Professional Documents

Culture Documents

Tra - Cw-A15 Removingreplasing All Valves

Tra - Cw-A15 Removingreplasing All Valves

Uploaded by

valveworkshseCopyright:

Available Formats

You might also like

- Risk Assessment For Testing & Commissioning of HVAC SystemDocument12 pagesRisk Assessment For Testing & Commissioning of HVAC SystemAnandu Ashokan75% (12)

- Radiography Work 004Document6 pagesRadiography Work 004BinayNo ratings yet

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- Risk Assessment For BridgeDocument31 pagesRisk Assessment For BridgeMariam Mousa100% (2)

- Risk Assessment For Noise Vibration Explosion and Fire 4Document1 pageRisk Assessment For Noise Vibration Explosion and Fire 4Ndifor Dinho50% (2)

- 125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتDocument3 pages125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتeng_hma75% (4)

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- TRA - CW-A01 - USING of TOOLSDocument15 pagesTRA - CW-A01 - USING of TOOLSvalveworkshseNo ratings yet

- TRA - CW-A12 - Use OF A TROLLEYDocument4 pagesTRA - CW-A12 - Use OF A TROLLEYvalveworkshseNo ratings yet

- HIRARC IBS Components Installation Rev 0Document21 pagesHIRARC IBS Components Installation Rev 0Suraindran ManoharanNo ratings yet

- Appendix 3 Risk Assessment of Post Fixed Rebar Drill & Fix With Chemical AnchorDocument13 pagesAppendix 3 Risk Assessment of Post Fixed Rebar Drill & Fix With Chemical Anchormohsin.meizaNo ratings yet

- Hirarc 2Document5 pagesHirarc 2dibhmNo ratings yet

- Hiradc For 36 Inch End FlangeDocument6 pagesHiradc For 36 Inch End FlangeMohd KhaidirNo ratings yet

- Hirarc 3Document6 pagesHirarc 3dibhmNo ratings yet

- Jesa FGDDocument26 pagesJesa FGDResearcherNo ratings yet

- Jesa-Construction of Chemical Storage Shelter For CPP RegenDocument28 pagesJesa-Construction of Chemical Storage Shelter For CPP RegenResearcherNo ratings yet

- Backfilling, Leveling RISK ASSESSMENTDocument6 pagesBackfilling, Leveling RISK ASSESSMENTVimal ViswanathNo ratings yet

- Risk Assessment - Sheet Piling DraftDocument8 pagesRisk Assessment - Sheet Piling DraftSinaNo ratings yet

- Gas Welding Risk AssessmentDocument8 pagesGas Welding Risk AssessmentvictorNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Risk Assesment For KerbstonesDocument11 pagesRisk Assesment For KerbstonesZain butt67% (3)

- Hirarc 1Document7 pagesHirarc 1dibhmNo ratings yet

- Risk Assessment For 4600002029Document213 pagesRisk Assessment For 4600002029Ows Anish67% (3)

- Wiac - Info PDF Jsa For Using Jack Hammer PRDocument3 pagesWiac - Info PDF Jsa For Using Jack Hammer PRmaiman.mzakiNo ratings yet

- HirarcDocument34 pagesHirarcBungsu HiperkesNo ratings yet

- Name Designation 1) Name: Name: Name: 2) Signature: Signature: Signature: 3) Date: Date: DateDocument34 pagesName Designation 1) Name: Name: Name: 2) Signature: Signature: Signature: 3) Date: Date: DateHarry Hasbullah100% (7)

- 103 Preparation For SeaDocument1 page103 Preparation For SeaMr-SmithNo ratings yet

- Appendix 5.1 JSA VCP Installation Rev 0Document17 pagesAppendix 5.1 JSA VCP Installation Rev 0BELLANo ratings yet

- 10 Damansara HIRARCDocument34 pages10 Damansara HIRARCTri Subakti50% (2)

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- Risk Assessment For All Activities - 9Document42 pagesRisk Assessment For All Activities - 9Sonu KrishnaNo ratings yet

- Co2 Cylinder House-JesaDocument24 pagesCo2 Cylinder House-JesaResearcherNo ratings yet

- Silo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment FormDocument9 pagesSilo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment Form891629100% (1)

- Rams TelehandlerDocument9 pagesRams TelehandlerRynoNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- RA For Tiling WorkDocument12 pagesRA For Tiling WorkSaeed AhmadNo ratings yet

- Block Work (Unit Masonary) RISK ASSESSMENTDocument8 pagesBlock Work (Unit Masonary) RISK ASSESSMENTVimal ViswanathNo ratings yet

- Shoring Systtem and Diving Riskassesment CommentsDocument5 pagesShoring Systtem and Diving Riskassesment CommentsMohamed Hasafy100% (1)

- CTRA-22-STM-133-TK-11-995 - CS-Cleaning-1st ENTRYDocument3 pagesCTRA-22-STM-133-TK-11-995 - CS-Cleaning-1st ENTRYMohamed RizwanNo ratings yet

- Plate Load Test RADocument5 pagesPlate Load Test RAmd rafiqueNo ratings yet

- Risk AssesmentDocument3 pagesRisk AssesmentShahd JaberNo ratings yet

- JSA - Anti Termite Treatment WorkDocument5 pagesJSA - Anti Termite Treatment WorkRaju Khalifa67% (3)

- Risk Assessment For Installation of Diesel Generator111111Document8 pagesRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- Activity Title Workshop: 1. Hazard Identification 2. Risk Analysis 3.risk ControlDocument10 pagesActivity Title Workshop: 1. Hazard Identification 2. Risk Analysis 3.risk ControlizzahNo ratings yet

- Risk Assesment @ro, WTP & STP PremDocument6 pagesRisk Assesment @ro, WTP & STP PremvarunthalariNo ratings yet

- Excavation Work RISK ASSESSMENTDocument8 pagesExcavation Work RISK ASSESSMENTVimal ViswanathNo ratings yet

- (General Scaffolding JRADocument7 pages(General Scaffolding JRA891629No ratings yet

- HIRARCDocument34 pagesHIRARCNaga Rajan100% (1)

- TRA - CW-A16 Disconnecting and Reconnecting of Motors and Associated EquipmentDocument9 pagesTRA - CW-A16 Disconnecting and Reconnecting of Motors and Associated EquipmentvalveworkshseNo ratings yet

- Tra 002Document6 pagesTra 002Bilal0% (1)

- Risk Assessment Form - KingGroveDocument12 pagesRisk Assessment Form - KingGroveeric chenNo ratings yet

- Building Materials Risk AssessmentDocument3 pagesBuilding Materials Risk AssessmentAhmed El-sherpiniNo ratings yet

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Document6 pagesRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008No ratings yet

- TRA - For Air Condition Prefab BuildingDocument8 pagesTRA - For Air Condition Prefab Buildingabdulhanan86457No ratings yet

- Risk AssessmentDocument6 pagesRisk AssessmentRenjith RaviNo ratings yet

- Risk AssesmentDocument4 pagesRisk AssesmentShahd JaberNo ratings yet

- 104 Preparation For Arrival at PortDocument1 page104 Preparation For Arrival at PortMr-SmithNo ratings yet

- Form 5.4a - Job Observation Control SheetDocument1 pageForm 5.4a - Job Observation Control SheetvalveworkshseNo ratings yet

- 71 - Intergrated-Checklist - Docx Version 1Document13 pages71 - Intergrated-Checklist - Docx Version 1valveworkshseNo ratings yet

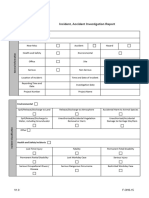

- F-OHS-15 Incident Accident Investigation ReportDocument7 pagesF-OHS-15 Incident Accident Investigation ReportvalveworkshseNo ratings yet

- Am Ims-P007-Control of Documented InformationDocument15 pagesAm Ims-P007-Control of Documented InformationvalveworkshseNo ratings yet

- Corrective Action ReportDocument4 pagesCorrective Action ReportvalveworkshseNo ratings yet

- Kippap-Handout-MSTE 40 COSH 1Document16 pagesKippap-Handout-MSTE 40 COSH 1Jae HanNo ratings yet

- Katalog Hanex TerbaruDocument34 pagesKatalog Hanex TerbaruMeita RatrianaNo ratings yet

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument8 pagesMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationAuroraNo ratings yet

- 4190-6130c Primer SDSDocument15 pages4190-6130c Primer SDSKristin CarrereNo ratings yet

- Trifluoroacetic Acid - MSDS - 299537 PDFDocument8 pagesTrifluoroacetic Acid - MSDS - 299537 PDFBigbearBigbearNo ratings yet

- PPG 0580-9000 Thinners - SDS - 058090005Document16 pagesPPG 0580-9000 Thinners - SDS - 058090005crushergaming1804No ratings yet

- Mcop Managing Electrical Risks in The Workplace v3Document63 pagesMcop Managing Electrical Risks in The Workplace v3Aizaz KhanNo ratings yet

- Line of Fire Training SlidesDocument39 pagesLine of Fire Training SlidesSiraj UddinNo ratings yet

- LATICRETE 335 Super Flex TDSDocument4 pagesLATICRETE 335 Super Flex TDSDheeraj GuptaNo ratings yet

- URC Insulation For Ducting (SWMS)Document9 pagesURC Insulation For Ducting (SWMS)syed khaja misbhuddinNo ratings yet

- M01-Advanced ElectricalElectronic SystemsDocument111 pagesM01-Advanced ElectricalElectronic SystemsTariku Tesfaye100% (1)

- Benzalkonium Chloride Solution, 17% MSDS - Revision 09-09-08Document7 pagesBenzalkonium Chloride Solution, 17% MSDS - Revision 09-09-08New TubeNo ratings yet

- MSDS New CAUSTIC SODADocument6 pagesMSDS New CAUSTIC SODAAlves EdattukaranNo ratings yet

- Baracarb® 5Document9 pagesBaracarb® 5Nural MuradliNo ratings yet

- FICHA DE SEGURIDAD DE DE GRASA SANITARIA FM - CSC - EpDocument6 pagesFICHA DE SEGURIDAD DE DE GRASA SANITARIA FM - CSC - EpControl de Calidad MontefioriNo ratings yet

- 910X533 ActivatorDocument9 pages910X533 ActivatorNICKYNo ratings yet

- MSDS - 97050 - 55610 Curing AgentDocument12 pagesMSDS - 97050 - 55610 Curing AgentGanesh R NairNo ratings yet

- SDS - Olin - KOH - 30 - US - SDS - US - EnglishDocument8 pagesSDS - Olin - KOH - 30 - US - SDS - US - EnglishLuis Carbajal CusiNo ratings yet

- Tectyl Spin 10 (En-Ghs-K)Document14 pagesTectyl Spin 10 (En-Ghs-K)Irna WatiNo ratings yet

- MSDS Pc-AbsDocument8 pagesMSDS Pc-AbsEduardo GarzaNo ratings yet

- Material Safety Data Sheet: Mono Ethylene GlycolDocument4 pagesMaterial Safety Data Sheet: Mono Ethylene GlycolANURAG SHARMANo ratings yet

- Safety Data Sheet: Opt I KL een-WF™Document9 pagesSafety Data Sheet: Opt I KL een-WF™Richard ReedNo ratings yet

- JSA Form - Installation of ATS atDocument4 pagesJSA Form - Installation of ATS atDarren OscarNo ratings yet

- Epikuron 100 G MSDSDocument9 pagesEpikuron 100 G MSDSIbad MuhammedNo ratings yet

- Ferric Chloride HexahydrateDocument6 pagesFerric Chloride HexahydrateDust HooNo ratings yet

- MSDS Isopropyl AlcoholDocument12 pagesMSDS Isopropyl AlcoholrezaNo ratings yet

- Cat Hydraulic Oil AdditiveDocument9 pagesCat Hydraulic Oil AdditiveAylin Salgado AvilaNo ratings yet

- Safety Data Sheet: Product Name: Volvo Synthetic Gearbox Oil 97315Document10 pagesSafety Data Sheet: Product Name: Volvo Synthetic Gearbox Oil 97315Hendry PardedeNo ratings yet

- Msds 2-Hydroxy-2-Methylpropiophenone ENDocument8 pagesMsds 2-Hydroxy-2-Methylpropiophenone ENClaudio BiaginiNo ratings yet

- Job Safety AnalysisDocument39 pagesJob Safety Analysisandi fahrul faridNo ratings yet

Tra - Cw-A15 Removingreplasing All Valves

Tra - Cw-A15 Removingreplasing All Valves

Uploaded by

valveworkshseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tra - Cw-A15 Removingreplasing All Valves

Tra - Cw-A15 Removingreplasing All Valves

Uploaded by

valveworkshseCopyright:

Available Formats

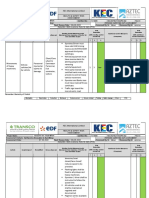

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 1 of 16

Office / Project Name SASOL

REMOVING/REPLASING ALL VALVES

Hazard Risk Value (Before Risk Value (After

Class Mitigation) Mitigation and Control Mitigation) Remarks or

Activity Hazards Risks

Measures References

CO

H S E LO Rating LO CON Rating

N

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control

Only a qualified, trained permit

receiver (only SASOL

personnel) can receive a permit.

Permits will be filled in with all

the relevant information

identifying all the risks and

Information

If permits are not filled in correctly or hazards for the tasks.

Communicati

contain the correct information, it can The permit receiver will have

on OHSA Act

lead to confusion where equipment can proof of his authorization to

Permit application Hazard X X X 4 5 E 1 5 M No: 83 of

start up whilst employees working on receive a permit upon

identification 1993

the equipment. application as well as a detailed

Unawareness

risk assessment and method

No Control

statement for the task being

performed, SAS 558,

JSTA/JSEA.

Permit application will only take

place according to the SASOL

Permit Procedure.

All employees involved in the

task will sign on the permit

before activity commences.

PPE: N/A.

Oil & Gas

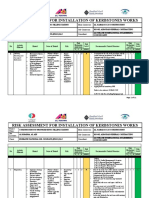

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 2 of 16

Elimination: N/A

1. wrong

Substitution: N/A

equipment

Engineering Control: N/A

prepared

Admin Control 1. Follow permit

2. stored

conditions (CSB: No Permit -

energy

No Work)

Equipment 3. stored

1. Injuries 2. SAS558 / JSTA / PDA

process prepared electricity

2. Electrocution √ √ 3 4 H 3. Isolation procedure 2 3 M

- equipment off 4. insufficient

3. Overcome by gas 4. Blank lists

line and perched. purching

5. Gas analyser record sheet

(gasses)

6. Calibration of gas analyser

5.

7. Supervision to be present at

insufficient /

all times and ensure that all

incorrect gas

procedures are followed.

testing

PPE: N/A.

1. Equipment 1. Wrong 1. Injuries √ √ 4 4 E Elimination: N/A 3 2 M

touched and equipment 2. Electrocution Substitution: N/A

tagged identified Engineering Control: N/A

2. Equipment 2. Stored Admin Control

safely locked out energy 1. Touch and Tag procedure to

and isolated 3. Stored be followed.

(Earthed) electricity 2. Isolation and Lock out

procedure to be followed (CSB)

(No examination, repair or

alteration may be performed on

electrical equipment unless the

equipment has been isolated

from all sources or supply and

made safe. Where isolation is

not possible, special

precautions as per Sasol SWI

must be followed)

3 .Follow permit conditions

(CSB: No Permit - No Work)

4. Only competent people to

perform work activity.

Oil & Gas

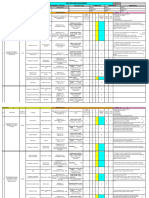

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 3 of 16

PPE: N/A.

Correct use of

PPE

1. Flame/Acid

Retardant Long

sleeve overall-

Sasol Standard

2. Electricians: Elimination: N/A

Level 5 Cut Substitution: N/A

Resistant (Maxi- Engineering Control: N/A

cut) gloves or Admin Control: N/A

1 . Incorrect

when working PPE:

issue of PPE

with stainly knife. PPE ( gloves / safety glasses /

2. Incorrect

Management, hard hat / safety boots /

selection of

Artisans, Semi- respiratory dust masks/ double

PPE 1. Exposure of Body Parts

skilled, Store- ear protection) (CSB)

3. Incorrect 2. Injuries (Severe)

man, HSE, other: No Metallic jewellery and

standard of 3. Cuts / Lacerations

Pig Skin Leather √ 3 4 H watches are allowed to be worn 2 3 M

PPE 4. Burns

Gloves by employees working on

4. Incorrect fit 5. Diciplinary action for not using

3. SABS and electrical equipment. PPE must

of PPE PPE

SANS approved ALWAYS be in a good

5. Incorrect

blue hard hat with condition. Supervision and

type of PPE

chin strap HSSE to do regular inspections.

6. Defective

4.Respiratory Should PPE not be in a good

PPE

dust mask with condition or faulty a fault report

CE number form must be filed with the

5. Safety glasses stores and HSSE in order to

with CE number investigate the matter.

6.Ear muffs 3M

Peltor

7.Ear plugs

8. Bova make

anckle height

safety boots

Uncouple: 1. Removal of 1. Electrocution √ √ 4 4 E Elimination: N/A 3 2 M

Disconnect incorrect 2. Property Damage Substitution: N/A

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 4 of 16

wiring, disconnect equipment 3. sudden release of pressure / gas Engineering Control:

tubing 2. process 4. Body pains and strains 1. Person to determine the

isolation 5. Fatique, unable to handle equipment weight of the equipment before

(release of weight, unaware of surroundings manual handling. Lifting

air) 6. Injuries equipment to be utilized should

3. stored 7. Overcome by gas the weight of the equipment

electricity exceed 20Kg. Employees to be

4. stored trained in good lifting practices.

energy (air (CSB)

neamatic, Admin Control

spring 2. Equipment to be touched and

loaded) tag,

5. Poor 3.Supervision to be present at

ergonomic all times and ensure that the

practices correct equipment are being

lifting, removed.

bending, 4. Permit conditions to be

twisting, followed (CSB: No Permit - No

overstrectchin Work)

g) 5. Only competent people to

6. Solitary perform the work.

work 6. Employees to be trained in

7. Poor good Ergonomic practices.

communicatio (Should it be diffucult or not

n safe to reach / work with

8. No equipment; a scaffold must be

supervision requested and errected in order

present to refrain employees from

9. Manual performing any unsafe

handling of movements or work activity)

equipment 7. Employees will not be

10. Confined permitted to work alone.

space entry Supervision to ensure that

teams are scheduled for work

activities.

8. Supervision to be present

when performing tasks

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 5 of 16

9. Supervision and employees

to ensure good communication

and clear instructions between

each other.

10. Only competent & fit

employees to enter and work in

confined spaces. (CSB) Permit

conditions to be followed.

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control

Lock out / Isolation / Tag out to

be done by registered

electrician and earthed. No

examination, repair or alteration

No lock out / may be performed on electrical

isolation/ tag Electrocution / Burns / Property equipment unless the

√ √ 4 4 E 3 2 M

out done. Not Damage / Fire equipment has been isolated

earthed. from all sources or supply and

made safe. Where isolation is

not possible, special

precautions as per Sasol SWI

must be followed. Permit

conditions to be followed at all

times.

PPE: N/A.

Equipment Damage to equipment and property √ 3 3 H Elimination: N/A 2 3 M

and Tools Substitution: N/A

(Use/Conditio Engineering Control: N/A

n/Selection & Admin Control

Storage) All equipment to be inspected

by a competent and appointed

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 6 of 16

person before rigging activity

and removal of equipment. Only

competent rigger to perform

rigging activity and supervision

to be present.

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control

Injuries (Cut, Pinch, Trap) √ 3 3 H 2 3 M

Use correct tool and lifting

equipment for the job.

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control

Use lanyards when working with

tools, tarpaulins to cover the

whole area and tool bags that

Falling Objects - when tools and lifting

√ 4 3 H are secured in order to store 3 2 M

equipment is no longer in use.

tools and lifting equipment not

in use. Openings in gratings

must also be covered in such a

way that people can’t go

through it.

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control Good

Housekeeping practices to be

utilized.

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 7 of 16

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control

Poor Employees to be trained in

Ergonomics good Ergonomic practices.

Practices (Should it be difficult or not safe

(Bending, Pains and Strains √ 3 2 M to reach / work with equipment; 1 2 L

twisting, a scaffold must be requested

Overstretchin and erected in order to refrain

g) employees from performing any

unsafe movements or work

activity)

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Use of self

Admin Control

retractable

Lacerations / Cuts / Property damage √ 3 4 H All employees whom are 1 4 M

stanley knives

required to use knifes will be

for cables

trained in the procedure

PPE: N/A.

.

Off cuts of Trip and Fall. Environmental pollution √ √ 3 4 E Elimination: N/A 1 4 H

cables and Substitution: N/A

equipment Engineering Control: N/A

Admin Control

Employees to be trained in the

environmental and waste

segregation plan. Good

Housekeeping practices to be

followed at all times.

PPE: N/A.

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 8 of 16

1. Incorrect

Tool or

equipment for Elimination: N/A

the job Substitution: N/A

2. Incorrect Engineering Control: N/A

use of the tool Admin Control

or equipment 1. All equipment to be

Correct Tool &

3. Poor inspected by a competent and

Equipment for the

condition of appointed person before use.

Job

tool or 2. Select and use correct tool

1. Use 1. Injuries (Cut, Pinch, Trap) √ 3 3 H 2 3 M

equipment and lifting equipment for the job.

2. Condition

4. Incorrect 3. Only competent employees

3. Selections

selection of to use tools and equipment

4. Storage

tool or 4. Tools and equipment to be

equipment for stored in a toolbox in or at the

the job stores when not in use.

5. Incorrect PPE: N/A.

storage of

tool or

equipment

Working at 1. Working at 1. Falling objects √ 4 3 H Elimination: N/A 3 2 M 3 Types of

heights and heights and 2. Trip and Fall over tools and Substitution: N/A tags is

climbing ladders climbing equipment Engineering Control: N/A available on

with tools and ladders with 3. Property damage 1. When Climbing ladders with a scaffold:

equipment: tools and 4. Injuries tools and equipment use 1. Red Tag -

1. Lanyards equipment 5. Fall from height approved toolbags (double Means the

2. Toolbags stitched without any metal scaffold is

3. Fish buckets baggles for strap support) in unsafe and

4. Certified order to secure tools and any access

manila rope with equipment. Remain 3 point is denied.

hook (as per contact at all times and do not No one is

Sasol spec) overload toolbags. Ensure allowed on

5. Fish bucket toolbags are properly closed to the

6. Tarpaulin before admitting to climb scaffold at

ladders and working on all.

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 9 of 16

platforms. Toolbags must be 2. Orange

safely secured out of the Tag - Means

walkways. Warn fellow there is

employees and people of falling modification

objects when climbing ladders. done and

2. When working at heights; not

barricade the floor area with classified as

solid orrange netting and place a safe

warning signs of falling objects scaffold.

and people working above in Any one

order to ensure that fellow who want to

people do not enter the red access the

zone area. Also warn people scaffold

working below you of falling must wear a

objects. certified

3. Use fish buckets for safety

placement of bolts, nuts, tools in harness and

use and equipment that are must be

being removed. 100% tie-off.

4. Use approved lanyards (tool There might

spiders) for the correct weight in be an

order to tie tools off when in missing

use. board or toe

5. Use lanyards on gratings and boards or

platforms (scaffolding) to cover what the

holes and ensure that tools, reason

bolts and nuts do not fall might be.

through openings) 3. Green

6. When equipment and tools Tag - Means

are exceeding the maximum the scaffold

weight of 20Kg or will cause a is safe for

risk when carrying; a competent use and its

employee must use a certified no need for

manila rope and softeners to lift fall

equipment or tools to the protection.

desired height were work will be

performed. Use a whistle when

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 10 of 16

lifting and lowering of

equipment and tools takes

place to warn fellow employees

of lifting danger and to stand

clear.

7. Working on temporary

structures such as scaffolding,

unsafe /high risk areas where

there is a potential risk for

falling, unstable platforms or on

top of ladders higher than the

3rd step; employees will wear a

certified and inspected harness

and be 100% tied down

(hooked). Only competent and

fit employees will be allowed to

work on heights and wear a

harness. Supervision to ensure

that employees are trained and

have the necessary WOH card

as proof with them at all times.

Admin ControlN/A

PPE: N/A.

Placement and 1. Equipment 1. Falling objects √ √ 4 4 E Elimination: N/A 3 2 M

Storage of not secured 2. Trip and Fall Substitution: N/A

equipment 2. No 3. Property damage Engineering Control: N/A

supervision 4. Injuries Admin Control

3. Poor 5. Employees taking shortcuts 1. Ensure that all equipment are

communicatio safely secured when being

n and unclear removed and placed for

instructions examination, maintenance,

repair or alterations in order not

to topple over or fall down

causing property damage and

injuries to people.

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 11 of 16

2. When removing equipment

from heights; the area at the

bottom must be clearly

barricaded and warning signs

displayed to warn people of the

red zone area. When working

above people; warm people of

falling object.

3. Remove all unused

equipment and tools in order to

prevent a congested area.

4. Only competent employees

to do lifting and lowering of

equipment.

All lifting equipment to be

inspected, on a register and

proof of valid certification from a

3rd party to be on hand. When

doing lifting and hoisting; use a

whistle in order to warn other

people of activity. 5.The

carrying of uneven shaped

equipment that are difficult to

carry or exceeding 20 Kg up or

down cat ladders are strictly

prohibited. (Small equipment

may be moved up and down the

cat ladders; provided that it is

secured in a tool bag and can't

fall out. Tool bags must not be

overloaded; instead more tool

bags should be utilized)

6. When placing equipment on

gratings use a tarpaulin

underneath to ensure that no

loose components or leaks

come down from the grating.

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 12 of 16

6. Supervision always to be

present with lifting activities in

order to ensure that equipment

are safely lifted and lowered,

secured when placed; out of

walkways and not in front of

emergency equipment.

7. Supervisors and employees

to ensure good communications

and clear instructions between

each other.

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control

Equipment All equipment to be inspected

Couple up: and Tools by a competent and appointed

connect wiring, (Use/Conditio Damage to equipment and property √ 3 3 H person before activity and 2 3 M

connect tubing n/Selection & removal of equipment. Only

Storage) competent people to perform

activity and supervision to be

present.

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Use correct tool and lifting

Injuries (Cut, Pinch, Trap) √ 3 3 H 2 3 M

equipment for the job.

Admin Control:N/A

PPE: N/A.

Falling Objects - when tools and lifting √ 4 3 H Elimination: N/A 3 2 M

equipment is no longer in use. Substitution: N/A

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 13 of 16

Engineering Control: N/A

Use lanyards when working with

tools, tarpaulins to cover the

whole area and tool bags that

are secured in order to store

tools and lifting equipment not

in use. Openings in gratings

must also be covered in such a

way that people cann't go

through it.

Admin Control;N/A

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control

Good Housekeeping practices

to be utilized.

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Incorrect Admin Control

commissionin Good communication between

Process failure / Explosions/Fire √ 4 3 H 2 2 M

g of management and employees

equipment when rigging and installing of

equipment.

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control

Only registered electrician and

competent employees to do

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 14 of 16

commissioning of equipment.

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control

Stop, think and act.

PPE: N/A.

Elimination: N/A

Substitution: N/A

Engineering Control: N/A

Admin Control

Good communication between

management and employees

Incorrect

when rigging and installing of

Do functional commissionin

Process failure / Explosions/Fire √ 4 3 H equipment. 2 2 M

check/calibration g of

Only registered electrician and

equipment

competent employees to do

commissioning of equipment

Stop, think and act.

PPE: N/A.

Assessment prepared by: L. Bezuidenhout

Approval by:

Designation and signature:

Name: S. Mangoato Date: Approval by: Rev No. 01

Designation and signature: Managing Director

Oil & Gas

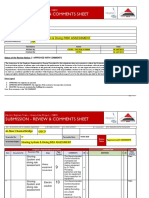

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 15 of 16

Hazard Class Rating Consequence

E – Extreme Insignificant Minor Moderate Major Catastrophic

H - Health

Risk

S - Safety H – High Risk 1 2 3 4 5

M – Medium

E - Environment

Risk Almost Certain 5 M H E E E Nobody

L – Low Risk Gets Hurt and

everybody

LIKELIHOOD

Likely 4 M H H E E goes home

Reviewed by: Sign: Date:

* Construction Manager safe and well

Possible 3 L M H H E

Reviewed by: Sign: Date:

* Project/ Site Manager

Unlikely 2 L M M H H

Reviewed by: Sign: Date:

HSSE Manager

Rare 1 L L L M M

Note: Communicate Risk Assessment to all people involved

RISK SCORE RISK LEVEL Guidelines for Risk Management

Immediate action required, activity must not start or be stopped if started. Senior management to be involved in approval to proceed. General manager /

15-25 E = EXTREME

project director / project manager to be involved in approval to proceed. Communication to the top management as required.

General manager / project director / project manager attention required to manage the impacts and ensure nominated controls are implemented and

8-14 H = HIGH meeting required objectives. Site / construction manager / office administration manager needs to be involved. Immediate action is required where

necessary. Manage by routine HSSE monitoring and inspections.

Site / construction manager / office administration manager attention required to manage the impacts and ensure nominated controls are implemented

4-7 M = MEDIUM

and meeting required objectives. Manage by routine HSSE monitoring and level 2 inspections.

Oil & Gas

REVISION: 01 DATE: APRIL 2024

DOCUMENT TITLE: CW-A15 REMOVING/REPLASING ALL VALVES HSE RISK ASSESSMENT SHEET PAGE: 16 of 16

1-3 L = LOW Identify aspects and implement the nominated controls to manage impacts. Manage by routine HSSE monitoring.

Oil & Gas

You might also like

- Risk Assessment For Testing & Commissioning of HVAC SystemDocument12 pagesRisk Assessment For Testing & Commissioning of HVAC SystemAnandu Ashokan75% (12)

- Radiography Work 004Document6 pagesRadiography Work 004BinayNo ratings yet

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- Risk Assessment For BridgeDocument31 pagesRisk Assessment For BridgeMariam Mousa100% (2)

- Risk Assessment For Noise Vibration Explosion and Fire 4Document1 pageRisk Assessment For Noise Vibration Explosion and Fire 4Ndifor Dinho50% (2)

- 125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتDocument3 pages125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتeng_hma75% (4)

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- TRA - CW-A01 - USING of TOOLSDocument15 pagesTRA - CW-A01 - USING of TOOLSvalveworkshseNo ratings yet

- TRA - CW-A12 - Use OF A TROLLEYDocument4 pagesTRA - CW-A12 - Use OF A TROLLEYvalveworkshseNo ratings yet

- HIRARC IBS Components Installation Rev 0Document21 pagesHIRARC IBS Components Installation Rev 0Suraindran ManoharanNo ratings yet

- Appendix 3 Risk Assessment of Post Fixed Rebar Drill & Fix With Chemical AnchorDocument13 pagesAppendix 3 Risk Assessment of Post Fixed Rebar Drill & Fix With Chemical Anchormohsin.meizaNo ratings yet

- Hirarc 2Document5 pagesHirarc 2dibhmNo ratings yet

- Hiradc For 36 Inch End FlangeDocument6 pagesHiradc For 36 Inch End FlangeMohd KhaidirNo ratings yet

- Hirarc 3Document6 pagesHirarc 3dibhmNo ratings yet

- Jesa FGDDocument26 pagesJesa FGDResearcherNo ratings yet

- Jesa-Construction of Chemical Storage Shelter For CPP RegenDocument28 pagesJesa-Construction of Chemical Storage Shelter For CPP RegenResearcherNo ratings yet

- Backfilling, Leveling RISK ASSESSMENTDocument6 pagesBackfilling, Leveling RISK ASSESSMENTVimal ViswanathNo ratings yet

- Risk Assessment - Sheet Piling DraftDocument8 pagesRisk Assessment - Sheet Piling DraftSinaNo ratings yet

- Gas Welding Risk AssessmentDocument8 pagesGas Welding Risk AssessmentvictorNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Risk Assesment For KerbstonesDocument11 pagesRisk Assesment For KerbstonesZain butt67% (3)

- Hirarc 1Document7 pagesHirarc 1dibhmNo ratings yet

- Risk Assessment For 4600002029Document213 pagesRisk Assessment For 4600002029Ows Anish67% (3)

- Wiac - Info PDF Jsa For Using Jack Hammer PRDocument3 pagesWiac - Info PDF Jsa For Using Jack Hammer PRmaiman.mzakiNo ratings yet

- HirarcDocument34 pagesHirarcBungsu HiperkesNo ratings yet

- Name Designation 1) Name: Name: Name: 2) Signature: Signature: Signature: 3) Date: Date: DateDocument34 pagesName Designation 1) Name: Name: Name: 2) Signature: Signature: Signature: 3) Date: Date: DateHarry Hasbullah100% (7)

- 103 Preparation For SeaDocument1 page103 Preparation For SeaMr-SmithNo ratings yet

- Appendix 5.1 JSA VCP Installation Rev 0Document17 pagesAppendix 5.1 JSA VCP Installation Rev 0BELLANo ratings yet

- 10 Damansara HIRARCDocument34 pages10 Damansara HIRARCTri Subakti50% (2)

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- Risk Assessment For All Activities - 9Document42 pagesRisk Assessment For All Activities - 9Sonu KrishnaNo ratings yet

- Co2 Cylinder House-JesaDocument24 pagesCo2 Cylinder House-JesaResearcherNo ratings yet

- Silo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment FormDocument9 pagesSilo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment Form891629100% (1)

- Rams TelehandlerDocument9 pagesRams TelehandlerRynoNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- RA For Tiling WorkDocument12 pagesRA For Tiling WorkSaeed AhmadNo ratings yet

- Block Work (Unit Masonary) RISK ASSESSMENTDocument8 pagesBlock Work (Unit Masonary) RISK ASSESSMENTVimal ViswanathNo ratings yet

- Shoring Systtem and Diving Riskassesment CommentsDocument5 pagesShoring Systtem and Diving Riskassesment CommentsMohamed Hasafy100% (1)

- CTRA-22-STM-133-TK-11-995 - CS-Cleaning-1st ENTRYDocument3 pagesCTRA-22-STM-133-TK-11-995 - CS-Cleaning-1st ENTRYMohamed RizwanNo ratings yet

- Plate Load Test RADocument5 pagesPlate Load Test RAmd rafiqueNo ratings yet

- Risk AssesmentDocument3 pagesRisk AssesmentShahd JaberNo ratings yet

- JSA - Anti Termite Treatment WorkDocument5 pagesJSA - Anti Termite Treatment WorkRaju Khalifa67% (3)

- Risk Assessment For Installation of Diesel Generator111111Document8 pagesRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- Activity Title Workshop: 1. Hazard Identification 2. Risk Analysis 3.risk ControlDocument10 pagesActivity Title Workshop: 1. Hazard Identification 2. Risk Analysis 3.risk ControlizzahNo ratings yet

- Risk Assesment @ro, WTP & STP PremDocument6 pagesRisk Assesment @ro, WTP & STP PremvarunthalariNo ratings yet

- Excavation Work RISK ASSESSMENTDocument8 pagesExcavation Work RISK ASSESSMENTVimal ViswanathNo ratings yet

- (General Scaffolding JRADocument7 pages(General Scaffolding JRA891629No ratings yet

- HIRARCDocument34 pagesHIRARCNaga Rajan100% (1)

- TRA - CW-A16 Disconnecting and Reconnecting of Motors and Associated EquipmentDocument9 pagesTRA - CW-A16 Disconnecting and Reconnecting of Motors and Associated EquipmentvalveworkshseNo ratings yet

- Tra 002Document6 pagesTra 002Bilal0% (1)

- Risk Assessment Form - KingGroveDocument12 pagesRisk Assessment Form - KingGroveeric chenNo ratings yet

- Building Materials Risk AssessmentDocument3 pagesBuilding Materials Risk AssessmentAhmed El-sherpiniNo ratings yet

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Document6 pagesRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008No ratings yet

- TRA - For Air Condition Prefab BuildingDocument8 pagesTRA - For Air Condition Prefab Buildingabdulhanan86457No ratings yet

- Risk AssessmentDocument6 pagesRisk AssessmentRenjith RaviNo ratings yet

- Risk AssesmentDocument4 pagesRisk AssesmentShahd JaberNo ratings yet

- 104 Preparation For Arrival at PortDocument1 page104 Preparation For Arrival at PortMr-SmithNo ratings yet

- Form 5.4a - Job Observation Control SheetDocument1 pageForm 5.4a - Job Observation Control SheetvalveworkshseNo ratings yet

- 71 - Intergrated-Checklist - Docx Version 1Document13 pages71 - Intergrated-Checklist - Docx Version 1valveworkshseNo ratings yet

- F-OHS-15 Incident Accident Investigation ReportDocument7 pagesF-OHS-15 Incident Accident Investigation ReportvalveworkshseNo ratings yet

- Am Ims-P007-Control of Documented InformationDocument15 pagesAm Ims-P007-Control of Documented InformationvalveworkshseNo ratings yet

- Corrective Action ReportDocument4 pagesCorrective Action ReportvalveworkshseNo ratings yet

- Kippap-Handout-MSTE 40 COSH 1Document16 pagesKippap-Handout-MSTE 40 COSH 1Jae HanNo ratings yet

- Katalog Hanex TerbaruDocument34 pagesKatalog Hanex TerbaruMeita RatrianaNo ratings yet

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument8 pagesMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationAuroraNo ratings yet

- 4190-6130c Primer SDSDocument15 pages4190-6130c Primer SDSKristin CarrereNo ratings yet

- Trifluoroacetic Acid - MSDS - 299537 PDFDocument8 pagesTrifluoroacetic Acid - MSDS - 299537 PDFBigbearBigbearNo ratings yet

- PPG 0580-9000 Thinners - SDS - 058090005Document16 pagesPPG 0580-9000 Thinners - SDS - 058090005crushergaming1804No ratings yet

- Mcop Managing Electrical Risks in The Workplace v3Document63 pagesMcop Managing Electrical Risks in The Workplace v3Aizaz KhanNo ratings yet

- Line of Fire Training SlidesDocument39 pagesLine of Fire Training SlidesSiraj UddinNo ratings yet

- LATICRETE 335 Super Flex TDSDocument4 pagesLATICRETE 335 Super Flex TDSDheeraj GuptaNo ratings yet

- URC Insulation For Ducting (SWMS)Document9 pagesURC Insulation For Ducting (SWMS)syed khaja misbhuddinNo ratings yet

- M01-Advanced ElectricalElectronic SystemsDocument111 pagesM01-Advanced ElectricalElectronic SystemsTariku Tesfaye100% (1)

- Benzalkonium Chloride Solution, 17% MSDS - Revision 09-09-08Document7 pagesBenzalkonium Chloride Solution, 17% MSDS - Revision 09-09-08New TubeNo ratings yet

- MSDS New CAUSTIC SODADocument6 pagesMSDS New CAUSTIC SODAAlves EdattukaranNo ratings yet

- Baracarb® 5Document9 pagesBaracarb® 5Nural MuradliNo ratings yet

- FICHA DE SEGURIDAD DE DE GRASA SANITARIA FM - CSC - EpDocument6 pagesFICHA DE SEGURIDAD DE DE GRASA SANITARIA FM - CSC - EpControl de Calidad MontefioriNo ratings yet

- 910X533 ActivatorDocument9 pages910X533 ActivatorNICKYNo ratings yet

- MSDS - 97050 - 55610 Curing AgentDocument12 pagesMSDS - 97050 - 55610 Curing AgentGanesh R NairNo ratings yet

- SDS - Olin - KOH - 30 - US - SDS - US - EnglishDocument8 pagesSDS - Olin - KOH - 30 - US - SDS - US - EnglishLuis Carbajal CusiNo ratings yet

- Tectyl Spin 10 (En-Ghs-K)Document14 pagesTectyl Spin 10 (En-Ghs-K)Irna WatiNo ratings yet

- MSDS Pc-AbsDocument8 pagesMSDS Pc-AbsEduardo GarzaNo ratings yet

- Material Safety Data Sheet: Mono Ethylene GlycolDocument4 pagesMaterial Safety Data Sheet: Mono Ethylene GlycolANURAG SHARMANo ratings yet

- Safety Data Sheet: Opt I KL een-WF™Document9 pagesSafety Data Sheet: Opt I KL een-WF™Richard ReedNo ratings yet

- JSA Form - Installation of ATS atDocument4 pagesJSA Form - Installation of ATS atDarren OscarNo ratings yet

- Epikuron 100 G MSDSDocument9 pagesEpikuron 100 G MSDSIbad MuhammedNo ratings yet

- Ferric Chloride HexahydrateDocument6 pagesFerric Chloride HexahydrateDust HooNo ratings yet

- MSDS Isopropyl AlcoholDocument12 pagesMSDS Isopropyl AlcoholrezaNo ratings yet

- Cat Hydraulic Oil AdditiveDocument9 pagesCat Hydraulic Oil AdditiveAylin Salgado AvilaNo ratings yet

- Safety Data Sheet: Product Name: Volvo Synthetic Gearbox Oil 97315Document10 pagesSafety Data Sheet: Product Name: Volvo Synthetic Gearbox Oil 97315Hendry PardedeNo ratings yet

- Msds 2-Hydroxy-2-Methylpropiophenone ENDocument8 pagesMsds 2-Hydroxy-2-Methylpropiophenone ENClaudio BiaginiNo ratings yet

- Job Safety AnalysisDocument39 pagesJob Safety Analysisandi fahrul faridNo ratings yet