Professional Documents

Culture Documents

Standard: Renault Automobiles Standardisation DQ - EDA / Department 67250

Standard: Renault Automobiles Standardisation DQ - EDA / Department 67250

Uploaded by

julio.delaredOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard: Renault Automobiles Standardisation DQ - EDA / Department 67250

Standard: Renault Automobiles Standardisation DQ - EDA / Department 67250

Uploaded by

julio.delaredCopyright:

Available Formats

STANDARD

01 - 50 - 101 / - -G

PUNCHED CIRCULAR HOLES

MANAGER(S) APPROVAL

NAME:

DEPARTMENT:

DATE:

SIGNATURE:

Required classification: 01 - 50 - 101 / - - F Dept. Tel. No.

Document manager A.T. NCC 60201 7XXXX

Technical leader(s) LEADER 99999 99999

Date of up date:

Renault Automobiles Standardisation

DQ - EDA / Department 67250

RENAULT 01 - 50 - 101 / - - G

This document is to be considered as a whole; the parts of which must not be separated.

© RENAULT 2011.

No duplication permitted without the consent of the issuing department.

No circulation permitted without the consent of RENAULT.

FIRST ISSUE

February 1976 ---

REVISION

August 1986 --A

Note: The indices B, C and D are notional indices (IT problem)

February 2001 - - E Validity confirmation.

This issue originates from the draft NC 2001 0103 / - - -.

September 2002 - - F Revision of NOTE 2: Addition of the phrase "The TP holes cannot be

created during stamping".

This issue originates from the draft NC 2002 0576 / - - -.

June 2011 - - G Addition of nominal diameter - 6, 8, 10, 12, 14, 16, 20, 25.and plug

column

Note 2: The standardised description cannot be used for the

punchings which are not represented in the standard. They must be

indicated and toleranced on the part drawing.

REFERENCED DOCUMENT

© RENAULT 2011 Page 2/4

RENAULT 01 - 50 - 101 / - - G

SELECTION OF DIAMETERS

The diameters must be selected preferably among the underlined values. The holes which can be

sealed are marked. The values in brackets should not be used any more for new projects.

NOMINAL DIAMETER OF HOLES (in mm)

Blanking Blanking

cap cap

(3.5) NO 12 YES

(3.7) NO 12.2 YES

(4.0) NO (12.7) YES

(4.2) NO 13.5 NO

(4.7) NO 14 NO

5.2 YES 14.5 YES

(5.7) NO 15.5 NO

6 NO 16 YES

6.2 NO 16.5 YES

(6.7) NO 18.5 NO

7.2 NO 20 YES

(7.7) NO 20.5 YES

8 YES 22.5 NO

8.2 YES 24.5 YES

(8.7) NO 25 YES

9.2 NO 30 YES

(9.7) NO 35 NO

10 YES 40 YES

10.2 YES 45 NO

(10.7) NO 50 YES

11.2 NO 80 YES

(11.7) NO 100 NO

NOTE 1: When a part includes many circular holes, it is recommended to standardise the

dimensions or to select holes with different dimensions.

© RENAULT 2011 Page 3/4

RENAULT 01 - 50 - 101 / - - G

DIMENSIONAL TOLERANCES

TOLERANCE BASED ON THE

OPERATIONS CODE * THICKNESS OF THE SHEET METAL

(in mm)

t≤2 2<t≤3 t>3

- Removal of paint which is not sealed by clipping

- Stamping pilot T.B. ± 1.5 ± 1.5 ± 1.5

- Lightening hole

- Removal of paint which is sealed by clipping

- Clearance hole for screws

+ 0.2 + 0.2 + 0.2

- Locating of 2 parts (approximate) T.O.

- 0.05 - 0.1 - 0.15

- Hole for grommet clipping

- Reference points

- Locating of 2 parts (accurate)

- Reference points T.P. ± 0.05 + 0.05 + 0.05

- Hole for an assembly by riveting - 0.1 - 0.15

- Clamps

- Circularity tolerance is included in the dimensional tolerance.

- Indication to be shown on the drawing:

- Example of description for a circular hole of diameter 14.5:

T.O. ∅ 14.5 (grommet clipping).

* TB = Rough hole.

TO = Ordinary hole.

TP = Accurate hole.

NOTE 2: The "TP" holes are not created during stamping

The list of different dimensions of circular holes indicate the punches which are in stock.

Due to fittability reasons, in mandatory cases, only the manager of the Department 65307

is authorised to accept the punches which are not represented.

The standardised description cannot be used for the punchings which are not represented

in the standard. They must be indicated and toleranced on the part drawing.

© RENAULT 2011 Page 4/4

You might also like

- Yanmar 3TNE78Document51 pagesYanmar 3TNE78zakki ahmadNo ratings yet

- Drilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsFrom EverandDrilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsRating: 5 out of 5 stars5/5 (1)

- Manual de Reparacion Dx140lcDocument918 pagesManual de Reparacion Dx140lcArbey Gonzalez100% (1)

- Printed in GermanyDocument20 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Roof Connections For Vertical Tanks (Roof Nozzles) (See Tables 7.2 and 7.3)Document6 pagesRoof Connections For Vertical Tanks (Roof Nozzles) (See Tables 7.2 and 7.3)TAHIR MAHMOODNo ratings yet

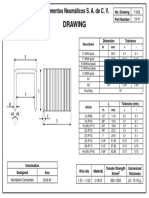

- Drawing: Implementos Neumáticos S. A. de C. VDocument1 pageDrawing: Implementos Neumáticos S. A. de C. VFRANCISCO JAVIER MALDONADONo ratings yet

- Asme B16.5-2017-02Document2 pagesAsme B16.5-2017-02andhucaos0% (1)

- Ee Ferrite Core Coil Formers: Core Type Partnumber Product DescriptionDocument26 pagesEe Ferrite Core Coil Formers: Core Type Partnumber Product DescriptionRudi AnotheerNo ratings yet

- STAD Balancing ValvesDocument10 pagesSTAD Balancing ValvesNestramiNo ratings yet

- PLATE (1007) : Rev. Date Revision Description Rev Mark NoDocument1 pagePLATE (1007) : Rev. Date Revision Description Rev Mark NoJasmin RedzepagicNo ratings yet

- Bgl-Fm-Qa-10b Monthly Rejection Tracking & AnalysisDocument66 pagesBgl-Fm-Qa-10b Monthly Rejection Tracking & AnalysisMohit SinghNo ratings yet

- TALAT Lecture 2406: Annex 2Document6 pagesTALAT Lecture 2406: Annex 2CORE MaterialsNo ratings yet

- Available Servclips - 2014Document1 pageAvailable Servclips - 2014HIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Valvulas MultipropositoDocument4 pagesValvulas MultipropositoSaulo ArturoNo ratings yet

- YDG2700 / 3700E: Parts CatalogDocument34 pagesYDG2700 / 3700E: Parts CatalogvivsencoNo ratings yet

- DK-Lok Tube Fittings - Tube To SAE O-Ring SealDocument6 pagesDK-Lok Tube Fittings - Tube To SAE O-Ring SealHLHDungNo ratings yet

- Final Project Dem4b (1069,1070,1052,1062)Document3 pagesFinal Project Dem4b (1069,1070,1052,1062)malztigreNo ratings yet

- Corte IPE220-IPE220Document7 pagesCorte IPE220-IPE220yonatandiazNo ratings yet

- HF DIT-Katalog 2016 EN - Technische InformationDocument30 pagesHF DIT-Katalog 2016 EN - Technische InformationDejan KostadinovicNo ratings yet

- Yagi Uda DesignDocument8 pagesYagi Uda DesignNobert WekesaNo ratings yet

- Not Released For Production: A C B FDocument1 pageNot Released For Production: A C B FNEXTECH ElectroicsNo ratings yet

- Detailed Estimate MathurDocument3 pagesDetailed Estimate Mathurahmed aarifNo ratings yet

- Boxnhl MBS (Design-D) Check SheetDocument13 pagesBoxnhl MBS (Design-D) Check SheetKumari SanayaNo ratings yet

- Parts Catalog: Last Update Mar., 2013Document147 pagesParts Catalog: Last Update Mar., 2013Said GedeonNo ratings yet

- WD CS 01 BFNS22.9 2018Document15 pagesWD CS 01 BFNS22.9 2018Dipanjan chakrabortyNo ratings yet

- Parts Catalog: 2010/10 (Oct.) PublishedDocument29 pagesParts Catalog: 2010/10 (Oct.) PublishedВладиславМасарскийNo ratings yet

- DS1000 5-Tap Silicon Delay Line: Features Pin AssignmentDocument6 pagesDS1000 5-Tap Silicon Delay Line: Features Pin AssignmentCharbel TadrosNo ratings yet

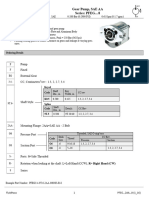

- PFEG - 2AA - 8 - Gear Pump, SAE AADocument2 pagesPFEG - 2AA - 8 - Gear Pump, SAE AAmarcos torresNo ratings yet

- Fatigue Design CalculationDocument3 pagesFatigue Design CalculationinnovativekarthiNo ratings yet

- NippleDocument2 pagesNipplerobert_candra_tarunaNo ratings yet

- SteinerDocument1 pageSteinerNguyễn QuỳnhNo ratings yet

- International Standard: Hexalobular Internal Driving Feature For Bolts and ScrewsDocument6 pagesInternational Standard: Hexalobular Internal Driving Feature For Bolts and ScrewsanhthoNo ratings yet

- Grinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataDocument4 pagesGrinnell Mechanical Products Rigid Coupling - Patented General Description Technical DataСергей КолесниковNo ratings yet

- Boss CE-5 (T)Document10 pagesBoss CE-5 (T)Dadson DadoNo ratings yet

- Placa Base 1Document1 pagePlaca Base 1julio gutierrezNo ratings yet

- r06 Piab Standard For DrawingDocument8 pagesr06 Piab Standard For Drawingsoryn_25No ratings yet

- Water-Fine Series Filter CartridgesDocument2 pagesWater-Fine Series Filter Cartridgesfernando brasolinNo ratings yet

- Qty Calculation Sheet - Blocks & BricksDocument8 pagesQty Calculation Sheet - Blocks & BricksHilal RomeNo ratings yet

- 0CS10-M45001 enDocument145 pages0CS10-M45001 enFrancois-Martin Morissette100% (1)

- Bothwell CatelogDocument61 pagesBothwell Catelogjafarfaj.husainNo ratings yet

- Boss dd3 TDocument10 pagesBoss dd3 TVictor AriizNo ratings yet

- Upvc Pressure CatalogueDocument7 pagesUpvc Pressure CatalogueAmir ShahzadNo ratings yet

- G+4 Labour Camp, Jabal Al Ajmi: Earth Works L B D Nos QtyDocument62 pagesG+4 Labour Camp, Jabal Al Ajmi: Earth Works L B D Nos QtykabeerNo ratings yet

- L100N5 Getm3 PDFDocument17 pagesL100N5 Getm3 PDFkarol1177No ratings yet

- KIP 3000 Parts Manual Ver 1 PDFDocument91 pagesKIP 3000 Parts Manual Ver 1 PDFivanoquirozNo ratings yet

- Muffler D8T - JJ501229Document2 pagesMuffler D8T - JJ501229ekakhoirulaNo ratings yet

- B Engine Unit: To IndexDocument50 pagesB Engine Unit: To Indexwei fooNo ratings yet

- Parts CatalogDocument77 pagesParts CatalogBarıs AtayNo ratings yet

- BCC ComprasionDocument2 pagesBCC ComprasionAnjani kumarNo ratings yet

- 2GM20FDocument129 pages2GM20FGeorgiNo ratings yet

- Climate Risk and Payout Flexibility Around The World-10Document1 pageClimate Risk and Payout Flexibility Around The World-10JohnNo ratings yet

- VVPX306R-V5 VVPX306R-V5.MR: 30 210 (Inside)Document1 pageVVPX306R-V5 VVPX306R-V5.MR: 30 210 (Inside)Ikie BarieNo ratings yet

- NIC Components NRM-S SeriesDocument1 pageNIC Components NRM-S SeriesNICCompNo ratings yet

- Parts Catalog: 0CS10-M40201ENDocument146 pagesParts Catalog: 0CS10-M40201ENKatie Pierce O SheaNo ratings yet

- Parts Manual Yanmar VIO50 2ADocument136 pagesParts Manual Yanmar VIO50 2AРоман МелешкоNo ratings yet

- Parts Catalog: 0CT10-M24400ENDocument129 pagesParts Catalog: 0CT10-M24400ENTom TrakNo ratings yet

- Documento - MX Comp1Document10 pagesDocumento - MX Comp1Mangesh BanaleNo ratings yet

- Dimension RFPDocument3 pagesDimension RFPMANIMARAN QCNo ratings yet

- Parafusos Com Gargantachapter 3Document7 pagesParafusos Com Gargantachapter 3Miguel QueirosNo ratings yet

- Modern Size-Exclusion Liquid Chromatography: Practice of Gel Permeation and Gel Filtration ChromatographyFrom EverandModern Size-Exclusion Liquid Chromatography: Practice of Gel Permeation and Gel Filtration ChromatographyNo ratings yet

- Mos QBDocument15 pagesMos QBKarnalPreethNo ratings yet

- JSS2 Basic Tech 1ST Term Question Bank 1Document2 pagesJSS2 Basic Tech 1ST Term Question Bank 1Holuwa DijexNo ratings yet

- Introduction On SpectrophotometerDocument7 pagesIntroduction On SpectrophotometerbubNo ratings yet

- Airline Abbreviation PDFDocument99 pagesAirline Abbreviation PDFsomendraNo ratings yet

- Experiment 4Document28 pagesExperiment 4nellyNo ratings yet

- Template Laporan DEDDocument2 pagesTemplate Laporan DEDaminNo ratings yet

- BJT Differential AmplifierDocument4 pagesBJT Differential Amplifierdominggo100% (4)

- New Microsoft Office Word DocumentDocument10 pagesNew Microsoft Office Word DocumentcitunairNo ratings yet

- 12V DC Linear Actuator Instructions Manual 12V DC Linear Actuator Instructions ManualDocument4 pages12V DC Linear Actuator Instructions Manual 12V DC Linear Actuator Instructions Manualdc190400841 MIAN AQIL GHAFFARNo ratings yet

- Experiment 9. Relative Rates of Electrophilic Aromatic SubstitutionDocument2 pagesExperiment 9. Relative Rates of Electrophilic Aromatic SubstitutionJoone Xyron CreenciaNo ratings yet

- EndPl MomConn LSDDocument54 pagesEndPl MomConn LSDTony RoseNo ratings yet

- Types of Robot SensorsDocument8 pagesTypes of Robot Sensorsmd anik hasanNo ratings yet

- Boyles Law EditedDocument10 pagesBoyles Law EditedRico FernandezNo ratings yet

- Middleware Comm Liberty Security Intro 3Document57 pagesMiddleware Comm Liberty Security Intro 3Souhail TounsiNo ratings yet

- Linux and Bash Command Cheat Sheet - The BasicsDocument1 pageLinux and Bash Command Cheat Sheet - The BasicsAssil BouazizNo ratings yet

- Communication Port Function M1120, M1136, M1138, M1139, M1143, D1036, D1109Document2 pagesCommunication Port Function M1120, M1136, M1138, M1139, M1143, D1036, D1109Vishwadeep Paul Alstrut India Private LimitedNo ratings yet

- E283C2Document22 pagesE283C2Steven YuNo ratings yet

- CLCentrifugal Pumps CL-100DDocument46 pagesCLCentrifugal Pumps CL-100DMara GonzálezNo ratings yet

- Quadratic SieveDocument7 pagesQuadratic SieveSUBODH VERMA 17BCE1241No ratings yet

- Book List For ParamaDocument6 pagesBook List For ParamaShafayet UddinNo ratings yet

- Evaluation Fixed Points For The Thermal Calibration Laboratory (Celebrating 10 Years of Slim Cell Production)Document12 pagesEvaluation Fixed Points For The Thermal Calibration Laboratory (Celebrating 10 Years of Slim Cell Production)Arun ChenthamarakshanNo ratings yet

- Animal Environment & Heat FlowDocument71 pagesAnimal Environment & Heat FlowSivakumar SadasivamNo ratings yet

- Performance Analysis of Locally Design Plastic Crushing Machine For Domestic and Industrial Use in NigeriaDocument6 pagesPerformance Analysis of Locally Design Plastic Crushing Machine For Domestic and Industrial Use in NigeriaRishokNo ratings yet

- 1.concepts of Growth & DevelopmentDocument107 pages1.concepts of Growth & DevelopmentYuvashreeNo ratings yet

- Gurong Pinoy Diagnostic TestDocument28 pagesGurong Pinoy Diagnostic TestPALCULIO JARED PRINCE100% (1)

- Response of Second Order System and Response To Step ForceDocument50 pagesResponse of Second Order System and Response To Step Forceedmar peregrinNo ratings yet

- Module 2 ProbabilityDocument28 pagesModule 2 Probabilitymeryroselicaros525No ratings yet

- Geotech Chapter 4Document16 pagesGeotech Chapter 4Casao JonroeNo ratings yet

- Bay O Net FuseDocument4 pagesBay O Net Fuseammad_w6565100% (1)