Professional Documents

Culture Documents

5s-Housekeeping NCII

5s-Housekeeping NCII

Uploaded by

Scarlette Beauty EnriquezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5s-Housekeeping NCII

5s-Housekeeping NCII

Uploaded by

Scarlette Beauty EnriquezCopyright:

Available Formats

Definition

The 5S method, which takes its name from the first letter of each of the five

operations, is a Japanese management technique derived from the Toyota

Production System (TPS). It is based on 5 simple principles:

1. Seiri : sort means eliminating anything that is unnecessary for the equipment to

work properly.

2. Seiton : straightening is the best way of eliminating pointless searching and

having all the material necessary for functional production according to the principle:

“a place for everything and everything in its place.”

3. Seiso : shining means keeping everything so clean that it shines.

In a clean environment, any leak or other abnormality can be detected faster.

Working in a clean environment improves motivation and safety. This is a

prerequisite for quality maintenance.

4. Seiketsu : standardizing means respecting the previous 3S.

The 3S are actions to take; so that cleanliness and elimination of the causes of

untidiness become the norm, it is essential to write them down as ordinary rules, as

standards.

Seiketsu helps to overcome the natural tendency to slovenliness and a return to old

habits.

5. Shitsuke : sustain after a period of 3 to 6 months (depending on the size and

complexity of the workshop), the time has come to evaluate the situation by means

of an in-depth audit. The audit is based on a very precise questionnaire, which

assesses the previous 4S, and which leads, if successful – to the site being certified.

You might also like

- 5S Good HousekeepingDocument27 pages5S Good HousekeepingWilbur Grageda100% (1)

- 5S in Apparel IndustryDocument9 pages5S in Apparel IndustryRamyaJudes100% (2)

- 5s and 3rsDocument30 pages5s and 3rsrazzberiNo ratings yet

- 5 S PrinciplesDocument2 pages5 S PrinciplesNirav RajyaguruNo ratings yet

- 5S MethodologyDocument2 pages5S MethodologyEmeth TeoNo ratings yet

- 5s PrincipleDocument9 pages5s PrincipleJoel OseraNo ratings yet

- Amity University: Five S (Operations and Quality Management)Document32 pagesAmity University: Five S (Operations and Quality Management)Surbhi BithelNo ratings yet

- LESSON 2-Occupational Health and SafetyDocument6 pagesLESSON 2-Occupational Health and Safetymelanielampera17No ratings yet

- What Is 5SDocument4 pagesWhat Is 5SemeralddeanmacapagalNo ratings yet

- 5s Procedures and ConceptsDocument19 pages5s Procedures and Conceptscameron williamNo ratings yet

- 5s, Kaizen, Kanban SystemDocument11 pages5s, Kaizen, Kanban SystemFirdaus AsryNo ratings yet

- 5S (Methodology)Document2 pages5S (Methodology)BG LimayeNo ratings yet

- 5 S PDFDocument6 pages5 S PDFMuhammad Hamza NaveedNo ratings yet

- What Is 5S 1585900253 PDFDocument6 pagesWhat Is 5S 1585900253 PDFbharatsinhchauhanNo ratings yet

- Republic of The Philippines1Document7 pagesRepublic of The Philippines1Clyde X2600No ratings yet

- 5s MethodologyDocument5 pages5s MethodologySer Crz JyNo ratings yet

- 5S DetailsDocument10 pages5S DetailsHemalakshmiNo ratings yet

- 5S Definition and BenefitsDocument16 pages5S Definition and Benefitsnatrix029No ratings yet

- 5s QCM NTDocument3 pages5s QCM NTnoyon debNo ratings yet

- 5S Workplace ManagementDocument9 pages5S Workplace Managementnsk79in@gmail.comNo ratings yet

- What Is 5S?: 5S Implementation in Welding WorkshopDocument1 pageWhat Is 5S?: 5S Implementation in Welding WorkshopNell Sabas AdolfoNo ratings yet

- 205 Quality Info Journal 15jan20Document9 pages205 Quality Info Journal 15jan20Rommel TayactacNo ratings yet

- Place. Can't This Be Implemented in The IT Industry To Organize The Computer System'sDocument3 pagesPlace. Can't This Be Implemented in The IT Industry To Organize The Computer System'sArgel Jermen A. JuanNo ratings yet

- Wepik Maximizing Efficiency An Introduction To The 5s Methodology 20230905003406zTbqDocument14 pagesWepik Maximizing Efficiency An Introduction To The 5s Methodology 20230905003406zTbqAry AlisboNo ratings yet

- 5S Practices: What Is The 5S System?Document2 pages5S Practices: What Is The 5S System?Mau Tau100% (1)

- Metodologia de Las 5SDocument8 pagesMetodologia de Las 5SANTONIO LEOBARDO CRUZ CRUZNo ratings yet

- 5S PicsDocument18 pages5S PicssweetfeverNo ratings yet

- Lesson 8Document10 pagesLesson 8Princess Czarina Delas AlasNo ratings yet

- Presented by A.Kalyana SundaramDocument26 pagesPresented by A.Kalyana SundaramsiccppNo ratings yet

- 5s, Sixsigma, TPM, PQM, Pert Etc.Document17 pages5s, Sixsigma, TPM, PQM, Pert Etc.manpreetsodhi08No ratings yet

- 5 SDocument1 page5 Sjustinroy1729No ratings yet

- 5 S ConceptsDocument24 pages5 S ConceptsFrancis MartinezNo ratings yet

- What Can 5S Do?Document2 pagesWhat Can 5S Do?md faisal minaNo ratings yet

- Follow 5 S'everyday To Be A Professional... : Japanese Words Which Are Seiri, Seiton, Seiso, Seiketsu and ShitsukeDocument1 pageFollow 5 S'everyday To Be A Professional... : Japanese Words Which Are Seiri, Seiton, Seiso, Seiketsu and Shitsukesujan_austNo ratings yet

- 5S (Methodology) : Navigation Search Japanese Transliterated EnglishDocument2 pages5S (Methodology) : Navigation Search Japanese Transliterated Englishkadam_pranavNo ratings yet

- 5S SystemDocument21 pages5S SystemArushNo ratings yet

- TLE IA CAG10 w8Document4 pagesTLE IA CAG10 w8ALLYSSA MAE PELONIANo ratings yet

- MethodDocument1 pageMethodkevin.0708coolNo ratings yet

- WM ALS Quarter 1 Module 5Document3 pagesWM ALS Quarter 1 Module 5RUTH MAE GULENGNo ratings yet

- Module IV (Ii)Document3 pagesModule IV (Ii)Siva BadrinathNo ratings yet

- A Work Place Organization Method: Deepak Singh Manager Quality AssuranceDocument21 pagesA Work Place Organization Method: Deepak Singh Manager Quality AssuranceDEEPAK SINGH SANGWAN100% (1)

- Hiroyuki Hirano: Amar RaveendranDocument19 pagesHiroyuki Hirano: Amar RaveendranyazhinNo ratings yet

- MTP PDFDocument7 pagesMTP PDFNarottamShandilyaNo ratings yet

- (Seiri) : Hiroyuki Hirano in His Book "5 Pillars of The Visual Workplace", All Starting With Letter S' Which MeansDocument7 pages(Seiri) : Hiroyuki Hirano in His Book "5 Pillars of The Visual Workplace", All Starting With Letter S' Which MeansNarottamShandilyaNo ratings yet

- MTP PDFDocument7 pagesMTP PDFNarottamShandilyaNo ratings yet

- 5S Methodology: 5S Is A FrameworkDocument2 pages5S Methodology: 5S Is A Frameworkshan ahmedNo ratings yet

- 5s ReportDocument15 pages5s ReportAkash KarbotkarNo ratings yet

- Phases of 5SDocument2 pagesPhases of 5SNaveeneutronNo ratings yet

- 5STTLMDocument14 pages5STTLMTesfayeNo ratings yet

- Week 8 CARPENTRYDocument19 pagesWeek 8 CARPENTRYFerdinand R. AlbertoNo ratings yet

- 5S Procedures and Concepts Learning Objective: After Reading This Information Sheet, The Student/ TraineeDocument4 pages5S Procedures and Concepts Learning Objective: After Reading This Information Sheet, The Student/ TraineeAlpha June CedulloNo ratings yet

- ISE 420 (Quality Improvement Methods) : by Group 6Document39 pagesISE 420 (Quality Improvement Methods) : by Group 6Abdullaziz AbdullahNo ratings yet

- Megaworld Global Estate Inc. 18 Jan 2013Document48 pagesMegaworld Global Estate Inc. 18 Jan 2013vishvendan100% (1)

- 5S Model in TQMDocument2 pages5S Model in TQMAsad AshfaqNo ratings yet

- 5'S of Philosophy: Sort (seiri 整理)Document4 pages5'S of Philosophy: Sort (seiri 整理)DonNo ratings yet

- 5s Lean ToolDocument11 pages5s Lean ToolRitu RajNo ratings yet

- Super 5SDocument31 pagesSuper 5SBong CordezNo ratings yet

- KAIZENDocument8 pagesKAIZENurbsafeNo ratings yet

- Implementation of 5S in Scientific Equipment Company: Shaman Gupta, Pankaj ChandnaDocument5 pagesImplementation of 5S in Scientific Equipment Company: Shaman Gupta, Pankaj ChandnarpbiradarNo ratings yet

- SHS Sardo FormDocument1 pageSHS Sardo FormScarlette Beauty EnriquezNo ratings yet

- Script HSKDocument2 pagesScript HSKScarlette Beauty EnriquezNo ratings yet

- SkirtDocument6 pagesSkirtScarlette Beauty EnriquezNo ratings yet

- Las Immersion 1 2Document13 pagesLas Immersion 1 2Scarlette Beauty EnriquezNo ratings yet

- EvalDocument14 pagesEvalScarlette Beauty EnriquezNo ratings yet

- Learning Engagement Plan Developed By: Qualification: Title of LEP: Unit of CompetenceDocument3 pagesLearning Engagement Plan Developed By: Qualification: Title of LEP: Unit of CompetenceScarlette Beauty EnriquezNo ratings yet

- First Day High QuestionsDocument7 pagesFirst Day High QuestionsScarlette Beauty EnriquezNo ratings yet

- Project Plan 2023 Food TechDocument2 pagesProject Plan 2023 Food TechScarlette Beauty EnriquezNo ratings yet

- Common Logical FallaciesDocument4 pagesCommon Logical FallaciesScarlette Beauty EnriquezNo ratings yet

- Guess The LogoDocument11 pagesGuess The LogoScarlette Beauty EnriquezNo ratings yet

- Lesson 2Document4 pagesLesson 2Scarlette Beauty EnriquezNo ratings yet

- PFS Traditional and Playful QuestionsDocument1 pagePFS Traditional and Playful QuestionsScarlette Beauty EnriquezNo ratings yet

- Philo Week 1 NotesDocument4 pagesPhilo Week 1 NotesScarlette Beauty EnriquezNo ratings yet

- Lesson Plan FormatDocument2 pagesLesson Plan FormatScarlette Beauty EnriquezNo ratings yet

- Holistic PartialThinking Activity 2023Document2 pagesHolistic PartialThinking Activity 2023Scarlette Beauty EnriquezNo ratings yet

- Philo 1st WWDocument3 pagesPhilo 1st WWScarlette Beauty EnriquezNo ratings yet

- Introduction To Philosphy Week1 Module1Document19 pagesIntroduction To Philosphy Week1 Module1Scarlette Beauty EnriquezNo ratings yet

- Intro To Philo q1 Module 2 Methods of Philosophizing 1Document22 pagesIntro To Philo q1 Module 2 Methods of Philosophizing 1Scarlette Beauty EnriquezNo ratings yet

- Lesson Plan FormatDocument1 pageLesson Plan FormatScarlette Beauty EnriquezNo ratings yet

- Activity Sheets For PhiloDocument23 pagesActivity Sheets For PhiloScarlette Beauty EnriquezNo ratings yet

- Philo Week 12 NotesDocument4 pagesPhilo Week 12 NotesScarlette Beauty EnriquezNo ratings yet

- Intro-to-Philosophy - Q1 - WEEK1-1 For TeacherDocument20 pagesIntro-to-Philosophy - Q1 - WEEK1-1 For TeacherScarlette Beauty EnriquezNo ratings yet

- LM Cookery G10Document402 pagesLM Cookery G10Riza Gaquit82% (269)

- Business Model Canvas (BMC) TemplateDocument1 pageBusiness Model Canvas (BMC) TemplateScarlette Beauty EnriquezNo ratings yet

- BE Form 6 DAILY ACCOMPLISHMENT REPORT 2023Document1 pageBE Form 6 DAILY ACCOMPLISHMENT REPORT 2023Scarlette Beauty EnriquezNo ratings yet

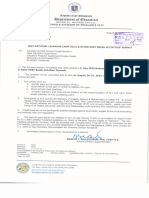

- DM No. 329 S. 2023 2023 Nationa Learning Camp NLC Other Eosy Break Activities SummitDocument1 pageDM No. 329 S. 2023 2023 Nationa Learning Camp NLC Other Eosy Break Activities SummitScarlette Beauty Enriquez100% (1)

- Demo DM SHS FastenersDocument4 pagesDemo DM SHS FastenersScarlette Beauty EnriquezNo ratings yet

- Work Immersion Matrix-HousekeepingDocument2 pagesWork Immersion Matrix-HousekeepingScarlette Beauty EnriquezNo ratings yet

- Personal Reflection NotesDocument17 pagesPersonal Reflection NotesScarlette Beauty EnriquezNo ratings yet

- Anecdotal Record 2Document1 pageAnecdotal Record 2Scarlette Beauty EnriquezNo ratings yet