Professional Documents

Culture Documents

106 206 2SC PCO IOM Operation Guide

106 206 2SC PCO IOM Operation Guide

Uploaded by

Exe HernandezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

106 206 2SC PCO IOM Operation Guide

106 206 2SC PCO IOM Operation Guide

Uploaded by

Exe HernandezCopyright:

Available Formats

th

12850-87 Avenue

Surrey, BC. Canada. V3W 3H9

Ph: 604-594-5404

Fx: 604-594-8845

www.singervalve.com

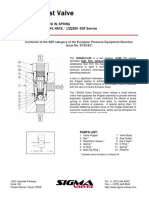

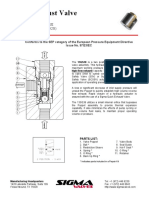

SINGER MODEL 106/206-2SC-PCO

Dual Solenoid Control Valve

Schematic A-7637A

ADJUSTING PROCEDURE:

DESCRIPTION:

Model 106/206-2SC-PCO is a valve positioned by This valve is normally operated by pulsing Solenoid

intermittent operation of Solenoid Valves (5) and (6). Valve (5) or (6) to position the Main Valve as

It is normally operated by a programmable process required. This means that the Main Valve moves in a

controller. The process controller is not included with step fashion. Size of these steps is determined by the

the standard valve. length of the pulse (time of of energization) and the

setting of Speed Controls (4) and (9).

DESCRIPTION OF OPERATION

Adjust pulse width and Speed Control settings to get

Main Valve (1) closes when the inlet pressure is

required control.

directed to the bonnet (above the diaphragm) and

opens when the bonnet is vented to the downstream. SERVICE SUGGESTIONS:

Refer to 106/206 PG “Description of Operation”.

1. See service suggestions for 106/206-PG Main

Solenoid Valves (5) and (6) are normally closed. Valve and Solenoid Valve.

When both solenoids are de-energized, Main Valve

(1) remains in position. Energizing Solenoid Valve (5) 2. Never energize the solenoid coil when the coil

closes the valve. Energizing Solenoid Valve (6) opens is removed from the Solenoid Valve.

the valve. 3. If the Main Valve fails to close, the inlet pressure

Solenoids Valves (5) and (6) are normally equipped is not connected to the bonnet because:

with 120 VAC coils. 12 or 24 Volt DC coils that can be - Isolating Valve (2A) or (2B) is closed.

driven by DC logic (SSR DRIVE) outputs from a - Strainer (3) is plugged.

process controller are available. - Closing Speed Control (4) is closed.

MANUAL-BY-PASS - Solenoid Valve (5) is de-energized or faulty.

- By-pass Valve (8) is open.

The pilot system is equipped with By-pass Valves (7) - Main Valve diaphragm is ruptured.

and (8) so that the Main Valve can be opened or - An obstruction in the Main Valve seat is

closed without electricity. To close the Main Valve preventing closure.

manually, By-pass Valve (7) should be opened while

By-pass Valve (8) is closed. Reversing this operation If the Main Valve does not open, pressure is not

will open the Main Valve. being relieved from the bonnet because:

- Solenoid Valve (6) is not energized or is

INSTALLATION:

faulty.

1. Refer to 106/206-PG “Installation”. - Opening Speed Control (9) is closed.

- Isolating Valve (2B) or (2C) is closed.

2. Check Solenoid Valves (5) and (6) for correct - There is not sufficient pressure drop available

voltage and operation. to open the Main Valve.

3. Wire Solenoid Valves (5) and (6) to the controller

as required.

4. Pressurize the valve slowly and bleed air from the

bonnet of the Main Valve. See 106/206-PG

Instructions.

IOM A-7637A Page 1 of 1 July 2005

You might also like

- Positive Displacement PumpDocument43 pagesPositive Displacement Pumpvenkeeku100% (2)

- 106 206 BPC IOM Operation GuideDocument3 pages106 206 BPC IOM Operation GuidePaul DeVinneyNo ratings yet

- Singer PRV ManualDocument3 pagesSinger PRV ManualAdityaNo ratings yet

- Solenoid Control Valve: Installation / Operation / MaintenanceDocument2 pagesSolenoid Control Valve: Installation / Operation / Maintenanceahmsa.morsyNo ratings yet

- SINGER MODEL 106/206-RPS: Pressure Relief or Sustaining ValveDocument2 pagesSINGER MODEL 106/206-RPS: Pressure Relief or Sustaining ValvezaidNo ratings yet

- Singer Valve 106 206 F Type 4 IOM Operation GuideDocument4 pagesSinger Valve 106 206 F Type 4 IOM Operation GuideSijo JoyNo ratings yet

- Pressure Reducing Valve: ModelDocument2 pagesPressure Reducing Valve: Modeljuliancardona77No ratings yet

- 106-SC-Product-PagesDocument3 pages106-SC-Product-PagesJordy LinoNo ratings yet

- Valve ActuatorsDocument32 pagesValve ActuatorsAntoine lazarus MaomyNo ratings yet

- Manual de PropietarioDocument22 pagesManual de PropietarioSergioPortillaLastarria100% (2)

- Singer ValveDocument2 pagesSinger ValverongdhanuonlineNo ratings yet

- IAM - Solenoid Valves Engineering InformationDocument26 pagesIAM - Solenoid Valves Engineering InformationIndustrial Automation and MechatronicsNo ratings yet

- Instructions: 06D Capacity Control Accessory PackagesDocument6 pagesInstructions: 06D Capacity Control Accessory PackagesSyed Ali KhanNo ratings yet

- Mustang Series M116-52 or M6116-52 (Globe), M1116-52 or M61116-52 (Angle) Installation InstructionsDocument2 pagesMustang Series M116-52 or M6116-52 (Globe), M1116-52 or M61116-52 (Angle) Installation InstructionsWattsNo ratings yet

- Valve Assemblies HandbookDocument34 pagesValve Assemblies HandbookJohn MuellerNo ratings yet

- 90G-21/90A-21 UL: UL Listed Pilot-Operated Pressure ControlDocument2 pages90G-21/90A-21 UL: UL Listed Pilot-Operated Pressure ControllesterNo ratings yet

- ASCO Solenoid Engineering SpecsDocument26 pagesASCO Solenoid Engineering SpecsviruspoolNo ratings yet

- Stainless Series S116-52 or S6116-52 (Globe), S1116-52 or S61116-52 (Angle) Installation InstructionsDocument2 pagesStainless Series S116-52 or S6116-52 (Globe), S1116-52 or S61116-52 (Angle) Installation InstructionsWattsNo ratings yet

- Series EMVII-6400SS Installation InstructionsDocument4 pagesSeries EMVII-6400SS Installation InstructionsWattsNo ratings yet

- 6991 1274 01a APCDocument15 pages6991 1274 01a APCpeter_157608700No ratings yet

- TM 90 21Document21 pagesTM 90 21enrique RiosNo ratings yet

- Model 115-3: Digital Electronic Control ValveDocument36 pagesModel 115-3: Digital Electronic Control ValveBruno GonçalvesNo ratings yet

- TM 90 21 PDFDocument22 pagesTM 90 21 PDFJuan MateNo ratings yet

- Tm-90-21-Ul (R-03/30/22)Document20 pagesTm-90-21-Ul (R-03/30/22)Mohamed Abou El hassanNo ratings yet

- Hydraulic SystemDocument16 pagesHydraulic Systemrevemin2024No ratings yet

- N5001 CRL60Document2 pagesN5001 CRL60Cao LanNo ratings yet

- 126 Model SheetDocument2 pages126 Model SheetAli BoraiNo ratings yet

- Quick Exh Valves 13QS40 - 41 - 80 Rev 0110Document2 pagesQuick Exh Valves 13QS40 - 41 - 80 Rev 0110khaldoun samiNo ratings yet

- 13QS38-39-90 Rev0422Document2 pages13QS38-39-90 Rev0422Murtaza AliNo ratings yet

- Quick Exhaust Valve 13QS38 - 39Document2 pagesQuick Exhaust Valve 13QS38 - 39simplementemoiNo ratings yet

- Control Valves: Block 6 Control Hardware: Electric/Pneumatic ActuationDocument112 pagesControl Valves: Block 6 Control Hardware: Electric/Pneumatic ActuationSumedha ChathurangaNo ratings yet

- Dimensions Specifications: 125 Booster Pump ControlDocument6 pagesDimensions Specifications: 125 Booster Pump ControlDheeraj ThakurNo ratings yet

- Bleed ValveDocument8 pagesBleed Valvejanju81100% (1)

- Mustang Series M116-31 or M6116-31 (Globe), M1116-31 or M61116-31 (Angle) Installation InstructionsDocument1 pageMustang Series M116-31 or M6116-31 (Globe), M1116-31 or M61116-31 (Angle) Installation InstructionsWattsNo ratings yet

- Pressure Surge ControlDocument13 pagesPressure Surge ControlmohdzamryNo ratings yet

- Wa-4 Alivio Ul-Fm 1116fmDocument4 pagesWa-4 Alivio Ul-Fm 1116fmeselcosac100% (1)

- 07GMK 6250 SuspensionDocument15 pages07GMK 6250 SuspensionВиталий РогожинскийNo ratings yet

- Mustang Series M114-2 or M6114-2 (Globe), M1114-2 or M61114-2 (Angle) Installation InstructionsDocument2 pagesMustang Series M114-2 or M6114-2 (Globe), M1114-2 or M61114-2 (Angle) Installation InstructionsWattsNo ratings yet

- On - Off ValveDocument5 pagesOn - Off Valvekresimir.mikoc9765No ratings yet

- 50B-4KG1/2050B-4KG1: Pressure Relief ValveDocument2 pages50B-4KG1/2050B-4KG1: Pressure Relief ValveEduardo CastilloNo ratings yet

- Manual Válvula OCV 115-3Document15 pagesManual Válvula OCV 115-3Sergio SosaNo ratings yet

- 6.6 KV BreakerDocument29 pages6.6 KV Breakerdan_geplNo ratings yet

- Series Features: Two-Stage Preset ValveDocument2 pagesSeries Features: Two-Stage Preset Valvefernando.juarezpetroserviciosNo ratings yet

- 450 PumpDocument15 pages450 PumpJader David Rocha MoralesNo ratings yet

- Check ValveDocument17 pagesCheck ValveDiana Lina100% (1)

- 50B-4KG1/2050B-4KG1: Pressure Relief ValveDocument2 pages50B-4KG1/2050B-4KG1: Pressure Relief ValveIngeniero aicNo ratings yet

- JbdlimDocument4 pagesJbdlimNoemi ZeballosNo ratings yet

- 08-Conv Valves Product InfoDocument18 pages08-Conv Valves Product Infoakrk777No ratings yet

- Xmastreeandoilwell HeadDocument24 pagesXmastreeandoilwell HeadagamcobainNo ratings yet

- Mustang Series M116-5 or M6116-5 (Globe), M1116-5 or M61116-5 (Angle) Installation InstructionsDocument2 pagesMustang Series M116-5 or M6116-5 (Globe), M1116-5 or M61116-5 (Angle) Installation InstructionsWattsNo ratings yet

- Classic Series F113-19 (Globe), F1113-19 (Angle) Specification SheetDocument1 pageClassic Series F113-19 (Globe), F1113-19 (Angle) Specification SheetWattsNo ratings yet

- Estrangulador SwacoDocument129 pagesEstrangulador SwacoKamilo Forero100% (5)

- Relief Valves 24RV16 Rev 0812Document2 pagesRelief Valves 24RV16 Rev 0812Murtaza AliNo ratings yet

- Claval PRV TM-90-01Document30 pagesClaval PRV TM-90-01DuxToyNo ratings yet

- 416C, 426C, 428C, 436C and 438C Hydraulic System TroubleshootingDocument10 pages416C, 426C, 428C, 436C and 438C Hydraulic System TroubleshootingJose Antonio SalasNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- MAN Turbocharger Programme 2010 PDFDocument32 pagesMAN Turbocharger Programme 2010 PDFblackgateNo ratings yet

- Materials GuideDocument178 pagesMaterials GuideMuhammad Fadhil natsirNo ratings yet

- AMACS Multipocket Vane WebDocument1 pageAMACS Multipocket Vane WebadrianioantomaNo ratings yet

- LESSON#9 SURGE PREVENTION IN THE CENTRIFUGAL COMPRESSOR - Jeff LeeDocument42 pagesLESSON#9 SURGE PREVENTION IN THE CENTRIFUGAL COMPRESSOR - Jeff LeeNimmakayala Manikanta100% (1)

- Productos BelimoDocument244 pagesProductos BelimovickmenNo ratings yet

- 81463015accumulator Charging ValveDocument3 pages81463015accumulator Charging ValveЯрослав ВалькоNo ratings yet

- Pump Data Sheet - Turbine 60 HZDocument1 pagePump Data Sheet - Turbine 60 HZDaniel Alonso Espinosa HerreraNo ratings yet

- ValvEx 2 PresentacionDocument15 pagesValvEx 2 PresentacionEgon GjerloffNo ratings yet

- Manual PN 52642 Direct Fired 11-12-13Document64 pagesManual PN 52642 Direct Fired 11-12-13Moises Quispe MendozaNo ratings yet

- Control of Nuclear Gloveboxes and Enclosures Using The No-Moving-Part Vortex Amplifier (VXA)Document11 pagesControl of Nuclear Gloveboxes and Enclosures Using The No-Moving-Part Vortex Amplifier (VXA)Dennis ChanNo ratings yet

- Reciprocating CompressorsDocument24 pagesReciprocating Compressorsluciano.almeidavieira07No ratings yet

- Darcy-Weisbach EquationDocument10 pagesDarcy-Weisbach Equationlhphong021191100% (1)

- NOV Varco Power Slips 2010Document7 pagesNOV Varco Power Slips 2010Arturo PerezNo ratings yet

- HydraulicDocument60 pagesHydraulicAswinNo ratings yet

- Dimension DB 611Document3 pagesDimension DB 611Ugo MorelliNo ratings yet

- Smardt Vs McQuay Less Than 400 TonsDocument15 pagesSmardt Vs McQuay Less Than 400 TonsLim YorkChuanNo ratings yet

- Hydraulic/Hydrostatic Schematic 864 (S/N 518911354-14999) (S/N 516811037-14999)Document2 pagesHydraulic/Hydrostatic Schematic 864 (S/N 518911354-14999) (S/N 516811037-14999)Ataa AssaadNo ratings yet

- Pipe TableDocument25 pagesPipe TableMarde Vinson OpamenNo ratings yet

- Cavitation Guide: Cla-ValDocument1 pageCavitation Guide: Cla-ValAnonymous CMS3dL1TNo ratings yet

- Hydraulic Calculation of Pipelines ReportDocument91 pagesHydraulic Calculation of Pipelines Reportkanokwan jaruek100% (1)

- Piping TrainingDocument446 pagesPiping TrainingshakeelahmadjsrNo ratings yet

- Control Valve Analysis1Document13 pagesControl Valve Analysis1Ekundayo JohnNo ratings yet

- Thermodynamic Process Tutorial 4 1Document2 pagesThermodynamic Process Tutorial 4 1Boon Khai ChienNo ratings yet

- 970f Hyd Chart PDFDocument2 pages970f Hyd Chart PDFhassan hamdyNo ratings yet

- Tie-In Service Tie-In Detail Connection Type of Remarks Class & Size Reference Piping Dwg. Isometric Shutdown Required or Not Line No. Equip./ Exist. Line No./ NEW P&IdDocument10 pagesTie-In Service Tie-In Detail Connection Type of Remarks Class & Size Reference Piping Dwg. Isometric Shutdown Required or Not Line No. Equip./ Exist. Line No./ NEW P&Idfasert sarytghNo ratings yet

- Bernoulli Equation Full ReportDocument6 pagesBernoulli Equation Full ReportChala1989No ratings yet

- Lab ReportDocument12 pagesLab Reportbotakmbg6035No ratings yet

- QTN 2336 - 3 Way L PortDocument2 pagesQTN 2336 - 3 Way L Portshahkunal11No ratings yet

- Cooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description SectionDocument23 pagesCooling: Air Conditioning Pack (21-51-00) Aircraft Maintenance Manual System Description Sectionnishat529No ratings yet