Professional Documents

Culture Documents

Maintenance List of TCG 2020 V16 K Ashraful

Maintenance List of TCG 2020 V16 K Ashraful

Uploaded by

AshrafulCopyright:

Available Formats

You might also like

- Honda Xr80r Xr100r Service Repair Manual 1998-2003 Xr80 Xr100Document227 pagesHonda Xr80r Xr100r Service Repair Manual 1998-2003 Xr80 Xr100Julián David Gallego González56% (9)

- Caterpillar 3406 Engine Service Manual S N 70v1Document7 pagesCaterpillar 3406 Engine Service Manual S N 70v1المهندسوليدالطويل67% (15)

- Un125nem2 (Mb8ea12akm) Un125nezm2 (Mb8ea12akm)Document91 pagesUn125nem2 (Mb8ea12akm) Un125nezm2 (Mb8ea12akm)surojit karmakar100% (1)

- ZF-EcoLife - The New Generation of Automatic Transmissions Level-1 TrainingDocument71 pagesZF-EcoLife - The New Generation of Automatic Transmissions Level-1 TrainingСергей Миненко90% (10)

- Maintenance CG132, WP 11-2Document18 pagesMaintenance CG132, WP 11-2MarioAndrésRamirezC.No ratings yet

- Twd1031ve Volvo PDFDocument37 pagesTwd1031ve Volvo PDFANH LÊ100% (2)

- Workshop ManualDocument48 pagesWorkshop ManualFauan SNo ratings yet

- Diagrama Electrico QSK19 MCRIDocument1 pageDiagrama Electrico QSK19 MCRIeduardomunadaca100% (1)

- MTU Gendrive Spec 4000Gx03 3F3H W2A 1 16Document4 pagesMTU Gendrive Spec 4000Gx03 3F3H W2A 1 16TapasNo ratings yet

- 4000 MTU Gendrive Spec 4000GxV12 V16 V20Document5 pages4000 MTU Gendrive Spec 4000GxV12 V16 V20Muhammet KöseNo ratings yet

- Genset Atlas Copco Qax 30Document2 pagesGenset Atlas Copco Qax 30dolenkpNo ratings yet

- Components Type of Lubricant Capacities SK210HDLC SK220XDLC-10Document4 pagesComponents Type of Lubricant Capacities SK210HDLC SK220XDLC-10ashish gautamNo ratings yet

- Catalog Big Capacity AHU DX DuctedDocument28 pagesCatalog Big Capacity AHU DX DuctedBistok ManurungNo ratings yet

- (PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressDocument5 pages(PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressArie AozNo ratings yet

- Hybrid Pump Variable & Fixed Flow Double & Triple T6H Piston & Vane PumpDocument14 pagesHybrid Pump Variable & Fixed Flow Double & Triple T6H Piston & Vane PumpKarthi KhesvaranNo ratings yet

- Diesel Engines 16V 4000 M53M63 1ADocument2 pagesDiesel Engines 16V 4000 M53M63 1AMario100% (1)

- Chapter 04 - Maintenance ScheduleDocument16 pagesChapter 04 - Maintenance SchedulenikolasthermosolutionsNo ratings yet

- AT400T41T M.Y. 2013 Cursor 13 Euro ViDocument16 pagesAT400T41T M.Y. 2013 Cursor 13 Euro ViCesar MartinezNo ratings yet

- 3 December 1991: Approved For Public Release Distribution Is UnlimitedDocument24 pages3 December 1991: Approved For Public Release Distribution Is UnlimitedAmmec Hdz EchNo ratings yet

- Law InternationalDocument7 pagesLaw InternationalnebaNo ratings yet

- 02 MIDEA Cassette Inverter (3.0-5.0 Ton)Document2 pages02 MIDEA Cassette Inverter (3.0-5.0 Ton)Mohd TabishNo ratings yet

- Diesel Engines 16V 4000 M63R/M63/M63L: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 16V 4000 M63R/M63/M63L: For Vessels With Unrestricted Continuous Operation (1A)bbssNo ratings yet

- Msh07crn1 Msh07hrn1 Msh09crn1 Msh09hrn1 Msh12crn1 Msh12hrn1Document359 pagesMsh07crn1 Msh07hrn1 Msh09crn1 Msh09hrn1 Msh12crn1 Msh12hrn1Stefan StanchevNo ratings yet

- Fixtures Cost Break UpDocument23 pagesFixtures Cost Break UpAshok AroraNo ratings yet

- 2007-013 Slew Ring Bolt Check Exchange Rev3 01Document4 pages2007-013 Slew Ring Bolt Check Exchange Rev3 01Luis EaNo ratings yet

- Mtu 12V 16V4000M90 1DSDocument2 pagesMtu 12V 16V4000M90 1DSzaki100% (1)

- Datablad MWM Gas Engine Tcg2020 enDocument8 pagesDatablad MWM Gas Engine Tcg2020 enAli NowrozNo ratings yet

- KNTC Offer To KIPL For K10C Cam ProjectDocument7 pagesKNTC Offer To KIPL For K10C Cam ProjectNathan ChenNo ratings yet

- Planetary Gearboxes For Mobile Applications Hydrotrac GFT Series 20Document4 pagesPlanetary Gearboxes For Mobile Applications Hydrotrac GFT Series 20Anonymous lIJl27QBXLNo ratings yet

- MTU Gendrive Spec 4000G 03 3D3E W2ADocument4 pagesMTU Gendrive Spec 4000G 03 3D3E W2APetrus GunturNo ratings yet

- Technical Data Sheet: Marine Diesel Engine D2862LE496 (V12-2000)Document3 pagesTechnical Data Sheet: Marine Diesel Engine D2862LE496 (V12-2000)mlaouhi MajedNo ratings yet

- Re 79093Document4 pagesRe 79093Anonymous lIJl27QBXLNo ratings yet

- York Ducted InverterDocument2 pagesYork Ducted InverterjABU100% (1)

- 13 Foth ZFDocument29 pages13 Foth ZFDaniel Alex SánchezNo ratings yet

- 09 CX Iveco Cursor 9Document45 pages09 CX Iveco Cursor 9Diego100% (3)

- NEW PREV MAINT PARTS & OIL GD511A-1s-nDocument2 pagesNEW PREV MAINT PARTS & OIL GD511A-1s-nkikki090kikkiNo ratings yet

- Hydraulic Power Unit: RE 51057, Edition: 2020-11, Bosch Rexroth AGDocument20 pagesHydraulic Power Unit: RE 51057, Edition: 2020-11, Bosch Rexroth AGHanzil HakeemNo ratings yet

- 1 5118668111280603310Document44 pages1 5118668111280603310Jéssica Tupy Paulo HenriqueNo ratings yet

- 2022-12-20 Ne-22038 Hyd Power Units Bro en WebDocument8 pages2022-12-20 Ne-22038 Hyd Power Units Bro en WebBeni SaputraNo ratings yet

- Maintenance Schedule Chart of Dozer-D85Ess-2: Item Part No Part Name QTY Replacement HoursDocument3 pagesMaintenance Schedule Chart of Dozer-D85Ess-2: Item Part No Part Name QTY Replacement HoursAsim Ghosh100% (1)

- Rotrex Technical Datasheet C30 Range PDFDocument7 pagesRotrex Technical Datasheet C30 Range PDFMichael SezeniasNo ratings yet

- VRS Working Width and DeflectionDocument4 pagesVRS Working Width and DeflectionBogdanBNo ratings yet

- Cost Estimation For Hull No. FMC-67Document5 pagesCost Estimation For Hull No. FMC-67Md. Ashraful Islam EngineerNo ratings yet

- 8V4000M40A3B10 MTU Engine-DataDocument11 pages8V4000M40A3B10 MTU Engine-DataAlex CorsaroNo ratings yet

- Re77502 2004-05Document20 pagesRe77502 2004-05pamururamuNo ratings yet

- Product Update 2010 - Smmsi Outdoor UnitsDocument3 pagesProduct Update 2010 - Smmsi Outdoor UnitssnowwooNo ratings yet

- Hatz Diesel B Series BrochureDocument8 pagesHatz Diesel B Series BrochureColdbloodedbikerNo ratings yet

- Sheet Service - SKT90SDocument2 pagesSheet Service - SKT90SAnanda risaNo ratings yet

- MTU Datasheet s4000px3 Constant SpeedDocument2 pagesMTU Datasheet s4000px3 Constant SpeedKrish100% (1)

- Prédimensionnemnt Type Projet H2 Mobilité MorrocoDocument16 pagesPrédimensionnemnt Type Projet H2 Mobilité Morrocoyassine ajjaouiNo ratings yet

- ZX240-3 Maintenance PlannerDocument2 pagesZX240-3 Maintenance PlannerGee K ToubulukwaNo ratings yet

- Cassette INVERTER YTKKE 18 To 55 YORKDocument2 pagesCassette INVERTER YTKKE 18 To 55 YORKAlejandroNo ratings yet

- Edm 10Document8 pagesEdm 10Ulises Baute Jr.No ratings yet

- Chapter 10 - Planetary Gear BoxesDocument54 pagesChapter 10 - Planetary Gear BoxesSankuparlang ShullaiNo ratings yet

- Zf-Ecolife: ZF Automatic Transmissions For BusesDocument2 pagesZf-Ecolife: ZF Automatic Transmissions For BusesTaoufikNo ratings yet

- ZX270-3 Maintenance PlannerDocument2 pagesZX270-3 Maintenance PlannerGee K ToubulukwaNo ratings yet

- Recent Maintenance HL Machines 2016Document37 pagesRecent Maintenance HL Machines 2016Ganesh DevadigaNo ratings yet

- 1B20 - 1B20V 1B27 1B30 - 1B30V 1B40 - 1B40V 1B50 - 1B50VDocument8 pages1B20 - 1B20V 1B27 1B30 - 1B30V 1B40 - 1B40V 1B50 - 1B50VchrisrobinsoncnpNo ratings yet

- 01.VD01 IND Informasi UmumDocument108 pages01.VD01 IND Informasi UmumBPP Jember Service100% (1)

- Omm Eh1100 PDFDocument13 pagesOmm Eh1100 PDFdayatNo ratings yet

- 1UR-FE Overview TundraDocument50 pages1UR-FE Overview TundraGrubleen ManNo ratings yet

- Jenbacher: 1. Leanox® Controller: - 1Document3 pagesJenbacher: 1. Leanox® Controller: - 1ArîfNo ratings yet

- 8905-Exhibit B Technical SpecificationsDocument30 pages8905-Exhibit B Technical SpecificationsManuel GonzalezNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Distribution System - TopicsDocument7 pagesDistribution System - Topicsjhoni gomezNo ratings yet

- Knocking and Anti KnockingDocument26 pagesKnocking and Anti KnockingsaadzzworldNo ratings yet

- Beli EqpDocument115 pagesBeli EqpRony CamaroNo ratings yet

- Thermodynamic CyclesDocument32 pagesThermodynamic CyclessunitbhaumikNo ratings yet

- APD165PDocument4 pagesAPD165PPercyNo ratings yet

- GE Oil & Gas Nuovo Pignone: Title: Part List: Drawing: Gas Turbine Ms5002DDocument1 pageGE Oil & Gas Nuovo Pignone: Title: Part List: Drawing: Gas Turbine Ms5002DMohammed ElarbedNo ratings yet

- How To: Index The Spark Plugs On A Ficht / Direct Injection OutboardDocument4 pagesHow To: Index The Spark Plugs On A Ficht / Direct Injection OutboardrfffffNo ratings yet

- Motor EmdDocument9 pagesMotor EmdHANSELL MIRANDA ALVANo ratings yet

- Kits Motor CTP F-720-181Document4 pagesKits Motor CTP F-720-181Pedro Alberto BenitesNo ratings yet

- TD824 1F161F40KDocument330 pagesTD824 1F161F40KEvaldas Štrapėla100% (1)

- Mercedes-Benz,: R4 - 155 KW (211 HP) OM 934Document4 pagesMercedes-Benz,: R4 - 155 KW (211 HP) OM 934Kevin TtitoNo ratings yet

- 1KD Engine Repair Manual Section 3 (Fuel System) Pub. No. CE302Document15 pages1KD Engine Repair Manual Section 3 (Fuel System) Pub. No. CE302ManuelNo ratings yet

- Service Manual: Common Rail System For ISUZU 4HK1 / 6HK1 Type EngineDocument49 pagesService Manual: Common Rail System For ISUZU 4HK1 / 6HK1 Type EngineLeonardo Medina100% (1)

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationDocument2 pagesMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationArun SNo ratings yet

- Spark-Glow-Plugs-Ignition-Catalogue 777Document1 pageSpark-Glow-Plugs-Ignition-Catalogue 777АлександрNo ratings yet

- Yamaha 40V Servicemanual PDFDocument224 pagesYamaha 40V Servicemanual PDFrainer100% (1)

- 4M06 Spec Sheet RevbDocument4 pages4M06 Spec Sheet RevbIKNo ratings yet

- DongfengDocument82 pagesDongfengtahutempebullatNo ratings yet

- lm6000 Business Unit Igt Packaging PDFDocument10 pageslm6000 Business Unit Igt Packaging PDFEDBNo ratings yet

- CI Engine PDFDocument39 pagesCI Engine PDFDileep VarmaNo ratings yet

- GSH 56 (Euro 0) Chainsaw: Engine Starter Assy Tank and Air Filter Chain Cover and Clutch CrankcaseDocument11 pagesGSH 56 (Euro 0) Chainsaw: Engine Starter Assy Tank and Air Filter Chain Cover and Clutch CrankcaseTaras BilanNo ratings yet

- Toyota 8fg30bDocument561 pagesToyota 8fg30bAngelo Kuibida100% (2)

- Lovato Gas Injection Systems PDFDocument29 pagesLovato Gas Injection Systems PDFJohannesNo ratings yet

- Emission Control Analysis On BS-VI Diesel Engine in Heavy VehicleDocument11 pagesEmission Control Analysis On BS-VI Diesel Engine in Heavy VehicleajayNo ratings yet

- Super ChargersDocument12 pagesSuper ChargersSealtiel1020No ratings yet

Maintenance List of TCG 2020 V16 K Ashraful

Maintenance List of TCG 2020 V16 K Ashraful

Uploaded by

AshrafulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance List of TCG 2020 V16 K Ashraful

Maintenance List of TCG 2020 V16 K Ashraful

Uploaded by

AshrafulCopyright:

Available Formats

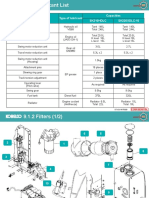

Maintenance

TCG 2020 K

Maintenance Level

Operating Hours

E1 E10 E20 E40 E50 E60 E70

As Specified x

50 x

4000 x

8000 x

12000 x

16000 x

20000 x

24000 x

28000 x

32000 x

32050 x

36000 x

40000 x

44000 x

48000 x

52000 x

56000 x

60000 x

64000 x

TCG 2020 K (November Rain=01618-878721) Page 1

Maintenance

TCG 2020 K

Maintenance Schedule E1

Maintenance Work Remark As specified CC JC

Clean engine if required 1 B 0-3-6

Lube oil system, complete lube oil analysis and replace according to Technical Bulletin (TR) 1 B 8-1-1

lube oil 2105

Coolant system, complete coolant analysis and according to Technical Bulletin (TR) 1 B 9-1-1

replace coolant 2091

Check engine preservation (preservation, application according to Technical Bulletin (TR) 1

of new corrosion protection, depreservation) 2116

Maintain crankcase breather (model Complete a control measurement Complete limit value measurement 1 B 3-1-9

UPF) after every 4000 OH, at the latest replace

replacing filter inserts after 16000 OH

Replace intake air filter If the low pressure limit at the latest after 4000 OH value is reached, if the 1 B 6-3-6

filter surface is damaged

Carry out test run If the engine was not run in Monthly operational readiness within a month 1 B 0-1-4

Service the battery If the engine was not run in Monthly 1

operational readiness within a month

Combustion gas system, sample taking and gas In accordance with every 4 months 1 B 7-18-1

analysis Technical Bulletin (TR) 3017

Check coolant according to Technical Bulletin (TR) every 6 months 1 B 9-1-1

2091

Replace coolant according to Technical Bulletin (TR) every 24 months 1 B 9-0-4

2091

Check spark plugs, replace if necessary Check limit value in the every 2000 OH 1 B 13-5-4

TEM system

Exchange cylinder heads when the max. valve clearance in between 16000 OH and 32000 OH 2 W 1-4-4

accordance with technical

specifications is reached

Run in the engine After replacing pistons or cylinder if required 3 W 0-1-3

liner

Replace or exchange starter if required 3 W 13-3-2

TCG 2020 K (November Rain=01618-878721) Page 2

Maintenance

TCG 2020 K

Maintenance Schedule E10

Maintenance Work Remark CC JC

Complete test and functioning run 1B 0-1-7

Inlet and outlet valves, check valve clearance and set 1B 1-1-1

Inlet and outlet valves, check valve depth Cylinder head mounted 1B 1-7-10

Maintenance Schedule E20

Maintenance Work Remark CC JC

Visually inspect system 1B 0-1-5

Maintenance Schedule E40

Maintenance Work Remark CC JC

TEM system, complete auxiliary device test 1B 0-1-6

Complete test and functioning run 1B 0-1-7

Inlet and outlet valves, check valve clearance and set 1B 1-1-1

Inlet and outlet valves, check valve depth Cylinder head mounted 1B 1-7-10

Check speed governor control linkage 1B 5-4-2

Check throttle valve 1B 7-23-3

Lube oil system, replace lube oil filter 1B 8-10-4

Exhaust gas system, check pollutant emissions 3W 0-1-9

Visually inspect combustion chamber Using an endoscope 3W 0-2-7

Check ignition timing 3W 13-5-3

TCG 2020 K (November Rain=01618-878721) Page 3

Maintenance

TCG 2020 K

Maintenance Schedule E50

Maintenance Work Remark CC JC

TEM system, complete auxiliary device test 1 B 0-1-6

Complete test and functioning run 1 B 0-1-7

Inlet and outlet valves, check valve clearance and set 1 B 1-1-1

Inlet and outlet valves, check valve depth Cylinder head mounted 1 B 1-7-10

Check speed governor control linkage 1 B 5-4-2

Check throttle valve 1 B 7-23-3

Lube oil system, replace lube oil filter 1 B 8-10-4

Exhaust gas system, check pollutant emissions 3 W 0-1-9

Visually inspect combustion chamber Using an endoscope 3 W 0-2-7

Check engine mount 3 W 3-7-1

Check exhaust pipe 3 W 6-1-1

Exchange exhaust turbocharger 3 W 6-6-4

Visually inspect mixture cooler Using an endoscope 3 W 6-4-11

Clean gas/air mixer 3 W 7-22-3

Check ignition timing 3 W 13-5-3

Check starter pinion and gear ring on the flywheel 3 W 12-6-4

TCG 2020 K (November Rain=01618-878721) Page 4

Maintenance

TCG 2020 K

Maintenance Schedule E60

Maintenance Work Remark CC JC

TEM system, complete auxiliary device test 1 B 0-1-6

Complete test and functioning run 1 B 0-1-7

Inlet and outlet valves, check valve clearance and set 1 B 1-1-1

Inlet and outlet valves, check valve depth Cylinder head mounted 1 B 1-7-10

Check speed governor control linkage 1 B 5-4-2

Check throttle valve 1 B 7-23-3

Lube oil system, replace lube oil filter 1 B 8-10-4

Check rubber expansion joint 1 B 12-3-2

Exhaust gas system, check pollutant emissions 3 W 0-1-9

Check vibration dampers, hose lines and flexible lines 3 W 0-3-4

Crankshaft, check axial clearance 3 W 2-1-4

Check con-rod bushing 3 W 2-3-7

Replace con-rod bearing 3 W 2-5-3

Check con-rods 3 W 2-3-5

Check piston bolt 3 W 2-9-7

Replace piston (complete) 3 W 2-9-8

Replace piston rings 3 W 2-10-1

Replace viscosity torsional damper 3 W 12-1-4

Replace cylinder liner 3 W 3-3-2

Check flange seat of cylinder liners and water compartments 3 W 3-10-4

Check engine mount 3 W 3-7-1

Replace valve tappet 3 W 4-2-3

Camshaft, check axial clearance 3 W 4-1-4

Visually inspect camshaft Camshaft installed 3 W 4-5-8

Check exhaust pipe 3 W 6-1-1

Exchange exhaust turbocharger 3 W 6-6-4

Clean mixture cooler 3 W 6-4-7

Clean gas/air mixer 3 W 7-22-3

Check electric cabling, cable set plug and sensor system 3 n.v.

Check ignition timing 3 W 13-5-3

Check starter pinion and gear ring on the flywheel 3 W 12-6-4

TCG 2020 K (November Rain=01618-878721) Page 5

Maintenance

TCG 2020 K

Maintenance Schedule E70

Maintenance Work Remark CC JC

TEM system, complete auxiliary device test 1 B 0-1-6

Complete test and functioning run 1 B 0-1-7

Inlet and outlet valves, check valve clearance and set 1 B 1-1-1

Inlet and outlet valves, check valve depth Cylinder head mounted 1 B 1-7-10

Check speed governor control linkage 1 B 5-4-2

Check throttle valve 1 B 7-23-3

Lube oil system, replace lube oil filter 1 B 8-10-4

Exhaust gas system, check pollutant emissions 3 W 0-1-9

Check vibration dampers, hose lines and flexible lines 3 W 0-3-4

Check crankshaft 3 W 2-1-7

Replace crankshaft sealing ring (drive side) 3 W 2-2-2

Replace crankshaft sealing ring (free side) 3 W 2-2-4

Replace con-rod bearing 3 W 2-5-3

Replace con-rods 3 W 2-3-6

Replace main bearing and thrust bearing or seal rings 3 W 2-7-2

Replace piston (complete) 3 W 2-9-8

Replace viscosity torsional damper 3 W 12-1-4

Replace cylinder liner 3 W 3-3-2

Check flange seat of cylinder liners and water compartments 3 W 3-10-4

Check engine mount 3 W 3-7-1

Replace valve tappet 3 W 4-2-3

Renew valve train 3 n.v.

Check camshaft 3 W 4-5-6

Check and clean gear drive 3 W 4-4-15

Speed control, exchange actuator 3 W 5-4-5

Check exhaust pipe 3 W 6-1-1

Replace exhaust compensators 3 W 6-1-11

Exchange exhaust turbocharger 3 W 6-6-4

Clean mixture cooler 3 W 6-4-7

Overhaul gas/air mixer 3 W 7-22-3

Lube oil system, replace pressure control valve 3 W 8-11-16

Replace lube oil pump 3 W 8-4-5

TCG 2020 K (November Rain=01618-878721) Page 6

Maintenance

TCG 2020 K

Maintenance Schedule E70

Maintenance Work Remark CC JC

Check electric cabling, cable set plug and sensor system 3 n.v.

Replace rubber expansion joint 3 W 12-3-1

Check ignition timing 3 W 13-5-3

Check starter pinion and gear ring on the flywheel 3 W 12-6-4

Camshaft, replace bearing Q W 4-1-1

Emergency Spare Parts List for Genset

SL NO Item Description Quantity

01. Cam-Shaft Pick-Up Sensor 01

02. Ring Gear Pick Up Sensor (Short) 01

03. Crank Case Pressure Sensor 01

04. Cylinder Temp Sensor 01

05. Receiver Temp Sensor 01

06. Lube Oil Pressure Sensor 01

07. Lube oil Temp Sensor 01

08. Water Circuit Temperature Sensor 01

09. Pre-chamber Spark Plug 02

N.B➔ This items have been suggested by KALTIMEX ENERGY

TCG 2020 K (November Rain=01618-878721) Page 7

You might also like

- Honda Xr80r Xr100r Service Repair Manual 1998-2003 Xr80 Xr100Document227 pagesHonda Xr80r Xr100r Service Repair Manual 1998-2003 Xr80 Xr100Julián David Gallego González56% (9)

- Caterpillar 3406 Engine Service Manual S N 70v1Document7 pagesCaterpillar 3406 Engine Service Manual S N 70v1المهندسوليدالطويل67% (15)

- Un125nem2 (Mb8ea12akm) Un125nezm2 (Mb8ea12akm)Document91 pagesUn125nem2 (Mb8ea12akm) Un125nezm2 (Mb8ea12akm)surojit karmakar100% (1)

- ZF-EcoLife - The New Generation of Automatic Transmissions Level-1 TrainingDocument71 pagesZF-EcoLife - The New Generation of Automatic Transmissions Level-1 TrainingСергей Миненко90% (10)

- Maintenance CG132, WP 11-2Document18 pagesMaintenance CG132, WP 11-2MarioAndrésRamirezC.No ratings yet

- Twd1031ve Volvo PDFDocument37 pagesTwd1031ve Volvo PDFANH LÊ100% (2)

- Workshop ManualDocument48 pagesWorkshop ManualFauan SNo ratings yet

- Diagrama Electrico QSK19 MCRIDocument1 pageDiagrama Electrico QSK19 MCRIeduardomunadaca100% (1)

- MTU Gendrive Spec 4000Gx03 3F3H W2A 1 16Document4 pagesMTU Gendrive Spec 4000Gx03 3F3H W2A 1 16TapasNo ratings yet

- 4000 MTU Gendrive Spec 4000GxV12 V16 V20Document5 pages4000 MTU Gendrive Spec 4000GxV12 V16 V20Muhammet KöseNo ratings yet

- Genset Atlas Copco Qax 30Document2 pagesGenset Atlas Copco Qax 30dolenkpNo ratings yet

- Components Type of Lubricant Capacities SK210HDLC SK220XDLC-10Document4 pagesComponents Type of Lubricant Capacities SK210HDLC SK220XDLC-10ashish gautamNo ratings yet

- Catalog Big Capacity AHU DX DuctedDocument28 pagesCatalog Big Capacity AHU DX DuctedBistok ManurungNo ratings yet

- (PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressDocument5 pages(PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressArie AozNo ratings yet

- Hybrid Pump Variable & Fixed Flow Double & Triple T6H Piston & Vane PumpDocument14 pagesHybrid Pump Variable & Fixed Flow Double & Triple T6H Piston & Vane PumpKarthi KhesvaranNo ratings yet

- Diesel Engines 16V 4000 M53M63 1ADocument2 pagesDiesel Engines 16V 4000 M53M63 1AMario100% (1)

- Chapter 04 - Maintenance ScheduleDocument16 pagesChapter 04 - Maintenance SchedulenikolasthermosolutionsNo ratings yet

- AT400T41T M.Y. 2013 Cursor 13 Euro ViDocument16 pagesAT400T41T M.Y. 2013 Cursor 13 Euro ViCesar MartinezNo ratings yet

- 3 December 1991: Approved For Public Release Distribution Is UnlimitedDocument24 pages3 December 1991: Approved For Public Release Distribution Is UnlimitedAmmec Hdz EchNo ratings yet

- Law InternationalDocument7 pagesLaw InternationalnebaNo ratings yet

- 02 MIDEA Cassette Inverter (3.0-5.0 Ton)Document2 pages02 MIDEA Cassette Inverter (3.0-5.0 Ton)Mohd TabishNo ratings yet

- Diesel Engines 16V 4000 M63R/M63/M63L: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 16V 4000 M63R/M63/M63L: For Vessels With Unrestricted Continuous Operation (1A)bbssNo ratings yet

- Msh07crn1 Msh07hrn1 Msh09crn1 Msh09hrn1 Msh12crn1 Msh12hrn1Document359 pagesMsh07crn1 Msh07hrn1 Msh09crn1 Msh09hrn1 Msh12crn1 Msh12hrn1Stefan StanchevNo ratings yet

- Fixtures Cost Break UpDocument23 pagesFixtures Cost Break UpAshok AroraNo ratings yet

- 2007-013 Slew Ring Bolt Check Exchange Rev3 01Document4 pages2007-013 Slew Ring Bolt Check Exchange Rev3 01Luis EaNo ratings yet

- Mtu 12V 16V4000M90 1DSDocument2 pagesMtu 12V 16V4000M90 1DSzaki100% (1)

- Datablad MWM Gas Engine Tcg2020 enDocument8 pagesDatablad MWM Gas Engine Tcg2020 enAli NowrozNo ratings yet

- KNTC Offer To KIPL For K10C Cam ProjectDocument7 pagesKNTC Offer To KIPL For K10C Cam ProjectNathan ChenNo ratings yet

- Planetary Gearboxes For Mobile Applications Hydrotrac GFT Series 20Document4 pagesPlanetary Gearboxes For Mobile Applications Hydrotrac GFT Series 20Anonymous lIJl27QBXLNo ratings yet

- MTU Gendrive Spec 4000G 03 3D3E W2ADocument4 pagesMTU Gendrive Spec 4000G 03 3D3E W2APetrus GunturNo ratings yet

- Technical Data Sheet: Marine Diesel Engine D2862LE496 (V12-2000)Document3 pagesTechnical Data Sheet: Marine Diesel Engine D2862LE496 (V12-2000)mlaouhi MajedNo ratings yet

- Re 79093Document4 pagesRe 79093Anonymous lIJl27QBXLNo ratings yet

- York Ducted InverterDocument2 pagesYork Ducted InverterjABU100% (1)

- 13 Foth ZFDocument29 pages13 Foth ZFDaniel Alex SánchezNo ratings yet

- 09 CX Iveco Cursor 9Document45 pages09 CX Iveco Cursor 9Diego100% (3)

- NEW PREV MAINT PARTS & OIL GD511A-1s-nDocument2 pagesNEW PREV MAINT PARTS & OIL GD511A-1s-nkikki090kikkiNo ratings yet

- Hydraulic Power Unit: RE 51057, Edition: 2020-11, Bosch Rexroth AGDocument20 pagesHydraulic Power Unit: RE 51057, Edition: 2020-11, Bosch Rexroth AGHanzil HakeemNo ratings yet

- 1 5118668111280603310Document44 pages1 5118668111280603310Jéssica Tupy Paulo HenriqueNo ratings yet

- 2022-12-20 Ne-22038 Hyd Power Units Bro en WebDocument8 pages2022-12-20 Ne-22038 Hyd Power Units Bro en WebBeni SaputraNo ratings yet

- Maintenance Schedule Chart of Dozer-D85Ess-2: Item Part No Part Name QTY Replacement HoursDocument3 pagesMaintenance Schedule Chart of Dozer-D85Ess-2: Item Part No Part Name QTY Replacement HoursAsim Ghosh100% (1)

- Rotrex Technical Datasheet C30 Range PDFDocument7 pagesRotrex Technical Datasheet C30 Range PDFMichael SezeniasNo ratings yet

- VRS Working Width and DeflectionDocument4 pagesVRS Working Width and DeflectionBogdanBNo ratings yet

- Cost Estimation For Hull No. FMC-67Document5 pagesCost Estimation For Hull No. FMC-67Md. Ashraful Islam EngineerNo ratings yet

- 8V4000M40A3B10 MTU Engine-DataDocument11 pages8V4000M40A3B10 MTU Engine-DataAlex CorsaroNo ratings yet

- Re77502 2004-05Document20 pagesRe77502 2004-05pamururamuNo ratings yet

- Product Update 2010 - Smmsi Outdoor UnitsDocument3 pagesProduct Update 2010 - Smmsi Outdoor UnitssnowwooNo ratings yet

- Hatz Diesel B Series BrochureDocument8 pagesHatz Diesel B Series BrochureColdbloodedbikerNo ratings yet

- Sheet Service - SKT90SDocument2 pagesSheet Service - SKT90SAnanda risaNo ratings yet

- MTU Datasheet s4000px3 Constant SpeedDocument2 pagesMTU Datasheet s4000px3 Constant SpeedKrish100% (1)

- Prédimensionnemnt Type Projet H2 Mobilité MorrocoDocument16 pagesPrédimensionnemnt Type Projet H2 Mobilité Morrocoyassine ajjaouiNo ratings yet

- ZX240-3 Maintenance PlannerDocument2 pagesZX240-3 Maintenance PlannerGee K ToubulukwaNo ratings yet

- Cassette INVERTER YTKKE 18 To 55 YORKDocument2 pagesCassette INVERTER YTKKE 18 To 55 YORKAlejandroNo ratings yet

- Edm 10Document8 pagesEdm 10Ulises Baute Jr.No ratings yet

- Chapter 10 - Planetary Gear BoxesDocument54 pagesChapter 10 - Planetary Gear BoxesSankuparlang ShullaiNo ratings yet

- Zf-Ecolife: ZF Automatic Transmissions For BusesDocument2 pagesZf-Ecolife: ZF Automatic Transmissions For BusesTaoufikNo ratings yet

- ZX270-3 Maintenance PlannerDocument2 pagesZX270-3 Maintenance PlannerGee K ToubulukwaNo ratings yet

- Recent Maintenance HL Machines 2016Document37 pagesRecent Maintenance HL Machines 2016Ganesh DevadigaNo ratings yet

- 1B20 - 1B20V 1B27 1B30 - 1B30V 1B40 - 1B40V 1B50 - 1B50VDocument8 pages1B20 - 1B20V 1B27 1B30 - 1B30V 1B40 - 1B40V 1B50 - 1B50VchrisrobinsoncnpNo ratings yet

- 01.VD01 IND Informasi UmumDocument108 pages01.VD01 IND Informasi UmumBPP Jember Service100% (1)

- Omm Eh1100 PDFDocument13 pagesOmm Eh1100 PDFdayatNo ratings yet

- 1UR-FE Overview TundraDocument50 pages1UR-FE Overview TundraGrubleen ManNo ratings yet

- Jenbacher: 1. Leanox® Controller: - 1Document3 pagesJenbacher: 1. Leanox® Controller: - 1ArîfNo ratings yet

- 8905-Exhibit B Technical SpecificationsDocument30 pages8905-Exhibit B Technical SpecificationsManuel GonzalezNo ratings yet

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- Distribution System - TopicsDocument7 pagesDistribution System - Topicsjhoni gomezNo ratings yet

- Knocking and Anti KnockingDocument26 pagesKnocking and Anti KnockingsaadzzworldNo ratings yet

- Beli EqpDocument115 pagesBeli EqpRony CamaroNo ratings yet

- Thermodynamic CyclesDocument32 pagesThermodynamic CyclessunitbhaumikNo ratings yet

- APD165PDocument4 pagesAPD165PPercyNo ratings yet

- GE Oil & Gas Nuovo Pignone: Title: Part List: Drawing: Gas Turbine Ms5002DDocument1 pageGE Oil & Gas Nuovo Pignone: Title: Part List: Drawing: Gas Turbine Ms5002DMohammed ElarbedNo ratings yet

- How To: Index The Spark Plugs On A Ficht / Direct Injection OutboardDocument4 pagesHow To: Index The Spark Plugs On A Ficht / Direct Injection OutboardrfffffNo ratings yet

- Motor EmdDocument9 pagesMotor EmdHANSELL MIRANDA ALVANo ratings yet

- Kits Motor CTP F-720-181Document4 pagesKits Motor CTP F-720-181Pedro Alberto BenitesNo ratings yet

- TD824 1F161F40KDocument330 pagesTD824 1F161F40KEvaldas Štrapėla100% (1)

- Mercedes-Benz,: R4 - 155 KW (211 HP) OM 934Document4 pagesMercedes-Benz,: R4 - 155 KW (211 HP) OM 934Kevin TtitoNo ratings yet

- 1KD Engine Repair Manual Section 3 (Fuel System) Pub. No. CE302Document15 pages1KD Engine Repair Manual Section 3 (Fuel System) Pub. No. CE302ManuelNo ratings yet

- Service Manual: Common Rail System For ISUZU 4HK1 / 6HK1 Type EngineDocument49 pagesService Manual: Common Rail System For ISUZU 4HK1 / 6HK1 Type EngineLeonardo Medina100% (1)

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationDocument2 pagesMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W Air Start Distributor OperationArun SNo ratings yet

- Spark-Glow-Plugs-Ignition-Catalogue 777Document1 pageSpark-Glow-Plugs-Ignition-Catalogue 777АлександрNo ratings yet

- Yamaha 40V Servicemanual PDFDocument224 pagesYamaha 40V Servicemanual PDFrainer100% (1)

- 4M06 Spec Sheet RevbDocument4 pages4M06 Spec Sheet RevbIKNo ratings yet

- DongfengDocument82 pagesDongfengtahutempebullatNo ratings yet

- lm6000 Business Unit Igt Packaging PDFDocument10 pageslm6000 Business Unit Igt Packaging PDFEDBNo ratings yet

- CI Engine PDFDocument39 pagesCI Engine PDFDileep VarmaNo ratings yet

- GSH 56 (Euro 0) Chainsaw: Engine Starter Assy Tank and Air Filter Chain Cover and Clutch CrankcaseDocument11 pagesGSH 56 (Euro 0) Chainsaw: Engine Starter Assy Tank and Air Filter Chain Cover and Clutch CrankcaseTaras BilanNo ratings yet

- Toyota 8fg30bDocument561 pagesToyota 8fg30bAngelo Kuibida100% (2)

- Lovato Gas Injection Systems PDFDocument29 pagesLovato Gas Injection Systems PDFJohannesNo ratings yet

- Emission Control Analysis On BS-VI Diesel Engine in Heavy VehicleDocument11 pagesEmission Control Analysis On BS-VI Diesel Engine in Heavy VehicleajayNo ratings yet

- Super ChargersDocument12 pagesSuper ChargersSealtiel1020No ratings yet