Professional Documents

Culture Documents

Hydraulic Power Unit Brochure

Hydraulic Power Unit Brochure

Uploaded by

s.notleyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Power Unit Brochure

Hydraulic Power Unit Brochure

Uploaded by

s.notleyCopyright:

Available Formats

High pressure small

hydraulic power

Characteristic:

Especially suitable for clamping devices and lifting

systems.

It has the following functions:

1. Low noise: meticulous construction, precise

quality, and low noise.

2. Low energy: With perfectly designed oil circuits,

the required energy is not wasted.

3. Space saving: The vertical installation of the

pump and motor is combined to save space.

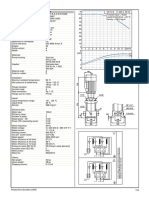

Parameter

4. Standard oil circuit, controlled return oil, easy

maintenance and repair.

Y -20 -1HP /P1 -H 4 V -Y1 /T G -K1

Number

insta Air of

Pressure Motor Tank

Series Tank(L) Motor Pump llati Motor power supply coolin directio

MPa speed color

on g nal

valves

not

20L 1HP have:b

lank K1:1

30L 2HP Y1:3-380V/50Hz set

4: T:AH0

P1:(gear B: 1-10 Y2:1-220-50Hz G:GR

1480r 608T- K2:2

Unit pump) C: 3.5-14 V Y3:3-220V/60Hz AY

40L 3HP 6: CA2 groups

H: 7-21 Y4:3-440V/60Hz

1780r E:AH1 K3:3

012- groups

`

60L 5HP CA2

Model Description

Motor(KW) Pressure Flow Pump

Series

(MPa) L/MIN(R:1480r)

Y-20-1HP/P1-B4V-Y1G-K1 10 4.3 gear pump

0.75

Y-20-1HP/P1-H4V-Y1G-K1 21 1.5 gear pump

Y-30-2HP/P1-C4V-Y1/TG-K1 14 5.8 gear pump

1.5

Y-30-2HP/P1-H4V-Y1/TG-K1 21 2.9 gear pump

Y-40-3HP/P1-C4V-Y1/TG-K1 14 8.7 gear pump

2.2

Y-40-3HP/P1-H4V-Y1/TG-K1 21 5.8 gear pump

Y-60-5HP/P2-C4V-Y1/EG-K1 14 14.5 gear pump

3.75

Y-60-5HP/P1-H4V-Y1/EG-K1 21 8.7 gear pump

Instructions for use:

1. The high-pressure small flow micro vertical system is designed and developed for customers

with compact installation space. It adopts the original HGP gear pump or quantitative blade

pump imported from Taiwan's Xinhong. Compared with low-end CBN gear pumps used by other

manufacturers in the market, it has the advantages of long service life, stable and reliable

operation, low noise, and slow temperature rise.

2. This model comes in two types: air-cooled and non air-cooled. If you need to use it

continuously for a long time, you must choose an air-cooled model with a standard fuel tank

capacity of 30-60L. The model without cooling has a fuel tank capacity of 20L, which is

smaller in size but cannot be used for a long time. Please ask customers to choose according

Dimensions

20L with 0.75KW motor reference size:

30L with 1.5KW motor reference size:

K4:4 groups + Electromagnetic pressure K2:2 groups (No electromagnetic

relief valve (No throttle valve installed) relief valve installed)

40L with 2.2KW motor reference size:

K2:2 groups + Electromagnetic pressure K2:Manual directional valve

relief valve (No throttle valve installed) + Manual pressure relief valve

60L with 3.7KW motor reference size:

Air-cooled

K2:2 groups + Electromagnetic pressure K1: One valve group

relief valve (No throttle valve installed)

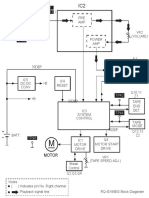

Schematic diagram

DC24

Optional installation:

throttle valve Two way

check

Oil port:PT3/8

Confirmation items before operation

1) Confirm the liquid level of the working oil in the fuel tank;

2) Check the main switch on the connected control board;

3) Check the cleanliness of the filter and replace it if necessary;

4) Check if the control device has an alarm signal, and if necessary, reset the existing signal.

Operation instructions and precautions for hydraulic stations

After completing the preparation work, please follow the following procedure for operation:

1) Close the main power switch;

2) Press the power control button;

3) Start the pump according to work requirements;

4) When the system is in an unmanned monitoring state, it must be shut down.

Instructions for using hydraulic oil

Please replace the hydraulic oil after the first three months of use, and replace the fluid once a

year thereafter

Pressure oil.

Suggestion: Use VG46 in summer; Use VG32 hydraulic oil in winter.

Working medium temperature range: 10-55 ° C

You might also like

- Renault Clio 2 Wiring Diagram PDFDocument14 pagesRenault Clio 2 Wiring Diagram PDFgustavo elbittar100% (5)

- HOSHIZAKI SERVICE MANUAL Logic Board Settings E1ck-811 PDFDocument118 pagesHOSHIZAKI SERVICE MANUAL Logic Board Settings E1ck-811 PDFLeo67% (3)

- ZAMIL PY Series Installation, Operation & Maintenance ManualDocument33 pagesZAMIL PY Series Installation, Operation & Maintenance Manualambuenaflor70% (10)

- Catálogo de Peças Skt90s - 2021 AtualizadoDocument540 pagesCatálogo de Peças Skt90s - 2021 AtualizadoleandroNo ratings yet

- In-Service Monitoring of Lubricating Oil For Auxiliary Power Plant EquipmentDocument20 pagesIn-Service Monitoring of Lubricating Oil For Auxiliary Power Plant Equipmentمحمد نصیریNo ratings yet

- LV5-1510-20-UL-SLR 1MW/ GFDI/6input/Insul - Monitor: Verdrahtungshinweise Wiring InstructionsDocument113 pagesLV5-1510-20-UL-SLR 1MW/ GFDI/6input/Insul - Monitor: Verdrahtungshinweise Wiring Instructionsedvaldo alves pintoNo ratings yet

- Service Manual: Crawler Dozers PR 711C - 751Document1,079 pagesService Manual: Crawler Dozers PR 711C - 751Ваня Малиш100% (1)

- 2-1. Structure and Function hx85x HyundaiDocument83 pages2-1. Structure and Function hx85x HyundaiAlfonso BerRamNo ratings yet

- Description Value: Printed From Grundfos CAPSDocument4 pagesDescription Value: Printed From Grundfos CAPSDima ArfNo ratings yet

- CR 5 - 3Document1 pageCR 5 - 3erdistraNo ratings yet

- CR10-16.Domestic and FlushingDocument5 pagesCR10-16.Domestic and Flushingrk mepNo ratings yet

- Data Motor Motor ListrikDocument10 pagesData Motor Motor ListrikAsrulNo ratings yet

- Application Tip: Using 2 Paralleling OptionDocument3 pagesApplication Tip: Using 2 Paralleling OptionMohamed MeeranNo ratings yet

- CR 5-4 A-A-A-E-HQQE: Position Qty. Description Single PriceDocument5 pagesCR 5-4 A-A-A-E-HQQE: Position Qty. Description Single Pricesunil kumarNo ratings yet

- Yuken 8 EDFHG-AMN English LeafletDocument4 pagesYuken 8 EDFHG-AMN English LeafletJose2806No ratings yet

- Oliju Productlist - 2018 - EN PDFDocument31 pagesOliju Productlist - 2018 - EN PDFJose Carlos SoaresNo ratings yet

- Hydraulic System FullDocument77 pagesHydraulic System FullSamuel Sanchez94% (36)

- Compact Power Unit R3Document5 pagesCompact Power Unit R3Raj K SharmaNo ratings yet

- Therma V Split Dec 2012Document52 pagesTherma V Split Dec 2012Osmar Franco PiresNo ratings yet

- Kirloskar CatalogueDocument8 pagesKirloskar CatalogueIon Vairamuthu100% (1)

- BServiceManualHW60NAA DDocument35 pagesBServiceManualHW60NAA Djesus quevedoNo ratings yet

- Manual Owner's ManualDocument48 pagesManual Owner's ManualJun Rong FooNo ratings yet

- Catalogo Bomba Sci BohmanDocument19 pagesCatalogo Bomba Sci Bohmanjimenezruben489No ratings yet

- Wiring Diagram ME-SFI M271 R171 Sheet 2Document6 pagesWiring Diagram ME-SFI M271 R171 Sheet 2koxeye3692No ratings yet

- 1100 Industrial Open Power Unit - Standard Product Selector Perkins V14Document3 pages1100 Industrial Open Power Unit - Standard Product Selector Perkins V14Nacer ZehaniNo ratings yet

- R410A Full DC Inverter Split Duct 50Hz Side Air-Discharge Type Service ManualDocument87 pagesR410A Full DC Inverter Split Duct 50Hz Side Air-Discharge Type Service ManualMiroslava ĐurićNo ratings yet

- Ftva SeriesDocument78 pagesFtva SeriesHuanNo ratings yet

- m16-1 C-R Packaged Air Conditioner-Final Drawing (Inc. Instruction Book) - CompressedDocument54 pagesm16-1 C-R Packaged Air Conditioner-Final Drawing (Inc. Instruction Book) - CompressedsfssullconnectNo ratings yet

- Series Parallel Pumps PDFDocument4 pagesSeries Parallel Pumps PDFMarc Danielle G Josue IINo ratings yet

- Technical Specification - 8X40Mtrs UV Vessel - Rev1Document15 pagesTechnical Specification - 8X40Mtrs UV Vessel - Rev1Basheer AhmedNo ratings yet

- Oil CentrifugeDocument2 pagesOil CentrifugeMuttappa T JainapurNo ratings yet

- LM - 388Document10 pagesLM - 388marcelo giussaniNo ratings yet

- Mta 18 WN 1Document129 pagesMta 18 WN 1Arlex Ricardo Guillen PetitNo ratings yet

- REXROTH Data - SheetDocument24 pagesREXROTH Data - SheetRADHAKRISHNANNo ratings yet

- Sewage Pump DASDocument11 pagesSewage Pump DASindra putraNo ratings yet

- Charging PDFDocument16 pagesCharging PDFred eagle winsNo ratings yet

- Hydraulic System.Document95 pagesHydraulic System.zae nurdinNo ratings yet

- General Features Prime StandbyDocument3 pagesGeneral Features Prime StandbyHabibNo ratings yet

- RQ SX46 56Document4 pagesRQ SX46 56Chef KaiserNo ratings yet

- Mini Power Packs Type Scla Drawing 10 DC Electric Motor DC Electric MotorDocument2 pagesMini Power Packs Type Scla Drawing 10 DC Electric Motor DC Electric MotorOleg080No ratings yet

- VERSATI II UputstvoDocument31 pagesVERSATI II UputstvoMiljanNo ratings yet

- Training Crawler 80 7 (A)Document19 pagesTraining Crawler 80 7 (A)Dragan100% (1)

- DEH PresentationDocument37 pagesDEH PresentationPRAMOD KUMAR NANDA100% (2)

- VEM3661T-InfoPacket OK.Document10 pagesVEM3661T-InfoPacket OK.Mariajose PuigcerverNo ratings yet

- Generators: Model: PDG20SS 20 KVA / Single PhaseDocument2 pagesGenerators: Model: PDG20SS 20 KVA / Single PhaseFritz NatividadNo ratings yet

- I-140 Electrical Training Rev 01Document75 pagesI-140 Electrical Training Rev 01Parangueo training CapacitacionNo ratings yet

- Electrical Load List - Rev. 00Document7 pagesElectrical Load List - Rev. 00swarupananda mohantyNo ratings yet

- General Features Prime StandbyDocument3 pagesGeneral Features Prime StandbyHabibNo ratings yet

- Panasonic 2019 Mechanical Relays Selection GuideDocument94 pagesPanasonic 2019 Mechanical Relays Selection GuideErasmo Franco SNo ratings yet

- Nimco Monoblock Control ValvesDocument66 pagesNimco Monoblock Control ValvesHui ChenNo ratings yet

- Starter 4Document3 pagesStarter 4SergPodoprigoraNo ratings yet

- 2005 Engine ElectricalDocument102 pages2005 Engine ElectricalMiguel OrtegaNo ratings yet

- CR 10-2 A-A-A-E-HQQE: Position Qty. Description Single PriceDocument3 pagesCR 10-2 A-A-A-E-HQQE: Position Qty. Description Single Pricerachman hardianNo ratings yet

- Hydraulic Pumps and Power Units English MetricDocument52 pagesHydraulic Pumps and Power Units English MetricrhapknexxNo ratings yet

- (SM) M (2 3 4 5) OE 14 42HFN1 Q (Multi Outdoor) - EngDocument57 pages(SM) M (2 3 4 5) OE 14 42HFN1 Q (Multi Outdoor) - EngDee RajaNo ratings yet

- FURUNO Fr1505 Mark3 SeriesDocument135 pagesFURUNO Fr1505 Mark3 SeriesPrinceBabuNo ratings yet

- 5c Product Catalog - YECAH - EN - PUBL-7895 (1215)Document20 pages5c Product Catalog - YECAH - EN - PUBL-7895 (1215)MinhNo ratings yet

- 37mw Man BW 12v4860 Hfo Power PlantDocument12 pages37mw Man BW 12v4860 Hfo Power PlantCellule SOTUBA2No ratings yet

- Vdocuments - MX Cameron Bop Control SystemsDocument38 pagesVdocuments - MX Cameron Bop Control SystemsOPERACIONES TOP OILNo ratings yet

- Zero-Voltage Switch With Adjustable Ramp T2117: FeaturesDocument15 pagesZero-Voltage Switch With Adjustable Ramp T2117: FeaturesNenad VukovicNo ratings yet

- FTK (X) - A Series (Wall Mount)Document54 pagesFTK (X) - A Series (Wall Mount)khant kyaw khaingNo ratings yet

- 6-4 Crawler TypeDocument22 pages6-4 Crawler TypeSumitomo Laos Sumitomo LaosNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 4.various Tests Part 1Document69 pages4.various Tests Part 1Rohit JoshiNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument21 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsmiriamNo ratings yet

- Q4 Performance Task 1 Charles KMT Law and Boyles LawDocument2 pagesQ4 Performance Task 1 Charles KMT Law and Boyles LawAndrie SegueraNo ratings yet

- Chemical Tanker Midship Section Prepared by Capt Ajay PuriDocument5 pagesChemical Tanker Midship Section Prepared by Capt Ajay Purinpankaj1No ratings yet

- NO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last CalibrationDocument39 pagesNO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last Calibrationmayur dhandeNo ratings yet

- Access To Safe Drinking Water PDFDocument47 pagesAccess To Safe Drinking Water PDFSahera ShaikNo ratings yet

- Air Compressor - Parts and FunctionDocument25 pagesAir Compressor - Parts and FunctionJohn Kris San LuisNo ratings yet

- Data Sheet Motor 15HP WegDocument1 pageData Sheet Motor 15HP WegRUBEN ACOSTANo ratings yet

- Emmvee Solar Systems Private Limited-ReportDocument6 pagesEmmvee Solar Systems Private Limited-Reportshashwat shukla100% (1)

- Well Control EquipmentDocument82 pagesWell Control EquipmentKhairuddin KhairuddinNo ratings yet

- Seminar Report On Wireless Power TransmissionDocument24 pagesSeminar Report On Wireless Power TransmissionsujiezNo ratings yet

- Climate Change Is A Change in The Pattern of WeatherDocument8 pagesClimate Change Is A Change in The Pattern of WeatherAdan SafdarNo ratings yet

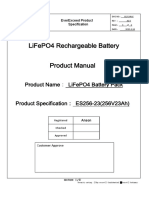

- ES256-23 (256V23Ah) LiFePO4 Battery Pack SpecificationDocument6 pagesES256-23 (256V23Ah) LiFePO4 Battery Pack SpecificationDAVID MENESES BOJORGESNo ratings yet

- Unisa WiL Project Schedule 2023Document2 pagesUnisa WiL Project Schedule 2023Sannah TeffoNo ratings yet

- EASA Power Q&ADocument3 pagesEASA Power Q&ASarathNo ratings yet

- Vishal Ic Engines Project ReportDocument13 pagesVishal Ic Engines Project ReportKAVIARASU ANo ratings yet

- DELTA - SAHARA BROCHURE 17 SEER (60Hz)Document2 pagesDELTA - SAHARA BROCHURE 17 SEER (60Hz)edchariNo ratings yet

- Service Manual KT610-KT620, KT715-KT745Document96 pagesService Manual KT610-KT620, KT715-KT745Felipe ArredondoNo ratings yet

- Planning Manual SIVACON S8 enDocument143 pagesPlanning Manual SIVACON S8 enالحمزة الراويNo ratings yet

- Arduino-Based Smart Electric VehicleDocument13 pagesArduino-Based Smart Electric VehicleNitesh RanjanNo ratings yet

- What Does The G20 DoDocument9 pagesWhat Does The G20 DoParvez ShakilNo ratings yet

- 4-List Working StandarDocument2 pages4-List Working StandarHeny YuslizarNo ratings yet

- DOMDocument14 pagesDOMMANSI SALUNKENo ratings yet

- 2006 Toyota Camry Engine ControlDocument11 pages2006 Toyota Camry Engine Control35.Hoàng Xuân TânNo ratings yet

- IAEA Desalination Economic Evaluation Programme (DEEP)Document20 pagesIAEA Desalination Economic Evaluation Programme (DEEP)connieNo ratings yet

- Central Electrónica Universal Universal Control Unit Universelle Elektronische AuswerteeinheitDocument2 pagesCentral Electrónica Universal Universal Control Unit Universelle Elektronische AuswerteeinheitDiego GarnicaNo ratings yet

- Medco 4Document36 pagesMedco 4primaNo ratings yet