Professional Documents

Culture Documents

1359 Broadway - 20th Floor - MEP Addendum - 1

1359 Broadway - 20th Floor - MEP Addendum - 1

Uploaded by

cristianldg2000Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1359 Broadway - 20th Floor - MEP Addendum - 1

1359 Broadway - 20th Floor - MEP Addendum - 1

Uploaded by

cristianldg2000Copyright:

Available Formats

MEP CONSULTANT

1430 Broadway

New York, NY 10018

V: 212.868.4660

F: 212.868.4680

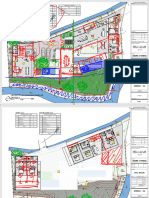

WEST 37TH ST.

COPY PRIVATE PRIVATE STORAGE

AREA OFFICE OFFICE ROOM

20-33 20-34 20-35 20-36

A#53

OPEN (N)PP-20

AREA

20-37

OPEN 30AS 30AS 30AS

AREA FCU-18 FCU-19 FCU-20

20-32 A#22,24 A#26,28 LD A#26,28

LD LD

30AS

A#29 A#29 A#29 FCU-21

A#25,27 LD

A#29

PRIVATE

OFFICE

20-38

MEETING

ROOM

20-30 30AS FEC

FCU-17 BC-4

J

PRIVATE

A#22,24

LD

A#29

LD

A#29

A#10,12

30AS

30AS

A#26,28

FCU-25

PHONE

A#51

- OPEN

OFFICE LD ROOM

20-29 A#29 20-39

30AS

PHONE 30AS FCU-22 PRIVATE

ROOM FCU-16 30AS OFFICE

A#26,28 LD FCU-23

20-28 A#22,24 LD

20-40

A#29 A#25,27 LD MENS

A#29 RESTROOM

30AS

STORAGE A#29 60AS ERV-1

ROOM EWH-2 A#34,36,38 20-41 ACCU-IT

20-27 RP EWH

A#42 ELECTRICAL

LD 30AS CLOSET A#44,46,48 A#45,47,49

IDF A#29

ROOM 30AS BC-3 TX-1 20-42

FCU-15 A#10,12 A#29 30AS

20-26 FCU-24 COMMUNICATIONS

A#21,23 LD A#29 CP

LD 30AS A#32 A#25,27 CLOSET

A#29 LD A#50,52 LD 20-43 PRIVATE

A#29 OFFICE

A#29

BRO

CORRIDOR AC-IT 30AS MD

A#30 20-44

20-25

COAT

CLOSET

20-24

ADW

P. E. P. E. P. E.

PHONE

ROOM

FEC

PRIVATE

20-23 OFFICE

CONFERENCE 20-45

AY

ROOM ELEVATOR

20-22 LOBBY

ADA 20-00

RESTROOM

20-21

ADA MD A#30

MD A#30 MD A#30

RESTROOM

MD A#30 FSD A#30 FSD A#30

20-20 PANTRY

AREA

FHC

PRIVATE 20-01

OFFICE EWH-1

P. E. P. E. P. E. PRIVATE

20-19 OFFICE

A#42 RP EWH 20-46

LACTATION A#33,35,37

ROOM A#29 LD

20-18

STORAGE 30AS WOMENS

CLOSET SHAFT FCU-1 RESTROOM

20-17 A#13,15 TX-2 20-02

LD 30AS

STAIR

20-16

A#29

A#31 A#21,23

FCU-14

LD

EWH-4

EWH A#40 FEC

ELECTRICAL 20TH FLOOR MER PART PLAN

A#29

SCALE:1/2"=1'-0"

PRIVATE A#10,12

OFFICE 30AS 30AS 0' 3' 6'

20-15 FCU-4 STORAGE

F. E. LD ROOM

PRIVATE

A#14,16 LD 30AS

A#29 A#29 LD EWH-3 FCU-13 20-03

OFFICE

A#29

BC-1

A#21,23 PRIVATE

1/2"= 1'-0"

20-14 A#42 RP EWH A#39,41,43 LD OFFICE

30AS A#29

FCU-5 30AS FCU-2 20-47

MEETING

ROOM FCU-3 MD A#13,15

F. E. 30AS A#30 LD

30AS

20-13 A#13,15 30AS BC-2 PRIVATE

LD FCU-8

A#14,16 A#29 A#10,12 OFFICE

LD A#29 A#17,19 LD 30AS 20-04

A#29 LD

A#29 FCU-12

COPY

AREA A#29 A#18,20

LD

20-12

F. E. A#29

FEC

F. E. 30AS 30AS 30AS

FCU-6 A#14,16 FCU-7 FCU-9 FCU-10

30AS A#17,19

LD LD

A#17,19 LD

A#18,20 LD

A#29 A#29 A#29 A#29 30AS

FCU-11

A#18,20

SEE MER PART PLAN LD OPEN

A#29 AREA

(N)PP-20 20-05

MER

ROOM

20-11

OPEN PRIVATE PRIVATE PRIVATE PANTRY

AREA OFFICE OFFICE OFFICE AREA

20-10 20-09 20-08 20-07 20-06

N

WEST 36TH ST.

ELECTRICAL 20TH FLOOR MECHANICAL POWER PLAN PANEL LEGEND

PREFIX PANEL VOLTAGE LOCATED

3 ISSUED FOR ADDENDUM #1 5/2/2024 JB

SCALE:1/8"=1'-0"

3 ISSUED FOR BID 4/26/2024 JB

8' 4' 0' 8' 'A' PP-20 120/208V MECHANICAL ROOM

2 ISSUED FOR DOB FILING 4/5/2024 MYS

1/8"= 1'-0" 1 ISSUED FOR REVIEW 3/22/2024 MYS

NO. REVISION DATE BY

TPG ARCHITECTURE, LLP

31 PENN PLAZA

132 WEST 31ST STREET, 5TH FLOOR, NEW YORK, NY 10001

212.768.0800 | TPGARCHITECTURE.COM

IN CONSIDERATION OF RECEIVING DRAWINGS FROM TPG ARCHITECTURE LLP IN

AN ELECTRONIC FORM, THE RECIPIENT AGREES, TO THE FULLEST EXTENT

PERMITTED BY LAW, TO HOLD HARMLESS AND INDEMNIFY TPG ARCHITECTURE

LLP FROM AND AGAINST ALL CLAIMS, LIABILITIES, LOSSES, DAMAGES, AND

COSTS, INCLUDING BUT NOT LIMITED TO ATTORNEY'S FEES, ARISING OUT OF,

OR IN ANY WAY CONNECTED WITH THE USE, RE-USE, MIS-USE, MODIFICATION,

OR MISINTERPRETATION OF THE MACHINE-READABLE INFORMATION PROVIDED

BY TPG ARCHITECTURE LLP UNDER THIS AGREEMENT.

PROJECT

S:\CAD\1359 BWAY\20FL_PROGYNY_DEMO BUILDOUT_23043.08\03-DWGS\E-201.DWG / Plot Date: May, 2, 2024 - 4:54 :PM

PROGYNY

2ND AND 20TH FLOOR

1359 BROADWAY

NEW YORK, NY 10018

DRAWING

ELECTRICAL

20TH FLOOR

MECHANICAL POWER

PLAN

SEAL DATE

1.29.24

PROJECT NO.

11523048-00

Last Saved By: AMETA / Save Date: 5/2/2024 4:51:41 PM

SCALE

AS SHOWN

CAD FILE NO. DOB PAGE

X of #

DWG NO.

NYC DOB NO.

E-201.00

MEP CONSULTANT

1430 Broadway

New York, NY 10018

V: 212.868.4660

F: 212.868.4680

GENERAL POWER NOTES

1. FIRE STOP ALL NEW PENETRATIONS CREATED WITH NEW INSTALLATION. FIRE

RATING SHALL MATCH EXISTING WALL OR CEILING RATING.

2. WIRING IN AREAS WHERE THERE IS NO CEILING, OPEN OR EXPOSED WALLS, AND

MECHANICAL ROOMS SHALL BE INSTALLED IN CONDUIT. MINIMUM SIZE OF

CONDUIT SHALL BE 3/4". CONDUIT TO BE RAN HIGH AND TIGHT TO THE BUILDING

STRUCTURE AND CLOSE TO SIDE OF BEAMS AND COLUMNS. MAIN CONDUIT

RUNS SHALL BE RAN A MINIMUM OF ONE COLUMN BAY FROM THE WINDOW LINE

AND AS CLOSE TO THE BUILDING CORE AS POSSIBLE. CONTRACTOR TO ISSUE

SHOP DRAWING ON CONDUIT ROUTES FOR REVIEW PRIOR TO INSTALLATION.

3. ALL EQUIPMENT (PULL BOXES, DISCONNECT SWITCHES, ETC) SHALL BE

N.I.C INSTALLED IN CONJUNCTION WITH THE MANUFACTURERS RECOMMENDATIONS,

THE NATIONAL ELECTRIC CODE AND THE NYC ELECTRIC CODE. IN CASES OF

CONFLICT, THE MORE STRINGENT REQUIREMENT SHALL BE MAINTAINED.

4. CIRCUIT ALL DEVICES TO PANEL BOARDS INDICATED BY MATCH LINES.

5. TYPICAL CIRCUITING SHOWS A MAXIMUM OF FOUR (4) COMPUTER OUTLETS PER

CIRCUIT AND A MAXIMUM OF SIX (6) CONVENIENCE OUTLETS PER 20A CIRCUIT.

6. EACH RECEPTACLE BRANCH CIRCUIT SHALL UTILIZE A SEPARATE NEUTRAL

CONDUCTOR.

7. RECEPTACLES FOR ALL COMPUTER CONTROLLED EQUIPMENT, INCLUDING

PERSONAL COMPUTERS, WILL BE CIRCUITED SEPARATELY FROM ALL OTHER

RECEPTACLES AND WILL BE CONNECTED WITH A CONTINUOUS GROUND

CONDUCTOR TO THE GROUND BUS IN THE SERVING BRANCH CIRCUIT PANEL

BOARD. ALL CIRCUITS SERVING COMPUTER EQUIPMENT SHALL CONTAIN AN

OVERSIZED NEUTRAL.

8. ALL DEDICATED OR COMPUTER RECEPTACLES IN THE RAISED FLOOR BOXES

ACCU-1 ACCU-2 ACCU-3 A#8 SHALL BE A DIFFERENT COLOR THAN CONVENIENCE RECEPTACLES.

GFCI COORDINATE COLOR WITH COLORS AS FOLLOWS:

GRAY - COMPUTER

WHITE - CONVENIENCE

9. DUPLEX RECEPTACLES COLORS SHALL BE AS FOLLOWS:

WP 200AS WP 200AS WP 200AS GRAY - COMPUTER

WHITE - CONVENIENCE

A#1,3,5 A#2,4,6 A#7,9,11 10. ALL 15A OR 20A 120V RECEPTACLES THAT ARE ACCESSIBLE SHALL BE GFCI

(GROUND FAULT CIRCUIT INTERRUPTER). RECEPTACLES THAT ARE NOT

ACCESSIBLE SHALL BE GIVEN A GFCI CIRCUIT BREAKER. TRIP RATING OF GFCI

SHALL NOT BE LESS THAN 30mA.

11. FOR EXISTING DEVICES, ASSOCIATED FEEDERS AND CONDUIT TO REMAIN,

CONTRACTOR SHALL INSTALL REQUIRED EQUIPMENT TO MAINTAIN CONTINUITY

AND FUNCTION OF THE EXISTING SYSTEM.

12. THE CONTRACTOR MUST COORDINATE WITH ARCHITECTURAL LAYOUTS AND

COORDINATE SPECIFICALLY WITH THE ARCHITECT AND ENGINEERS FOR ALL

TRADE LAYOUTS WITHIN THE SHOP DRAWING FOR REVIEW AND APPROVAL.

13. EQUIPMENT IS SHOWN FOR DIAGRAMMATIC PURPOSES ONLY. PHYSICAL

DIMENSIONS OF EQUIPMENT AND EXACT LOCATIONS SHALL BE FIELD VERIFIED.

14. CONDUITS FOR FLOOR BOXES WILL BE DONE THROUGH TRENCHING ONLY.

15. CONTRACTOR SHALL PERFORM GROUND PENETRATING RADAR ALLFOR

LOCATIONS WHERE GROUND PENETRATION IS REQUIRED PRIOR TO

COMMENCEMENT OF ALL WORK.

POWER PLAN KEY NOTES:

N.I.C CONTRACTOR SHALL FOLLOW THE REFRIGERANT PIPING FOR THE NEW

ELECTRICAL CONDUITS THAT ARE FEEDING THE NEW AC UNITS FROM THE

20TH FLOOR MECHANICAL ROOM. REFER TO MECHANICAL DRAWINGS FOR

ROUTING. REFER TO E-200 FOR PANEL LOCATION.

PANEL LEGEND

PREFIX PANEL VOLTAGE LOCATED

'A' PP-20 120/208V 20TH FLOOR

MECHANICAL ROOM

N.I.C

N.I.C

N.I.C

3 ISSUED FOR ADDENDUM #1 5/2/2024 JB

3 ISSUED FOR BID 4/26/2024 JB

2 ISSUED FOR DOB FILING 4/5/2024 MYS

1 ISSUED FOR REVIEW 3/22/2024 MYS

ELECTRICAL 22ND FLOOR ROOF POWER PLAN NO. REVISION DATE BY

SCALE:1/4"=1'-0"

4' 2' 0' 4'

1/4"= 1'-0"

TPG ARCHITECTURE, LLP

31 PENN PLAZA

132 WEST 31ST STREET, 5TH FLOOR, NEW YORK, NY 10001

212.768.0800 | TPGARCHITECTURE.COM

IN CONSIDERATION OF RECEIVING DRAWINGS FROM TPG ARCHITECTURE LLP IN

AN ELECTRONIC FORM, THE RECIPIENT AGREES, TO THE FULLEST EXTENT

PERMITTED BY LAW, TO HOLD HARMLESS AND INDEMNIFY TPG ARCHITECTURE

LLP FROM AND AGAINST ALL CLAIMS, LIABILITIES, LOSSES, DAMAGES, AND

COSTS, INCLUDING BUT NOT LIMITED TO ATTORNEY'S FEES, ARISING OUT OF,

OR IN ANY WAY CONNECTED WITH THE USE, RE-USE, MIS-USE, MODIFICATION,

OR MISINTERPRETATION OF THE MACHINE-READABLE INFORMATION PROVIDED

BY TPG ARCHITECTURE LLP UNDER THIS AGREEMENT.

PROJECT

S:\CAD\1359 BWAY\20FL_PROGYNY_DEMO BUILDOUT_23043.08\03-DWGS\E-202.DWG / Plot Date: May, 2, 2024 - 4:54 :PM

PROGYNY

2ND AND 20TH FLOOR

1359 BROADWAY

NEW YORK, NY 10018

DRAWING

ELECTRICAL

22ND FLOOR

ROOF POWER PLAN

SEAL DATE

1.29.24

PROJECT NO.

11523048-00

Last Saved By: AMETA / Save Date: 5/2/2024 4:50:36 PM

SCALE

AS SHOWN

CAD FILE NO. DOB PAGE

X of #

DWG NO.

NYC DOB NO.

E-202.00

MEP CONSULTANT

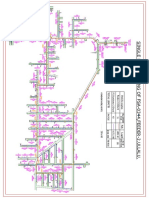

(E)BUS DUCT 1430 Broadway

New York, NY 10018

V: 212.868.4660

F: 212.868.4680

ELEC. CLOSET ELEC. CLOSET SUITE

NOTES

1. SEE DRAWING E-001 FOR GENERAL NOTES, REMOVAL NOTES, ABBREVIATIONS, AND SYMBOL LISTS.

2. SEE DRAWING E-400 FOR ELECTRICAL PANEL SCHEDULES.

3. SEE DRAWING E-600 FOR ELECTRICAL SPECIFICATIONS.

4. PRIOR TO THE COMMENCEMENT OF WORK, THE CONTRACTOR SHALL PROVIDE SHOP DRAWINGS FOR ALL ELECTRICAL

CLOSETS, INDICATING NEW AND EXISTING EQUIPMENT AND NOTING ALL CODE REQUIRED CLEARANCES.

600AS

500AF REMOVED REMOVED REMOVED REMOVED REMOVED REMOVED REMOVED KEY NOTES

200AS 100AS LP-20H DP-20 RP-20 RP-20A RP-20B ELEC. PNL ELEC. PNL 1. SUB METERING TO BE INSTALLED BY CPL.

200AF 100AF 225A MLO 500A MCB 225A MLO 225A MLO 225A MLO CR CS 2. EXISTING FEEDER THAT IS FEEDING PANEL LP-19H TO BE SWUNG OVER TO PANEL P19A LOCATED IN THE BUS DUCT

400AS 120/208V 120/208V 120/208V 120/208V 120/208V 225A MLO 225A MLO CLOSET ON THE 19TH FLOOR. PROVIDE NEW 60A 3-POLE BREAKER IN PANEL P19A TO FEED PANEL LP-19H. PROVIDE 4#6 +

200AF 1#10G IN 1"C. COORDINATE WITH CPL FOR SUB METERING.

24 POLE 30 POLE 42 POLE 42 POLE 42 POLE 120/208V 120/208V

42 POLE 42 POLE

LEGEND

ROOM

DEMARCATION

CONDUIT AND WIRE

20TH FLOOR 20TH FLOOR

TO BE REMOVED

ELECTRICAL PARTIAL DEMOLITION RISER DIAGRAM NEW CONDUIT AND

WIRE

N.T.S.

EXISTING CONDUIT

AND WIRE TO REMAIN

(E)BUS DUCT

ELEC. CLOSET FREIGHT ELEV. MECH. ROOM IT ROOM

LOBBY

F3 F2

600AS NEW

F1

600AF LP-20

100A MCB FEED THROUGH

120/208V F1

400AS 24 POLE

NEW NEW NEW NEW

400AF 30, 4W

RP-20A RP-20B PP-20 IT PANEL

400A MCB 400A MLO 600A MCB 100A MLO

F2

F1

120/208V 120/208V 120/208V 120/208V

84 POLE 42 POLE 54 POLE 24POLE

30, 4W 30, 4W 30, 4W 30, 4W

20TH FLOOR 20TH FLOOR

FEEDER LEGEND:

NEW ELECTRICAL PARTIAL RISER DIAGRAM

N.T.S. F1

F2

F3

3 ISSUED FOR ADDENDUM #1 5/2/2024 JB

3 ISSUED FOR BID 4/26/2024 JB

2 ISSUED FOR DOB FILING 4/5/2024 MYS

1 ISSUED FOR REVIEW 3/22/2024 MYS

NO. REVISION DATE BY

TPG ARCHITECTURE, LLP

31 PENN PLAZA

132 WEST 31ST STREET, 5TH FLOOR, NEW YORK, NY 10001

212.768.0800 | TPGARCHITECTURE.COM

IN CONSIDERATION OF RECEIVING DRAWINGS FROM TPG ARCHITECTURE LLP IN

AN ELECTRONIC FORM, THE RECIPIENT AGREES, TO THE FULLEST EXTENT

PERMITTED BY LAW, TO HOLD HARMLESS AND INDEMNIFY TPG ARCHITECTURE

LLP FROM AND AGAINST ALL CLAIMS, LIABILITIES, LOSSES, DAMAGES, AND

COSTS, INCLUDING BUT NOT LIMITED TO ATTORNEY'S FEES, ARISING OUT OF,

OR IN ANY WAY CONNECTED WITH THE USE, RE-USE, MIS-USE, MODIFICATION,

OR MISINTERPRETATION OF THE MACHINE-READABLE INFORMATION PROVIDED

BY TPG ARCHITECTURE LLP UNDER THIS AGREEMENT.

PROJECT

S:\CAD\1359 BWAY\20FL_PROGYNY_DEMO BUILDOUT_23043.08\03-DWGS\E-300.DWG / Plot Date: May, 2, 2024 - 4:54 :PM

PROGYNY

2ND AND 20TH FLOOR

1359 BROADWAY

NEW YORK, NY 10018

DRAWING

ELECTRICAL

RISER DIAGRAM

SEAL DATE

1.29.24

PROJECT NO.

11523048-00

Last Saved By: AMETA / Save Date: 5/2/2024 4:50:34 PM

SCALE

AS SHOWN

CAD FILE NO. DOB PAGE

X of #

DWG NO.

NYC DOB NO.

E-300.00

MEP CONSULTANT

1430 Broadway

New York, NY 10018

V: 212.868.4660

F: 212.868.4680

3 ISSUED FOR ADDENDUM #1 5/2/2024 JB

3 ISSUED FOR BID 4/26/2024 JB

2 ISSUED FOR DOB FILING 4/5/2024 MYS

1 ISSUED FOR REVIEW 3/22/2024 MYS

NO. REVISION DATE BY

TPG ARCHITECTURE, LLP

31 PENN PLAZA

132 WEST 31ST STREET, 5TH FLOOR, NEW YORK, NY 10001

212.768.0800 | TPGARCHITECTURE.COM

IN CONSIDERATION OF RECEIVING DRAWINGS FROM TPG ARCHITECTURE LLP IN

AN ELECTRONIC FORM, THE RECIPIENT AGREES, TO THE FULLEST EXTENT

PERMITTED BY LAW, TO HOLD HARMLESS AND INDEMNIFY TPG ARCHITECTURE

LLP FROM AND AGAINST ALL CLAIMS, LIABILITIES, LOSSES, DAMAGES, AND

COSTS, INCLUDING BUT NOT LIMITED TO ATTORNEY'S FEES, ARISING OUT OF,

OR IN ANY WAY CONNECTED WITH THE USE, RE-USE, MIS-USE, MODIFICATION,

OR MISINTERPRETATION OF THE MACHINE-READABLE INFORMATION PROVIDED

BY TPG ARCHITECTURE LLP UNDER THIS AGREEMENT.

PROJECT

S:\CAD\1359 BWAY\20FL_PROGYNY_DEMO BUILDOUT_23043.08\03-DWGS\E-400.DWG / Plot Date: May, 2, 2024 - 4:54 :PM

PROGYNY

2ND AND 20TH FLOOR

1359 BROADWAY

NEW YORK, NY 10018

DRAWING

ELECTRICAL

PANEL

SCHEDULES

SEAL DATE

1.29.24

PROJECT NO.

11523048-00

Last Saved By: AMETA / Save Date: 5/1/2024 10:50:52 AM

SCALE

AS SHOWN

CAD FILE NO. DOB PAGE

X of #

DWG NO.

NYC DOB NO.

E-400.00

MEP CONSULTANT

1430 Broadway

New York, NY 10018

V: 212.868.4660

FIRE ALARM NOTES F: 212.868.4680

1. PRIOR TO SUBMISSION OF BIDS: THE ELECTRICAL CONTRACTOR SHALL CONTACT FIRE ALARM SYMBOL LIST

THE BUILDING FIRE ALARM VENDOR AND BUILDING CHIEF ENGINEER FOR

DIRECTIONS.

2. ALL FIRE ALARM DEVICES SHALL BE PURCHASED FROM BUILDING FIRE ALARM

VENDOR TO ASSURE COMPATIBILITY WITH THE EXISTING SYSTEM. ALL FIRE ALARM SMOKE DETECTOR

DEVICES SHALL BE UL LISTED AND NYC APPROVED. THE FIRE ALARM VENDORS EL DENOTES ELEVATOR RECALL

PRICE SHALL INCLUDE ALL REQUIRED DEVICES (ZONES, BATTERIES, ETC.) TO MAKE

THIS A COMPLETE WORKING SYSTEM.

3. THIS IS NOT A POINT TO POINT WIRING DIAGRAM. USE THIS DIAGRAM FOR DUCT MOUNTED SMOKE DETECTOR

ESTIMATING PURPOSES ONLY. PRIOR TO STARTING ANY WORK, A WORKING POINT

TO POINT WIRING DIAGRAM SHALL BE OBTAINED FROM BUILDING FIRE ALARM

VENDOR. THE EXACT LOCATION AND QUANTITIES OF FIRE ALARM DEVICES, REFER

STROBE

TO FLOOR PLANS.

4. CONTRACTOR TO PROTECT AND MAINTAIN ALL REMAINING FIRE ALARM DEVICES

AND CABLING DURING CONSTRUCTION. FIRE STOP ALL OPENINGS IN FLOOR AND B

WALL. C SPEAKER STROBE

5. ALL REPROGRAMMING OF SOFTWARE, HARDWARE AND THE FINAL CONNECTIONS

TO EXISTING FIRE DATA GATHERING PANEL SHALL BE DONE BY BUILDING FIRE TO NEAREST

ALARM VENDOR, BUT THIS CONTRACTOR SHALL INCLUDE PRICE OF THIS WORK IN ADDRESSABLE FIRE ALARM EL EL EL EL FOR DOOR RELEASE PULL STATION

THE BID PRICE. THE FIRE ALARM VENDOR SHALL ALSO INCLUDE ALL EQUIPMENT DATA GATHERING PANEL

(DGP, CABLES STROBE PANEL, PROGRAMMING, ETC.) REQUIRED TO MAKE THE

SYSTEM OPERABLE.

6. STROBE LIGHTS SHALL BE ADA APPROVED TYPE AND SHALL BE MOUNTED AT 80" EX RELAY

ABOVE FINISHED FLOOR OR 6" BELOW CEILING, WHICHEVER IS LOWER. STROBE A

LIGHTS SHALL BE RATED AT 75 CANDELA.

7. ALL EXISTING BASE BUILDING DEVICES ARE TO REMAIN UNLESS OTHERWISE NOTED. WARDEN STATION

REACTIVATE AND LEAVE IN WORKING CONDITION UPON COMPLETION OF THIS

PROJECT.

8. IF EXISTING BASE BUILDING DEVICES ARE NOT IN WORKING ORDER, THE 20TH FLOOR 20TH FLOOR

CONTRACTOR SHALL REPAIR/REPLACE AS PART OR THIS SCOPE OF WORK. FIRE SMOKE DAMPER

9. THE INSTALLATION SHALL COMPLY WITH THE BUILDING CODE OF THE CITY OF NEW

YORK, NATIONAL ELECTRICAL CODE WITH NEW YORK CITY AMENDMENTS TO THE

NATIONAL ELECTRICAL CODE AND RELATED ADMINISTRATIVE PROVISIONS AND THE

PARTIAL FIRE ALARM RISER DIAGRAM FAN SHUTDOWN RELAY

NYC FIRE DEPARTMENT REQUIREMENTS. N.T.S.

10. THE CONTRACTOR SHALL FILE A-433 AND OBTAIN APPROVAL FROM THE FIRE

DEPARTMENT.

11. PROVIDE ALTERNATE STROBE LIGHT AND SPEAKER CIRCUITS A & B TO FEED NEW STROBE BOOSTER PANEL

DEVICES TO BALANCE LOAD AND TO ELIMINATE ADJACENT DEVICES WIRED TO SAME

CIRCUITS.

12. LOCATIONS FOR ALL SPEAKER/STROBES & OTHER F.A. & SECURITY DEVICES ARE TO

BE VERIFIED WITH ARCHITECT PRIOR TO INSTALLATION. PARTIAL RISER DIAGRAM NOTES: EXISTING WIRING

13. CONTRACTOR SHALL VERIFY EXACT LOCATION OF NEAREST USABLE DGP WITHE

BASE BLDG FIRE ALARM REPRESENTATIVE PRIOR TO SUBMISSION OF BID. 1. CONTRACTOR SHALL REMOVE ALL EXISTING FIRE ALARM DEVICES WITHIN AREA OF

14. CONNECT ALL SPEAKERS (IN SPEAKER/STROBE DEVICES) INDEPENDENTLY TO THE WORK. PROVIDE NEW DEVICES AS SHOWN ON PLAN. NEW WIRING

EXISTING FIRE ALARM CONTROL PANEL. 2. WIRE SECURITY RELAY TO FIRE ALARM LOOP AS PER THE BUILDING FIRE ALARM

15. ALL INACCESSIBLE DUCT DETECTORS SHALL HAVE A REMOTE LED INDICATOR. VENDOR'S REQUIREMENTS & NYC FIRE DEPARTMENT RULES. PROVIDE NECESSARY

16. CONTRACTOR SHALL BE RESPONSIBLE FOR SUBMISSION OF AS-BUILTS TO WIRING, DEVICES, ACCESSORIES & RE-PROGRAMING TO ENSURE THAT THE EX EXISTING TO REMAIN

ENGINEER MINIMUM 1 WEEK PRIOR TO FIRE DEPARTMENT TESTING OR CLIENT ELECTRO-MAGNETIC LOCK SYSTEMS WILL FUNCTION PROPERLY DURING

MOVE-IN, WHICHEVER COMES FIRST. EMERGENCY SITUATIONS.

17. FIRE ALARM WIRING SHALL BE CLASS B AND LEVEL OF SURVIVABILITY SHALL BE 3. PROVIDE ALL NECESSARY MODULES TO OBTAIN SYNCHRONIZATION OF ALL FIRE

R TO BE REMOVED

LEVEL 1. ALARM STROBES (NEW AND EXISTING)

18. PRIOR TO BID, CONTACT THE FIRE ALARM VENDOR FOR COMPLETE AND TOTAL BID

PACKAGE INCLUDING ANY NEW STROBE POWER PANELS AND DATA GATHERING

PANELS REQUIRED FOR A FULLY FUNCTIONAL SYSTEM. PROVIDE THESE DEVICES AS RL TO BE RELOCATED

REQUIRED

19. ALL HVAC UNITS 2,000 CFM OR MORE SHALL BE PROVIDED WITH DUCT DETECTORS FIRE ALARM WIRING SCHEDULE

AND A RELAY FOR SHUT DOWN. COORDINATE WITH THE FIRE ALARM VENDOR AND RE

HVAC CONTRACTOR RELOCATED

20. ALL WIRING FOR THE FIRE ALARM SYSTEM (NEW AND EXISTING TO REMAIN) IN OPEN 1 PAIR #16 AWG FPLP PER CIRCUIT - ADDRESSABLE LOOP

OR EXPOSED CEILING AREAS SHALL BE IN CONDUIT. EXISTING WIRING TO REMAIN

SHALL BE REINSTALLED IN CONDUIT. 1 PAIR #14 AWG FPLP PER CIRCUIT - VISUAL CIRCUIT

1 PAIR #14 AWG FPLP PER CIRCUIT - SPEAKER CIRCUIT FIRE ALARM MATRIX

DEVICES

1 PAIR #16 AWG FPLP PER CIRCUIT - TELEPHONE CIRCUIT

ELEVATOR MACHINE ROOM SMOKE DETECTOR

ELEVATOR LOBBY SMOKE DETECTOR

DUCT DETECTOR (RETURN)

DUCT DETECTOR (SUPPLY)

SMOKE/HEAT DETECTOR

* FIRE ALARM ZONE IS DEFINED AS

MANUAL PULL STATION

WATERFLOW SWITCH

THE FLOOR ABOVE AND BELOW THE

FLOOR, AS WELL AS THE FLOOR THAT

TAMPER SWITCH

IS IN ALARM.

STATUS INDICATION AT FACP X X X X X X X X

AUDIBLE NOTIFICATION FIRE ZONE * X X X X X X X

VISUAL NOTIFICATION FIRE ZONE * X X X X X X X

FAN SHUTDOWN X X X X X X X

DAMPER CLOSE X X X X X X X

DOOR RELEASE X X X X X X X

ELEVATOR RECALL X X X

CENTRAL OFFICE NOTIFICATION X X X X X X X X

3 ISSUED FOR ADDENDUM #1 5/2/2024 JB

3 ISSUED FOR BID 4/26/2024 JB

2 ISSUED FOR DOB FILING 4/5/2024 MYS

1 ISSUED FOR REVIEW 3/22/2024 MYS

NO. REVISION DATE BY

TPG ARCHITECTURE, LLP

31 PENN PLAZA

132 WEST 31ST STREET, 5TH FLOOR, NEW YORK, NY 10001

212.768.0800 | TPGARCHITECTURE.COM

IN CONSIDERATION OF RECEIVING DRAWINGS FROM TPG ARCHITECTURE LLP IN

AN ELECTRONIC FORM, THE RECIPIENT AGREES, TO THE FULLEST EXTENT

PERMITTED BY LAW, TO HOLD HARMLESS AND INDEMNIFY TPG ARCHITECTURE

LLP FROM AND AGAINST ALL CLAIMS, LIABILITIES, LOSSES, DAMAGES, AND

COSTS, INCLUDING BUT NOT LIMITED TO ATTORNEY'S FEES, ARISING OUT OF,

OR IN ANY WAY CONNECTED WITH THE USE, RE-USE, MIS-USE, MODIFICATION,

OR MISINTERPRETATION OF THE MACHINE-READABLE INFORMATION PROVIDED

BY TPG ARCHITECTURE LLP UNDER THIS AGREEMENT.

PROJECT

S:\CAD\1359 BWAY\20FL_PROGYNY_DEMO BUILDOUT_23043.08\03-DWGS\FA-001.DWG / Plot Date: May, 2, 2024 - 4:54 :PM

PROGYNY

2ND AND 20TH FLOOR

1359 BROADWAY

NEW YORK, NY 10018

DRAWING

FIRE ALARM

SYMBOLS, NOTES

AND ABBREVIATIONS

SEAL DATE

1.29.24

PROJECT NO.

11523048-00

Last Saved By: AMETA / Save Date: 5/2/2024 4:50:31 PM

SCALE

AS SHOWN

CAD FILE NO. DOB PAGE

X of #

DWG NO.

NYC DOB NO.

FA-001.00

MEP CONSULTANT

1430 Broadway

New York, NY 10018

V: 212.868.4660

F: 212.868.4680

WEST 37TH ST. FIRE ALARM NOTES:

COPY PRIVATE PRIVATE STORAGE

AREA OFFICE OFFICE ROOM

20-33 20-34 20-35 20-36

75CD N

OPEN

AREA

N N N N

N N 20-37

OPEN

AREA

N N

20-32

N

75CD

PRIVATE

OFFICE

20-38

MEETING

ROOM N N

20-30 FEC N N

TP

PRIVATE PHONE

OFFICE ROOM

20-29 20-39

PHONE PRIVATE

ROOM TP OFFICE

TP N N ”

20-28 N N 20-40

N 15CD MENS

STORAGE RESTROOM

ROOM N N 15CD 20-41

N N

20-27

N 15CD DOOR RELEASE N ELECTRICAL

IDF N 15CD CLOSET

ROOM N 30CD 20-42

N

20-26 N COMMUNICATIONS

N

CLOSET

N N PRIVATE

N 20-43

N 15CD OFFICE

BRO

CORRIDOR

20-44

20-25

COAT

CLOSET

20-24

ADW

75CD

P. E. P. E. P. E.

PHONE TP

ROOM

FEC

N PRIVATE

20-23 OFFICE

CONFERENCE 20-45

AY

ROOM ELEVATOR

20-22 TP LOBBY

ADA 75CD 20-00

N N

RESTROOM EL EL

15CD

20-21 N N N 15CD

ADA N

RESTROOM TP

N

20-20 PANTRY

AREA

PRIVATE 20-01

OFFICE P. E. P. E. P. E. PRIVATE

N OFFICE

20-19 15CD N N

LACTATION 20-46

75CD

ROOM N 15CD N

20-18

STROBE BOOSTED

STORAGE PANEL N N WOMENS

CLOSET SHAFT 15CD

RESTROOM

20-17 15CD

N 20-02

STAIR N

20-16 FEC

N N

PRIVATE

OFFICE 75CD

TP

20-15 STORAGE

F. E. N N N ROOM

PRIVATE 20-03

OFFICE TP N N

N N N PRIVATE

20-14 EL 15CD OFFICE

N N

N N 20-47

MEETING N

ROOM

F. E.

20-13 PRIVATE

OFFICE

N N 20-04

COPY

AREA N N

20-12

F. E.

TP

FEC

N

EL

F. E.

N 30CD N N N N N N N N

15CD N

OPEN

AREA

N N N N 20-05

MER N

ROOM

N N

20-11

N 75CD N 75CD

N 75CD

N N OPEN PRIVATE PRIVATE PRIVATE PANTRY

AREA OFFICE OFFICE OFFICE AREA

20-10 20-09 20-08 20-07 20-06

N

WEST 36TH ST.

3 ISSUED FOR ADDENDUM #1 5/2/2024 JB

3 ISSUED FOR BID 4/26/2024 JB

FIRE ALARM 20TH FLOOR PLAN 2

1

ISSUED FOR DOB FILING

ISSUED FOR REVIEW

4/5/2024

3/22/2024

MYS

MYS

SCALE:1/8"=1'-0"

8' 4' 0' 8' NO. REVISION DATE BY

1/8"= 1'-0"

TPG ARCHITECTURE, LLP

31 PENN PLAZA

132 WEST 31ST STREET, 5TH FLOOR, NEW YORK, NY 10001

212.768.0800 | TPGARCHITECTURE.COM

IN CONSIDERATION OF RECEIVING DRAWINGS FROM TPG ARCHITECTURE LLP IN

AN ELECTRONIC FORM, THE RECIPIENT AGREES, TO THE FULLEST EXTENT

PERMITTED BY LAW, TO HOLD HARMLESS AND INDEMNIFY TPG ARCHITECTURE

LLP FROM AND AGAINST ALL CLAIMS, LIABILITIES, LOSSES, DAMAGES, AND

COSTS, INCLUDING BUT NOT LIMITED TO ATTORNEY'S FEES, ARISING OUT OF,

OR IN ANY WAY CONNECTED WITH THE USE, RE-USE, MIS-USE, MODIFICATION,

OR MISINTERPRETATION OF THE MACHINE-READABLE INFORMATION PROVIDED

BY TPG ARCHITECTURE LLP UNDER THIS AGREEMENT.

PROJECT

S:\CAD\1359 BWAY\20FL_PROGYNY_DEMO BUILDOUT_23043.08\03-DWGS\FA-100.DWG / Plot Date: May, 2, 2024 - 4:54 :PM

PROGYNY

2ND AND 20TH FLOOR

1359 BROADWAY

NEW YORK, NY 10018

DRAWING

FIRE ALARM

20TH FLOOR PLAN

SEAL DATE

1.29.24

PROJECT NO.

11523048-00

Last Saved By: AMETA / Save Date: 5/2/2024 4:52:43 PM

SCALE

AS SHOWN

CAD FILE NO. DOB PAGE

X of #

DWG NO.

NYC DOB NO.

FA-100.00

MEP CONSULTANT

GENERAL NOTES 1430 Broadway

1. ALL PIPING PENETRATING THROUGH FIRE-RATED PARTITIONS SHALL BE SEALED

New York, NY 10018

WITH MATCHING FIRE-RATED MATERIAL. V: 212.868.4660

F: 212.868.4680

2. ALL PIPING AND CONDUIT RUNS SHALL BE COORDINATED WITH ALL TRADES.

CONTRACTORS SHALL ADVISE OF ANY CONFLICTS OR INTERFERENCES PRIOR TO

INSTALLATION.

3. CONTRACTOR SHALL SUBMIT COORDINATED SHOP DRAWING FOR THE

REFRIGERANT PIPING AND CONDENSATE PIPING FOR REVIEW AND APPROVAL BY

ENGINEER OF RECORD PRIOR TO ANY INSTALLATIONS.

4. CONTRACTOR SHALL SUBMIT COORDINATED PIPING SHOP DRAWING TO VRF

MANUFACTURER FOR REFRIGERANT PIPING SIZE CONFIRMATION. CONTRACTOR

SHALL NOT INSTALL ANY PIPING UNTIL SIZES ARE CONFIRMED WITH

MANUFACTURER.

N.I.C 5. REFRIGERANT PIPING SHALL BE HARD TEMPER TYPE 'L' COPPER PIPING WITH

BRAZED SEAMS. ALL FITTINGS SHALL BE WROUGHT COPPER TYPE MEETING

ANSIB16.22 SPECIFICATION.

6. FLUX SHALL NOT BE USED FOR BRAZING PROCEDURE. USE PHOSPHOR-COPPER

BRAZING FILLER METAL.

NEW OUTDOOR VRF UNITS TO INSTALLED ON STEEL 7. ALL REFRIGERANT PIPING SHALL BE CLEANED OF ALL DUST, DIRT, CUTTING OIL,

MOISTURE OR ANY OTHER CONTAMINATION PRIOR TO CHARGING THE SYSTEM

1 DUNNAGE W/ SPRING VIBRATION ISOLATORS.

COORDINATE WITH THE STRUCTURAL DRAWINGS FOR WITH REFRIGERANT.

UNIT SUPPORT.

8. CONTRACTOR SHALL PROVIDE ALL TRAPS, INVERTED TRAPS AND INTERMEDIATE

TYP. FOR (3) TRAPS IN REFRIGERANT PIPING AS REQUIRED BY UNIT MANUFACTURERS IOM DUE

TO CHANGE IN ELEVATION.

9. PRIOR TO FINAL CONNECTIONS AND ADDITION OF REFRIGERANT CHARGE,

CONTRACTOR SHALL PRESSURE TEST ALL REFRIGERANT PIPING TO 300PSIG FOR

30 MINUTES WITH DRY NITROGEN. THERE SHALL BE NO DROP IN TEST PRESSURE

OVER 30 MINUTE DURATION.

ACCU-1 ACCU-2 ACCU-3 10. ALL REFRIGERANT PIPING SHALL BE INSULATED WITH 1-1/2" CLOSED CELL FOAM

INSULATION WITH ALL JOINTS AND SEAMS SEALED AND TAPED.

11. ALL REFRIGERANT AND CONDENSATE PIPING INSTALLED IN EXTERIOR SPACES

SHALL BE COVERED WITH ALUMINUM JACKETING.

12. ALL REFRIGERANT PIPING SHALL BE SUPPORTED WITH CLAMP ON KINDORF

MAIN REFRIGERANT PIPING FROM OUTDOOR VRF UNITS SIZED PER THE TRAPEZE HANGERS AS PER DESIGN DETAIL. PIPE CLAMPS SHALL BE

MANUFACTURERS SPECIFICATIONS. PIPING SHALL BE RUN TIGHT TO THE CUSH-A-THERM CLAMPS WITH RIGID CLOSED CELL FOAM INSULATION. CLAMPS

PARAPET AND STACKED ON TOP OF ONE ANOTHER. EXISTING ROOFTOP AC UNITS MOUNTED ON STEEL SHALL NOT BE INSTALLED IN DIRECT CONTACT WITH PIPING.

DUNNAGE SHALL REMAIN AND BE PROTECTED.

(6) PIPES IN TOTAL.

N.I.C

EXISTING ROOFTOP AC UNIT TO

REMAIN AND BE PROTECTED.

PIPING TO BE RUN DOWN ALONG THE EXTERIOR OF THE BUILDING DOWN TO THE

20TH FLOOR. PIPING SHALL BE INSTALLED TIGHT TO THE WALL. COORDINATE WITH

BUILDING ENGINEERING FOR FINAL ROUTING. REFER TO DWG M-106 FOR 20TH

FLOOR PENETRATION LOCATION AND ROUTING CONTINUATION.

(6) PIPES IN TOTAL

N.I.C

N.I.C

N.I.C

1 3 ISSUED FOR ADDENDUM #1 5/2/2024 JB

3 ISSUED FOR BID 4/26/2024 JB

2 ISSUED FOR DOB FILING 4/5/2024 MYS

1 ISSUED FOR REVIEW 3/22/2024 MYS

MECHANICAL 22ND FLOOR ROOF PLAN NO. REVISION DATE BY

SCALE:1/4"=1'-0"

4' 2' 0' 4'

1/4"= 1'-0"

TPG ARCHITECTURE, LLP

31 PENN PLAZA

132 WEST 31ST STREET, 5TH FLOOR, NEW YORK, NY 10001

212.768.0800 | TPGARCHITECTURE.COM

IN CONSIDERATION OF RECEIVING DRAWINGS FROM TPG ARCHITECTURE LLP IN

AN ELECTRONIC FORM, THE RECIPIENT AGREES, TO THE FULLEST EXTENT

PERMITTED BY LAW, TO HOLD HARMLESS AND INDEMNIFY TPG ARCHITECTURE

LLP FROM AND AGAINST ALL CLAIMS, LIABILITIES, LOSSES, DAMAGES, AND

COSTS, INCLUDING BUT NOT LIMITED TO ATTORNEY'S FEES, ARISING OUT OF,

OR IN ANY WAY CONNECTED WITH THE USE, RE-USE, MIS-USE, MODIFICATION,

OR MISINTERPRETATION OF THE MACHINE-READABLE INFORMATION PROVIDED

BY TPG ARCHITECTURE LLP UNDER THIS AGREEMENT.

S:\CAD\1359 BWAY\20FL_PROGYNY_DEMO BUILDOUT_23043.08\03-DWGS\M-105-ROOF.DWG / Plot Date: May, 2, 2024 - 4:47 :PM

PROJECT

PROGYNY

2ND AND 20TH FLOOR

1359 BROADWAY

NEW YORK, NY 10018

DRAWING

MECHANICAL

22ND FLOOR ROOF PLAN

SEAL DATE

1.29.24

PROJECT NO.

11523048-00

Last Saved By: CHIRST / Save Date: 5/2/2024 10:07:18 AM

SCALE

AS SHOWN

CAD FILE NO. DOB PAGE

8 of 13

DWG NO.

NYC DOB NO.

M-105.00

MEP CONSULTANT

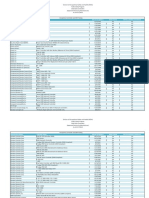

1430 Broadway

SPLIT AIRCOOLED VRF HEAT RECOVERY INDOOR UNITS MFR. (AS STD.) "MITSUBISHI ELECTRIC - TRANE" New York, NY 10018

ELECTRICAL

V: 212.868.4660

RATED PERFORMANCE CLG. DESIGN PERFORMANCE HTG. DESIGN PERFORMANCE FAN INFORMATION REFRIGERANT PIPE

F: 212.868.4680

AC UNIT SERVICE LOCATION MODEL OUTDOOR UNIT BRANCH UNIT UNIT TYPE REFRIGERANT COOLING HEATING T.C S.C. EAT DB EAT WB T.C EAT DB LOW MED HIGH NOISE UNIT WEIGHT LIQUID PIPE GAS PIPE

(CFM) (CFM) (CFM) VOLTS Ø HZ MCA MAX FUSE (db(A)) (LBS) (INCHES) (INCHES)

BTU/HR BTU/HR BTU/HR BTH/HR DEG F DEG F BTU/HR DEG F

FCU-1 20-22 20-19 TPEFYP015MA144A ACCU-1 BC-1 CEILING-CONCELED (DUCTED) R410A 15,000 17,000 15,018 11,371 80 67 12,341 70 - - 494 208 1 60 2.9 15 - - - -

FCU-2 20-00/12 20-15 TPEFYP018MA144A ACCU-1 BC-1 CEILING-CONCELED (DUCTED) R410A 18,000 20,000 18,022 13,724 80 67 14,519 70 - - 600 208 1 60 2.9 15 - - - -

FCU-3 20-19 20-14 TPEFYP015MA144A ACCU-1 BC-1 CEILING-CONCELED (DUCTED) R410A 15,000 17,000 15,018 11,371 80 67 12,341 70 - - 494 208 1 60 2.9 15 - - - -

FCU-4 20-18/23 20-13 TPEFYP015MA144A ACCU-1 BC-1 CEILING-CONCELED (DUCTED) R410A 15,000 17,000 15,018 11,371 80 67 12,341 70 - - 494 208 1 60 2.9 15 - - - -

FCU-5 20-13 20-13 TPEFYP006MA144A ACCU-1 BC-1 CEILING-CONCELED (DUCTED) R410A 6,000 6,700 6,007 5,763 80 67 4,864 70 - - 300 208 1 60 1.8 15 - - - -

FCU-6 20-10 20-10 TPEFYP036MA144A ACCU-1 BC-1 CEILING-CONCELED (DUCTED) R410A 36,000 40,000 36,044 28,406 80 67 29,039 70 - - 1271 208 1 60 4.3 15 - - - -

FCU-7 20-10 20-10 TPEFYP036MA144A ACCU-1 BC-1 CEILING-CONCELED (DUCTED) R410A 36,000 40,000 36,044 28,406 80 67 29,039 70 - - 1271 208 1 60 4.3 15 - - - -

FCU-8 20-9/8/7/4 20-09 TPEFYP018MA144A ACCU-1 BC-1 CEILING-CONCELED (DUCTED) R410A 18,000 20,000 18,022 13,724 80 67 14,519 70 - - 600 208 1 60 2.9 15 - - - -

FCU-9 20-10 20-10 TPEFYP036MA144A ACCU-2 BC-2 CEILING-CONCELED (DUCTED) R410A 36,000 40,000 32,124 26,902 80 67 24,398 70 - - 1271 208 1 60 4.3 15 - - - -

FCU-10 20-10 20-10 TPEFYP036MA144A ACCU-2 BC-2 CEILING-CONCELED (DUCTED) R410A 36,000 40,000 32,124 26,902 80 67 24,398 70 - - 1271 208 1 60 4.3 15 - - - -

FCU-11 20-05 20-05 TPEFYP042MA144A ACCU-2 BC-2 CEILING-CONCELED (DUCTED) R410A 48,000 54,000 42,832 31,477 80 67 32,937 70 - - 1306 208 1 60 4.4 15 - - - -

FCU-12 20-05 20-04 TPEFYP012MA144A ACCU-2 BC-2 CEILING-CONCELED (DUCTED) R410A 12,000 13,500 10,708 7,832 80 67 8,234 70 - - 371 208 1 60 2.1 15 - - - -

FCU-13 20-05 20-46/47 TPEFYP024MA144A ACCU-2 BC-2 CEILING-CONCELED (DUCTED) R410A 24,000 27,000 21,416 18,228 80 67 16,469 70 - - 883 208 1 60 2.9 15 - - - -

FCU-14 20-01 20-06 TPEFYP036MA144A ACCU-2 BC-2 CEILING-CONCELED (DUCTED) R410A 36,000 40,000 32,124 26,902 80 67 24,398 70 - - 1271 208 1 60 4.3 15 - - - -

FCU-15 20-30 20-27 TPEFYP015MA144A ACCU-3 BC-3 CEILING-CONCELED (DUCTED) R410A 15,000 17,000 13,409 10,742 80 67 9,030 70 - - 494 208 1 60 2.9 15 - - - -

FCU-16 20-28/29 20-29 TPEFYP008MA144A ACCU-3 BC-3 CEILING-CONCELED (DUCTED) R410A 8,000 9,000 7,151 6,105 80 67 4,780 70 - - 300 208 1 60 1.8 15 - - - -

FCU-17 20-32 20-32 TPEFYP024MA144A ACCU-3 BC-3 CEILING-CONCELED (DUCTED) R410A 24,000 27,000 21,454 18,242 80 67 14,341 70 - - 883 208 1 60 2.9 15 - - - -

FCU-18 20-32 20-32 TPEFYP024MA144A ACCU-3 BC-3 CEILING-CONCELED (DUCTED) R410A 24,000 27,000 21,454 18,242 80 67 14,341 70 - - 883 208 1 60 2.9 15 - - - -

FCU-19 20-32 20-32 TPEFYP024MA144A ACCU-3 BC-3 CEILING-CONCELED (DUCTED) R410A 24,000 27,000 21,454 18,242 80 67 14,341 70 - - 883 208 1 60 2.9 15 - - - -

FCU-20 20-37 20-37 TPEFYP024MA144A ACCU-3 BC-3 CEILING-CONCELED (DUCTED) R410A 24,000 27,000 21,454 18,242 80 67 14,341 70 - - 883 208 1 60 2.9 15 - - - -

FCU-21 20-37 20-37 TPEFYP036MA144A ACCU-3 BC-4 CEILING-CONCELED (DUCTED) R410A 36,000 40,000 32,182 26,923 80 67 21,246 70 - - 1271 208 1 60 4.3 15 - - - -

FCU-22 20-34/35/39 20-34 TPEFYP015MA144A ACCU-3 BC-4 CEILING-CONCELED (DUCTED) R410A 15,000 17,000 13,409 10,742 80 67 9,030 70 - - 494 208 1 60 2.9 15 - - - -

FCU-23 20-38/40 20-39 TPEFYP024MA144A ACCU-3 BC-4 CEILING-CONCELED (DUCTED) R410A 24,000 27,000 21,454 18,242 80 67 14,341 70 - - 883 208 1 60 2.8 15 - - - -

FCU-24 20-44/45 20-01 TPEFYP024MA144A ACCU-3 BC-4 CEILING-CONCELED (DUCTED) R410A 24,000 27,000 21,454 18,242 80 67 14,341 70 - - 883 208 1 60 2.9 15 - - - -

FCU-25 20-32 20-32 TPEFYP024MA144A ACCU-3 BC-4 CEILING-CONCELED (DUCTED) R410A 24,000 27,000 21,454 18,242 80 67 14,341 70 - - 883 208 1 60 2.9 15 - - - -

NOTES:

1. SELECTION BASED ON EQUIPMENT MANUFACTURED BY MITSUBISHI ELECTRIC / TRANE.

2. SEE OUTDOOR CONDENSING UNIT SCHEDULE FOR DETAILS REGARDING CONNECTION CAPACITY, OUTDOOR CONDITIONS AND OTHER FACTORS ASSOCIATED WITH CORRECTED CAPACITIES.

3. INDOOR (FAN COIL UNIT) AND OUTDOOR (CONDENSING UNIT) SHALL BE OF THE SAME MANUFACTURER AND SHALL BE CERTIFIED FOR USE WITH EACH OTHER. REMOTE CONDENSING UNITS SHALL BE SECURELY MOUNTED AS DETAILED IN THE MANUFACTURERS INSTALLATION MANUAL AND THE

DESIGN DOCUMENTS.

4. CONTRACTOR TO CONFIRM REFRIGERANT PIPING SIZES WITH THE MANUFACTURER BASED ON ACTUAL FIELD ROUTING OF REFRIGERANT PIPING. ROUTE AS SHOWN ON DESIGN DOCUMENTS IS SCHEMATIC AND SHALL BE VERIFIED BY THE CONTRACTOR. CONTRACTOR TO SUBMIT REFRIGERANT

PIPING SHOP DRAWING FOR MANUFACTURER AND ENGINEER OF RECORD REVIEW.

5. ALL FCUs SHALL BE PROVIDED WITH AN INTERNAL, FACTORY INSTALLED CONDENSATE PUMP CAPABLE OF 25" OF LIFT.

6. PROVIDE MITSUBISHI PAR-40MAAU FACTORY REMOTE CONTROLLER FOR EACH EVAPORATOR UNIT.

7. PROVIDE MITSUBISHI FBM2-1-A, FBM2-2-A, FBM2-3-A, OR FBM2-4-A MERV 13 FILTER BOX FOR EACH FCU, COORDINATE INVERTIBLE FILTER ACCESS SIDE AND FIELD CONVERTIBLE INLET OPENING CONFIGURATION WITH FIELD CONDITIONS. INSTALL NEW MERV 13 FILTERS.

8. OUTSIDE AIR DUCTWORK SHALL BE CONNECTED TO OPENING ON UNIT CASING W/ FLEXIBLE CONNECTION, REFER TO MANUFACTURER IOM .

9. BMS CONTRACTOR SHALL PROVIDE REQUIRED CONTROLLERS TO INTERLOCK RADIATOR CONTROL VALVE AND LEAK DETECTION.

10. PROVIDE SECONDARY STAINLESS STEEL DRIP PAN BELOW EACH EVAPORATOR WITH LEAK DETECTOR. UPON ACTIVATION OF LEAK DETECTOR, ASSOCIATED AC/FCU, BRANCH CONTROLLER OR CONDENSING UNIT SHALL SHUT DOWN AND SOUND LOCAL AND BMS ALARM.

11. CONTRACTOR SHALL CONSTANT AIR REGULATOR (CAR) AND VOLUME DAMPERS AT EACH FCU OA CONNECTION, AND BALANCE TO CFM VALUES INDICATED ONPLAN.

12. CONTRACTOR TO PROVIDE MODULATING MOTORIZED DAMPER AT OA CONNECTION TO EACH CONFERENCE ROOM FCU. MOTORIZED DAMPER ACTUATORS BY BMS CONTRACTOR (BUILDING STD.); DAMPER MATERIAL SHALL BE EXTRUDED ALUMINUM BODY WITH INSULATED BLADES AND LOW

LEAKAGE SILICONE SEALS (MFR. TAMCO MODEL NO. 9000 PER BUILDING STD. -CONTACT TIM DAILY: 212-643-8001).

CEILING DIFFUSERS/RETURN GRILLES MFR. (AS STD.) "TITUS" SPLIT AIRCOOLED VRF HEAT RECOVERY OUTDOOR UNITS MFR. (AS STD.) "MITSUBISHI ELECTRIC - TRANE"

RATED PERFORMANCE CLG. DESIGN PERFORMANCE HTG. DESIGN PERFORMANCE ELECTRICAL REFRIGERANT PIPE CONNECTION SIZE

CFM NOMINAL MAX. CFM MAX S.P. UNIT

FACE SIZE MODEL REMARKS FAN NOISE AHRI AHRI

RANGE NECK SIZE NC (IN. H 0)

2 AC SERVICE LOCATION MODEL UNIT TYPE REFRIGERANT EAT EAT WEIGHT LIQUID SUCTION HP GAS

T.C. HEATING T.C. T.C. (CFM) MAX (dB(A)) IEER/EER COP

UNIT DB DB VOLTS Ø HZ MCA SCCR (LBS) PIPE PIPE PIPE

BTU/H BTU/H BTU/H BTU/H FUSE

DEG F DEG F (INCHES) (INCHES) (INCHES)

0-130 6"Ø 10 0.OO3 24"x24" OMNI

ACCU-1 BC-1 22ND FL ROOFTOP TURYE1683AN41AN N GENERATION R-2, VRF, HEAT RECOVERY R-410A 168,000 188,000 159,950 90 126,820 10.8 - 208 3 60 70 110 5 85.5 887 7/8" - 1-1/8" 19.4/10.5 3.42

131-220 8"Ø 10 0.029 24"x24" OMNI

10 ACCU-2 BC-2 22ND FL ROOFTOP TURYE1923AN41AN N GENERATION R-2, VRF, HEAT RECOVERY R-410A 192,000 215,000 171,330 90 130,835 10.8 - 208 3 60 80 125 5 85.5 887 7/8" - 1-1/8" 26.5/12.2 3.76

221-330 10"Ø 0.038 24"x24" OMNI

431-600 21 0.101 ACCU-3 BC-3 & BC-4 22ND FL ROOFTOP TURYE2403AN40AN N GENERATION R-2, VRF, HEAT RECOVERY R-410A 240,000 255,000 216,330 90 143,950 10.8 - 208 3 60 82 125 5 68 887 7/8" - 1-1/8" 22.8/10.5 3.42

12"Ø 24"x24" OMNI

601-750 14"Ø 20 0.124 24"x24" OMNI NOTES:

1. SELECTION BASED ON EQUIPMENT MANUFACTURED BY MITSUBISHI ELECTRIC / TRANE.

- 24"x12" - - 12"x24" 350RL GRILLE 2. UNIT SHALL BE CERTIFIED, LISTED AND LABELED PER AHRI1230.

3. CONDENSING UNITS TO BE PROVIDED WITH MODULATING INVERTER DRIVEN SCROLL COMPRESSORS.

- 24"x24" - - 24"x24" 350RL GRILLE 4. INSTALLING CONTRACTOR MUST HAVE SUCCESSFULLY COMPLETED MANUFACTURERS CERTIFIED INSTALLATION CLASS WITHIN THE PAST 36 MONTHS.

5. ENTIRE SYSTEM SHALL BE PROVIDED WITH A 10 YEAR, PARTS ONLY WARRANTY, INCLUDING COMPRESSORS. CONTRACTOR TO COMPLY WITH MANUFACTURER PROCEDURES FOR EXTENDED SYSTEM WARRANTY INCLUDING PIPING DOCUMENTATION, INSTALLATION QUALITY MANAGEMENT, INSTALLER TRAINING,

AND MANUFACTURER INSPECTIONS. CONTRACTOR SHALL OBTAIN AND PROVIDE MANUFACTURER'S EXTENDED WARRANTY.

NOTES: 6. CONTRACTOR TO CONFIRM REFRIGERANT PIPING SIZES WITH THE MANUFACTURER BASED ON ACTUAL FIELD ROUTING OF REFRIGERANT PIPING. ROUTE AS SHOWN ON DESIGN DOCUMENTS IS SCHEMATIC AND SHALL BE VERIFIED BY THE CONTRACTOR.

7. CONDENSING UNIT STATIC PRESSURE SETTING TO BE FIELD CHANGED TO MAX. AVAILABLE FOR DUCTED EXHAUST CONFIGURATION. REFER TO MANUFACTURERS IOM.

1. COORDINATE EXACT LOCATION WITH ARCHITECTS DRAWINGS. 8. PROVIDE FACTORY ACCESSORY BASE PAN HEATER AND REQUIRED CONTROL BOX, TO BE FIELD INSTALLED BY THE CONTRACTOR. INSTALL PER MANUFACTURER IOM.

9. AIR SOURCE CONDENSING UNITS SHALL HAVE RATED CAPACITY DATA FROM -13F TO 122F.

2. PROVIDE DIFFUSERS WITH EQUALIZING GRID AND OPPOSED BLADE DAMPERS 10. PROVIDE MITSUBISHI TE-200A SYSTEM CENTRALIZED CONTROLLER WITH BACNET INTERFACE W/ ACTIVATED LICENSE FOR CONNECTION OF EQUIPMENT TO BASE BUILDING BMS. INTEGRATION TO BMS SHALL BE COMPLETED BY BMS CONTRACTOR.

3. PROVIDE IN LAY-IN CEILINGS WITH TYPE 3 FRAME. 11. MOTORIZED DAMPER ACTUATORS BY BMS CONTRACTOR (BUILDING STD.); DAMPER MATERIAL SHALL BE EXTRUDED ALUMINUM BODY WITH INSULATED BLADES AND LOW LEAKAGE SILICONE SEALS (MFR. TAMCO MODEL NO. 9000 PER BUILDING STD. -CONTACT TIM DAILY: 212-643-8001).

4. FOR 2-WAY OR 3-WAY BLOW, BLANK OFF NEXT (NECK TO BE NEXT SIZE. 12. CONTRACTOR TO PROVIDE 16 GAUGE STAINLESS STEEL DRIP PAN W/ 2" LIP AND SOLDERED SEAMS. BENEATH CONDENSING UNIT. PITCH PAN TOWARDS DRAIN CONNECTION AND PROVIDE 3/4" DRAIN PIPE TO FLOOR DRAIN IN MER. REFER TO MER PART PLANS FOR ADDITIONAL INFORMATION.

5. ALL SUPPLY REGISTERS SHALL BE DOUBLE DEFLECTING TYPE, FRONT BLADES VERTICAL AS MANUFACTURED BY "TITUS", 13. CONTRACTOR SHALL PROVIDE (4) 1" DEFLECTION SPRING VIBRATION ISOLATORS FOR EACH CONDENSING UNIT.

MODEL 300RS.

6. PROVIDE TITUS "LIGHTSHIELD" FOR ALL CEILING RETURN GRILLES.

7. PROVIDE CORD OPERATED DAMPERS WHERE GRILLES ARE INSTALLED IN INACCESSIBLE CEILINGS.

MFR. (AS STD.)

CONSTANT AIR REGULATORS (CAR) "ALDES" VRF BRANCH SELECTOR MFR. (AS STD.) "MITSUBISHI ELECTRIC - TRANE"

LOW PRESSURE DIA X DIMENSIONS ELECTRICAL

CFM NOMINAL DEPTH

RANGE MODEL REMARKS MAXIMUM CAPACITY UNIT WEIGHT

MINIMUM PIPE INSULATION THICKNESS (THICKNESS IN INCHES) (PER EC403.2.10) RANGE NECK SIZE

(IN WG) (IN) UNIT TAG SERVICE LOCATION MODEL UNIT TYPE REFRIGERANT (BTU) (PER PORT)

WIDTH HEIGHT DEPTH VOLTS Ø HZ MCA

MAX (LBS)

FUSE

30-85 4"Ø 0.12-1.2 4.1"X3.0" CAR3

FLUID OPERATING INSULATION CONDUCTIVITY NOMINAL PIPE OF TUBE SIZE (INCHES)

TEMPERATURE RANGE CONDUCTIVITY MEAN RATING 86-180 5"Ø 0.12-1.2 5.2"X3.8" CAR3 BC-1 FCU-1 to FCU-8 OFFICE 20-14 TCMBM1012JA21N4 MAIN R410A 54,000 - - - 208 1 60 1.19 20 133

AND USAGE (°F) (BTU×IN/(H×FT2×°F)) TEMPERATURE, (°F) <1 1 TO < 1½ 1½ TO < 4 4 TO < 8 8≥

BC-2 FCU-9 to FCU-14 OFFICE 20-07 TCMBM0108JA11N4 MAIN R410A 54,000 - - - 208 1 60 0.83 20 108

181-260 6"Ø 0.12-1.2 6.1"X4.6" CAR3

> 350 0.32-.34 250 4.5 5.0 5.0 5.0 5.0

251-350 0.29-0.32 200 3.0 4.0 4.5 4.5 4.5 261-385 8"Ø 0.12-1.2 8.2"X6.7" CAR3 BC-3 FCU-15 to FCU-20 PHONE RM 20-28 TCMBM0108JA11N4 MAIN R410A 54,000 - - - 208 1 60 0.83 20 108

201-250 0.27-0.30 150 2.5 2.5 2.5 3.0 3.0 386-620 10"Ø 0.12-1.2 10.2"X8.3" CAR3 BC-4 FCU-21 to FCU-25 OFFICE 20-34 TCMBS0108KB21N4 SUB R410A 54,000 - - - 208 1 60 0.74 20 70

141-200 0.25-0.29 125 1.5 1.5 2.0 2.0 2.0

105-140 0.21-0.28 100 1.0 1.0 1.5 1.5 1.5 NOTES:

NOTES:

40-60 0.21-.027 75 0.5 0.5 1.0 1.0 1.0 1.

2.

PROVIDE WITH BALANCING DAMPER AT EACH FCU OA CONNECTION, BALANCE TO CFM VALUES INDICATED ON DRAWING M-100.

PROVIDE WITH DOUBLE LIP GASKET, DUCT COLLARS, ETC. 1. SELECTION BASED ON EQUIPMENT MANUFACTURED BY MITSUBISHI ELECTRIC / TRANE.

2. UNIT SHALL BE CERTIFIED, LISTED AND LABELED PER AHRI1230.

< 40 0.20-0.26 50 0.5 1.0 1.0 1.0 1.5 3.

4.

COORDINATE SUPPLY/EXHAUST ORIENTATIONS WITH EACH SYSTEM, REFER TO PLANS.

INSTALL AS PER MANUFACTURER'S INSTALLATION REQUIREMENTS WITH APPROPRIATE DUCT DIAMETER LENGTHS 3. INSTALLING CONTRACTOR MUST HAVE SUCCESSFULLY COMPLETED MANUFACTURERS CERTIFIED INSTALLATION CLASS WITHIN THE PAST 36 MONTHS.

5. UPSTREAM AND DOWNSTREAM OF THE CAR DAMPER. 4. ALL VRF EQUIPMENT SHALL BE PROVIDED WITH A 10 YEAR, PARTS ONLY WARRANTY, INCLUDING COMPRESSORS.

6. ANTI-MICROBIAL, ANTI-STATIC, AND FLAME RETARDANT. 5. PROVIDE CONDENSATE DRAIN FROM EACH BRANCH SELECTOR TO FLOOR DRAIN. REFER TO PLANS.

7. 7-YEAR WARRANTY. 6. PROVIDE SECONDARY STAINLESS STEEL DRIP PAN BELOW EACH BRANCH SELECTOR WITH LEAK DETECTOR. UPON ACTIVATION OF LEAK DETECTOR, ASSOCIATED AC/FCU, BRANCH CONTROLLER OR CONDENSING UNIT SHALL SHUT DOWN AND SOUND LOCAL AND BMS ALARM.

8. UL-2043 LISTED. 7. CONTRACTOR TO CONFIRM REFRIGERANT PIPING SIZES WITH THE MANUFACTURER BASED ON ACTUAL FIELD ROUTING OF REFRIGERANT PIPING. ROUTE AS SHOWN ON DESIGN DOCUMENTS IS SCHEMATIC AND SHALL BE VERIFIED BY THE CONTRACTOR.

9. CONTRACTOR TO FIELD VERIFY AND ADJUST TO INDICATED CFM. PROVIDE AD OR FLANGED DUCT JOIN UPSTREAM FOR SERVICE.

ENERGY RECOVERY VENTILATOR MFR. (AS STD.) "RENEWAIRE"

ELECTRICAL DATA SUMMER AIR DATA WINTER AIR DATA SUMMER/WINTER FILTER

INTAKE BLOWER EXHAUST BLOWER

UNIT LOCATION OUTDOOR AIR RETURN AIR OUTDOOR AIR RETURN AIR WEIGHT LBS. MODEL

MAX. LOAD SAVINGS RATIO TYPE

ESP IN. ESP IN. RPM VOLTS Ø HZ MCA

QTY. HP CFM RPM QTY. HP CFM FUSE D.B. W.B. D.B. W.B. D.B. W.B. D.B. W.B. (%)

H2O H2O

ERV-1 MER-20-10 1 2 2000 1 1650 1 2 1470 0.45 1200 208 3 60 16.5 20 89.7 77.0.0 75.0 62.7 12.8 10.2 72.0 56 64.3/62.6 MERV-8 712 ERV-20-30L

CP-IT AC-IT DRIP PAN 70 20 1/30 115 1 60 4.5 VCMA-P LITTLE GIANT PLENUM RATED

1 3 ISSUED FOR ADDENDUM #1 5/2/2024 JB

NOTES:

NOTES:

3 ISSUED FOR BID 4/26/2024 JB

1. UNIT SHALL BE CERTIFIED, LISTED AND LABELED PER UL AND AHRI1060.

1. PROVIDE FLOAT OPERATED HIGH WATER ALARM AND AUTOMATIC CUT-OUT SWITCH TO PREVENT RECEIVER OVERFLOW.

2. PROVIDE FACTORY EC DIRECT DRIVE FAN MOTORS FOR BOTH AIRSTREAMS.

2. OVERFLOW SWITCH SHALL SHUT DOWN AC UNIT & SOUND ALARM UPON HIGH WATER LEVEL. ALARM SHALL SOUND ON BMS. 2 ISSUED FOR DOB FILING 4/5/2024 MYS

3. PROVIDE FACTORY PREMIUM RENEWAIRE CONTROLS PACKAGE WITH BACNET FACTORY ACTIVATION FOR TIE IN TO BASE BUILDING BMS.

4. PROVIDE FACTORY NON-FUSED DISCONNECT AS STANDARD, MOUNTED ON ENCLOSURE.

5. MECHANICAL CONTRACTOR SHALL FIELD MODIFY UNIT TO REMOVE HOODS AND ADD DUCT FLANGE FOR DUCT CONNECTIONS TO ERV. 1 ISSUED FOR REVIEW 3/22/2024 MYS

6. CONTRACTOR SHALL PROVIDE 1" DEFLECTION SPRING VIBRATION ISOLATORS FOR EACH ERV UNIT.

NO. REVISION DATE BY

CEILING DIFFUSERS/RETURN GRILLES MFR. (AS STD.) "TITUS"

1

CFM NOMINAL MAX. CFM MAX S.P.

FACE SIZE MODEL REMARKS

RANGE NECK SIZE NC (IN. H20)

0-130 6"Ø 10 0.OO3 24"x24" OMNI

TPG ARCHITECTURE, LLP

131-220 8"Ø 10 0.029 24"x24" OMNI AC-IT IDF 20-26 850 36.7 25.2 80° 67° - - R-410A 208 1 1/3 1.0 - 0.8 15 15 - TGE031-36K-WALH ACCU-IT 95° 1710 0.5 1 0.75 18.8 22.1 88 13.2 35 208 3 270 13.8 TGC033-HE SEE NOTES BELOW 31 PENN PLAZA

10 132 WEST 31ST STREET, 5TH FLOOR, NEW YORK, NY 10001

221-330 10"Ø 0.038 24"x24" OMNI NOTES: 212.768.0800 | TPGARCHITECTURE.COM

1. PROVIDE WALL MOUNTED THERMOSTAT, HOT GAS BY-PASS, FLOODED CONDENSER, OIL SEPARATOR, SUCTION LINE ACCUMULATOR FIVE YEAR COMPRESSOR PARTS WARRANTY, POWER AND

431-600 12"Ø 21 0.101 24"x24" OMNI CONTROL WIRING, DISCONNECT SWITCH, HANGER RODS, VIBRATION ISOLATORS, CONDENSATE PUMP, PIPING, ADDITIONAL REFRIGERANT AND SPARE PARTS, DRIP PANS.

IN CONSIDERATION OF RECEIVING DRAWINGS FROM TPG ARCHITECTURE LLP IN

2. AC AND ACCU SHALL BE WIRED SEPARATELY

601-750 20 0.124 AN ELECTRONIC FORM, THE RECIPIENT AGREES, TO THE FULLEST EXTENT

14"Ø 24"x24" OMNI 3. CONTRACTOR TO FURNISH AND INSTALL ALL REFRIGERANT PIPING AND TRIM ACCESSORIES. PERMITTED BY LAW, TO HOLD HARMLESS AND INDEMNIFY TPG ARCHITECTURE

4. INSULATE PIPING AS REQUIRED LLP FROM AND AGAINST ALL CLAIMS, LIABILITIES, LOSSES, DAMAGES, AND

- 24"x12" - - 12"x24" 350RL GRILLE 5. PROVIDE HANGERS, VIBRATION ISOLATORS. COSTS, INCLUDING BUT NOT LIMITED TO ATTORNEY'S FEES, ARISING OUT OF,

6. PROVIDE FILTERS OR IN ANY WAY CONNECTED WITH THE USE, RE-USE, MIS-USE, MODIFICATION,

- 24"x24" - - 24"x24" 350RL GRILLE 7. CONDENSER INTAKE/DISCHARGE DUCTWORK SHALL BE INSTALLED WITH 2" RIGID INSULATION PER DESIGN SPECIFICATIONS OR MISINTERPRETATION OF THE MACHINE-READABLE INFORMATION PROVIDED

8. ROUTE 3/4" CONDENSATE PIPING TO FUNNEL DRAIN IN RESTROOM. SEE PLUMBING DRAWINGS FOR LOCATION. BY TPG ARCHITECTURE LLP UNDER THIS AGREEMENT.

S:\CAD\1359 BWAY\20FL_PROGYNY_DEMO BUILDOUT_23043.08\03-DWGS\M-400, 401.DWG / Plot Date: May, 2, 2024 - 4:47 :PM

PROJECT

NOTES:

1. COORDINATE EXACT LOCATION WITH ARCHITECTS DRAWINGS. EXHAUST FANS MFR. (AS STD.) GREENHECK PROGYNY

2. PROVIDE DIFFUSERS WITH EQUALIZING GRID AND OPPOSED BLADE DAMPERS FAN DATA MOTOR DATA 2ND AND 20TH FLOOR

3. PROVIDE IN LAY-IN CEILINGS WITH TYPE 3 FRAME.

4. FOR 2-WAY OR 3-WAY BLOW, BLANK OFF NEXT (NECK TO BE NEXT SIZE. UNIT No. SERVICE LOCATION

CFM

S.P.

IN. RPM TYPE SIZE FLA HP DRIVE

ELECTRICAL DATA WEIGHT MODEL REMARKS 1359 BROADWAY

5. ALL SUPPLY REGISTERS SHALL BE DOUBLE DEFLECTING TYPE, FRONT BLADES VERTICAL AS MANUFACTURED BY "TITUS",

MODEL 300RS.

W.G. VOLTS PH. HZ

NEW YORK, NY 10018

6. PROVIDE TITUS "LIGHTSHIELD" FOR ALL CEILING RETURN GRILLES. TX-1 MEN'S & ADA RESTROOMSMEN'S 300 0.2 1103 INLINE 390 1.5 1/10 DIRECT 115 1 60 24 CSP-A390-VG -

RESTROOM

7. PROVIDE CORD OPERATED DAMPERS WHERE GRILLES ARE INSTALLED IN INACCESSIBLE CEILINGS. DRAWING

8. ALL ROUND DIFFUSERS SHALL BE TITUS MODEL TMRA. TX-2 WOMEN'S RESTROOM WOMEN'S 230 0.2 949 INLINE 390 1.5 1/10 DIRECT 115 1 60 24 CSP-A390-VG -

RESTROOM

NOTES:

MECHANICAL

2. PROVIDE ISOLATION KIT, HANGERS, & SUPPORTS.

SCHEDULES

3. PROVIDE FLEXIBLE CONNECTIONS. (1 OF 2)

4. PROVIDE DISCONNECT SWITCHES.

5. PROVIDE UNIT MOUNTED SPEED CONTROLLERS.

6. PROVIDE BMS TIMECLOCK CONTROLS.

SEAL DATE

1.29.24

PROJECT NO.

11523048-00

Last Saved By: CHIRST / Save Date: 5/2/2024 2:01:24 PM

SCALE

AS SHOWN

CAD FILE NO. DOB PAGE

9 of 13

DWG NO.

NYC DOB NO.

M-400.00

You might also like

- XT2235-x (Devon 4G - Moto g32) - MB Component Location - L3 RepairDocument2 pagesXT2235-x (Devon 4G - Moto g32) - MB Component Location - L3 RepairluumNo ratings yet

- ManualDocument58 pagesManualolololoNo ratings yet

- DY 20L ManualDocument154 pagesDY 20L Manualhmbx100% (6)

- PaternosterDocument9 pagesPaternosterLiz-silva EssienNo ratings yet

- OTIS LINK Escalator: Installation ManualDocument56 pagesOTIS LINK Escalator: Installation ManualVlad ShkrebtyNo ratings yet

- NGP Con BRG Gad 836 2 - V15Document1 pageNGP Con BRG Gad 836 2 - V15PadmalavMahatoNo ratings yet

- ELEVATION A Balcony Railing Drawings (Al Ashram BLDG Cont)Document1 pageELEVATION A Balcony Railing Drawings (Al Ashram BLDG Cont)TAHANo ratings yet

- As Built - RCP L1Document1 pageAs Built - RCP L1Minh HiểnNo ratings yet

- Inortsa UltiDocument1 pageInortsa UltijefaturaplantainortsaNo ratings yet

- NFPC - Oasis Water - Jebel Ali - 2021-09-07 - Proposed Nissei Layout - 2023-05-17Document1 pageNFPC - Oasis Water - Jebel Ali - 2021-09-07 - Proposed Nissei Layout - 2023-05-17Projects DPCSNo ratings yet

- Produced by An Autodesk Student Version: Existing Repair & Maruti PointDocument1 pageProduced by An Autodesk Student Version: Existing Repair & Maruti PointAvinash SharmaNo ratings yet

- Access Control SystemDocument1 pageAccess Control SystemMD SajjadNo ratings yet

- Appendik I - Park PB 04-Layout1Document1 pageAppendik I - Park PB 04-Layout1Art Sensation 2019No ratings yet

- Saudi Arabian Oil Company: BA-528728 002 A 0B1 282 RestrictedDocument4 pagesSaudi Arabian Oil Company: BA-528728 002 A 0B1 282 RestrictedMohamed Wasim ShaikhNo ratings yet

- Lincoln Bridge GAD OverviewDocument1 pageLincoln Bridge GAD OverviewCouncilDistrict11No ratings yet

- Blockplan - Delima VillageDocument1 pageBlockplan - Delima VillageSunardi KusumahNo ratings yet

- UWP 25418 001 Elevated Water Tank 5000L CR02 PDFDocument1 pageUWP 25418 001 Elevated Water Tank 5000L CR02 PDFer.praveenraj30No ratings yet

- DN#1200 TB1 - 3Document1 pageDN#1200 TB1 - 3Arbaz KhanNo ratings yet

- A202 Moo MooDocument1 pageA202 Moo MooHdo AliNo ratings yet

- Alfonso SDPDocument1 pageAlfonso SDPErwin AbellanedaNo ratings yet

- Sector-17-LAYOUT PLANDocument1 pageSector-17-LAYOUT PLANAmit K. YadavNo ratings yet

- Gedung 2 LT 1Document1 pageGedung 2 LT 1Rifani DewiNo ratings yet

- Pre Plan SetDocument17 pagesPre Plan SetLorenzblazeeNo ratings yet

- Basement Plan CCTV Layout: KSK Capital LLCDocument1 pageBasement Plan CCTV Layout: KSK Capital LLCMD SajjadNo ratings yet

- Access Control SystemDocument1 pageAccess Control SystemMD SajjadNo ratings yet

- G-102-01 (790DBBC) Al-Shahaniya: AR-SF-102-00Document1 pageG-102-01 (790DBBC) Al-Shahaniya: AR-SF-102-00AslamNo ratings yet

- Proposed Invert LevelDocument1 pageProposed Invert LevelABHISHEK JAINNo ratings yet

- FSBP Lakeshore at The Fountains 3-4-473859Document1 pageFSBP Lakeshore at The Fountains 3-4-473859raj niraliNo ratings yet

- Gandhidham Bungalow - Option 2 - Site PlanDocument1 pageGandhidham Bungalow - Option 2 - Site PlanahirkishanNo ratings yet

- Vivekanand Education Society's College of Architecture: StorageDocument1 pageVivekanand Education Society's College of Architecture: StorageKalpak SurveNo ratings yet

- Vivekanand Education Society's College of Architecture: StorageDocument1 pageVivekanand Education Society's College of Architecture: StorageKalpak SurveNo ratings yet

- Li 1Document1 pageLi 1K MNo ratings yet

- Ugt DetailDocument1 pageUgt DetailPRIAMCON PMCNo ratings yet

- Firearm Business ZoningDocument1 pageFirearm Business ZoningCaitlyn KelleherNo ratings yet

- Location Map: Tristan Erwin R. AlonzoDocument1 pageLocation Map: Tristan Erwin R. AlonzoRowin LunaNo ratings yet

- Project Ruby: As Built DrawingDocument1 pageProject Ruby: As Built DrawingTôn Huỳnh ĐoànNo ratings yet

- Parks Conservation Vacant LandDocument1 pageParks Conservation Vacant LandxxfjphxxNo ratings yet

- Planta 04 Sin ColorDocument1 pagePlanta 04 Sin ColorDIEGO FERNANDO GARCIA CARMONANo ratings yet

- 5th Floor Marked Up Steel LocationsDocument1 page5th Floor Marked Up Steel LocationsCos CostyNo ratings yet

- 3 Phase VE Bus BMS System 5 Pin With 3xquattro and 4x200ah 24V Li Rev C1Document1 page3 Phase VE Bus BMS System 5 Pin With 3xquattro and 4x200ah 24V Li Rev C1Alba Car MarNo ratings yet

- DDDDDDDDDDocument1 pageDDDDDDDDDNideesh RobertNo ratings yet

- TS - 1 Fa Rockefeller Plaza - 7TH FL - Arch & Meps-Tc-Sec-Av - Addendum #1 - 101323Document2 pagesTS - 1 Fa Rockefeller Plaza - 7TH FL - Arch & Meps-Tc-Sec-Av - Addendum #1 - 101323cristianldg2000No ratings yet

- Combined AC Dwgs-31Document1 pageCombined AC Dwgs-31ibrahimsirpiNo ratings yet

- Approved Plan 1Document1 pageApproved Plan 1sibusiso.chisi9No ratings yet

- SLD - CBSE Patna - PDF 2Document1 pageSLD - CBSE Patna - PDF 2nbcccbsepatnaNo ratings yet

- Denah & Detail SaluranDocument13 pagesDenah & Detail SaluranIfal FatoniNo ratings yet

- Approved Drawing and Section WaterDocument2 pagesApproved Drawing and Section WaterSamer KhaledNo ratings yet

- Facultad de Ingeniería Y ArquitecturaDocument1 pageFacultad de Ingeniería Y ArquitecturaGimena Perez GonzalesNo ratings yet

- Miami Beach Historic Districts and SitesDocument1 pageMiami Beach Historic Districts and SitesvitruviuzNo ratings yet

- DRAFT LAYOUT - FeedbackDocument6 pagesDRAFT LAYOUT - Feedbackyudis tiraNo ratings yet

- Departamento de Antioquia HOJA No. 130IA1 Buriticá: Carta General Carta General Carta General Carta GeneralDocument1 pageDepartamento de Antioquia HOJA No. 130IA1 Buriticá: Carta General Carta General Carta General Carta GeneralwalterNo ratings yet

- Fsa 0180 F2Document1 pageFsa 0180 F2Mani CadNo ratings yet

- 50 MLD Stp. Proj - Road Section (08-07-2019)Document1 page50 MLD Stp. Proj - Road Section (08-07-2019)Jitender KumarNo ratings yet

- CDHC DWG SD 125 MB01 ST 2003 1Document1 pageCDHC DWG SD 125 MB01 ST 2003 1HAITHAM ALINo ratings yet

- KP 15-16Document1 pageKP 15-16atma82419No ratings yet

- Overall Wiring Diagram: Xelos A 22Document20 pagesOverall Wiring Diagram: Xelos A 22Biju PrestcomNo ratings yet

- Hl1Tonyms Ver.D Silkscreen Top Spell Mode:1X2: VersionsDocument2 pagesHl1Tonyms Ver.D Silkscreen Top Spell Mode:1X2: VersionsSnaked514No ratings yet

- MEGA-STUP-VS-NS-PK4-GAD-01 (R4) SHEET-1 YARD GAD - 19-09-2016-ModelDocument1 pageMEGA-STUP-VS-NS-PK4-GAD-01 (R4) SHEET-1 YARD GAD - 19-09-2016-Modelsoujanya rajeshNo ratings yet

- Fsa 0344 F2Document1 pageFsa 0344 F2Nagamani ManiNo ratings yet

- StiltDocument1 pageStiltTrupti ChandreNo ratings yet

- Skinney MedSpa at 30 E 60th Street - 100% CD Electrical DrawingsDocument5 pagesSkinney MedSpa at 30 E 60th Street - 100% CD Electrical Drawingscristianldg2000No ratings yet

- 767 31st and 33rd Floor Prebuilts SBS Estimate March 2022 Gamewell FCI Pricing TemplateDocument1 page767 31st and 33rd Floor Prebuilts SBS Estimate March 2022 Gamewell FCI Pricing Templatecristianldg2000No ratings yet

- Habit Lancaster Electrical DDocument2 pagesHabit Lancaster Electrical Dcristianldg2000No ratings yet

- TS - 1 Fa Rockefeller Plaza - 7TH FL - Arch & Meps-Tc-Sec-Av - Addendum #1 - 101323Document2 pagesTS - 1 Fa Rockefeller Plaza - 7TH FL - Arch & Meps-Tc-Sec-Av - Addendum #1 - 101323cristianldg2000No ratings yet

- Electrical DrawingsDocument4 pagesElectrical Drawingscristianldg2000No ratings yet

- G.F.Floor PlanDocument1 pageG.F.Floor Plansurender yadavNo ratings yet

- Major Projects in Bangalore-TkeiDocument44 pagesMajor Projects in Bangalore-TkeiveersainikNo ratings yet

- Augusta Evo: Car DoorsDocument21 pagesAugusta Evo: Car DoorsCoil98No ratings yet

- List of Top 15 Elevator Companies in IndiaDocument18 pagesList of Top 15 Elevator Companies in IndiaVishal Rajaram JoshiNo ratings yet

- Elevator and Escalator BrandsDocument13 pagesElevator and Escalator BrandsjajaNo ratings yet

- Call Report: Thyssenkrupp Elevator QATARDocument3 pagesCall Report: Thyssenkrupp Elevator QATARChaimaNo ratings yet

- Uibxrctzksaw3xcjp&h 8115-tc 115-125-Ton Truck Crane NetworkDocument11 pagesUibxrctzksaw3xcjp&h 8115-tc 115-125-Ton Truck Crane NetworkAnibal CunoNo ratings yet

- DEFCON-22-Deviant-Ollam-and-Howard-Payne-Elevator Hacking-From-the-Pit-to-the-Penthouse PDFDocument244 pagesDEFCON-22-Deviant-Ollam-and-Howard-Payne-Elevator Hacking-From-the-Pit-to-the-Penthouse PDFIsmael Pimentel ZuñigaNo ratings yet

- 4'-4" 3'-9" 11" 4" 8" 6 3/8" 4'-2" ROUGH 6'-0" PLATFORM 6'-3 1/4" D.B.G. 8'-3" Clear Hoistway 3'-0" CLEARDocument3 pages4'-4" 3'-9" 11" 4" 8" 6 3/8" 4'-2" ROUGH 6'-0" PLATFORM 6'-3 1/4" D.B.G. 8'-3" Clear Hoistway 3'-0" CLEARJuan DavidNo ratings yet

- Plan Electrique Ascenseur 11085289Document39 pagesPlan Electrique Ascenseur 11085289Mohamed AbdolahNo ratings yet

- Sais Short Air 3100-3300-5300-6300 EuDocument4 pagesSais Short Air 3100-3300-5300-6300 EuAli DiabNo ratings yet

- Osin Putra Nadeak - 5213121029 - Tugas B.inggris MenterjemahkanDocument4 pagesOsin Putra Nadeak - 5213121029 - Tugas B.inggris MenterjemahkanLasro Banjar nahorNo ratings yet

- Marico PresentationDocument35 pagesMarico PresentationReza FarizaNo ratings yet

- ElevatorDocument10 pagesElevatorThömAs MédizàNo ratings yet

- Lift Comparison - KONE RepliedDocument1 pageLift Comparison - KONE RepliedNghiaNo ratings yet

- Dumb WaiterDocument10 pagesDumb WaiterAbenliciousNo ratings yet

- (Hot Elevator)Document13 pages(Hot Elevator)Jayaram VallabhaneniNo ratings yet

- Controller With EMI PDFDocument8 pagesController With EMI PDFJms QuinteroNo ratings yet

- ScrewbnDocument15 pagesScrewbnDeepika-deepix AroraNo ratings yet

- SL Fuji Escalator and Elevator PDFDocument27 pagesSL Fuji Escalator and Elevator PDFAs'at NeverDiesNo ratings yet

- Original Rudra: ContactDocument2 pagesOriginal Rudra: Contactoriginal ElevatorsNo ratings yet

- Sky Lobbies: Lorem Ipsum Dolor Sit Amet, Consectetur Adipiscing ElitDocument13 pagesSky Lobbies: Lorem Ipsum Dolor Sit Amet, Consectetur Adipiscing ElitPavithra.GNo ratings yet

- Goods Lift Sizes - Google SearchDocument1 pageGoods Lift Sizes - Google Searchsushma sharmaNo ratings yet

- PDFDocument27 pagesPDFStevenNo ratings yet

- OTM 2024 - Exhibition Floor Plan (JWCC) - AvailabilityDocument1 pageOTM 2024 - Exhibition Floor Plan (JWCC) - AvailabilityGagandeep SinghNo ratings yet

- Gen2 OtisDocument6 pagesGen2 Otiskenneth perezNo ratings yet

- Controller With EMIDocument11 pagesController With EMIMohammed Qaid AlathwaryNo ratings yet