Professional Documents

Culture Documents

Bu - 08 - 05 - 2024

Bu - 08 - 05 - 2024

Uploaded by

Hugo SantosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bu - 08 - 05 - 2024

Bu - 08 - 05 - 2024

Uploaded by

Hugo SantosCopyright:

Available Formats

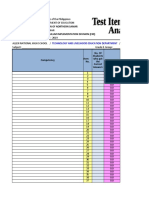

Daily Report CHPP II

Operational control room

08/05/2024 08/05/2024

D-1 Total Feed Coking Thermal Production Availability Utilization Feed Rate Coke yield Total Yield Up Time Ply ASH COKE Thermal Ash Moisture Coke

Plan: 68 000 t 11 696 t 12 716 t 24 412 t 97% 86% 3 400 t 17% 36% 20,0h BTA5 Target Done Target Done Target Done

Actual: 55 906 t 9 368 t 8 978 t 18 346 t 70% 89% 3 748 t 17% 33% 14,9h BTA5 10,5% 11,1% 32,0% 31,1% 13,0% 14,6%

CHPP Performance

(Up time) 0:00h 6:00h 12:00h 18:00h 23:59h

% Impacts by Sector

Mechanics 67%

Electrical 3%

Vulcanization 7%

Operation 21%

Mine 1%

Instrumentation 2%

TOP 5 WASH PLANT IMPACTS D-1 TIME KPI (Key Performance Indicator)

Modular Preventive Maintenance 19:55h Availability

High level on reject bin 10CBN01 and on overflow pile 5:16h Utilization

Blockage of reflux delivery line and desliming cyclones due to damaged sideliner on secondary crusher 02DSC01 3:55h Availability

Cutting Belt tear on coking conveyor 08CCV01 1:47h Availability

Cleaning and calibration of reflux classifier 5CRX201 1:41h Utilization

low feed rate 1:45h Feed rate

MODULE C1

D-1 Total Feed Coking Thermal Production Availability Utilization Feed Rate Coke yield Total Yield Up Time Ply

C1 Performance

Plan: 17 000 t 2 924 t 3 179 t 6 103 t 97% 86% 850 t 17% 36% 20,0h BTA5

(Up time)

0:00h 6:00h 12:00h 18:00h 23:59h

Actual: 19 006 t 3 185 t 3 052 t 6 237 t 94% 93% 904 t 17% 33% 21,0h BTA5

Vulcanization 39%

Operation 51%

Mine 3%

% Impacts by Sector

Instrumentation 7%

0%

0%

0%

0%

0%

0%

0%

0%

TOP 3 WASH PLANT IMPACTS D-1 TIME KPI (Key Performance Indicator)

High level on reject bin 10CBN01 and on overflow pile 1:07h Utilization

Cutting Belt tear on coking conveyor 08CCV01 0:46h Availability

Remotion of piece of metal on coking conveyor 08CCV01 0:22h Availability

Low density on dense medium circuit (02:01h) ; Low coal supply due to maintenance of PE4601 (00:50h) 3:41h Feed rate

MODULE C2

D-1 Total Feed Coking Thermal Production Availability Utilization Feed Rate Coke yield Total Yield Up Time Ply

C2 Performance

Plan: 17 000 t 2 924 t 3 179 t 6 103 t 97% 86% 850 t 17% 36% 20,0h BTA5

(Up time)

0:00h 6:00h 12:00h 18:00h 23:59h

Actual: 18 988 t 3 182 t 3 049 t 6 231 t 97% 86% 952 t 17% 33% 20,0h BTA5

Mechanics 11%

Operation 78%

Mine 2%

% Impacts by Sector

Vulcanization 3%

Instrumentation 6%

0%

0%

0%

0%

0%

0%

0%

TOP 3 WASH PLANT IMPACTS D-1 TIME KPI (Key Performance Indicator)

Cleaning and calibration of reflux classifier 5CRX201 1:41h Utilization

High level on reject bin 10CBN01 and on overflow pile 1:11h Utilization

Damaged panel and stringer on coarse reject screen 4CSC204 0:26h Availability

High level on reject bin 10CBN01 and on overflow pile (01:23h) ; Low coal supply due to maintenance of PE4601 (00:47h) 2:16h Feed rate

MODULE D1

D-1 Total Feed Coking Thermal Production Availability Utilization Feed Rate Coke yield Total Yield Up Time Ply

D1 Performance

Plan: 17 000 t 2 924 t 3 179 t 6 103 t 97% 86% 850 t 17% 36% 20,0h BTA5

(Up time)

0:00h 6:00h 12:00h 18:00h 23:59h

Actual: 2 260 t 379 t 363 t 742 t 17% 64% 869 t 17% 33% 2,6h BTA5

Mechanics 93%

Operation 7%

0%

% Impacts by Sector

0%

0%

0%

0%

0%

0%

0%

0%

0%

TOP 3 B1 IMPACTS D-1 TIME KPI (Key Performance Indicator)

Modular Preventive Maintenance 19:55h Availability

High level on reject bin 10CBN01 and on overflow pile 1:28h Utilization

Low density on dense medium circuit 0:00h Utilization

Low density on dense medium circuit (00:29h) ; (h) 0:29h Feed rate

MODULE D2

D-1 Total Feed Coking Thermal Production Availability Utilization Feed Rate Coke yield Total Yield Up Time Ply

D2 Performance

Plan: 17 000 t 2 924 t 3 179 t 6 103 t 97% 86% 850 t 17% 36% 20,0h BTA5

(Up time)

0:00h 6:00h 12:00h 18:00h 23:59h

Actual: 15 652 t 2 623 t 2 514 t 5 136 t 73% 92% 972 t 17% 33% 16,1h BTA5

Electrical 13%

Vulcanization 5%

% Impacts by Sector

Mechanics 18%

Operation 7%

Mine 0%

Instrumentation 1%

0%

0%

0%

0%

0%

0%

TOP 3 B1 IMPACTS D-1 TIME KPI (Key Performance Indicator)

Blockage of reflux delivery line and desliming cyclones due to damaged sideliner on secondary crusher 02DSC01 3:55h Availability

High level on reject bin 10CBN01 and on overflow pile 1:28h Utilization

Overcurrent on coking CM pump 4DPP206 1:05h Availability

High level on reject bin 10CBN01 and on overflow pile (00:27h) ; Inspection (00:08h) 0:35h Feed rate

PRODUCTION BUILD UP

COKING THERMAL

You might also like

- Wrestling Strength and ConditioningDocument12 pagesWrestling Strength and ConditioningTintin BilatbatNo ratings yet

- IB Prepared PsychologyDocument29 pagesIB Prepared PsychologyAlina Kubra100% (2)

- Sandra Brown Ostateca Lui HawkDocument22 pagesSandra Brown Ostateca Lui HawkAdel ChaabaneNo ratings yet

- Cheat Sheet - Redshift Performance OptimizationDocument17 pagesCheat Sheet - Redshift Performance OptimizationlbittencourtxavierNo ratings yet

- 495-Assignment-1-Frontsheet-1-đã chuyển đổi-đã gộp-đã nénDocument11 pages495-Assignment-1-Frontsheet-1-đã chuyển đổi-đã gộp-đã nénHưng Trần100% (1)

- Cii Ped 2020 r11Document39 pagesCii Ped 2020 r11S BNo ratings yet

- Upstream Weekly Report - 110121 DRAFTDocument2 pagesUpstream Weekly Report - 110121 DRAFTMarkyNo ratings yet

- Weekly Report Proteksi Petir #Minggu - 09 (OKI Pulp & Paper Mills)Document4 pagesWeekly Report Proteksi Petir #Minggu - 09 (OKI Pulp & Paper Mills)Kusnadi AnginNo ratings yet

- Ak Kit Assembly PPM Reduction: ©2015 Tecumseh Products CompanyDocument8 pagesAk Kit Assembly PPM Reduction: ©2015 Tecumseh Products CompanyphanikishoreburraNo ratings yet

- 1 PM 56K HOURS (The Running Hrs Now Exceeding 9758 HRS) 2 PM 56K HOURS (The Running Hrs Now Exceeding 944 HRS) 3Document2 pages1 PM 56K HOURS (The Running Hrs Now Exceeding 9758 HRS) 2 PM 56K HOURS (The Running Hrs Now Exceeding 944 HRS) 3Zaini SarbiniNo ratings yet

- Reliability Improvement of Coker Charge PumpDocument18 pagesReliability Improvement of Coker Charge Pumprachmadi adyNo ratings yet

- Helioscope Simulation 13776609 SummaryDocument3 pagesHelioscope Simulation 13776609 Summarytaibamalik457No ratings yet

- Davao - 09162022 - Grain TerminalDocument17 pagesDavao - 09162022 - Grain TerminalGaryl FebNo ratings yet

- Plastics Industry Workshop: Scott R. Kroeger General Manager Husky Injection Molding Systems, Inc. October 2004Document65 pagesPlastics Industry Workshop: Scott R. Kroeger General Manager Husky Injection Molding Systems, Inc. October 2004Ashish RaiNo ratings yet

- Review Mingguan Teknik SAI April 2019 6 April + WorsopDocument16 pagesReview Mingguan Teknik SAI April 2019 6 April + Worsopfattih19diwa_fdhNo ratings yet

- 2022 - Heapleach Pad C Stage 1 - Lev 1 Project Milestone (W3-Apr-22)Document4 pages2022 - Heapleach Pad C Stage 1 - Lev 1 Project Milestone (W3-Apr-22)rony 2222No ratings yet

- DPR-HUBCO WSCW - Vajihar Pipeline Project (09-Aug-2021)Document26 pagesDPR-HUBCO WSCW - Vajihar Pipeline Project (09-Aug-2021)Anwar TextilesNo ratings yet

- Shanghai Ifc Chiller Plant OptimizationDocument45 pagesShanghai Ifc Chiller Plant OptimizationYen NguyenNo ratings yet

- Upstream Weekly Report - 110114Document4 pagesUpstream Weekly Report - 110114MarkyNo ratings yet

- Upstream Weekly Report - 110121 (C1 Update)Document3 pagesUpstream Weekly Report - 110121 (C1 Update)MarkyNo ratings yet

- Country Presentation Sri LankaDocument9 pagesCountry Presentation Sri LankaDushNo ratings yet

- Helioscope Simulation 14242560 SummaryDocument3 pagesHelioscope Simulation 14242560 SummaryAlex Saul Villajuan ReyesNo ratings yet

- 7f Fact Sheet Product SpecificationsDocument1 page7f Fact Sheet Product SpecificationsFerdinandjaNo ratings yet

- Disclaimer: Building Energy Audits, Second Edition. These Resources Are Provided "As Is" Without Warranty of AnyDocument9 pagesDisclaimer: Building Energy Audits, Second Edition. These Resources Are Provided "As Is" Without Warranty of AnyFrancisco SalazarNo ratings yet

- Bio-Cel MCP: Mechanical Cleaning ProcessDocument6 pagesBio-Cel MCP: Mechanical Cleaning Processshah younisNo ratings yet

- CWEP Flash Report - 19 April Day ShiftDocument1 pageCWEP Flash Report - 19 April Day ShiftAjazuddin MohammedNo ratings yet

- Lh-Energy Distribution - 2021Document1 pageLh-Energy Distribution - 2021hongchuyenNo ratings yet

- Daily Report Installation: Description of Work in The FieldDocument2 pagesDaily Report Installation: Description of Work in The FieldAdeImanudinNo ratings yet

- Highlights of Loco Shed IzzatnagarDocument7 pagesHighlights of Loco Shed IzzatnagarShrish ShankhdharNo ratings yet

- S06 - Turbine LossesDocument116 pagesS06 - Turbine LossesAmore S100% (1)

- Hudabia Textile Unit-2Document3 pagesHudabia Textile Unit-2Osama AzizNo ratings yet

- Poweredge r750Document1 pagePoweredge r750bayasgalantuguldur.bNo ratings yet

- MEP Work StatusDocument44 pagesMEP Work StatusHamayet RaselNo ratings yet

- Workshop DJEBTKE-KESDM: Energy SharingDocument26 pagesWorkshop DJEBTKE-KESDM: Energy SharingIqbal MairiansyahNo ratings yet

- Helioscope Simulation 14296405 SummaryDocument3 pagesHelioscope Simulation 14296405 SummaryLuis Renato Vadillo GarciaNo ratings yet

- OEE (Overall Equipment Efectiveness) Enhancement Analysis Using The SMED (Single Minute Exchange Die) Method at Extruder Departement Tire ManufactureDocument25 pagesOEE (Overall Equipment Efectiveness) Enhancement Analysis Using The SMED (Single Minute Exchange Die) Method at Extruder Departement Tire ManufactureBudy AriyantoNo ratings yet

- Spectrum Simulacion Clinica Avidanti 20240305Document3 pagesSpectrum Simulacion Clinica Avidanti 20240305jefersontorogetialNo ratings yet

- 03d. Schubert, Usa (Ing)Document15 pages03d. Schubert, Usa (Ing)Jose AltamiranoNo ratings yet

- 1Q19 Presentation EECL VFDocument45 pages1Q19 Presentation EECL VFHelena AraujoNo ratings yet

- Rekapitulasi Downtime Mesin Converting & Laminasi Per September 2020Document260 pagesRekapitulasi Downtime Mesin Converting & Laminasi Per September 2020Ade AdeNo ratings yet

- AAST HRM Final Exam AnswerDocument24 pagesAAST HRM Final Exam AnswerMohamed RezkNo ratings yet

- QE Monthly Status Report - Oct - 2021 AutosavedDocument20 pagesQE Monthly Status Report - Oct - 2021 AutosavedMahadeva BogegowdaNo ratings yet

- Upstream Weekly Report - 110128Document3 pagesUpstream Weekly Report - 110128MarkyNo ratings yet

- P1113-Meranti Fortnightly Report Period 16-Aug To 28-Aug22 (No. 6) - UpdateDocument9 pagesP1113-Meranti Fortnightly Report Period 16-Aug To 28-Aug22 (No. 6) - Updateezuan ESVNo ratings yet

- PII Knowledge Sharing - Edo Raihan-FinalDocument92 pagesPII Knowledge Sharing - Edo Raihan-FinalDeddy LesmanaNo ratings yet

- Break Down Analysis: Aerosol Production Line RB SambaDocument20 pagesBreak Down Analysis: Aerosol Production Line RB SambaSumeet TrehanNo ratings yet

- Progress Report For SUW, BPE, HAZM, KHAB&MOSDocument3 pagesProgress Report For SUW, BPE, HAZM, KHAB&MOSDilip KumarNo ratings yet

- Helioscope Simulation 13233814 SummaryDocument3 pagesHelioscope Simulation 13233814 SummaryandisaputrawuNo ratings yet

- PLTS 10kW PT Torabika Eka Semesta Simulation ReportDocument3 pagesPLTS 10kW PT Torabika Eka Semesta Simulation ReportFerdi OfficeNo ratings yet

- Sr. No. Description: AL-KHALIQUE CNG Filling Station Estimated Cost of LandDocument36 pagesSr. No. Description: AL-KHALIQUE CNG Filling Station Estimated Cost of LandSaram WarraichNo ratings yet

- 229kw PDDP Tech DetailsDocument10 pages229kw PDDP Tech Detailsplantmanager.pddpcsNo ratings yet

- Roche Tina Quant Hba1C: Setting A New Precedent in Hba1C Lab EfficiencyDocument23 pagesRoche Tina Quant Hba1C: Setting A New Precedent in Hba1C Lab EfficiencyrezqiNo ratings yet

- Safety Measures During Oil Exploration & Drilling: DR Naveen RajDocument22 pagesSafety Measures During Oil Exploration & Drilling: DR Naveen RajRATHOD AKASHNo ratings yet

- Weekly Report Proteksi Petir #Minggu - 05 (OKI Pulp & Paper Mills)Document1 pageWeekly Report Proteksi Petir #Minggu - 05 (OKI Pulp & Paper Mills)Kusnadi AnginNo ratings yet

- Helioscope Simulation 13987880 SummaryDocument4 pagesHelioscope Simulation 13987880 Summaryg.arrietaNo ratings yet

- 01 17-10-04 Hybrid Traction SNCF Phclement FdegardinDocument19 pages01 17-10-04 Hybrid Traction SNCF Phclement FdegardinQayoom 789No ratings yet

- SummaryDocument3 pagesSummaryahmararshad420No ratings yet

- Che 4172 Final Poster 1Document1 pageChe 4172 Final Poster 1api-355877355No ratings yet

- Case Study Operating Revenue Costs Full Vrx1riemDocument16 pagesCase Study Operating Revenue Costs Full Vrx1riemmichaelfamura97No ratings yet

- Project Executive ReportDocument59 pagesProject Executive Reportroman reignsNo ratings yet

- Productivity Improvement Report Goal: DL Percentage Cost 43% To 35%Document4 pagesProductivity Improvement Report Goal: DL Percentage Cost 43% To 35%Larzen de OcampoNo ratings yet

- 33 DwgreeDocument3 pages33 DwgreeengrwaleedashrafNo ratings yet

- LMS100 Power PlantsDocument2 pagesLMS100 Power PlantsMiladAmaniNo ratings yet

- Standardization Daily ReportDocument2 pagesStandardization Daily ReportIndra Abdi WardanaNo ratings yet

- Microturbines: Applications for Distributed Energy SystemsFrom EverandMicroturbines: Applications for Distributed Energy SystemsRating: 5 out of 5 stars5/5 (1)

- TT2 - 2.8 OptimizersDocument63 pagesTT2 - 2.8 OptimizershalodosNo ratings yet

- Invertec V160S & V160 TP PDFDocument60 pagesInvertec V160S & V160 TP PDFIron MaskNo ratings yet

- Penerapan Kurikulum ThailandDocument26 pagesPenerapan Kurikulum ThailandRAAR GamingNo ratings yet

- Project Report On DYEING OF FabricsDocument2 pagesProject Report On DYEING OF FabricsChasity ColeNo ratings yet

- Gde GC Consumables MasterDocument36 pagesGde GC Consumables MastersatishNo ratings yet

- Job Safety Analysis and Risk AssessmentDocument9 pagesJob Safety Analysis and Risk AssessmentWK PangNo ratings yet

- 50 Tips For Designing Constructable Steel Buildings Q and A PDFDocument15 pages50 Tips For Designing Constructable Steel Buildings Q and A PDFYoussef AliNo ratings yet

- Potensi Daur Ulang Sampah Upacara Adat Di Pulau Bali: Jurnal EcocentrismDocument8 pagesPotensi Daur Ulang Sampah Upacara Adat Di Pulau Bali: Jurnal Ecocentrismdaffa pratamaNo ratings yet

- A5c10y0 F000 G20 42 501 Checksum 0581Document7 pagesA5c10y0 F000 G20 42 501 Checksum 0581Craici LauraNo ratings yet

- SLK Math 10 Q1W2 Arithmetic Sequence and Arithmetic MeansDocument17 pagesSLK Math 10 Q1W2 Arithmetic Sequence and Arithmetic MeansAlaisa Claire Dela TorreNo ratings yet

- Division of Northern Samar Curriculum Implementation Division (Cid)Document8 pagesDivision of Northern Samar Curriculum Implementation Division (Cid)gener r. rodelasNo ratings yet

- Answer Key For Grade 10 English - Test Series 1Document6 pagesAnswer Key For Grade 10 English - Test Series 1Chahak JainNo ratings yet

- Woubet GashawDocument101 pagesWoubet GashawAbdilbasit HamidNo ratings yet

- PESU BTech Jan2017 6thsemCourseInfoDocument51 pagesPESU BTech Jan2017 6thsemCourseInforakshithrajNo ratings yet

- Psychological StatisticsDocument6 pagesPsychological StatisticsMarielle Francisco0% (1)

- Brachistochrone Problem Inside The Earth Revisited: Motohiko SaitohDocument4 pagesBrachistochrone Problem Inside The Earth Revisited: Motohiko SaitohFlor Hernandez TiscareñoNo ratings yet

- 7.3 Extending Skills: ExampleDocument1 page7.3 Extending Skills: ExampleDavid SavenNo ratings yet

- Descriptive Text MaterialsDocument2 pagesDescriptive Text MaterialsAyin Katili100% (1)

- Workshop Equipment MM 2013 PDFDocument86 pagesWorkshop Equipment MM 2013 PDFBaciu NicolaeNo ratings yet

- Hybrid Robot Design - PBenTzviDocument13 pagesHybrid Robot Design - PBenTzviIvan AvramovNo ratings yet

- Class A3A1Document20 pagesClass A3A1SalimNo ratings yet

- Process, CPK: Capability IndexDocument4 pagesProcess, CPK: Capability IndexMohini MaratheNo ratings yet

- Thomas L. Pazdernik, Laszlo Kerecsen-Rapid Review Pharmacology, 3rd Edition-Mosby (2010)Document784 pagesThomas L. Pazdernik, Laszlo Kerecsen-Rapid Review Pharmacology, 3rd Edition-Mosby (2010)dtech2No ratings yet

- Audit Plan Djabestment PDFDocument3 pagesAudit Plan Djabestment PDFSHE DTUNo ratings yet