Professional Documents

Culture Documents

General Brochure Print Version

General Brochure Print Version

Uploaded by

KasprutzConneryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Brochure Print Version

General Brochure Print Version

Uploaded by

KasprutzConneryCopyright:

Available Formats

SI MULATION ENVIRONMENT

Flownex® SE determines pressure drop [flow] and heat

transfer [temperature] for the connected components of a

complete system in steady state and transient, e.g. pumps

or compressors, pipes, valves, tanks and heat exchangers.

System level

thermal-fluid flow

Simulation Software

TYPICAL USES

ANALYSIS DESIGN TRAINING

Simulation. System sizing. System behavior examination.

Performance assessment. Component sizing. Performing basic flow and

Modification assessment. Determining operating ranges. heat transfer calculations.

Fault root cause assessment. Flow, temperature, pressure, Thermohydraulic principles

power consumption, etc. and properties referencing.

Testing of control philosophy.

A FEW

FLOWNEX®

LICENSE

HOLDERS

BRINGING NUCLEAR Flownex® is developed in an

QUALITY and STANDARDS ISO 9001:2008 quality assurance system

TO SYSTEM SIMULATION and NQA1 supplier approved environment.

INDUSTRIES

WATER POWER GENERATION RESEARCH & MILITARY, SHIPPING

RETICULATION SYSTEMS DEVELOPMENT & AEROSPACE

Water distribution, Pumping Renewable energy systems, Innovative engineering, Proof Hydraulic, pneumatic, fuel

stations, Treatment plants, Fossil fuel systems, Nuclear of concept, Layout and inte- and environmental control

Network maintenance. systems, Simulators. gration, Control philosophy systems.

design.

OIL & GAS SYSTEMS MINING SYSTEMS HVAC-R SYSTEMS PROCESS SYSTEMS

Exploration, Production, Re- Chilled water reticulation, Refrigeration, Heating systems, Process design, Process control,

fining, Transportation. Ventilation, Compressed air, Ventilation systems, Process operations.

Slurry distribution. Air-conditioning.

ADVANTAGES

1. Simulates simple sub-systems to com-

plete systems, anything from ventilation

and reticulation networks, detail internal

3. Rapidly runs 1000 s of simulations ‒

allowing for multiple scenario tests,

operating modes and eliminates uncertainty

5. Integrated simulations with Excel,

Fluent, Ansys Mechanical, Ansys

Icepack, Matlab, Simulink, Labview,

turbomachinery flows up to boilers and around environmental conditions and MathCad and an OPC link for commercial

complete power generation cycles like manufacturing tolerances. hardware control systems. Easily integrate

Rankine and Brayton cycles. existing proprietary correlations, soft-

ware and data.

2. Simulates integrated flow, heat transfer,

mechanical and control systems gives

you a complete system response. This

4. Users require only typical engineering

design parameters to use the empirical

and semi-empirical models in Flownex®,

6. Fast configuration with all inclusive

fluid thermal systems and plant

components.

includes liquid, gas, two-phase, mixtures, allowing for crucial design decisions in

heat transfer, mechanical and control complex simulations to be made easily

systems. Ensures robust controllable systems. without a fluid systems specialist.

Flownex gave new meaning to complex

systems fluid flow analyses in our company.

Chris Coetzee // MBA, PrEng // Managing Director // Resonant

www.flownex.com +27 18 297 0326/7 enquire@flownex.com

You might also like

- Multiple Choice Chemical Technician ReviewerDocument23 pagesMultiple Choice Chemical Technician ReviewerKuo Sarong100% (20)

- Introduction To Internal Erosion in Dams and Their Foundations 12 20 21Document78 pagesIntroduction To Internal Erosion in Dams and Their Foundations 12 20 21Renathielly Fernanda da SilvaNo ratings yet

- Mocom Basic PlusDocument148 pagesMocom Basic PlusIvan50% (2)

- Chemistry Matters Ch11 Textbk ANSDocument3 pagesChemistry Matters Ch11 Textbk ANSZeneon82% (17)

- GE Osmonics SWRO 200C O&M Manual LDocument38 pagesGE Osmonics SWRO 200C O&M Manual LIsaac Deusdedit Salazar Ehuan100% (1)

- (A. C. Bajpai, Irene M. Calus, J. A. FairleyDocument316 pages(A. C. Bajpai, Irene M. Calus, J. A. FairleyGull GillNo ratings yet

- System Level Thermal-Fluid Flow: Typical UsesDocument2 pagesSystem Level Thermal-Fluid Flow: Typical UsesSanthosh LingappaNo ratings yet

- Flownex SE Brochure (Digital)Document12 pagesFlownex SE Brochure (Digital)KasprutzConneryNo ratings yet

- Flown Ex Simulation EnvironmentDocument12 pagesFlown Ex Simulation EnvironmentSanthosh LingappaNo ratings yet

- Annals of Nuclear Energy: Technical NoteDocument8 pagesAnnals of Nuclear Energy: Technical NoteyeenNo ratings yet

- Afram Et Al. - 2017 - Artificial Neural Network (ANN) Based Model Predictive Control (MPC) and Optimization of HVAC Systems A State of TDocument18 pagesAfram Et Al. - 2017 - Artificial Neural Network (ANN) Based Model Predictive Control (MPC) and Optimization of HVAC Systems A State of TNimai KowlessurNo ratings yet

- HVAC Brochure - 2016 PDFDocument2 pagesHVAC Brochure - 2016 PDFsanthoshnlNo ratings yet

- 1 s2.0 S1359431114011223 MainDocument8 pages1 s2.0 S1359431114011223 MainHana NisrinaNo ratings yet

- Turbine-Brochure 2020 PrintDocument4 pagesTurbine-Brochure 2020 PrintsrashmiiiscNo ratings yet

- Aerospace: Typical UsesDocument2 pagesAerospace: Typical UsessrashmiiiscNo ratings yet

- Flownex ProfileDocument4 pagesFlownex Profilecrazy_nm_addNo ratings yet

- Flownex Profile PDFDocument4 pagesFlownex Profile PDFSrashmiNo ratings yet

- Design of Automatic Control System For Cooling Unit Using Fuzzy Logic ControllerDocument21 pagesDesign of Automatic Control System For Cooling Unit Using Fuzzy Logic Controllerمحمد القاضيNo ratings yet

- Typical Uses:: Design Analysis TrainingDocument4 pagesTypical Uses:: Design Analysis TrainingSrashmiNo ratings yet

- Ipc 9521Document4 pagesIpc 9521ashu0470No ratings yet

- Typical Uses:: Design Analysis TrainingDocument2 pagesTypical Uses:: Design Analysis TrainingSrashmiNo ratings yet

- Flownex - Nuclear Power BrochureDocument2 pagesFlownex - Nuclear Power BrochureKasprutzConneryNo ratings yet

- AFT XStream Data SheetDocument2 pagesAFT XStream Data SheetdelitesoftNo ratings yet

- AFT ImpulseDocument2 pagesAFT Impulseersin83aydinNo ratings yet

- Vol4 No1 3Document13 pagesVol4 No1 3Fernando GarnicaNo ratings yet

- Cont Ent S Mai N Menu Sear CH Hel PDocument8 pagesCont Ent S Mai N Menu Sear CH Hel PAli AliNo ratings yet

- Teoria de GovernadoresDocument8 pagesTeoria de GovernadoresLuis Humberto Ruiz BetanzosNo ratings yet

- Flow Simulator: Fluid System SolutionDocument2 pagesFlow Simulator: Fluid System SolutionRicardo NuñezNo ratings yet

- 4.3 Control Center Upgrading: B. J. GeddesDocument15 pages4.3 Control Center Upgrading: B. J. GeddesAngel RamosNo ratings yet

- Datasheet AVEVA ProcessSimulationDocument8 pagesDatasheet AVEVA ProcessSimulation5320002No ratings yet

- A Review of High Fidelity, Gas Turbine Engine SimulationsDocument8 pagesA Review of High Fidelity, Gas Turbine Engine SimulationsSoumendu BanikNo ratings yet

- Software: Curtiss-Wright Flow Control Service CorpDocument1 pageSoftware: Curtiss-Wright Flow Control Service CorpRaul tejadaNo ratings yet

- Accor Commissioning of Engineering ServicesDocument50 pagesAccor Commissioning of Engineering ServicesFarid Hasanli100% (1)

- Chen 2014Document11 pagesChen 2014hosseinNo ratings yet

- 1 s2.0 S1474667017305876 MainDocument6 pages1 s2.0 S1474667017305876 MainArifuadinNo ratings yet

- Modeling Simulation and Control of Large Scale CryDocument6 pagesModeling Simulation and Control of Large Scale CryPhilippe GayetNo ratings yet

- Optimising Safety Relief and Flare SystemsDocument8 pagesOptimising Safety Relief and Flare SystemsJoseph McMullenNo ratings yet

- Typical Uses:: Gas ProcessingDocument4 pagesTypical Uses:: Gas ProcessingsanthoshnlNo ratings yet

- Electrical Power and Energy Systems: A. Khodabakhshian, R. HooshmandDocument8 pagesElectrical Power and Energy Systems: A. Khodabakhshian, R. HooshmandNabin AdhikariNo ratings yet

- Burner ManagementDocument6 pagesBurner ManagementAbdallah ShabanNo ratings yet

- OTC 10945 Reliability Analysis of Permanent Downhole Monitoring SystemsDocument10 pagesOTC 10945 Reliability Analysis of Permanent Downhole Monitoring SystemsLulut Fitra FalaNo ratings yet

- Control System AdvancementsDocument15 pagesControl System AdvancementstungluongNo ratings yet

- LhcsDocument4 pagesLhcsgilangaspNo ratings yet

- BK 313 Sec 3.3Document62 pagesBK 313 Sec 3.3Andreea LilianaNo ratings yet

- 990 1775 1 PBDocument8 pages990 1775 1 PBJHNo ratings yet

- Hvac and Lighting Control Using PLC and Scada ForDocument9 pagesHvac and Lighting Control Using PLC and Scada ForIvan OxfordNo ratings yet

- Conveyor DCI 0311Document2 pagesConveyor DCI 0311Kelvin Kindice MapurisaNo ratings yet

- Flow Assurance Overview-2Document44 pagesFlow Assurance Overview-2emenneNo ratings yet

- M.S.Kirubhananth: Senior Instrument TechnicianDocument4 pagesM.S.Kirubhananth: Senior Instrument TechnicianDonNo ratings yet

- DownloadDocument11 pagesDownloadMehrshad GhasemabadiNo ratings yet

- Reference List Process Control Systems For Power Plants: Bilfinger Mauell GMBHDocument32 pagesReference List Process Control Systems For Power Plants: Bilfinger Mauell GMBHrajavinugmailcomNo ratings yet

- White Paper: Computer Simulation of Buoy Mooring SystemsDocument12 pagesWhite Paper: Computer Simulation of Buoy Mooring Systemssmithwork100% (1)

- 82191C Brochure APPL ADV200-HVAC ENDocument20 pages82191C Brochure APPL ADV200-HVAC ENbaros07No ratings yet

- Modeling and Control of A Real Time Shell and Tube Heat ExchangerDocument9 pagesModeling and Control of A Real Time Shell and Tube Heat ExchangerJudy Ann BoseNo ratings yet

- Estad-Jsi 2014Document3 pagesEstad-Jsi 2014INDRAJIT SAONo ratings yet

- Ansys Coupling: Maintain Accuracy While Decreasing Solving TimesDocument2 pagesAnsys Coupling: Maintain Accuracy While Decreasing Solving TimessrashmiiiscNo ratings yet

- DcsDocument22 pagesDcsSethu Naidu100% (1)

- Gea S1210Document2 pagesGea S1210Noé ChungaNo ratings yet

- Building Automation InteractiveDocument19 pagesBuilding Automation Interactivedev aditya100% (1)

- Flare NetDocument2 pagesFlare NetPetrol SollyNo ratings yet

- DCX CC DublinEvapCoolingDocument3 pagesDCX CC DublinEvapCoolingahmedhamdi731No ratings yet

- 3000164en PDFDocument16 pages3000164en PDFhNo ratings yet

- An Optimal Control Strategy For Complex Building Central Chilled Water Systems For Practical and Real-Time ApplicationsDocument11 pagesAn Optimal Control Strategy For Complex Building Central Chilled Water Systems For Practical and Real-Time ApplicationssaruthanNo ratings yet

- Journal of Process Control: Soroush Rastegarpour, Riccardo Scattolini, Luca FerrariniDocument10 pagesJournal of Process Control: Soroush Rastegarpour, Riccardo Scattolini, Luca FerrariniAhmed AKBASNo ratings yet

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

- Rabigh WTP & Dam ReportDocument16 pagesRabigh WTP & Dam ReportShehroz Ahmad ShoaibNo ratings yet

- Week 13, Stormwater Management Design (SUDS), DETENTION PONDSDocument12 pagesWeek 13, Stormwater Management Design (SUDS), DETENTION PONDSlehlabileNo ratings yet

- Pakistan Engineering Council Code DetailsDocument11 pagesPakistan Engineering Council Code DetailsaountariqNo ratings yet

- Pds Hempadur 85671 En-GbDocument2 pagesPds Hempadur 85671 En-GbbpajicNo ratings yet

- Aerated LagoonsDocument8 pagesAerated LagoonsusmansherdinNo ratings yet

- SIA - PRESTORMING - GS-I - 2023-24 - ALL INDIA MOCK TEST I - EXPLANATION - CompressedDocument77 pagesSIA - PRESTORMING - GS-I - 2023-24 - ALL INDIA MOCK TEST I - EXPLANATION - Compressedathira vijayanNo ratings yet

- Tamil Nadu Urban Infrastructure Financial Services Limited (TNUIFSL)Document50 pagesTamil Nadu Urban Infrastructure Financial Services Limited (TNUIFSL)Srithar KNo ratings yet

- Sds 401Document9 pagesSds 401wulandariyunniaNo ratings yet

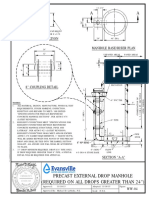

- Drop ManholeDocument1 pageDrop ManholeorganicspolybondNo ratings yet

- St-05 (r1) - 120mld STP - R.C Details of Plinth Beam For Air Blower Building-A3-11.07.2020-ModelDocument1 pageSt-05 (r1) - 120mld STP - R.C Details of Plinth Beam For Air Blower Building-A3-11.07.2020-Modeljuliyet strucNo ratings yet

- Imel Talag Las Technical Drafting G9 Week 4Document9 pagesImel Talag Las Technical Drafting G9 Week 4Imel Aguado TalagNo ratings yet

- HEC-HMS Application Sri Lanka Devanmini and Najim 2013Document8 pagesHEC-HMS Application Sri Lanka Devanmini and Najim 2013Macklera MrutuNo ratings yet

- High Order Thinking Skill Questions Class XDocument10 pagesHigh Order Thinking Skill Questions Class Xjan12th2004No ratings yet

- 150 KLD AhlayaDocument17 pages150 KLD Ahlayaalok_rajpoot786100% (1)

- 15.02 - Pavement Design V2 PDFDocument13 pages15.02 - Pavement Design V2 PDFShida ShidotNo ratings yet

- CH 6 Water ResourcesDocument18 pagesCH 6 Water ResourcesVishesh RajputNo ratings yet

- Beston (Henan) Machinery Co., LTDDocument22 pagesBeston (Henan) Machinery Co., LTDsuratman sastroNo ratings yet

- Blyde RiverDocument3 pagesBlyde Rivernk4j3tk34j5No ratings yet

- The Urban Heat Island Phenomenon in Malaysia - Doc NewDocument15 pagesThe Urban Heat Island Phenomenon in Malaysia - Doc NewRamsrajNo ratings yet

- AXIAL Product LabelDocument6 pagesAXIAL Product LabelVipin KansalNo ratings yet

- Effects of Inappropriate Waste DisposalDocument9 pagesEffects of Inappropriate Waste DisposalFrancis Gabriell OrtizNo ratings yet

- ACV HeatMaster 201Document28 pagesACV HeatMaster 201Gabo CanalesNo ratings yet

- Cbse 12 TH 2014 English Core Compt 06 Outside DelhiDocument11 pagesCbse 12 TH 2014 English Core Compt 06 Outside Delhiarjunprasannan7No ratings yet