Professional Documents

Culture Documents

JSP For SS No. 37 Backfilling and Compaction

JSP For SS No. 37 Backfilling and Compaction

Uploaded by

V Srinivas Prasad RaoCopyright:

Available Formats

You might also like

- Field Report at TIADocument36 pagesField Report at TIAOmaryMakalle65% (26)

- Jsa For HydrotestDocument10 pagesJsa For HydrotestAnonymous CcGYhZb080% (5)

- Jha For Batching Plant OprationDocument7 pagesJha For Batching Plant Oprationpoovazhagan80% (5)

- Barangay ListDocument22 pagesBarangay ListAnonymous FqiIrcf100% (2)

- Installation of Copper Pipes and Fittings.: Barq Group Risk AssessmentDocument8 pagesInstallation of Copper Pipes and Fittings.: Barq Group Risk AssessmentYousaf Richu75% (4)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (2)

- DOD - MST-INSU-007 (Rev-A) - FOAM INJECTION FOR VALVES AND FLANGES ON COLD INSULATION WORKDocument7 pagesDOD - MST-INSU-007 (Rev-A) - FOAM INJECTION FOR VALVES AND FLANGES ON COLD INSULATION WORKProfessional Trust100% (1)

- JSP For SS 9013 No. JSP#04 Cutting and Bending of Steel Reinforcement BarsDocument8 pagesJSP For SS 9013 No. JSP#04 Cutting and Bending of Steel Reinforcement BarsAbdul Rasheed Mangrio100% (1)

- JSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentDocument10 pagesJSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentAbdul Rasheed Mangrio50% (2)

- Page - 1: (In Sequence) (Injuries, Damage, Illness, Pollution, Etc)Document10 pagesPage - 1: (In Sequence) (Injuries, Damage, Illness, Pollution, Etc)shafiezubier5No ratings yet

- JSP For SS 9013 No. JSP#03 Excavation Using Electrical Jack HammerDocument11 pagesJSP For SS 9013 No. JSP#03 Excavation Using Electrical Jack HammerAbdul Rasheed MangrioNo ratings yet

- OHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelDocument9 pagesOHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelEbrahsm ElshenawyNo ratings yet

- JSP For SS No. 7 PACU InstallationDocument13 pagesJSP For SS No. 7 PACU InstallationJaafar LagayanNo ratings yet

- JSP For SS No. 8 Installation of EOT CraneDocument28 pagesJSP For SS No. 8 Installation of EOT CraneJaafar LagayanNo ratings yet

- JSP For SS No. 4 Commissioning of High Voltage EquipmentDocument21 pagesJSP For SS No. 4 Commissioning of High Voltage EquipmentmohammedtofiqahmedNo ratings yet

- JSP For SS No. 1 Battery Charging and TestingDocument11 pagesJSP For SS No. 1 Battery Charging and TestingmohammedtofiqahmedNo ratings yet

- JSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)Document16 pagesJSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)mohammedtofiqahmedNo ratings yet

- JSP For SS No. 5 Tower Crane InstallationDocument15 pagesJSP For SS No. 5 Tower Crane InstallationmohammedtofiqahmedNo ratings yet

- Job Safety SiteDocument11 pagesJob Safety SiteMohd Arfeen RezaNo ratings yet

- JSP For SS No. 3 Lifting of Heavy Equipment Using CraneDocument14 pagesJSP For SS No. 3 Lifting of Heavy Equipment Using CranemohammedtofiqahmedNo ratings yet

- Ohs-Pr-09-03-F07 (A) JSP No. 46 Cable PullingDocument16 pagesOhs-Pr-09-03-F07 (A) JSP No. 46 Cable PullingbilalgradioshNo ratings yet

- JSP For SS No. 2 GIS-GIB-Swithgear InstallationDocument19 pagesJSP For SS No. 2 GIS-GIB-Swithgear InstallationmohammedtofiqahmedNo ratings yet

- JSP For SS No. 9 Filling of Battery Fluid Inside Battery RoomDocument15 pagesJSP For SS No. 9 Filling of Battery Fluid Inside Battery RoomJaafar LagayanNo ratings yet

- JSP For SS No. 42 Line Stability Test (JD-RDS BB-1 PMD 110 KV)Document11 pagesJSP For SS No. 42 Line Stability Test (JD-RDS BB-1 PMD 110 KV)Mohd Arfeen RezaNo ratings yet

- JSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaDocument11 pagesJSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaJaafar LagayanNo ratings yet

- JSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsDocument10 pagesJSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsJaafar LagayanNo ratings yet

- 8.JSP No.30 Hydro Testing of Gas Pipe LineDocument9 pages8.JSP No.30 Hydro Testing of Gas Pipe LineabbasNo ratings yet

- JSP For OHTL No. 12 Jumper Installation WorksDocument13 pagesJSP For OHTL No. 12 Jumper Installation WorksJaafar LagayanNo ratings yet

- JSP For OHTL No. 17 Underline Gantry Installation and ErectionDocument15 pagesJSP For OHTL No. 17 Underline Gantry Installation and ErectionJaafar LagayanNo ratings yet

- JSP For OHTL No. 15 Erection of Common Body StructureDocument14 pagesJSP For OHTL No. 15 Erection of Common Body StructureJaafar LagayanNo ratings yet

- JSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyDocument10 pagesJSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyJaafar LagayanNo ratings yet

- JSP For Communication Local TestDocument8 pagesJSP For Communication Local TestJaafar LagayanNo ratings yet

- JSP For OHTL No. 16 Erection of Upper Body StructureDocument14 pagesJSP For OHTL No. 16 Erection of Upper Body StructureJaafar Lagayan100% (1)

- JSA For Erection of Precast..Document18 pagesJSA For Erection of Precast..Shafie ZubierNo ratings yet

- PS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)Document27 pagesPS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)RABIE EL MAGHWRY ABDELKHALEK ELGHAMRY0% (1)

- JSP For Open Loop Close Loop Test For Protection PanelDocument9 pagesJSP For Open Loop Close Loop Test For Protection PanelJaafar LagayanNo ratings yet

- JSP For Electrical Test (End To End Test)Document8 pagesJSP For Electrical Test (End To End Test)Jaafar LagayanNo ratings yet

- STL Varun Ehs M A02 Hira R0Document6 pagesSTL Varun Ehs M A02 Hira R0lsm projectNo ratings yet

- 7 - Dewatering of Rain Water From Compression Project AreaDocument4 pages7 - Dewatering of Rain Water From Compression Project AreaAijaz AhmedNo ratings yet

- Permit To Work Ref TemplateDocument2 pagesPermit To Work Ref Templatenatamas systemsNo ratings yet

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- JSA Excavation For Lighting Pole FoundationDocument18 pagesJSA Excavation For Lighting Pole FoundationMohammad Al Masa'deh100% (1)

- 0081 To Install Protective Canvas On Pick Up Line For Export Hose Via Rope AccessDocument6 pages0081 To Install Protective Canvas On Pick Up Line For Export Hose Via Rope AccessShoresafe ConsultingNo ratings yet

- Jsa Panel SullayilDocument6 pagesJsa Panel SullayilthennarasuNo ratings yet

- NEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalDocument15 pagesNEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalKarthik babuNo ratings yet

- 1 RA Water Works (Revised)Document21 pages1 RA Water Works (Revised)Muhammad Shahid Iqbal0% (1)

- JSP For Installation of AC-DC PanelsDocument11 pagesJSP For Installation of AC-DC PanelsAbdulsalam AneezeNo ratings yet

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- DOD-JHA-040A (Rev-C) Night Shift WorkDocument9 pagesDOD-JHA-040A (Rev-C) Night Shift WorkMohammedNo ratings yet

- JSP For Grounding Grid InstallationDocument11 pagesJSP For Grounding Grid InstallationAbdulsalam AneezeNo ratings yet

- Eepsp Ra Swro 003 - 00aDocument9 pagesEepsp Ra Swro 003 - 00afayaz5233No ratings yet

- Job Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantDocument9 pagesJob Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantZia ur RehmanNo ratings yet

- DOD-MST-EQ-025 (Rev-C) RE-COATING OF FLARE DERRICKDocument5 pagesDOD-MST-EQ-025 (Rev-C) RE-COATING OF FLARE DERRICKMohammedNo ratings yet

- JSP For Installation of Cable TrayDocument11 pagesJSP For Installation of Cable TrayAbdulsalam AneezeNo ratings yet

- OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE TF-00877 Mobilization and Preparation of Site OfficesDocument11 pagesOHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE TF-00877 Mobilization and Preparation of Site OfficesRAI AHTESHAM HaiderNo ratings yet

- Manual Excavation For Identified Depth and Elevation of Existing PipelineDocument15 pagesManual Excavation For Identified Depth and Elevation of Existing PipelineshahbazchafekarNo ratings yet

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehNo ratings yet

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- JSP For Installation of Capacitor BankDocument12 pagesJSP For Installation of Capacitor BankAbdulsalam AneezeNo ratings yet

- Government of Tamil Nadu: Department of Employment and Training (Training Wing)Document75 pagesGovernment of Tamil Nadu: Department of Employment and Training (Training Wing)SanjaiNo ratings yet

- Berkenkotter v. CADocument5 pagesBerkenkotter v. CAjealousmistressNo ratings yet

- Cayanan Vs North StarDocument2 pagesCayanan Vs North StarMosarah AltNo ratings yet

- (A) Implementation of ABCDocument4 pages(A) Implementation of ABCMalik Asim AzizNo ratings yet

- SAP CO Useful TablesDocument28 pagesSAP CO Useful Tableskcshiong100% (1)

- Digital Signatures OverviewDocument40 pagesDigital Signatures OverviewrajusampathiraoNo ratings yet

- Formulation, Implementation, and Control of Competitive StrategyDocument11 pagesFormulation, Implementation, and Control of Competitive StrategyWam OwnNo ratings yet

- G4-T6 How To Use Moving Average Crossovers To Enter TradesDocument4 pagesG4-T6 How To Use Moving Average Crossovers To Enter TradesThe ShitNo ratings yet

- Print Rumus ModelDocument1 pagePrint Rumus ModelArianto PardedeNo ratings yet

- Departmental Interpretation and Practice Notes No. 7 (Revised)Document33 pagesDepartmental Interpretation and Practice Notes No. 7 (Revised)Difanny KooNo ratings yet

- Role of MNC in IndiaDocument41 pagesRole of MNC in IndiaKhundongbam SureshNo ratings yet

- Tally - ERP 9: Settle Multiple Bills Through Bill Settlement in Tally - ERP 9Document5 pagesTally - ERP 9: Settle Multiple Bills Through Bill Settlement in Tally - ERP 9Kashif KhanNo ratings yet

- Declining SuratDocument34 pagesDeclining Suratvaishalitadvi053No ratings yet

- CWTSDocument19 pagesCWTSjoshNo ratings yet

- Production TheoryDocument72 pagesProduction TheoryAnirudh Dutta100% (1)

- List of Numbers To Block and AvoidDocument48 pagesList of Numbers To Block and Avoidmutiara912No ratings yet

- Cash DepartmentDocument2 pagesCash DepartmentTaimur ZiaNo ratings yet

- Pengaruh Ukuran Perusahaan Dan Corporate Governance Terhadap Manajemen Laba Di Industri Perbankan IndonesiaDocument16 pagesPengaruh Ukuran Perusahaan Dan Corporate Governance Terhadap Manajemen Laba Di Industri Perbankan IndonesiaJessica AnggiNo ratings yet

- PED and CE MarkingDocument4 pagesPED and CE Markingdhanu_aquaNo ratings yet

- 4 - Asari Yoko Co., Ltd. v. Kee BocDocument2 pages4 - Asari Yoko Co., Ltd. v. Kee BocnathNo ratings yet

- Fiat SDocument27 pagesFiat SAzizul AnwarNo ratings yet

- Notice: Notice of Investigation: Certain Liquid Crystal Display Modules, Products Containing Same, and Methods For Using The SameDocument1 pageNotice: Notice of Investigation: Certain Liquid Crystal Display Modules, Products Containing Same, and Methods For Using The SameJustia.comNo ratings yet

- Legal and Public Policy Considerations For Product PlanningDocument17 pagesLegal and Public Policy Considerations For Product PlanningprincekamutikanjoreNo ratings yet

- Tax Invoice: Rekha Indane Gramin VITRAK (0000270706)Document2 pagesTax Invoice: Rekha Indane Gramin VITRAK (0000270706)sujeet sharmaNo ratings yet

- Arrow Delivery Services: Date Particulars PR. Debit (DR)Document4 pagesArrow Delivery Services: Date Particulars PR. Debit (DR)Jihane TanogNo ratings yet

- Oj C 2016 272 Full en TXTDocument156 pagesOj C 2016 272 Full en TXTpluto14No ratings yet

- Indian Companies IILF Chennai 2019Document106 pagesIndian Companies IILF Chennai 2019raghunath670743No ratings yet

- Types of Advertising MediaDocument6 pagesTypes of Advertising MediaspdwibediNo ratings yet

JSP For SS No. 37 Backfilling and Compaction

JSP For SS No. 37 Backfilling and Compaction

Uploaded by

V Srinivas Prasad RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSP For SS No. 37 Backfilling and Compaction

JSP For SS No. 37 Backfilling and Compaction

Uploaded by

V Srinivas Prasad RaoCopyright:

Available Formats

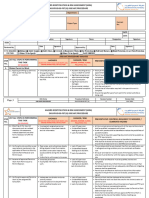

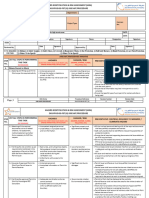

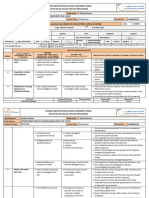

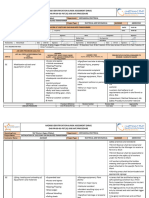

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

Operating Area: CENTRAL Department: PDC

Project Name: Construction of 132/13.8kV Substation # 8387 and Ext. 132kV GIS at S/S # 8164 & S/S # 8219

Contractor Name: NESMA Project Type: SUBSTATION Contract No.: 4400015504

JOB/TASK TYPE: Backfilling and Compaction DATE: 24/01/2023

JOB SAFETY PROCEDURE N0: 37 COMPILED BY: Abdul Wahab DATE: 24/01/2023

Name Designation Signature Name Designation Signature

HIRA Civil Engineer Qc. Civil Engr.

TEAM

Sub Con Civil Engineer Safety Officer

Reviewed by: Md Safiullah Date: 24-01-23 Signature: Approved by: Fahad Almehmadi Date: 24-01-23 Signature:

P.P.E. REQUIRED ☐ Helmet, ☐ Safety Goggles, ☐ Safety Shoes, ☐ Coverall, ☐ Respiratory Musk, ☐ Ear Protection, ☐ Full body Harness, ☐ Hand Protection, ☐ Arc Flash Protection, ☐

FOR TASK: Others To be Specify: __________________________, ☐ Others To be Specify: __________________________

JOB SAFE PROCEDURE ANALYSIS

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

1. Obtain Permit to Work

OHS Forms Procedure Reference Revision Number Revision Date

Page | 1 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

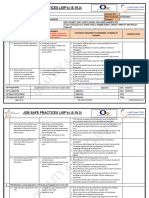

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

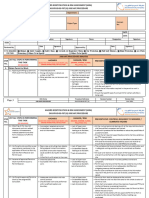

1.1. Applying and filling-up permit

● Untrained personnel. ● Accident resulting ● Work permit receiver and issuer must be identified and with an

to Work as per the required

serious injury or death appointment letter.

activity. ● Wrong information or details are to worker

written in the PTW. ● Permit Issuer and Receiver must be qualified, trained and

● Significant property and

competent.

● Other activities may not be cover appurtenances damage

with the PTW. ● Work permit system shall be properly implemented as per the

● Loss of production

SEC 5 Star Safety standard and work permit procedure.

● Significant cost due to

damages ● Ensure that all activities and the safety precautions are covered

● Governmental violation with the work permit.

● Ensure that all information required in the permit to work is

● Environmental

complaint complete.

● Ensure that specific type of work permit for certain activities is

being used.

1.2. Attaching all the required

● Incompetent assigned personnel. ● Lack of Supervision ● All the involved personnel dealing with all the required

documents such as a related

● Unidentified Hazards documents shall be qualified, competent and trained.

checklist, risk assessment, ● Unidentified or incomplete hazards

method statement and other and risk information. leading to an Accident. ● A safe work practice shall be identified to reduce the possibilities

forms necessary to fulfill the ● Lack of productivity of accident/incident.

request.

● Ensure that all required supporting documents shall be available

as per PTW requirements.

● All the required related documents as identified to be attached in

PTW shall be reviewed and evaluated by issuer and receiver to

ensure that all hazard and risk is identified and complete.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 2 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

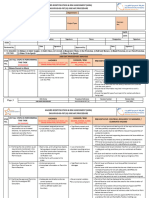

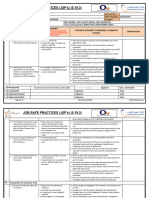

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

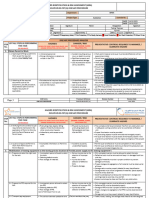

1.3. Verifying the site condition as

● Open areas, protruding sharp ● Lack of Supervision ● The workplace shall be pre-checked, free from any obstruction

per requirements mentioned in

objects, falling objects limited ● Unidentified Hazards and in safe good working condition prior to a combined

the application of Permit to

illuminations and other leading to an Accident. verification visit.

Work by both the Permit

construction hazards may cause

Receiver and Permit Issuer. ● Lack of productivity ● All Issuer and receiver must be aware of the hazard present in the

accidents during the verification

area and must be familiar with the ingress and egress of the

visit.

project site.

● Unfamiliarity with access to the

areas.

1.4. Issuance of approved Permit to

● Untrained personnel. ● Lack of Supervision ● Permit Issuer and Receiver must be qualified, trained and

Work from Permit Issuer to

● Unidentified Hazards competent.

Permit Receiver. ● Incomplete information on Permit

to work. leading to an Accident. ● Permit Issuer shall ensure that the site was visited to ensure that

Lack of productivity

workplace hazards and risk are adequately identified and

mitigating measure shall be established.

● Permit Issuer and Receiver shall ensure that all the information

required in the permit to work are reviewed, completed and

signed.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 3 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

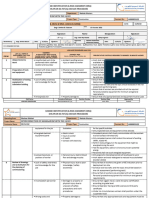

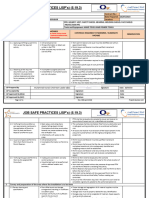

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

1.5. Verifying the approved Permit

● Inadequate coordination and area ● Lack of Supervision ● Permit to Work shall be displayed at the worksite

to Work by the assigned SEC

control protocol. ● Unidentified Hazards

Consultant. ● Permit Receiver shall not leave the area for the whole duration of

● Unauthorized work to be leading to an Accident. permit to work.

performed within a defined ● Lack of productivity

● Work shall not proceed without the presence of approved PTW

location and boundary.

and the Permit Receiver overseeing the activity.

● Permit Receiver shall account all workers under his Permit to

Work before the start of work.

● Work shall not be started until duly approved Permit to Work is

available at the site and that Safety Toolbox meeting was

conducted.

● Ensure all the information required in the permit to work shall be

completed, signed and updated by the authorized personnel.

2. Mobilization of equipment and dump truck filled with backfilling materials.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 4 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

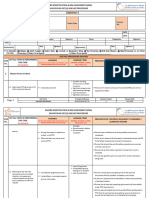

2.1 Mobilize heavy equipment to • Damage to property once

● Congestion due to other ground ● Proper planning and survey of the route to be taken by the

the site such as skid loader, the equipment toppled.

activity. equipment.

roller compactor. • Equipment breakdown

● Blindspot for operator during can cause by the stiff ● Planning and survey to determine the exclusion zone for the

maneuvering. access activity.

• Entry of unskilled

● Unauthorized personnel. employee can result in ● Exclusion zone to be barricaded and signage posted.

emergency situation due to

● Inexperienced or untrained ● Proper coordination with other working teams who will be

unfimilarization with safe

personnel. working procedures & affected by the mobilization of equipment.

● Equipment’s poor condition. emergency protocols. ● No unauthorized personnel or not part of the team shall be

allowed on the working area.

● Uneven pavement or ground.

● Verification of operator’s third-party certification prior start of

● Nearby structures that may

the activity.

obstruct the mobilization.

● Verification of equipment’s third-party certification.

● All equipment must be thoroughly physically inspected and

ensure that in good working condition.

● Assign flagman and spotter to assist the operator and control

traffic on the area.

● Survey of the route for uneven and un-compacted ground.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 5 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

2.2 Mobilize dump truck filled with • Damage to property once

● Area congestion due to other on- ● Proper planning and survey of the route to be taken by the

backfilling materials. the equipment toppled.

going activity. equipment.

• Equipment breakdown

● Blindspot for the operator. can cause by the stiff ● Proper coordination with other working teams who will be

access affected by the mobilization of equipment.

● Unauthorized personnel. • Entry of unskilled

employee can result in ● No unauthorized personnel or not part of the team shall be

● Inexperienced or untrained

emergency situation due to allowed on the working area.

personnel. unfimilarization with safe ● Verification of driver’s government driving license prior start of

● Equipment’s poor condition. working procedures &

emergency protocols. the activity.

● Uneven and/or un-compacted ● All equipment must be thoroughly physically inspected and

ground. ensure that in good working condition.

● Nearby structures that may cause ● Assign flagman and spotter to assist the operator and control

obstruction. traffic on the area.

● Unsecured cargo / materials. ● Survey of the route for uneven and un-compacted ground.

● Ensure that tailgate is securely locked.

● Materials to be secured with nets/screen or other applicable

materials to prevent from overflowing or spilling.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 6 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

2.3 Position the dump truck on a • Vehicular accident result

● Unassisted maneuvering of the ● No unauthorized personnel or not part of the team to be allowed

strategic location that is in injury to personnel and

dump truck. on the exclusion zone.

accessible to other related property damage of

equipment. ● Unauthorized personnel. adjacent structure or ● Ensure barricade and signage are maintained within the

appurtenances perimeter.

● Incompetent personnel. • Entry of unskilled

employee can result in ● Strategic planning for the location of the dump truck to be

● Uneven and/or un-compacted

emergency situation due to positioned for easy access to other related equipment.

ground. unfimilarization with safe ● Dump truck driver to be assisted by spotter or flagman while

working procedures &

emergency protocols. maneuvering and positioning.

● Only trained and authorized personnel shall be assigned and

performing the activity.

● Verification that grounds are properly compacted and leveled.

2.4 Dump backfilling materials. • Vehicular accident result

● Abrupt operation (dumping). ● Ensure that no unauthorized personnel or not part of the team in

in injury to personnel and

the area.

● Accumulation of dust. property damage of

adjacent structure or ● Driver/operator to slowly tilt the truck’s bed for the gradual

● Unauthorized personnel. appurtenances release of backfilling materials.

Respiratory irritation

● All personnel must be equipped with the appropriate type of dust

mask and safety glass.

2.5 Prepare and select the right • Muscular injuries (back

● Ergonomics (overreaching of ● Proper storage and segregation of all material must be observed

tools for the manual task and pain, strain, fractures)

materials). at all times.

mobilize to the worksite. • pinch/crash points

● Improper manual handling. resulting hand injuries ● Storage racks must be properly labeled for easy identification.

● Unorganized or poor storage of ● Storage areas must not be congested of materials. Space capacity

materials. must be strictly observed.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 7 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

● Area congestion / limited space. ● Good housekeeping must always be maintained in storage and

working areas to avoid slip, trip, and fall.

● Contact with sharp edges.

● Access must always be clear and free from any obstruction.

● Poor housekeeping.

● The worker shall lift materials closer to the body and load shall

not exceed half of the worker's weight.

● Large materials shall be carried by a minimum of two people.

● Use of proper and appropriate PPE must always be observed.

3. Soil backfilling using dump truck and skid load.

3.1 Dump the backfilling materials • Vehicular accident result

● Unassisted maneuvering of ● A dump truck to be assisted by spotter or flagman during

on a strategic location. in injury to personnel and

equipment. maneuvering.

property damage of

● Area congestion due to vehicle and adjacent structure or ● Ensure a safe distance of dump truck from excavation edge to

personnel movement. appurtenances avoid disturbance of excavation walls.

• Serious accident that may

● The positioning of equipment near result to severe injury or ● No unauthorized personnel or not part of the team shall be

the excavation. property damage allowed on the work area.

● Dust accumulation. ● All personnel must be equipped with the appropriate type of dust

mask and safety glass.

● Unauthorized personnel.

● Only trained and competent personnel shall be assigned on the

● Incompetent personnel.

activity.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 8 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

3.2 Spread backfilling materials • Vehicular accident result

● Incompetent personnel. ● Verification of operator’s third-party certification.

with the skid loader. in injury to personnel and

● Equipment’s poor condition. property damage of ● Verification of equipment’s third-party certification.

adjacent structure or

● Unauthorized personnel. appurtenances ● Equipment must be thoroughly inspected and ensure in good

• Serious accident that may working condition prior to deployment and utilization for the

● Maneuvering of equipment.

result to severe injury or activity.

● Dust accumulation. property damage

● Spotter to assist equipment during maneuvering.

● No proper access and egress. ● Ensure that the excavation wall will not be disturbed during the

● Extreme weather condition. operation.

● No unauthorized personnel or not part of the team shall be

allowed on the work area.

● All personnel must be equipped with the appropriate type of dust

mask and safety glass.

● Proper access to be provided.

● Continuous monitoring of weather condition.

● Sufficient break time and rehydrating drinks to be provided

during hot weather condition.

● Provision of resting shelter for all workers.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 9 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

3.3 Push the material back and • Vehicular accident result

● Incompetent personnel. ● Verification of operator’s third-party certification.

forth to level the surface. in injury to personnel and

● Equipment’s poor condition. property damage of ● Verification of equipment’s third-party certification.

adjacent structure or

● Unauthorized personnel. appurtenances ● Equipment must be thoroughly inspected and ensure in good

• Serious accident that may working condition prior to deployment and utilization for the

● Unassisted maneuvering of

result to severe injury or activity.

equipment. property damage

● Spotter to assist equipment during maneuvering.

● Dust accumulation.

● Ensure that the excavation wall will not be disturbed during the

● Extreme weather condition.

operation.

● No unauthorized personnel or not part of the team shall be

allowed on the work area.

● All personnel must be equipped with the appropriate type of dust

mask and safety glass.

● Continuous monitoring of weather condition.

● Sufficient break time and rehydrating drinks to be provided

during hot weather condition.

● Provision of resting shelter for all workers.

3.4 Level some surface manually

● Ergonomics (awkward posture and ● Ensure that correct type of tools will be used for the activity (i.e.,

with a shovel. • Muscular injuries (Back

repetitive movement). with long handle shovel).

pain, strain, fractures)

● Exposure to dust. • Vehicular accident result ● All tools must be thoroughly inspected and in good working

in injury to personnel and condition.

● No proper access and egress. property damage of

adjacent structure or ● Workers must be equipped with the appropriate type of dust

OHS Forms Procedure Reference Revision Number Revision Date

Page | 10 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

appurtenances mask and safety glass.

● Defective tools.

• Serious accident that may ● Ensure workers are equipped with all appropriate PPEs such as

● Splintered shovel’s handle. result to severe injury or

(list all applicable PPEs).

property damage

● Extreme weather condition. ● Ensure proper access will be provided.

● Unprotected excavation wall. ● Continuous monitoring of weather condition.

● Sufficient break time and rehydrating drinks to be provided

during hot weather condition.

● Excavation wall protection must be in place to avoid collapse on

workers.

4. Soil compaction using roller compactor, plate compactor.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 11 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

4.1 Mobilize the roller and plate • Accident resulting Injury

● Congestion due to other ground ● Proper planning and survey of the route to be taken by the

compactor to the worksite. to personnel and property

activity. equipment.

damage of adjacent

● Blindspot for the operator. structure or appurtenances ● Planning and survey to determine the exclusion zone for the

activity.

● Unauthorized personnel.

● Proper coordination with other working teams who will be

● Inexperienced or untrained

affected by the mobilization of equipment.

personnel.

● No unauthorized personnel or not part of the team shall be

● Equipment’s poor condition.

allowed on the working area.

● Uneven pavement or ground. ● Verification of operator’s third-party certification prior start of

the activity.

● Verification of equipment’s third-party certification.

● All equipment must be thoroughly physically inspected and

ensure that in good working condition.

● Assign flagman and spotter to assist the operator and control

traffic on the area.

● Survey of the route for uneven and un-compacted ground.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 12 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

4.2 Compact the leveled surface • Accident resulting Injury

● Incompetent personnel. ● Only trained, competent and designated person must be working

using roller compactor. to personnel and property

on the job at hand.

● Equipment’s poor condition. damage of adjacent

structure or appurtenances ● Ensure that equipment is thoroughly inspected and in good

● Unauthorized personnel.

working condition.

● Exposure to continuous vibration. ● Compactor must be equipped with the ergonomic seat to

● The abrupt operation that may lead minimize worker’s exposure to continuous vibration.

to toppling down of equipment. ● No unauthorized personnel or not part of the team shall be

● Exposure to dust. allowed in the area.

● Ensure that backfilling materials are properly leveled.

● Extreme weather condition.

● No abrupt or hasten operation of equipment to maintain stability

while traveling on the backfilled area.

● Workers must be equipped with the appropriate type of dust

mask and safety glass.

● Dust control to be continuously applied.

● Continuous monitoring of weather condition.

● Sufficient break time and rehydrating drinks to be provided

during hot weather condition.

4.3 Use plate compactor on some • Accident resulting Injury

● Untrained or unskilled personnel. ● Only trained, competent and designated person must be working

areas where roller compactor to personnel and property

on the job at hand.

cannot reach. ● Equipment’s poor condition. damage of adjacent

structure or appurtenances ● Ensure that equipment is thoroughly inspected and in good

● Exposure to continuous vibration.

working condition.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 13 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

● Abrupt operation of equipment. ● Sufficient break time and alternate operator to minimize the

worker’s exposure to continuous vibration.

● Exposure to dust.

● No abrupt or hasten operation of equipment to maintain stability

● Extreme weather condition.

during operation.

● Workers must be equipped with the appropriate type of dust

mask, safety glass and all appropriate PPEs such as (list all

applicable PPEs).

● Continuous monitoring of weather condition.

● Sufficient break time and rehydrating drinks to be provided

during hot weather condition.

5. Housekeeping and clear the area

5.1 Prior to housekeep, wearing

● Inadequate PPE. ● Install appropriate notices and signage.

personal protective equipment

such as safety gloves and mask ● Special personal protective equipment must be observed like

must be fulfilled by the

personnel involved. coverall clothing, rubber gloves, respiratory equipment, clear

goggles and etc.

● Close supervision by the Engineer, Supervisor or Foreman must

observe.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 14 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

5.2 Removal of tools, equipment,

● Presence of sharp edges. ● Appropriate personal protective equipment should be observed

and other excesses/ unused

materials manually. like coverall, hand gloves, eye protection, and etc.

● Poor supervision / untrained

personnel. ● Tools and other materials should be properly arranged/ removed

inside the battery room if not in use.

● First aid kit should be available with adequate quantity of

medicines.

● A spill kit should be available in the area.

● Close supervision by the Engineer, Supervisor or Foreman must

observe.

5.3 Disposing of waste to

● Tools and materials scattered on ● Proper disposal and segregation of waste / used materials.

dedicated waste bin/container.

the floor.

● Provision of an appropriate waste container in the area.

● Close supervision by the Engineer, Supervisor or Foreman must

observe.

5.4 Sweeping and cleaning the

● Inadequate PPE. ● Appropriate personal protective equipment should be observed

area.

like coverall, hand gloves, eye protection, and etc.

● Presence of waste material.

● Observe the “use the right tool” rule.

● Inappropriate tools.

● Close supervision by the Engineer, Supervisor or Foreman must

observe.

6. Closing of Permit to Work

OHS Forms Procedure Reference Revision Number Revision Date

Page | 15 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

6.1 Returning of the Permit to

● Inadequate communication. ● Significant property and ● Permit Receiver & Issuer shall ensure that housekeeping is done

Work to Permit Issuer for

Untrained personnel. appurtenances damage before, during and after the work.

closing.

● Governmental violation ● All waste materials generated from the work shall be properly

Environmental disposed and shall not be left unattended at the worksite.

complaint

● Electrical equipment shall be properly secured, distribution board

● Accident resulting closed and padlocked.

serious injury or death

● All materials used at the site such as chemicals, flammable and

to worker

combustible materials shall be stored at the designated storage

at the end of each day.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 16 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

6.2 Verifying the site condition as

● Poor housekeeping. ● Significant property and ● Permit Receiver shall ensure that housekeeping is done before,

per requirements mentioned in

appurtenances damage during and after the work.

the closing of Permit to Work ● Undisposed waste materials.

by both the Permit Issuer and ● Governmental violation ● All waste materials generated from the work shall be properly

Permit Receiver. ● Unaccounted workers.

● Environmental disposed and shall not be left unattended at the worksite.

● Unsecured electrical equipment complaint ● Electrical equipment shall be properly secured, distribution board

/energized equipment. ● Loss of production closed and padlocked.

● Poor storage of chemical, ● Accident resulting ● All materials used at the site such as chemicals, flammable and

flammable and combustible serious injury or death combustible materials shall be stored at the designated storage

materials and etc. to worker

at the end of each day.

Significant cost due to

● Unattended unsafe condition. damages. ● Mobile equipment shall properly park on a designated equipment

● Unfamiliarity with access to the laydown.

areas and the present construction ● Ensure that all workers are accounted and there was no

hazard. incident/accident occurred which is not reported.

● All Issuer and receiver must be aware of the hazard present in the

area and must be familiar with the ingress and egress of the

project site.

6.3 Signing/clearing of the Permit

● Inadequate communication. ● Accident resulting ● Work permit issuer and receiver must be qualified, trained and

to Work by the Permit Issuer

serious injury or death competent.

upon verification of site ● Untrained personnel. to worker

condition and satisfactorily ● Proper communication should be observed.

comply with the requirements

mentioned.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 17 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

ST

LIST ALL STEPS IN HAZARDS DANGER / RISK

EP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

PERFORMING THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, (INJURIES, DAMAGE,

No LOSS, DAMAGE INTERRUPTION, OR POLLUTION? ILLNESS, POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

.

6.4 Keeping and recording of the • Miscommunication between ● Significant property and ● Permit Receiver & Issuer shall ensure that housekeeping is done

completed and signed Permit work teams

appurtenances damage before, during and after the work.

to Work by ensuring that the

permit to work register is duly ● Governmental violation ● All waste materials generated from the work shall be properly

accomplished. Environmental disposed and shall not be left unattended at the worksite.

complaint

● Electrical equipment shall be properly secured, distribution board

● Accident resulting closed and padlocked.

serious injury or death

● All materials used at the site such as chemicals, flammable and

to worker

combustible materials shall be stored at the designated storage

at the end of each day.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 18 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

You might also like

- Field Report at TIADocument36 pagesField Report at TIAOmaryMakalle65% (26)

- Jsa For HydrotestDocument10 pagesJsa For HydrotestAnonymous CcGYhZb080% (5)

- Jha For Batching Plant OprationDocument7 pagesJha For Batching Plant Oprationpoovazhagan80% (5)

- Barangay ListDocument22 pagesBarangay ListAnonymous FqiIrcf100% (2)

- Installation of Copper Pipes and Fittings.: Barq Group Risk AssessmentDocument8 pagesInstallation of Copper Pipes and Fittings.: Barq Group Risk AssessmentYousaf Richu75% (4)

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document7 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson Escamillan100% (2)

- DOD - MST-INSU-007 (Rev-A) - FOAM INJECTION FOR VALVES AND FLANGES ON COLD INSULATION WORKDocument7 pagesDOD - MST-INSU-007 (Rev-A) - FOAM INJECTION FOR VALVES AND FLANGES ON COLD INSULATION WORKProfessional Trust100% (1)

- JSP For SS 9013 No. JSP#04 Cutting and Bending of Steel Reinforcement BarsDocument8 pagesJSP For SS 9013 No. JSP#04 Cutting and Bending of Steel Reinforcement BarsAbdul Rasheed Mangrio100% (1)

- JSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentDocument10 pagesJSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentAbdul Rasheed Mangrio50% (2)

- Page - 1: (In Sequence) (Injuries, Damage, Illness, Pollution, Etc)Document10 pagesPage - 1: (In Sequence) (Injuries, Damage, Illness, Pollution, Etc)shafiezubier5No ratings yet

- JSP For SS 9013 No. JSP#03 Excavation Using Electrical Jack HammerDocument11 pagesJSP For SS 9013 No. JSP#03 Excavation Using Electrical Jack HammerAbdul Rasheed MangrioNo ratings yet

- OHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelDocument9 pagesOHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelEbrahsm ElshenawyNo ratings yet

- JSP For SS No. 7 PACU InstallationDocument13 pagesJSP For SS No. 7 PACU InstallationJaafar LagayanNo ratings yet

- JSP For SS No. 8 Installation of EOT CraneDocument28 pagesJSP For SS No. 8 Installation of EOT CraneJaafar LagayanNo ratings yet

- JSP For SS No. 4 Commissioning of High Voltage EquipmentDocument21 pagesJSP For SS No. 4 Commissioning of High Voltage EquipmentmohammedtofiqahmedNo ratings yet

- JSP For SS No. 1 Battery Charging and TestingDocument11 pagesJSP For SS No. 1 Battery Charging and TestingmohammedtofiqahmedNo ratings yet

- JSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)Document16 pagesJSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)mohammedtofiqahmedNo ratings yet

- JSP For SS No. 5 Tower Crane InstallationDocument15 pagesJSP For SS No. 5 Tower Crane InstallationmohammedtofiqahmedNo ratings yet

- Job Safety SiteDocument11 pagesJob Safety SiteMohd Arfeen RezaNo ratings yet

- JSP For SS No. 3 Lifting of Heavy Equipment Using CraneDocument14 pagesJSP For SS No. 3 Lifting of Heavy Equipment Using CranemohammedtofiqahmedNo ratings yet

- Ohs-Pr-09-03-F07 (A) JSP No. 46 Cable PullingDocument16 pagesOhs-Pr-09-03-F07 (A) JSP No. 46 Cable PullingbilalgradioshNo ratings yet

- JSP For SS No. 2 GIS-GIB-Swithgear InstallationDocument19 pagesJSP For SS No. 2 GIS-GIB-Swithgear InstallationmohammedtofiqahmedNo ratings yet

- JSP For SS No. 9 Filling of Battery Fluid Inside Battery RoomDocument15 pagesJSP For SS No. 9 Filling of Battery Fluid Inside Battery RoomJaafar LagayanNo ratings yet

- JSP For SS No. 42 Line Stability Test (JD-RDS BB-1 PMD 110 KV)Document11 pagesJSP For SS No. 42 Line Stability Test (JD-RDS BB-1 PMD 110 KV)Mohd Arfeen RezaNo ratings yet

- JSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaDocument11 pagesJSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaJaafar LagayanNo ratings yet

- JSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsDocument10 pagesJSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsJaafar LagayanNo ratings yet

- 8.JSP No.30 Hydro Testing of Gas Pipe LineDocument9 pages8.JSP No.30 Hydro Testing of Gas Pipe LineabbasNo ratings yet

- JSP For OHTL No. 12 Jumper Installation WorksDocument13 pagesJSP For OHTL No. 12 Jumper Installation WorksJaafar LagayanNo ratings yet

- JSP For OHTL No. 17 Underline Gantry Installation and ErectionDocument15 pagesJSP For OHTL No. 17 Underline Gantry Installation and ErectionJaafar LagayanNo ratings yet

- JSP For OHTL No. 15 Erection of Common Body StructureDocument14 pagesJSP For OHTL No. 15 Erection of Common Body StructureJaafar LagayanNo ratings yet

- JSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyDocument10 pagesJSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyJaafar LagayanNo ratings yet

- JSP For Communication Local TestDocument8 pagesJSP For Communication Local TestJaafar LagayanNo ratings yet

- JSP For OHTL No. 16 Erection of Upper Body StructureDocument14 pagesJSP For OHTL No. 16 Erection of Upper Body StructureJaafar Lagayan100% (1)

- JSA For Erection of Precast..Document18 pagesJSA For Erection of Precast..Shafie ZubierNo ratings yet

- PS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)Document27 pagesPS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)RABIE EL MAGHWRY ABDELKHALEK ELGHAMRY0% (1)

- JSP For Open Loop Close Loop Test For Protection PanelDocument9 pagesJSP For Open Loop Close Loop Test For Protection PanelJaafar LagayanNo ratings yet

- JSP For Electrical Test (End To End Test)Document8 pagesJSP For Electrical Test (End To End Test)Jaafar LagayanNo ratings yet

- STL Varun Ehs M A02 Hira R0Document6 pagesSTL Varun Ehs M A02 Hira R0lsm projectNo ratings yet

- 7 - Dewatering of Rain Water From Compression Project AreaDocument4 pages7 - Dewatering of Rain Water From Compression Project AreaAijaz AhmedNo ratings yet

- Permit To Work Ref TemplateDocument2 pagesPermit To Work Ref Templatenatamas systemsNo ratings yet

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- JSA Excavation For Lighting Pole FoundationDocument18 pagesJSA Excavation For Lighting Pole FoundationMohammad Al Masa'deh100% (1)

- 0081 To Install Protective Canvas On Pick Up Line For Export Hose Via Rope AccessDocument6 pages0081 To Install Protective Canvas On Pick Up Line For Export Hose Via Rope AccessShoresafe ConsultingNo ratings yet

- Jsa Panel SullayilDocument6 pagesJsa Panel SullayilthennarasuNo ratings yet

- NEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalDocument15 pagesNEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalKarthik babuNo ratings yet

- 1 RA Water Works (Revised)Document21 pages1 RA Water Works (Revised)Muhammad Shahid Iqbal0% (1)

- JSP For Installation of AC-DC PanelsDocument11 pagesJSP For Installation of AC-DC PanelsAbdulsalam AneezeNo ratings yet

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- DOD-JHA-040A (Rev-C) Night Shift WorkDocument9 pagesDOD-JHA-040A (Rev-C) Night Shift WorkMohammedNo ratings yet

- JSP For Grounding Grid InstallationDocument11 pagesJSP For Grounding Grid InstallationAbdulsalam AneezeNo ratings yet

- Eepsp Ra Swro 003 - 00aDocument9 pagesEepsp Ra Swro 003 - 00afayaz5233No ratings yet

- Job Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantDocument9 pagesJob Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantZia ur RehmanNo ratings yet

- DOD-MST-EQ-025 (Rev-C) RE-COATING OF FLARE DERRICKDocument5 pagesDOD-MST-EQ-025 (Rev-C) RE-COATING OF FLARE DERRICKMohammedNo ratings yet

- JSP For Installation of Cable TrayDocument11 pagesJSP For Installation of Cable TrayAbdulsalam AneezeNo ratings yet

- OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE TF-00877 Mobilization and Preparation of Site OfficesDocument11 pagesOHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE TF-00877 Mobilization and Preparation of Site OfficesRAI AHTESHAM HaiderNo ratings yet

- Manual Excavation For Identified Depth and Elevation of Existing PipelineDocument15 pagesManual Excavation For Identified Depth and Elevation of Existing PipelineshahbazchafekarNo ratings yet

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehNo ratings yet

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- JSP For Installation of Capacitor BankDocument12 pagesJSP For Installation of Capacitor BankAbdulsalam AneezeNo ratings yet

- Government of Tamil Nadu: Department of Employment and Training (Training Wing)Document75 pagesGovernment of Tamil Nadu: Department of Employment and Training (Training Wing)SanjaiNo ratings yet

- Berkenkotter v. CADocument5 pagesBerkenkotter v. CAjealousmistressNo ratings yet

- Cayanan Vs North StarDocument2 pagesCayanan Vs North StarMosarah AltNo ratings yet

- (A) Implementation of ABCDocument4 pages(A) Implementation of ABCMalik Asim AzizNo ratings yet

- SAP CO Useful TablesDocument28 pagesSAP CO Useful Tableskcshiong100% (1)

- Digital Signatures OverviewDocument40 pagesDigital Signatures OverviewrajusampathiraoNo ratings yet

- Formulation, Implementation, and Control of Competitive StrategyDocument11 pagesFormulation, Implementation, and Control of Competitive StrategyWam OwnNo ratings yet

- G4-T6 How To Use Moving Average Crossovers To Enter TradesDocument4 pagesG4-T6 How To Use Moving Average Crossovers To Enter TradesThe ShitNo ratings yet

- Print Rumus ModelDocument1 pagePrint Rumus ModelArianto PardedeNo ratings yet

- Departmental Interpretation and Practice Notes No. 7 (Revised)Document33 pagesDepartmental Interpretation and Practice Notes No. 7 (Revised)Difanny KooNo ratings yet

- Role of MNC in IndiaDocument41 pagesRole of MNC in IndiaKhundongbam SureshNo ratings yet

- Tally - ERP 9: Settle Multiple Bills Through Bill Settlement in Tally - ERP 9Document5 pagesTally - ERP 9: Settle Multiple Bills Through Bill Settlement in Tally - ERP 9Kashif KhanNo ratings yet

- Declining SuratDocument34 pagesDeclining Suratvaishalitadvi053No ratings yet

- CWTSDocument19 pagesCWTSjoshNo ratings yet

- Production TheoryDocument72 pagesProduction TheoryAnirudh Dutta100% (1)

- List of Numbers To Block and AvoidDocument48 pagesList of Numbers To Block and Avoidmutiara912No ratings yet

- Cash DepartmentDocument2 pagesCash DepartmentTaimur ZiaNo ratings yet

- Pengaruh Ukuran Perusahaan Dan Corporate Governance Terhadap Manajemen Laba Di Industri Perbankan IndonesiaDocument16 pagesPengaruh Ukuran Perusahaan Dan Corporate Governance Terhadap Manajemen Laba Di Industri Perbankan IndonesiaJessica AnggiNo ratings yet

- PED and CE MarkingDocument4 pagesPED and CE Markingdhanu_aquaNo ratings yet

- 4 - Asari Yoko Co., Ltd. v. Kee BocDocument2 pages4 - Asari Yoko Co., Ltd. v. Kee BocnathNo ratings yet

- Fiat SDocument27 pagesFiat SAzizul AnwarNo ratings yet

- Notice: Notice of Investigation: Certain Liquid Crystal Display Modules, Products Containing Same, and Methods For Using The SameDocument1 pageNotice: Notice of Investigation: Certain Liquid Crystal Display Modules, Products Containing Same, and Methods For Using The SameJustia.comNo ratings yet

- Legal and Public Policy Considerations For Product PlanningDocument17 pagesLegal and Public Policy Considerations For Product PlanningprincekamutikanjoreNo ratings yet

- Tax Invoice: Rekha Indane Gramin VITRAK (0000270706)Document2 pagesTax Invoice: Rekha Indane Gramin VITRAK (0000270706)sujeet sharmaNo ratings yet

- Arrow Delivery Services: Date Particulars PR. Debit (DR)Document4 pagesArrow Delivery Services: Date Particulars PR. Debit (DR)Jihane TanogNo ratings yet

- Oj C 2016 272 Full en TXTDocument156 pagesOj C 2016 272 Full en TXTpluto14No ratings yet

- Indian Companies IILF Chennai 2019Document106 pagesIndian Companies IILF Chennai 2019raghunath670743No ratings yet

- Types of Advertising MediaDocument6 pagesTypes of Advertising MediaspdwibediNo ratings yet