Professional Documents

Culture Documents

12 Series-30

12 Series-30

Uploaded by

RE musicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 Series-30

12 Series-30

Uploaded by

RE musicCopyright:

Available Formats

Section 6

MAINTENANCE

Figure 6-5 Pressure Switch (P/N 040694) clockwise to increase or counterclockwise to de-

crease the setting.

Above 100 PSIG (689kPa), the regulator should al-

low pressure to flow into the control chamber of the

Sullicon Control. The Sullicon Control lever should

start to move at this time.

Cycle the control system several times and recheck

all pressure settings.

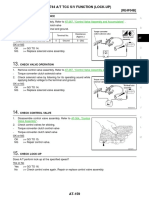

MINIMUM PRESSURE/CHECK VALVE MAINTE-

NANCE

Refer to Figure 6-6. Minimum pressure/check valve

(P/N 241581) maintenance is quite minimal. The only

part which normally requires replacement is the O-

ring on the piston. To replace this ring, order seal re-

pair kit No. 250020-344. and follow the procedure ex-

plained below.

! WARNING

Before performing maintenance on the valve, be

sure that all pressure has been relieved in the com-

pressor sump, and all downstream pressure has

been vented to the atmosphere. Also be sure that

the components of the compressor are cool to the

touch.

Figure 6-6 Minimum Pressure / Check Valve

(P/N 241581 - 12 Series)

(P/N 250016-618 - 16 Series)

desired pressure, the pressure switch setting will re-

quire adjustment (refer to Figure 6-5).

! DANGER

DO NOT touch the electrical contacts, terminal or

leads with any metallic object. Severe electrical

shock may occur.

FOR PRESSURE RANGE ADJUSTMENT:

1. Remove cover to pressure switch.

2. Turn the range adjusting screw to the high pres-

sure setting. Turning the screw counterclockwise

lowers both the high and low pressure equally.

FOR DIFFERENTIAL ADJUSTMENT:

Differential is the difference between the high and

low pressure settings, 10 PSIG (7kPa) is typical.

Turn the differential adjusting screw to the lower (re-

set) setting. Turning the screw counterclockwise

widens the differential by lowering the reset (lower)

setting only.

When the pressure switch adjustment is complete,

the pressure regulator should be adjusted for the

pressure at which modulation of air delivery should

begin. In this case, that pressure will be 100 PSIG

(689kPa). The regulator is adjusted by loosening the

jam nut on the end of the cone shaped cover of the

pressure regulator (refer to Figure 6-11 for the loca- * Repair Kit P/N 250026-758 - 12 Series

tion). With the jam nut loose, turn the adjusting screw ** Repair Kit P/N 250019-444 - 16 Series

24

You might also like

- Mazda 323f RelejiDocument7 pagesMazda 323f RelejimrgbbNo ratings yet

- Atlas Copco Stationary Air Compressors SF1 - SF2 - SF4 SF6T - SF8T. Parts List. From Following Serial Number OnwardsDocument24 pagesAtlas Copco Stationary Air Compressors SF1 - SF2 - SF4 SF6T - SF8T. Parts List. From Following Serial Number OnwardsBorisNo ratings yet

- GA 315 VSD Part List (2002-06)Document37 pagesGA 315 VSD Part List (2002-06)Sales AydinkayaNo ratings yet

- Cat 330C Electric PlanDocument2 pagesCat 330C Electric PlanRajan Mullappilly67% (3)

- SM-VOLVO L120E WHEEL LOADER Service Repair ManualDocument14 pagesSM-VOLVO L120E WHEEL LOADER Service Repair ManualSameh Mohamed100% (1)

- Auto Transmission Air Pressure TestDocument1 pageAuto Transmission Air Pressure TestChinthaka Nayana Kumara RajapakshaNo ratings yet

- MAN B&W S70MC-C Starting and ReversingDocument82 pagesMAN B&W S70MC-C Starting and ReversingDaniel Tsvetilov75% (8)

- XA (T, V) S 650-750-850 JD7 Compressors: Committed To Sustainable ProductivityDocument61 pagesXA (T, V) S 650-750-850 JD7 Compressors: Committed To Sustainable Productivityamerica1591100% (1)

- HydraulicCA251 W2 10241 1ENDocument13 pagesHydraulicCA251 W2 10241 1ENAdrian Alonso Bustos Gonzalez100% (1)

- SM-800.40 FlexAirValve PDFDocument31 pagesSM-800.40 FlexAirValve PDFJIM CAMPBELLNo ratings yet

- Carlyle IOM 5H-F CompressorDocument40 pagesCarlyle IOM 5H-F CompressorBenito Antonio Formoso LouroNo ratings yet

- N1 Reducing ValveDocument8 pagesN1 Reducing ValveAlexander Mugabe100% (1)

- Type 167A Three-W Ay Switching Valve: Instruction ManualDocument4 pagesType 167A Three-W Ay Switching Valve: Instruction Manualluis rodriguezNo ratings yet

- Gas Pressure Regulator RB 1700 RB 1800 RB 1800FDocument16 pagesGas Pressure Regulator RB 1700 RB 1800 RB 1800FMORELLI silvioNo ratings yet

- Fordson Major Systeme HydrauliqueDocument23 pagesFordson Major Systeme HydrauliqueNicolas100% (1)

- CRA Quick ManualDocument2 pagesCRA Quick ManualCarlos LinoNo ratings yet

- E211502 Eng Aug00Document6 pagesE211502 Eng Aug00Mohammed sabatinNo ratings yet

- HLIW145-EB AdjustmentsDocument38 pagesHLIW145-EB AdjustmentsBastian Bazaes100% (1)

- E Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievingDocument30 pagesE Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievinghaggNo ratings yet

- 320B Caterpillar, Testing in Adjusting Relief LineDocument8 pages320B Caterpillar, Testing in Adjusting Relief LineLuisNo ratings yet

- Conveyor Tensioning Device: TP501 Festo DidacticDocument9 pagesConveyor Tensioning Device: TP501 Festo DidacticGiang TônNo ratings yet

- Fluid Power ControlDocument40 pagesFluid Power ControlSonali DeyNo ratings yet

- SIS 2.0 320c Akh00182Document5 pagesSIS 2.0 320c Akh00182Jorge RojasNo ratings yet

- $RVS28IBDocument100 pages$RVS28IBChomiNo ratings yet

- Skip Handling: TP501 Festo DidacticDocument7 pagesSkip Handling: TP501 Festo DidacticHossam AbdelhameedNo ratings yet

- AT Nissan EnglishDocument20 pagesAT Nissan EnglishjoseNo ratings yet

- Operating Instructions Pressure Controller Type ROBOTER": 1. Function 1.1Document2 pagesOperating Instructions Pressure Controller Type ROBOTER": 1. Function 1.1shob1984No ratings yet

- Valvulas Limitadores de La Valvula de ControlDocument5 pagesValvulas Limitadores de La Valvula de ControlRafael RodriguezNo ratings yet

- Volvo D12 - Manutenção 5Document9 pagesVolvo D12 - Manutenção 5UNICARGAS SU, Lda.No ratings yet

- Vaicar KatalogDocument67 pagesVaicar KatalogSami Enis ArıoğluNo ratings yet

- 09GMK 6250 - Hydraulikanlage - EnglDocument8 pages09GMK 6250 - Hydraulikanlage - EnglВиталий РогожинскийNo ratings yet

- SteeringDocument7 pagesSteeringyeremia kristianNo ratings yet

- Water Pump Pressure Control Switch Adjustment Nut Direction1Document12 pagesWater Pump Pressure Control Switch Adjustment Nut Direction1ver_at_workNo ratings yet

- Controles Et Réglages D6RIIDocument36 pagesControles Et Réglages D6RIIEZIUZENo ratings yet

- Excavadora Hidraulica 345b (Relief Valve Pruebas - y - Ajustes)Document17 pagesExcavadora Hidraulica 345b (Relief Valve Pruebas - y - Ajustes)Maquinaria Pesada ServisNo ratings yet

- Basics of Pressure RegulationDocument18 pagesBasics of Pressure Regulationar174_569868987No ratings yet

- Tm-90-21-Ul (R-03/30/22)Document20 pagesTm-90-21-Ul (R-03/30/22)Mohamed Abou El hassanNo ratings yet

- Rt500 1 Service AdjustmentsDocument29 pagesRt500 1 Service AdjustmentsjulianmataNo ratings yet

- PG Dial Governor Back Pressure Controller: Operation ManualDocument12 pagesPG Dial Governor Back Pressure Controller: Operation ManualrNo ratings yet

- Hydraulic Pump Displacement Solenoid Valve Test and Adjustment - tm1508 - Service ADVISOR™2 PDFDocument10 pagesHydraulic Pump Displacement Solenoid Valve Test and Adjustment - tm1508 - Service ADVISOR™2 PDFseba64870% (1)

- ATT Stop and Control Valves-WriteupDocument3 pagesATT Stop and Control Valves-WriteupVijay MahantNo ratings yet

- Suntec Pump Aj6ac Aj6aeDocument2 pagesSuntec Pump Aj6ac Aj6aeMarco Fabricio Contreras MorochoNo ratings yet

- Adjust Relief390fDocument4 pagesAdjust Relief390fMAdhie WaraNo ratings yet

- Test Procedure (Margin Pressure and Load Sensing Pressure)Document10 pagesTest Procedure (Margin Pressure and Load Sensing Pressure)Halil KaraNo ratings yet

- 07 - Hydraulic ComponentsDocument306 pages07 - Hydraulic Componentsphdum23No ratings yet

- Power Team PE400 ManualDocument3 pagesPower Team PE400 ManualTitanplyNo ratings yet

- Hyd0026 DX Main Pump k3 - k5 - t5Document35 pagesHyd0026 DX Main Pump k3 - k5 - t5Abdelrahman SharafNo ratings yet

- Desarmado y Armado Hidrau 416CDocument99 pagesDesarmado y Armado Hidrau 416CedhuamNo ratings yet

- 08 - Column Pressure ReliefDocument10 pages08 - Column Pressure ReliefjeedanNo ratings yet

- L90DDocument8 pagesL90DДмитрий БорисовNo ratings yet

- Woodward Speed Setting MechDocument6 pagesWoodward Speed Setting Mechmanuel1122No ratings yet

- Section 13D - Engine Air System PDFDocument6 pagesSection 13D - Engine Air System PDFrobbertmdNo ratings yet

- Hydrostatic Pump - 15HPDocument14 pagesHydrostatic Pump - 15HPMicheal Booka WhelanNo ratings yet

- SPC Idc 2ls Iom Operation GuideDocument8 pagesSPC Idc 2ls Iom Operation GuideisurukalharaNo ratings yet

- 12 Series-29Document1 page12 Series-29RE musicNo ratings yet

- Adaptomode Inlet Pressure Regulators: ® Types: A4AS, A4AB, A4AD, A4AZDocument16 pagesAdaptomode Inlet Pressure Regulators: ® Types: A4AS, A4AB, A4AD, A4AZpedroNo ratings yet

- A2H Actuator CatalogDocument6 pagesA2H Actuator CatalogahnafNo ratings yet

- PPSL3050 Manual 2 SpringDocument2 pagesPPSL3050 Manual 2 SpringLeAnn WysockiNo ratings yet

- PRM FRDocument7 pagesPRM FRGelber Norberto Gutierrez PalaciosNo ratings yet

- Second-Stage Nozzle Control: GeneralDocument4 pagesSecond-Stage Nozzle Control: GeneralSara VaccaNo ratings yet

- Full Bore Emerg Unloading Valve O&m - 02-24-2011Document9 pagesFull Bore Emerg Unloading Valve O&m - 02-24-2011Enrique AssmannNo ratings yet

- Hyundai Excel X2 1989-1998 Air Conditioning PDFDocument53 pagesHyundai Excel X2 1989-1998 Air Conditioning PDFAamir Nasir KhanNo ratings yet

- Applications Guide: Pneumatic VAV Reset Volume ControllersDocument15 pagesApplications Guide: Pneumatic VAV Reset Volume ControllersSean ByrneNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- 12 Modifying Service Plans: 11.1 Modifying Settings For Compressor ElementDocument2 pages12 Modifying Service Plans: 11.1 Modifying Settings For Compressor ElementRE musicNo ratings yet

- 37Document1 page37RE musicNo ratings yet

- 12 Series-27Document1 page12 Series-27RE musicNo ratings yet

- 7.15 Activating Automatic Restart After Voltage FailureDocument2 pages7.15 Activating Automatic Restart After Voltage FailureRE musicNo ratings yet

- 37 38Document2 pages37 38RE musicNo ratings yet

- 17 Programmable Settings: 17.1 ParametersDocument2 pages17 Programmable Settings: 17.1 ParametersRE musicNo ratings yet

- 13.3 To Modify A Command: ImportantDocument2 pages13.3 To Modify A Command: ImportantRE musicNo ratings yet

- 35 36Document2 pages35 36RE musicNo ratings yet

- 14 Configuration Menu: FunctionDocument2 pages14 Configuration Menu: FunctionRE musicNo ratings yet

- Atlas Copco Stationary Air CompressorsDocument2 pagesAtlas Copco Stationary Air CompressorsRE musicNo ratings yet

- 4 Quick Look at Actual Compressor Status 5 Status Data MenuDocument2 pages4 Quick Look at Actual Compressor Status 5 Status Data MenuRE musicNo ratings yet

- User ManualDocument2 pagesUser ManualRE musicNo ratings yet

- 6 Measured Data Menu 7 Counters Menu: Function FunctionDocument2 pages6 Measured Data Menu 7 Counters Menu: Function FunctionRE musicNo ratings yet

- 7.7 Set of Parameters 7.9 Calling Up/modifying Loading PressureDocument2 pages7.7 Set of Parameters 7.9 Calling Up/modifying Loading PressureRE musicNo ratings yet

- Elektronikon I Regulator: 1 General DescriptionDocument2 pagesElektronikon I Regulator: 1 General DescriptionRE musicNo ratings yet

- GA5 GA7 GA11 Instruction Book 7Document1 pageGA5 GA7 GA11 Instruction Book 7RE musicNo ratings yet

- 2.2 Pictographs: Abbre-Desig - Function Viation Nation Prog Rset RTRN Unld XtraDocument2 pages2.2 Pictographs: Abbre-Desig - Function Viation Nation Prog Rset RTRN Unld XtraRE musicNo ratings yet

- ATLAS COPCO Instruction Book GA 30+, GA 37, GA 45-16Document1 pageATLAS COPCO Instruction Book GA 30+, GA 37, GA 45-16RE musicNo ratings yet

- GA5 GA7 GA11 Instruction Book 6Document1 pageGA5 GA7 GA11 Instruction Book 6RE musicNo ratings yet

- ATLAS COPCO Instruction Book GA 30+, GA 37, GA 45-5Document1 pageATLAS COPCO Instruction Book GA 30+, GA 37, GA 45-5RE musicNo ratings yet

- Atlas Copco Stationary Air CompressorsDocument2 pagesAtlas Copco Stationary Air CompressorsRE musicNo ratings yet

- GA5 GA7 GA11 Instruction Book 4Document1 pageGA5 GA7 GA11 Instruction Book 4RE musicNo ratings yet

- ATLAS COPCO Instruction Book GA 30+, GA 37, GA 45-19Document1 pageATLAS COPCO Instruction Book GA 30+, GA 37, GA 45-19RE musicNo ratings yet

- Atlas Copco GA 15 To GA 30 Part List 41Document1 pageAtlas Copco GA 15 To GA 30 Part List 41RE musicNo ratings yet

- Atlas Copco GA 15 To GA 30 Part List 42Document1 pageAtlas Copco GA 15 To GA 30 Part List 42RE musicNo ratings yet

- Atlas Copco GA 15 To GA 30 Part List 44Document1 pageAtlas Copco GA 15 To GA 30 Part List 44RE musicNo ratings yet

- Atlas Copco GA 15 To GA 30 Part List 35Document1 pageAtlas Copco GA 15 To GA 30 Part List 35RE musicNo ratings yet

- Atlas Copco GA 15 To GA 30 Part List 40Document1 pageAtlas Copco GA 15 To GA 30 Part List 40RE musicNo ratings yet

- Atlas Copco GA 15 To GA 30 Part List 38Document1 pageAtlas Copco GA 15 To GA 30 Part List 38RE musicNo ratings yet

- Atlas Copco GA 15 To GA 30 Part List 37Document1 pageAtlas Copco GA 15 To GA 30 Part List 37RE musicNo ratings yet

- Cable ADSS - Flex Span - AFL PDFDocument5 pagesCable ADSS - Flex Span - AFL PDFOsmar Adolfo Davila SoriaNo ratings yet

- Diagnostic Trouble Codes (DTC) : DTC P0716 Turbine Speed Sensor Circuit PerformanceDocument3 pagesDiagnostic Trouble Codes (DTC) : DTC P0716 Turbine Speed Sensor Circuit Performanceluis eduardo corzo enriquezNo ratings yet

- Scorpion: User InstructionsDocument18 pagesScorpion: User InstructionsWuryAgusNo ratings yet

- Double E Safety Chuck ManualDocument30 pagesDouble E Safety Chuck ManualAlex ChaconNo ratings yet

- Working Order of Line-2 Ass CTST-GTB, MB, KPD MLCPDocument39 pagesWorking Order of Line-2 Ass CTST-GTB, MB, KPD MLCPNewDelhi RSSNo ratings yet

- Documents Referenced in Appendix A of The National Plumbing Code of Canada 2005 Table A-1.3.1.2.Document6 pagesDocuments Referenced in Appendix A of The National Plumbing Code of Canada 2005 Table A-1.3.1.2.ashishtanjeaaNo ratings yet

- THYRIPART Generator Excitation Circuit CheckDocument5 pagesTHYRIPART Generator Excitation Circuit CheckБогдан Кендзер100% (2)

- Cad Lab ManualDocument1 pageCad Lab ManualRAM SINGHNo ratings yet

- WilTec Hydraulic 12 Ton Press With ManometerDocument6 pagesWilTec Hydraulic 12 Ton Press With ManometerWaleed MuradNo ratings yet

- RAB PLTS Hybrid (SPH) - 230Vac-Price ListDocument33 pagesRAB PLTS Hybrid (SPH) - 230Vac-Price ListilhamNo ratings yet

- 4 Iw 6GN1 3Document1 page4 Iw 6GN1 3lebanese.intlNo ratings yet

- Hand and Power Tool SafetyDocument25 pagesHand and Power Tool Safetykittu2207No ratings yet

- Wire¤t Rating PDFDocument2 pagesWire¤t Rating PDFVIKRAM DESAINo ratings yet

- Thaioil Pigging Organization Chart: Coordinator Project ManagerDocument1 pageThaioil Pigging Organization Chart: Coordinator Project Managerpirapon kumanon100% (1)

- 1HC210629518Document27 pages1HC210629518MayurNo ratings yet

- NG - CD - HD16 9 1939SX P080 - A - PDF - hd16 9 1939sx p080 - 605159Document2 pagesNG - CD - HD16 9 1939SX P080 - A - PDF - hd16 9 1939sx p080 - 605159O mecanicoNo ratings yet

- Alternative Source For Gas Supply To Indorama ProjectDocument4 pagesAlternative Source For Gas Supply To Indorama ProjectChidiebere Samuel OkogwuNo ratings yet

- Air Powered Man Rider Winch LS2-150RLP Series ModelsDocument12 pagesAir Powered Man Rider Winch LS2-150RLP Series ModelsHesam Ghaffari100% (1)

- DAC Universal Spare Parts June 09 Sirona NR 1 - UKDocument14 pagesDAC Universal Spare Parts June 09 Sirona NR 1 - UKÖzer YildirimNo ratings yet

- Olympus BH-2 Microscope Head - Part ListDocument20 pagesOlympus BH-2 Microscope Head - Part ListMahnaz BakhshiNo ratings yet

- AC ReplyDocument1 pageAC ReplyMohammed JavidNo ratings yet

- 0 Logica Price List 2017 Costrut - 7 - IngDocument22 pages0 Logica Price List 2017 Costrut - 7 - IngoxooxooxoNo ratings yet

- Brochure RIG D1Document20 pagesBrochure RIG D1ltovar01No ratings yet

- Datasheet GX 50 - 150 - 092022Document7 pagesDatasheet GX 50 - 150 - 092022star2002sun5gmail.comNo ratings yet

- Commented - HT PANEL 11kV and 33kVDocument8 pagesCommented - HT PANEL 11kV and 33kVGautam MishraNo ratings yet

- DWE4120 B3 T1 Dewalt PBDocument4 pagesDWE4120 B3 T1 Dewalt PBJose MolinaNo ratings yet