Professional Documents

Culture Documents

WEA 1.5 ME-0002english.01

WEA 1.5 ME-0002english.01

Uploaded by

towerman5001Copyright:

Available Formats

You might also like

- Brady Link360 Lockout Tagout Short FormDocument2 pagesBrady Link360 Lockout Tagout Short FormReynaldo GrantNo ratings yet

- Clark CEM20-35AC Service ManualDocument342 pagesClark CEM20-35AC Service ManualRobin De WaeleNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Safe Work Procedure - LOTO (Sample)Document3 pagesSafe Work Procedure - LOTO (Sample)cta2100% (1)

- Procedure For Lock Out Tag OutDocument10 pagesProcedure For Lock Out Tag OutBineesh100% (1)

- Lockout Tagout ProgramDocument6 pagesLockout Tagout ProgramYuli AstutyNo ratings yet

- Control of Hazardous EnergyDocument31 pagesControl of Hazardous EnergyJennifer Quino100% (1)

- WEA 1.5 ME-0001english.01Document3 pagesWEA 1.5 ME-0001english.01towerman5001No ratings yet

- WEA 1.5 EL-0019english.01Document3 pagesWEA 1.5 EL-0019english.01towerman5001No ratings yet

- WEA 1.5 EL-0020english.00Document4 pagesWEA 1.5 EL-0020english.00towerman5001No ratings yet

- Loto Policy SampleDocument6 pagesLoto Policy Sampleyemi adelakunNo ratings yet

- Lock Out ProgramDocument6 pagesLock Out Programsimson100% (1)

- Lock Out Tag OutDocument2 pagesLock Out Tag OutPablo Arreola RomeroNo ratings yet

- Lock Out Tag OutDocument47 pagesLock Out Tag OutAldrien Cabinte100% (1)

- 5971-160 Reversal Switch Users Manual Rev CDocument31 pages5971-160 Reversal Switch Users Manual Rev CArctusNo ratings yet

- Lock Out Tag Out SWPPDocument3 pagesLock Out Tag Out SWPPsaleenasirajNo ratings yet

- Lockout TagoutDocument8 pagesLockout TagoutJezreel TolentinoNo ratings yet

- SWP-10 LockoutTagout (LOTO)Document6 pagesSWP-10 LockoutTagout (LOTO)ShafiqNo ratings yet

- Lockout Tagout DLS Sample 2017Document12 pagesLockout Tagout DLS Sample 2017Archana SoorajNo ratings yet

- FLNG Hse Proc 136 Said CommentsDocument19 pagesFLNG Hse Proc 136 Said CommentsSaidKaedBayAndericoNo ratings yet

- 2 LotoDocument23 pages2 LotoAviects Avie JaroNo ratings yet

- Applications of Lockout 1Document23 pagesApplications of Lockout 1sivakumarNo ratings yet

- Ev 006Document6 pagesEv 006Budhi HermawanNo ratings yet

- LOTO Training - Energy IsolationDocument25 pagesLOTO Training - Energy IsolationMohamed Ibrahim100% (5)

- Chapter 5 SAFETY PROCEDURES AND METHODSDocument28 pagesChapter 5 SAFETY PROCEDURES AND METHODSMelchor CarabayasNo ratings yet

- Loto VeneervisionDocument2 pagesLoto Veneervisionapi-362234935No ratings yet

- WKS 6 Forest Harvesting Lockout Sawmill IsolationDocument4 pagesWKS 6 Forest Harvesting Lockout Sawmill IsolationJuan Ismael Carmona RodríguezNo ratings yet

- Leader's Guide: Lockout/Tagout For Authorized EmployeesDocument8 pagesLeader's Guide: Lockout/Tagout For Authorized EmployeesTagliya TagoNo ratings yet

- Electrical SafetyDocument30 pagesElectrical SafetyJustin CarolinoNo ratings yet

- Sample Loto ProcedureDocument4 pagesSample Loto ProcedureSkariah MathewsNo ratings yet

- LOTO Template ProgramDocument13 pagesLOTO Template Programyemi adelakun100% (1)

- Elec Hazard Awareness Study GuideDocument5 pagesElec Hazard Awareness Study GuideBố Đăng KhánhNo ratings yet

- Lockout-Tagout ProcedureDocument17 pagesLockout-Tagout ProcedureshaikhbwcNo ratings yet

- Loto ProcedureDocument3 pagesLoto ProceduremararijoelNo ratings yet

- Lockout Tagout TrainingDocument26 pagesLockout Tagout Trainingeileen_muu485No ratings yet

- Isolation of Plant ProcedureDocument10 pagesIsolation of Plant ProcedureTiến Dũng VũNo ratings yet

- Lockout Tagout Program (Short Ver)Document1 pageLockout Tagout Program (Short Ver)General CommunicationNo ratings yet

- Revised by Njalbee 5/14Document8 pagesRevised by Njalbee 5/14Srinivas MurthyNo ratings yet

- AV-SWP-29 Electrical Isolation Iss 1Document4 pagesAV-SWP-29 Electrical Isolation Iss 1Kevin DeLimaNo ratings yet

- Total Productive MaintenanceDocument31 pagesTotal Productive MaintenanceNo HopeNo ratings yet

- Lockout Tagout ProcedureDocument7 pagesLockout Tagout ProcedureKadesh Hanah McCarthyNo ratings yet

- S-Loto Written ProceduresDocument10 pagesS-Loto Written ProceduresRajiv SharmaNo ratings yet

- PTP 08.1 HandoutDocument11 pagesPTP 08.1 HandoutJayNo ratings yet

- LOTO: Lockout Tagout: & Tryout ProcedureDocument29 pagesLOTO: Lockout Tagout: & Tryout ProcedureAli JafferyNo ratings yet

- Tagging and Lockout ProcedureDocument4 pagesTagging and Lockout ProcedureibrahimkhansahilNo ratings yet

- XXX Revised April 6, 2005 Standard Operating Procedure No. S-100Document12 pagesXXX Revised April 6, 2005 Standard Operating Procedure No. S-100Peter Nai HoNo ratings yet

- 11.1 LOCK OUT PROCEDUREDocument1 page11.1 LOCK OUT PROCEDUREWelma JohnsonNo ratings yet

- Electrical LOTOTODocument3 pagesElectrical LOTOTOHakim MiswanNo ratings yet

- General Lockout - Tagout ProcedureDocument2 pagesGeneral Lockout - Tagout ProcedurelhNo ratings yet

- Lockout/Tagout Compliance Guide and ChecklistDocument7 pagesLockout/Tagout Compliance Guide and ChecklistNoel Santos100% (1)

- Lockout/Tagout Compliance Guide and ChecklistDocument7 pagesLockout/Tagout Compliance Guide and ChecklistJeffrey Jan PerezNo ratings yet

- CAT-06 Hazardous Energy Control-EnglishDocument13 pagesCAT-06 Hazardous Energy Control-EnglishGemNo ratings yet

- PTW LOTO-TrainingDocument29 pagesPTW LOTO-TrainingDanish AliNo ratings yet

- lotoFINALDocument19 pageslotoFINALElvyn Fabellore HerreraNo ratings yet

- 2.2 Lock Out, Tag Out and Try OutDocument11 pages2.2 Lock Out, Tag Out and Try OutSuad BushiNo ratings yet

- 013B1E5BB37201AD - 4 - Lockout, TagoutDocument15 pages013B1E5BB37201AD - 4 - Lockout, TagoutNikhil Dangariya Regal Petro Trading FZENo ratings yet

- Hoods Instruction ManualDocument20 pagesHoods Instruction ManualedgarlimasNo ratings yet

- Safety Work Permit System: Corporate S&EsDocument34 pagesSafety Work Permit System: Corporate S&Essatej desaiNo ratings yet

- Lock Out and Tag Out Standart ManualDocument25 pagesLock Out and Tag Out Standart ManualEka Candra IrawanNo ratings yet

- Loto Procedure: Construction of Coal Berth, Civil Works & Stock Yard Development at ParadipDocument12 pagesLoto Procedure: Construction of Coal Berth, Civil Works & Stock Yard Development at ParadipTarun KakkarNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- 4-List Working StandarDocument2 pages4-List Working StandarHeny YuslizarNo ratings yet

- Frecon Solar Inverter Price List 2024 HsgupdatedDocument3 pagesFrecon Solar Inverter Price List 2024 HsgupdatedHussien FrragNo ratings yet

- Unit-I University QuestionsDocument6 pagesUnit-I University QuestionsHakimuddin BohariNo ratings yet

- Hitachi Zaxis 145WDocument28 pagesHitachi Zaxis 145WAndrea797No ratings yet

- Betobar DC CatalogueDocument30 pagesBetobar DC CatalogueMorteza MahdaviNo ratings yet

- Con SumosDocument38 pagesCon SumosJosué JimenezNo ratings yet

- X2090allegatoDEPLIANT1-2X Suhr 08-21 enDocument4 pagesX2090allegatoDEPLIANT1-2X Suhr 08-21 enAntonioNo ratings yet

- CO Refrigerant Applications: General DescriptionDocument3 pagesCO Refrigerant Applications: General DescriptionPedro Gabriel Rivas RamirezNo ratings yet

- Central Electrónica Universal Universal Control Unit Universelle Elektronische AuswerteeinheitDocument2 pagesCentral Electrónica Universal Universal Control Unit Universelle Elektronische AuswerteeinheitDiego GarnicaNo ratings yet

- Power Systems (K-Wiki - CH 4 - Stability)Document32 pagesPower Systems (K-Wiki - CH 4 - Stability)Priyanshu GuptaNo ratings yet

- Principles of Sustainable LivingDocument54 pagesPrinciples of Sustainable LivingRhodjane Dela CruzNo ratings yet

- Climate Change Is A Change in The Pattern of WeatherDocument8 pagesClimate Change Is A Change in The Pattern of WeatherAdan SafdarNo ratings yet

- Seminar Report On Wireless Power TransmissionDocument24 pagesSeminar Report On Wireless Power TransmissionsujiezNo ratings yet

- CHE1001 - Ammonia Production Final ReportDocument48 pagesCHE1001 - Ammonia Production Final ReportkhavthompsonNo ratings yet

- Company Profile-SRG GROUPDocument6 pagesCompany Profile-SRG GROUPRajeev KumarNo ratings yet

- °F °C Ohms °F °C Ohms °F °C Ohms: BAPI Sensor Specifi CationsDocument2 pages°F °C Ohms °F °C Ohms °F °C Ohms: BAPI Sensor Specifi Cationsaneesh88No ratings yet

- EIA Report (9.1)Document350 pagesEIA Report (9.1)imran hossainNo ratings yet

- KSB Etanorm 96 1450 SuperpumpDocument1 pageKSB Etanorm 96 1450 SuperpumpMohamed AyoubNo ratings yet

- Learn The Basics of Home Electrical WiringDocument3 pagesLearn The Basics of Home Electrical WiringZen Resti MaulanaNo ratings yet

- Revised TRA FormDocument4 pagesRevised TRA FormJoemar CaprancaNo ratings yet

- Final Interim Report Myza 25034Document18 pagesFinal Interim Report Myza 25034hasnizaNo ratings yet

- Officer's Particulars: Musat Radu-StefanDocument7 pagesOfficer's Particulars: Musat Radu-StefanRadu M.No ratings yet

- End-Of-Life Alternatives of Glass Reinforced Polyester Boat Hulls Compared by LcaDocument8 pagesEnd-Of-Life Alternatives of Glass Reinforced Polyester Boat Hulls Compared by LcaPhong TuanNo ratings yet

- Well Control EquipmentDocument82 pagesWell Control EquipmentKhairuddin KhairuddinNo ratings yet

- UNIT - 5 - FIRE PROTECTION and SOLAS RequirementsDocument85 pagesUNIT - 5 - FIRE PROTECTION and SOLAS RequirementsLikhith LikhithNo ratings yet

- Programme For The 16th Chlorine Symposium - Thyssenkrupp Uhde Chlorine Engineers, 15th - 17th June 2016, Dortmund, GermanyDocument2 pagesProgramme For The 16th Chlorine Symposium - Thyssenkrupp Uhde Chlorine Engineers, 15th - 17th June 2016, Dortmund, GermanyChristian Josue Herrera CordobaNo ratings yet

- Haramaya University Haramaya Institute of Technology Department of Mechanical EngineeringDocument18 pagesHaramaya University Haramaya Institute of Technology Department of Mechanical Engineeringadd aduNo ratings yet

- MGES ET L01 QuizDocument3 pagesMGES ET L01 QuizSquareNo ratings yet

- Potential Hydroelectric Power Plant in Ounasjoki RiverDocument5 pagesPotential Hydroelectric Power Plant in Ounasjoki RiverKamil IssaNo ratings yet

WEA 1.5 ME-0002english.01

WEA 1.5 ME-0002english.01

Uploaded by

towerman5001Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WEA 1.5 ME-0002english.01

WEA 1.5 ME-0002english.01

Uploaded by

towerman5001Copyright:

Available Formats

Procedure-No.

:

Lockout / Tagout Work Instruction

1.5 MW Wind Turbine Generator System WEA 1.5/ME-0002

Service Job: Locking of the low-speed shaft Page 1 of 2

IDENTIFICATION OF EQUIPMENT / PROCESS / CIRCUIT

Machine room / Low-speed shaft (gearing)

PROCEDURAL STEPS

Step 1: Preparation for Shutdown / Notification of affected employees

• Personnel who may be affected shall be notified prior to the application and after the removal of

lockout/tagout devices. In addition to this lockout procedure, the Authorized Employee must be

aware of any additional safety requirements when dealing with this type of equipment. If there

are any questions see your service leader or EHS Coordinator before proceeding

• Affected employees who use or work near the equipment have been notified that it is being shut

down and lockout/tagout devices will be applied.

The wind turbine must be in the “Manual Stop” mode.

Step 2: Identification of energy sources and magnitudes

Mechanical hazard!

Step 3/4: Deactivation of energy sources & application of energy control devices

• The energy-isolating devices (disconnects, switches, valves, etc) have been positioned to stop

energy flow to the equipment, process or circuit. The authorized individuals shall attach and

secure lockout and/or tagout devices. Verify that the energy isolating devices remain “locked

out“ and in a safe or “OFF“position.

Switch the energy source off as follows:

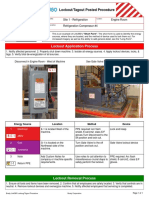

1. Insert the shaft locking mechanism using the lever and firmly

tighten the locking nut (wing nut).

2. Attach the claw to the locking lever as shown in the photo and

attach the PG cable.

3. Mount a personal lock to the claw and secure with a label.

Reviewed by ……………………………. Approved by ……………………………. Date: 2004-09-20

Henning Lütze (Chief Engineer) Jose Jimenez (EHS Manager) Review: 1

- FOR GE-INTERNAL USE ONLY -

Procedure-No.:

Lockout / Tagout Work Instruction

1.5 MW Wind Turbine Generator System WEA 1.5/ME-0002

Service Job: Locking of the low-speed shaft Page 2 of 2

Step 5: Control of stored energy

• The authorized individual has ensured that all potentially hazardous energy (stored, residual,

chemical or potential) is relieved, dissipated, restrained, drained or otherwise controlled.

Additional measures may be necessary to prevent re-accumulation of energy to protect

individuals. Examples of stored energy include accumulators, capacitors, gravity and chemical

lines.

The following measures should be implemented for protection from stored energy:

It should be verified that the locking mechanism is firmly seated.

Note:

Check that the locking nut is firmly seated.

Step 6: Verification of isolation

• The authorized individual shall verify that the isolation and de-energization have been

accomplished by following steps 4/5 in the current instruction prior to starting servicing on

equipment, process and circuit that have been locked out and tagged out. Verification must

confirm that the equipment, process or circuit has achieved a “zero“ energy state (verification of

zero energy state can be accomplished by test equipment, circuit activation attempts, gages,

visual inspection, etc).

Step 7: Re-energization of equipment

The authorized individual shall perform the following before returning the equipment to service:

1. Inspect the work area to ensure that non-essential items have been removed, guards are in

place, the machine/equipment/process or circuit is operationally intact, and all personnel are

in a safe location.

2. Remove locks, tags and lockout devices from each energy-isolation device by the authorized

individual who applied the device.

3. Notify affected personnel that energy is about to be restored to the machine, equipment,

process and circuit.

4. Visually inspect and/or cycle test the equipment for servicing and/or maintenance task

completion. If the task is completed the machine, equipment, process and circuit may be

returned to service. If the task is not completed, repeat the necessary LOTO steps.

5. Follow the proper sequential startup steps for the equipment, process or circuit.

Observe the following points for restoring operation standby:

1. Remove the label, lock and claw from the PG cable on the low-

speed shaft locking mechanism.

2. Loosen the locking nut and release the locking mechanism.

• Affected employees are notified that the equipment is ready to use.

Reviewed by ……………………………. Approved by ……………………………. Date: 2004-09-20

Henning Lütze (Chief Engineer) Jose Jimenez (EHS Manager) Review: 1

- FOR GE-INTERNAL USE ONLY -

You might also like

- Brady Link360 Lockout Tagout Short FormDocument2 pagesBrady Link360 Lockout Tagout Short FormReynaldo GrantNo ratings yet

- Clark CEM20-35AC Service ManualDocument342 pagesClark CEM20-35AC Service ManualRobin De WaeleNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Safe Work Procedure - LOTO (Sample)Document3 pagesSafe Work Procedure - LOTO (Sample)cta2100% (1)

- Procedure For Lock Out Tag OutDocument10 pagesProcedure For Lock Out Tag OutBineesh100% (1)

- Lockout Tagout ProgramDocument6 pagesLockout Tagout ProgramYuli AstutyNo ratings yet

- Control of Hazardous EnergyDocument31 pagesControl of Hazardous EnergyJennifer Quino100% (1)

- WEA 1.5 ME-0001english.01Document3 pagesWEA 1.5 ME-0001english.01towerman5001No ratings yet

- WEA 1.5 EL-0019english.01Document3 pagesWEA 1.5 EL-0019english.01towerman5001No ratings yet

- WEA 1.5 EL-0020english.00Document4 pagesWEA 1.5 EL-0020english.00towerman5001No ratings yet

- Loto Policy SampleDocument6 pagesLoto Policy Sampleyemi adelakunNo ratings yet

- Lock Out ProgramDocument6 pagesLock Out Programsimson100% (1)

- Lock Out Tag OutDocument2 pagesLock Out Tag OutPablo Arreola RomeroNo ratings yet

- Lock Out Tag OutDocument47 pagesLock Out Tag OutAldrien Cabinte100% (1)

- 5971-160 Reversal Switch Users Manual Rev CDocument31 pages5971-160 Reversal Switch Users Manual Rev CArctusNo ratings yet

- Lock Out Tag Out SWPPDocument3 pagesLock Out Tag Out SWPPsaleenasirajNo ratings yet

- Lockout TagoutDocument8 pagesLockout TagoutJezreel TolentinoNo ratings yet

- SWP-10 LockoutTagout (LOTO)Document6 pagesSWP-10 LockoutTagout (LOTO)ShafiqNo ratings yet

- Lockout Tagout DLS Sample 2017Document12 pagesLockout Tagout DLS Sample 2017Archana SoorajNo ratings yet

- FLNG Hse Proc 136 Said CommentsDocument19 pagesFLNG Hse Proc 136 Said CommentsSaidKaedBayAndericoNo ratings yet

- 2 LotoDocument23 pages2 LotoAviects Avie JaroNo ratings yet

- Applications of Lockout 1Document23 pagesApplications of Lockout 1sivakumarNo ratings yet

- Ev 006Document6 pagesEv 006Budhi HermawanNo ratings yet

- LOTO Training - Energy IsolationDocument25 pagesLOTO Training - Energy IsolationMohamed Ibrahim100% (5)

- Chapter 5 SAFETY PROCEDURES AND METHODSDocument28 pagesChapter 5 SAFETY PROCEDURES AND METHODSMelchor CarabayasNo ratings yet

- Loto VeneervisionDocument2 pagesLoto Veneervisionapi-362234935No ratings yet

- WKS 6 Forest Harvesting Lockout Sawmill IsolationDocument4 pagesWKS 6 Forest Harvesting Lockout Sawmill IsolationJuan Ismael Carmona RodríguezNo ratings yet

- Leader's Guide: Lockout/Tagout For Authorized EmployeesDocument8 pagesLeader's Guide: Lockout/Tagout For Authorized EmployeesTagliya TagoNo ratings yet

- Electrical SafetyDocument30 pagesElectrical SafetyJustin CarolinoNo ratings yet

- Sample Loto ProcedureDocument4 pagesSample Loto ProcedureSkariah MathewsNo ratings yet

- LOTO Template ProgramDocument13 pagesLOTO Template Programyemi adelakun100% (1)

- Elec Hazard Awareness Study GuideDocument5 pagesElec Hazard Awareness Study GuideBố Đăng KhánhNo ratings yet

- Lockout-Tagout ProcedureDocument17 pagesLockout-Tagout ProcedureshaikhbwcNo ratings yet

- Loto ProcedureDocument3 pagesLoto ProceduremararijoelNo ratings yet

- Lockout Tagout TrainingDocument26 pagesLockout Tagout Trainingeileen_muu485No ratings yet

- Isolation of Plant ProcedureDocument10 pagesIsolation of Plant ProcedureTiến Dũng VũNo ratings yet

- Lockout Tagout Program (Short Ver)Document1 pageLockout Tagout Program (Short Ver)General CommunicationNo ratings yet

- Revised by Njalbee 5/14Document8 pagesRevised by Njalbee 5/14Srinivas MurthyNo ratings yet

- AV-SWP-29 Electrical Isolation Iss 1Document4 pagesAV-SWP-29 Electrical Isolation Iss 1Kevin DeLimaNo ratings yet

- Total Productive MaintenanceDocument31 pagesTotal Productive MaintenanceNo HopeNo ratings yet

- Lockout Tagout ProcedureDocument7 pagesLockout Tagout ProcedureKadesh Hanah McCarthyNo ratings yet

- S-Loto Written ProceduresDocument10 pagesS-Loto Written ProceduresRajiv SharmaNo ratings yet

- PTP 08.1 HandoutDocument11 pagesPTP 08.1 HandoutJayNo ratings yet

- LOTO: Lockout Tagout: & Tryout ProcedureDocument29 pagesLOTO: Lockout Tagout: & Tryout ProcedureAli JafferyNo ratings yet

- Tagging and Lockout ProcedureDocument4 pagesTagging and Lockout ProcedureibrahimkhansahilNo ratings yet

- XXX Revised April 6, 2005 Standard Operating Procedure No. S-100Document12 pagesXXX Revised April 6, 2005 Standard Operating Procedure No. S-100Peter Nai HoNo ratings yet

- 11.1 LOCK OUT PROCEDUREDocument1 page11.1 LOCK OUT PROCEDUREWelma JohnsonNo ratings yet

- Electrical LOTOTODocument3 pagesElectrical LOTOTOHakim MiswanNo ratings yet

- General Lockout - Tagout ProcedureDocument2 pagesGeneral Lockout - Tagout ProcedurelhNo ratings yet

- Lockout/Tagout Compliance Guide and ChecklistDocument7 pagesLockout/Tagout Compliance Guide and ChecklistNoel Santos100% (1)

- Lockout/Tagout Compliance Guide and ChecklistDocument7 pagesLockout/Tagout Compliance Guide and ChecklistJeffrey Jan PerezNo ratings yet

- CAT-06 Hazardous Energy Control-EnglishDocument13 pagesCAT-06 Hazardous Energy Control-EnglishGemNo ratings yet

- PTW LOTO-TrainingDocument29 pagesPTW LOTO-TrainingDanish AliNo ratings yet

- lotoFINALDocument19 pageslotoFINALElvyn Fabellore HerreraNo ratings yet

- 2.2 Lock Out, Tag Out and Try OutDocument11 pages2.2 Lock Out, Tag Out and Try OutSuad BushiNo ratings yet

- 013B1E5BB37201AD - 4 - Lockout, TagoutDocument15 pages013B1E5BB37201AD - 4 - Lockout, TagoutNikhil Dangariya Regal Petro Trading FZENo ratings yet

- Hoods Instruction ManualDocument20 pagesHoods Instruction ManualedgarlimasNo ratings yet

- Safety Work Permit System: Corporate S&EsDocument34 pagesSafety Work Permit System: Corporate S&Essatej desaiNo ratings yet

- Lock Out and Tag Out Standart ManualDocument25 pagesLock Out and Tag Out Standart ManualEka Candra IrawanNo ratings yet

- Loto Procedure: Construction of Coal Berth, Civil Works & Stock Yard Development at ParadipDocument12 pagesLoto Procedure: Construction of Coal Berth, Civil Works & Stock Yard Development at ParadipTarun KakkarNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- 4-List Working StandarDocument2 pages4-List Working StandarHeny YuslizarNo ratings yet

- Frecon Solar Inverter Price List 2024 HsgupdatedDocument3 pagesFrecon Solar Inverter Price List 2024 HsgupdatedHussien FrragNo ratings yet

- Unit-I University QuestionsDocument6 pagesUnit-I University QuestionsHakimuddin BohariNo ratings yet

- Hitachi Zaxis 145WDocument28 pagesHitachi Zaxis 145WAndrea797No ratings yet

- Betobar DC CatalogueDocument30 pagesBetobar DC CatalogueMorteza MahdaviNo ratings yet

- Con SumosDocument38 pagesCon SumosJosué JimenezNo ratings yet

- X2090allegatoDEPLIANT1-2X Suhr 08-21 enDocument4 pagesX2090allegatoDEPLIANT1-2X Suhr 08-21 enAntonioNo ratings yet

- CO Refrigerant Applications: General DescriptionDocument3 pagesCO Refrigerant Applications: General DescriptionPedro Gabriel Rivas RamirezNo ratings yet

- Central Electrónica Universal Universal Control Unit Universelle Elektronische AuswerteeinheitDocument2 pagesCentral Electrónica Universal Universal Control Unit Universelle Elektronische AuswerteeinheitDiego GarnicaNo ratings yet

- Power Systems (K-Wiki - CH 4 - Stability)Document32 pagesPower Systems (K-Wiki - CH 4 - Stability)Priyanshu GuptaNo ratings yet

- Principles of Sustainable LivingDocument54 pagesPrinciples of Sustainable LivingRhodjane Dela CruzNo ratings yet

- Climate Change Is A Change in The Pattern of WeatherDocument8 pagesClimate Change Is A Change in The Pattern of WeatherAdan SafdarNo ratings yet

- Seminar Report On Wireless Power TransmissionDocument24 pagesSeminar Report On Wireless Power TransmissionsujiezNo ratings yet

- CHE1001 - Ammonia Production Final ReportDocument48 pagesCHE1001 - Ammonia Production Final ReportkhavthompsonNo ratings yet

- Company Profile-SRG GROUPDocument6 pagesCompany Profile-SRG GROUPRajeev KumarNo ratings yet

- °F °C Ohms °F °C Ohms °F °C Ohms: BAPI Sensor Specifi CationsDocument2 pages°F °C Ohms °F °C Ohms °F °C Ohms: BAPI Sensor Specifi Cationsaneesh88No ratings yet

- EIA Report (9.1)Document350 pagesEIA Report (9.1)imran hossainNo ratings yet

- KSB Etanorm 96 1450 SuperpumpDocument1 pageKSB Etanorm 96 1450 SuperpumpMohamed AyoubNo ratings yet

- Learn The Basics of Home Electrical WiringDocument3 pagesLearn The Basics of Home Electrical WiringZen Resti MaulanaNo ratings yet

- Revised TRA FormDocument4 pagesRevised TRA FormJoemar CaprancaNo ratings yet

- Final Interim Report Myza 25034Document18 pagesFinal Interim Report Myza 25034hasnizaNo ratings yet

- Officer's Particulars: Musat Radu-StefanDocument7 pagesOfficer's Particulars: Musat Radu-StefanRadu M.No ratings yet

- End-Of-Life Alternatives of Glass Reinforced Polyester Boat Hulls Compared by LcaDocument8 pagesEnd-Of-Life Alternatives of Glass Reinforced Polyester Boat Hulls Compared by LcaPhong TuanNo ratings yet

- Well Control EquipmentDocument82 pagesWell Control EquipmentKhairuddin KhairuddinNo ratings yet

- UNIT - 5 - FIRE PROTECTION and SOLAS RequirementsDocument85 pagesUNIT - 5 - FIRE PROTECTION and SOLAS RequirementsLikhith LikhithNo ratings yet

- Programme For The 16th Chlorine Symposium - Thyssenkrupp Uhde Chlorine Engineers, 15th - 17th June 2016, Dortmund, GermanyDocument2 pagesProgramme For The 16th Chlorine Symposium - Thyssenkrupp Uhde Chlorine Engineers, 15th - 17th June 2016, Dortmund, GermanyChristian Josue Herrera CordobaNo ratings yet

- Haramaya University Haramaya Institute of Technology Department of Mechanical EngineeringDocument18 pagesHaramaya University Haramaya Institute of Technology Department of Mechanical Engineeringadd aduNo ratings yet

- MGES ET L01 QuizDocument3 pagesMGES ET L01 QuizSquareNo ratings yet

- Potential Hydroelectric Power Plant in Ounasjoki RiverDocument5 pagesPotential Hydroelectric Power Plant in Ounasjoki RiverKamil IssaNo ratings yet