoNo ratings yet

- Westinghouse Manuals PDFDocument38 pagesWestinghouse Manuals PDFCarl HensonNo ratings yet

- Ilovepdf MergedDocument3 pagesIlovepdf MergedbhitauracscNo ratings yet

- Katalog Intilon Swallow NewDocument16 pagesKatalog Intilon Swallow NewwahanasuryagNo ratings yet

- Hi-Cap Wedge Stock QD SheavesDocument18 pagesHi-Cap Wedge Stock QD SheavesAlex LopezNo ratings yet

- A New Years Waltz Auld Lang SyneDocument2 pagesA New Years Waltz Auld Lang SynemattiaNo ratings yet

- Foundation Plan 2Nd Floor Framing Plan: C1/F1 C1/F1 C1/F1 C1/F1 C1 C1 C1 C1Document1 pageFoundation Plan 2Nd Floor Framing Plan: C1/F1 C1/F1 C1/F1 C1/F1 C1 C1 C1 C1Bess Adrane JurolanNo ratings yet

- Random Wave AnalysisDocument6 pagesRandom Wave Analysisnehan245No ratings yet

- 3 Email - 20231127 - 0001Document2 pages3 Email - 20231127 - 0001zephradebe1No ratings yet

- Kaneko Sangyo Co, LTD PDFDocument16 pagesKaneko Sangyo Co, LTD PDFNguyễn NgọcNo ratings yet

- Specificatie Tehnica Topaz-32d.semnatDocument14 pagesSpecificatie Tehnica Topaz-32d.semnatRudy Osvaldo Garcia CharacayoNo ratings yet

- 280T Crawler CraneDocument3 pages280T Crawler CraneRiyan EsapermanaNo ratings yet

- aPP fORMDocument1 pageaPP fORMMark Roger Huberit IINo ratings yet

- Datsun 180B Model 610 Series Service ManualDocument497 pagesDatsun 180B Model 610 Series Service ManualGanden IsRoniNo ratings yet

- All My LifeDocument5 pagesAll My Lifegalaxy guardiansNo ratings yet

- FX50SMJ 2Document4 pagesFX50SMJ 2luckyz80No ratings yet

- Another Brick in The Wall PDFDocument8 pagesAnother Brick in The Wall PDFFelipe Quinones100% (1)

- GAD For Strainer - StampedDocument2 pagesGAD For Strainer - StampedAnıl ÖztürkNo ratings yet

- 1st g+10Document1 page1st g+10leo.citygasNo ratings yet

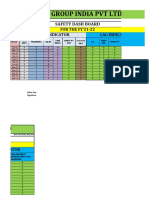

- 2.2 e Lead Lag Indicator With Graph (Fy 2021-22)Document3 pages2.2 e Lead Lag Indicator With Graph (Fy 2021-22)subodh kumarNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionDocument1 pageIS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionSvapneshNo ratings yet

- Madarski L'.:Ardas: MottoDocument2 pagesMadarski L'.:Ardas: MottoŽeljko ČeganjacNo ratings yet

- Isometric Sewerline Layout GroundDocument1 pageIsometric Sewerline Layout GroundRed RedNo ratings yet

- L) R - ..Illilï'"::. - TR - :Ïï::TDocument1 pageL) R - ..Illilï'"::. - TR - :Ïï::TAlexandre SoldaNo ratings yet

- Touch Screen SpecificationDocument1 pageTouch Screen SpecificationDJ_CROWNNo ratings yet

- 087 - Raihan Azmi - RENCANAGARISDocument1 page087 - Raihan Azmi - RENCANAGARISRaihan AzmiNo ratings yet

- Rev. Change Details by DateDocument1 pageRev. Change Details by DateInkanata SacNo ratings yet

- Saq NewtonDocument4 pagesSaq NewtonUmam AdzharNo ratings yet

- J / / / 50 I, I I,,# I, 1 I Iiiiii, I Illill I / I LLLLLDocument20 pagesJ / / / 50 I, I I,,# I, 1 I Iiiiii, I Illill I / I LLLLLbaskaranjay5502No ratings yet

- Adobe Scan 09 Jun 2021Document3 pagesAdobe Scan 09 Jun 2021digiprepareNo ratings yet

- Scan 16 Nov 2022Document1 pageScan 16 Nov 2022اورنگزیب ملکNo ratings yet

- CV Radescu, Nicolae Vol. 1 - 0099Document10 pagesCV Radescu, Nicolae Vol. 1 - 0099CPPNo ratings yet

- 1Document1 page1Serigne Abdoul Aziz MbodjNo ratings yet

- Minitask2 ScienceDocument1 pageMinitask2 ScienceMaynard SonidoNo ratings yet

- Mitsu D Relays For Phase-Fault Ro Tect I On Types KZS-L - 3 - A Appli Example SP Ettingr Con and Oper Characteri Setting in Teata Mainte Ord Inf ApDocument20 pagesMitsu D Relays For Phase-Fault Ro Tect I On Types KZS-L - 3 - A Appli Example SP Ettingr Con and Oper Characteri Setting in Teata Mainte Ord Inf Apfarzad dalaviNo ratings yet

- Isolator Installation SequencesDocument11 pagesIsolator Installation Sequencesoscargon19No ratings yet

- Monday Blues #1: E7 A7 A7/E B7 B7 ( 5)Document2 pagesMonday Blues #1: E7 A7 A7/E B7 B7 ( 5)程于晏No ratings yet

- Growing Up in the Valley: Pioneer Childhood in the Lower Fraser ValleyFrom EverandGrowing Up in the Valley: Pioneer Childhood in the Lower Fraser ValleyNo ratings yet

- 003 Arch3Document1 page003 Arch3kingjam dimacaling2019No ratings yet

- Specification For Precast Concrete WorksDocument39 pagesSpecification For Precast Concrete Worksm.nurhishamm100% (2)

- Tabla de Ampacidades 310.16 NEC (NFPA 70) - Como Utilizar La Tabla de AmpacidadesDocument3 pagesTabla de Ampacidades 310.16 NEC (NFPA 70) - Como Utilizar La Tabla de AmpacidadesMaxNo ratings yet

- Sample General Structural NotesDocument14 pagesSample General Structural NotesNicole FrancisNo ratings yet

- 92 - Summary of Items Discussed in 4 - 2021 ADF On 13.8.2021Document20 pages92 - Summary of Items Discussed in 4 - 2021 ADF On 13.8.2021trickyggNo ratings yet

- Civil Technical SpecificationDocument137 pagesCivil Technical SpecificationSamiul IslamNo ratings yet

- Philip Johnson KanuDocument10 pagesPhilip Johnson KanuPriya VermaNo ratings yet

- Hartzell Propeller IncDocument24 pagesHartzell Propeller IncJacksonNo ratings yet

- 23 PWDDocument110 pages23 PWDAfeef Ibn Albra100% (1)

- Fghijk LFMK Ino Pfjfo QRQMGMK in Sqo Itjfo Qno Ufo VK Fo Pgtuk MfoDocument14 pagesFghijk LFMK Ino Pfjfo QRQMGMK in Sqo Itjfo Qno Ufo VK Fo Pgtuk MfoOscar Manuel Ruiz CastroNo ratings yet

- Soil Stabilization Using With Waste Crumb Rubber TireDocument4 pagesSoil Stabilization Using With Waste Crumb Rubber Tirelinda ritongaaNo ratings yet

- Price List Updated TGL 08 Feb 21 SupermaketDocument11 pagesPrice List Updated TGL 08 Feb 21 SupermaketHeGun HokNo ratings yet

- Paraline Perspective Projections NoteDocument52 pagesParaline Perspective Projections NotePai Lang ZhenNo ratings yet

- GPT - 1-8 Link-Seal - 08.2021 - WebDocument22 pagesGPT - 1-8 Link-Seal - 08.2021 - WebRAJKUMARNo ratings yet

- Steel Fiber Reinforced Concrete Ground Slabs: CriterioDocument12 pagesSteel Fiber Reinforced Concrete Ground Slabs: CriterioAmanuel TekalignNo ratings yet

- Cold Mix Technology - BitChemDocument49 pagesCold Mix Technology - BitChemAnirudh SarkarNo ratings yet

- Glasgow University Library ReferenceDocument9 pagesGlasgow University Library ReferenceSubhishasri A K VNo ratings yet

- Basic Question For Intern Students - 2Document2 pagesBasic Question For Intern Students - 2Thomas MehariNo ratings yet

- Seminar Report On Highway Management SystemDocument22 pagesSeminar Report On Highway Management SystemAditya ansuman RoutNo ratings yet

- 17 Structures - MORTH QueriesDocument3 pages17 Structures - MORTH QueriesAmit PhadatareNo ratings yet

- Application Product Code ' ': Steel, Aluminium and Timber Substructure Tda-S TDB-S TDC-S Steel Substructure TDBL-TDocument9 pagesApplication Product Code ' ': Steel, Aluminium and Timber Substructure Tda-S TDB-S TDC-S Steel Substructure TDBL-Tshare4learnNo ratings yet

- Neoloy CS-Highway 6, Israel v2019.2 PDFDocument4 pagesNeoloy CS-Highway 6, Israel v2019.2 PDFsahilNo ratings yet

- Free Plan in Modern Villas Architecture PDFDocument73 pagesFree Plan in Modern Villas Architecture PDFengjell sinajNo ratings yet

- Sikagrout - 214 inDocument4 pagesSikagrout - 214 invk SNo ratings yet

- Leakage Test Procedure For Crude Oil Storage Tank: (Arial 12)Document6 pagesLeakage Test Procedure For Crude Oil Storage Tank: (Arial 12)Ahmad MohammadNo ratings yet

- Sheltar House EstimateDocument21 pagesSheltar House EstimateAnil sainiNo ratings yet

- BoQ Full FormDocument14 pagesBoQ Full Formiqbal hussain qureshiNo ratings yet