Professional Documents

Culture Documents

PRJP - 1572

PRJP - 1572

Uploaded by

Srinivas KROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PRJP - 1572

PRJP - 1572

Uploaded by

Srinivas KRCopyright:

Available Formats

Pramana Research Journal ISSN NO: 2249-2976

BRAKE FAILURE INDICATOR

K Kanishka Chowdary¹,G Satya Subhash²,D C Likith Kumar³,K Uma Sai⁴,V Akhil⅝

¹ ² ³ ⁴ ⅝ students,Electrical and electronics engineering department, Pragati engineering

college, surampalem.

ABSTRACT

Automobiles have been the primary mode of transportation for most of us and we depend on

them for our day to day commute. Brake failure indicator circuit is a circuit that constantly

monitore the condition of brake.The sensor which is attached to the circuit of a brake failure

by monitoring the brake switch and reminds you the condition of brake every time when brake

is appiled. This mechanism involves a Brake wire which runs from the brake lever to the

braking mechanism set-up of the vehicle. It is this wire that gets pulled when we apply brakes

to stop our vehicle. Machines are widely controlled by automated control system. To meet the

need of growing population economic, effective and reliable control of machines as well as

their control system is necessary. The main objective of this project is to continuously monitor

the braking system at each and every time during the operation of the vehicle. Now a days,

accidents are occurring due to lot of reasons, the one of the main reason is brake failure, it

caused to due to poor maintenance, improper use and product defect, in order to safe guard

the valuable human for accident the accident monitoring of brake is very important issue in

automobile. The brake failure indicator circuit is a circuit that monitors constantly of the

condition of brakes and provides an audio visual indication. When the brake is applied in order

to slow down or to stop the vehicle the green LED blinks and the buzzer beeps for about one

second if the brake system is accurate and working properly. If brake system fails the red LED

glows and the buzzer do not beep when the brakes are applied.

INTRODUCTION

A brake is a mechanical device that hinder, restrain, or prevents motion, slowing or stopping a

moving object or preventing its motion.Most of the brakes generally uses friction between two

surfaces pressed together to change the form of the kinetic energy of the moving object into

heat, despite the fact that other methods of energy conversion may be employed for the same.

For example, regenerative braking converts a large amount of the energy to electrical energy

along with the heat energy, which may be stored or can be sent back to the source for later use.

Some other methods convert the kinetic energy into potential energy in such stored forms as

pressurized oil or pressurized air. Magnetic fields is used in Eddy current brakes to convert

kinetic energy into electric current in the brake disc, fin, or rail, which is converted into heat

energy. Still there are other braking methods to transform kinetic energy into different forms,

for example by transferring the energy to a rotating flywheel.

Volume 10, Issue 5, 2020 156 https://pramanaresearch.org/

Pramana Research Journal ISSN NO: 2249-2976

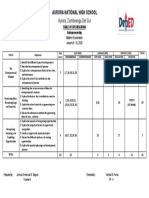

DIAGRAMANDEXPLANATION

WORKING OF THIS BRAKE FAILURE CIRCUIT

Once the connection is made power the circuit, make sure the Brake cable (here I have used a normal

yellow wire to represent the brake cable) is connected across the +5V and base of BC557 through a

resistor as shown in the circuit. If everything works as expected you should see the Green LED turned

on and the Buzzer and Red Light Turned Off. Now, cut/remove the brake cable the Red LED and the

Buzzer should start flashing.

COMPONENTS USED IN BRAKE FAILURE INDICATOR:

BUZZER :

A buzzer is a small yet efficient component to add sound features to our project/system. It is

very small and compact 2-pin structure hence can be easily used on, PCB Board which makes

this a widely used component in most electronic applications.

There are two types are buzzers that are commonly available. The one shown here is a simple

buzzer which when powered will make a Continuous Beeeeeeppp.... sound, the other type is

called a readymade buzzer which will look bulkier than this and will produce a Beep. Beep.

Beep. Sound due to the internal oscillating circuit present inside it. But, the one shown here is

most widely used because it can be customised with help of other circuits to fit easily in our

application. This buzzer can be used by simply powering it using a DC power supply ranging

from 4V to 9V. A simple 9V battery can also be used, but it is recommended to use a regulated

+5V or +6V DC supply. The buzzer is normally associated with a switching circuit to turn ON

or turn OFF the buzzer at required time and require interval.

Volume 10, Issue 5, 2020 157 https://pramanaresearch.org/

Pramana Research Journal ISSN NO: 2249-2976

LED :

A light-emitting diode (LED) is a semiconductor light source that emits light when current

flows through it. Electrons in the semiconductor recombine with electron holes, releasing

energy in the form of photons. The colour of the light (corresponding to the energy of the

photons) is determined by the energy required for electrons to cross the band gap of the

semiconductor. White light is obtained by using multiple semiconductors or a layer of light-

emitting phosphor on the semiconductor device.

Appearing as practical electronic components in 1962, the earliest LEDs emitted low-intensity

infrared light. Infrared LEDs are used in remote-control circuits, such as those used with a wide

variety of consumer electronics. The first visible-light LEDs were of low intensity and limited

to red. Modern LEDs are available across the visible, ultraviolet, and infrared wavelengths,

with high light output.

PCB ( PRINTED CIRCUIT BOARD)

A printed circuit board (PCB) mechanically supports and electrically connects electrical or

electronic components using conductive tracks, pads and other features etched from one or

more sheet layers of copper laminated onto and/or between sheet layers of a ((non-conductive

substrate. Components are generally soldered onto the PCB to both electrically connect and

mechanically fasten them to it. Printed circuit boards are used in all but the simplest electronic

products. They are also used in some electrical products, such as passive switch boxes.

Volume 10, Issue 5, 2020 158 https://pramanaresearch.org/

Pramana Research Journal ISSN NO: 2249-2976

Alternatives to PCBs include wire wrap and point-to-point construction, both once popular but

now rarely used. PCBs require additional design effort to lay out the circuit, but manufacturing

and assembly can be automated. Specialized CAD software is available to do much of the work

of layout. Mass-producing circuits with PCBs is cheaper and faster than with other wiring

methods, as components are mounted and wired in one operation. Large numbers of PCBs can

be fabricated at the same time, and the layout only has to be done once. PCBs can also be made

manually in small quantities, with reduced benefits.

RESISTOR

A resistor is a passive two-terminal electrical component that implement electrical resistance

as a circuit flow, adjust signal levels, to divide voltages, bias active elements, and terminate

transmission lines, among other uses. High power resistors that can dissipate many watts of

electrical power as heat, may be used as parts of motor controls, in power distribution systems,

or as test loads for generators.Fixed resistors have resistances that only change slightly with

temperature, time or operating voltage. Variable resistors can be used to adjust circuit elements

(such as a volume control or a lamp dimmer), or as sensing devices for heat, light, humidity,

force, or chemical activity.

Resistors are common elements of electrical networks and electronic circuits and are ubiquitous

in electronic equipment. Practical resistors as discrete components can be composed of various

compounds and forms. Resistors are also implemented within integrated circuits.

Volume 10, Issue 5, 2020 159 https://pramanaresearch.org/

Pramana Research Journal ISSN NO: 2249-2976

BATTERY

Battery is a device consisting of one or more electrochemical cells with external connections

for powering electrical devices such as flashlights, mobile phones, and electric cars. When a

battery is supplying electric power, its positive terminal is the cathode and its negative

terminal is the anode. The terminal marked negative is the source of electrons that will flow

through an external electric circuit to the positive terminal. When a battery is connected to an

external electric load, a redox reaction converts high-energy reactants to lower-energy

products, and the free-energy difference is delivered to the external circuit as electrical

energy. Historically the term "battery" specifically referred to a device composed of multiple

cells, however the usage has evolved to include devices composed of a single cell.

CAPACITOR

In October 1745, Ewald Georg von Kleist of Pomerania, Germany, found that charge could

be stored by connecting a high-voltage electrostatic generator by a wire to a volume of water

in a hand-held glass jar.[4] Von Kleist's hand and the water acted as conductors, and the jar

as a dielectric (although details of the mechanism were incorrectly identified at the time).

Von Kleist found that touching the wire resulted in a powerful spark, much more painful than

that obtained from an electrostatic machine. The following year, the Dutch physicist Pieter

van Musschenbroek invented a similar capacitor, which was named the Leyden jar, after the

University of Leiden where he worked.[5] He also was impressed by the power of the shock

he received, writing, "I would not take a second shock for the kingdom of France."[6]

Daniel Gralath was the first to combine several jars in parallel to increase the charge storage

capacity.[7] Benjamin Franklin investigated the Leyden jar and came to the conclusion that

Volume 10, Issue 5, 2020 160 https://pramanaresearch.org/

Pramana Research Journal ISSN NO: 2249-2976

the charge was stored on the glass, not in the water as others had assumed. He also adopted

the term "battery",[8][9] (denoting the increasing of power with a row of similar units as in a

battery of cannon), subsequently applied to ((clusters of electrochemical cells.[10] Leyden

jars were later made by coating the inside and outside of jars with metal foil, leaving a space

at the mouth to prevent arcing between the foils.[citation needed] The earliest unit of

capacitance was the ((jar, equivalent to about 1.11 nanofarads.[11]

Leyden jars or more powerful devices employing flat glass plates alternating with foil

conductors were used exclusively up until about 1900, when the invention of wireless (radio)

created a demand for standard capacitors, and the steady move to higher frequencies required

capacitors with lower inductance. More compact construction methods began to be used,

such as a flexible dielectric sheet (like oiled paper) sandwiched between sheets of metal foil,

rolled or folded into a small package.

A capacitor is a device that stores electrical energy in an electric field. It is a ((passive electronic

component with two ((terminals.

The effect of a capacitor is known as capacitance. While some capacitance exists between any

two electrical conductors in proximity in a circuit, a capacitor is a component designed to add

capacitance to a circuit. The capacitor was originally known as a condenser or compensator.

This name and its cognates are still widely used in many languages, but rarely in English, one

notable exception being condenser microphones, also called capacitor microphones. The

physical form and construction of practical capacitors vary widely and many types of capacitor

are in common use.

555 TIMER :

The IC was designed in 1971 by Hans R. Camenzind under contract to signetics, later

acquired by Philips semiconductors, now NXP

In 1962, Camenzind joined PR Mallory's Laboratory for Physical Science in Burlington,

Massachusetts.[5] He designed a pulse-width modulation(PWM) amplifier for audio

applications;[8] however, it was not successful in the market because there was no power

transistor included. He became interested in tuners such as a gyrator and a phase-locked loop

(PLL). He was hired by Signetics to develop a PLL IC in 1968. He designed an oscillator for

PLLs such that the frequency did not depend on the power supply voltage or temperature.

Volume 10, Issue 5, 2020 161 https://pramanaresearch.org/

Pramana Research Journal ISSN NO: 2249-2976

Signetics subsequently laid off half of its employees due to a recession; development on the

PLL was thus frozen.

Camenzind proposed the development of a universal circuit based on the oscillator for PLLs

and asked that he develop it alone, borrowing equipment from Signetics instead of having his

pay cut in half. Other engineers argued the product could be built from existing parts;

however, the marketing manager approved the idea. Among 5xx numbers that were assigned

for analog ICs, the part number "555" was chosen.

Camenzind also taught circuit design at Northeastern University in the morning attending the

university himself at night working toward a Master's degree in Business Administration.The

first design for the 555 was reviewed in the summer of 1971. Assessed to be without error, it

proceeded to layout design. A few days later, Camenzind got the idea of using a direct

resistance instead of a constant current source finding later that it worked. The change

decreased the required 9 pins to 8 so the IC could be fit in an 8-pin package instead of a 14-

pin package. This revised design passed a second design review with the prototype completed

in October 1971.

ADVANTAGES :

1) No need of external battery. Circuit can be powered from the vehicle’s battery itself.

2) Power consumption is comparably less.

3) It is not depend on the petrol level.

4) Operating principle is very easy.

5) Installation is simplified very much.

Volume 10, Issue 5, 2020 162 https://pramanaresearch.org/

Pramana Research Journal ISSN NO: 2249-2976

6) The safety of driver is ensured.

7) Brake failure is notified to the surrounding traffic via buzzer.

8) The cost is low.

APPLICATIONS :

1) Four wheeler application

2) Two wheeler application

3) Mechanical Crane

4) Mechanical machines

FUTURE SCOPES :

1) It can be used with high sensitivity pressure sensor.

2) If in case the brake fails, brake failure indicator can also be used in order to shut down

the vehicle’s engine.

3) The circuit will work in vehicles only with negative grounding.

4) The brake switch is fluid operated and does not function if fluid pressure drops to leakage.

INSTRUCTION TO USE :

1) Always operate vehicles with proper negative grounding.

2) Keep the volume of audio visual indicator sound high so it can be easily hear by operator.

3) is important and necessary to attach the sensor with brake switch.

4) Always monitor the level of fluid leakage and its condition.

CONCLUSION

1) The main purpose of this project is to provide such a device to vehicles operator so

that any harmful damage and accidents cause by failure of brake switch can be easily

prevented by the proper indication of working condition of brake switch. There are many

aims of this project describe as:-

2) To sense the pressure drop due to the pressure leakage.

3) To indicate the proper working condition of brake switch.

Volume 10, Issue 5, 2020 163 https://pramanaresearch.org/

Pramana Research Journal ISSN NO: 2249-2976

4) To observe the level of hydraulic pressure.

5) To calculate the fluid braking pressure when the brake is applied.

6) To prevent small number of accident occurs in trains and boats by the failure of brake

switch.

REFERENCES

1) http://saranyasblog.blogspot.in/2009/02/introduction-brake-failure-indicator.html

2) https://en.wikipedia.org/wiki/Brake

3) http://www.edwardslawok.com/types-of-auto-brakes.html

4) http://westislandgarage.com/en/auto-repairs/55-systeme-de-freinage

5) http://www.smartmotorist.com/driving-guideline/failure-of-vehicles-braking-

system.html

6) http://www.e-z.net/~ts/hybrakes.htm

7)

http://www.electronicsforu.com/electronicsforu/circuitarchives/view_article.asp?sno=232

Volume 10, Issue 5, 2020 164 https://pramanaresearch.org/

You might also like

- Seminar Report On Numerical RelayDocument20 pagesSeminar Report On Numerical RelayAnurag Determined100% (1)

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- ECEN 214 - Electrical Circuit Theory Fall 2017: Smiller@tamu - EduDocument4 pagesECEN 214 - Electrical Circuit Theory Fall 2017: Smiller@tamu - EduAllie JuneNo ratings yet

- TOS ENTREPRENEURSHIP Midterm ExamDocument1 pageTOS ENTREPRENEURSHIP Midterm Examjoshua baguio100% (2)

- SAT Subject Tests: Math Level 2Document2 pagesSAT Subject Tests: Math Level 2Б. МолорNo ratings yet

- Test Project: Name: Sub CodeDocument23 pagesTest Project: Name: Sub CodePavithra IsravelNo ratings yet

- PWM Based DC Motor Speed ControlDocument76 pagesPWM Based DC Motor Speed ControlEr Meghvrat AryaNo ratings yet

- 97 Design PDFDocument8 pages97 Design PDFKhaled RabeaNo ratings yet

- Group No 16Document18 pagesGroup No 16Roshan DodiyaNo ratings yet

- Dual Axis Solar Panel ComponentsDocument11 pagesDual Axis Solar Panel ComponentsRaj Kothari MNo ratings yet

- Ahmednagar College: Department of Electronics "Rain Detector" MR - Sujal KanojiyaDocument16 pagesAhmednagar College: Department of Electronics "Rain Detector" MR - Sujal KanojiyaSujal KanojiyaNo ratings yet

- Major ProjectDocument4 pagesMajor ProjectSaroj kumar BiswasNo ratings yet

- Automatic Power Factor CompensationDocument5 pagesAutomatic Power Factor CompensationIJARSCT JournalNo ratings yet

- Parts of Energy Generating TilesDocument8 pagesParts of Energy Generating TilesSahal T YousephNo ratings yet

- Energy ManagementDocument55 pagesEnergy ManagementNjitnumNo ratings yet

- Why An Electronic Choke Circuit Diagram Is ImportantDocument10 pagesWhy An Electronic Choke Circuit Diagram Is ImportantjackNo ratings yet

- Earthing TypesDocument6 pagesEarthing TypesbharatisrmNo ratings yet

- Brake Failure IndicatorDocument15 pagesBrake Failure IndicatorSubham Chakraborty100% (2)

- Advance Building ServicesDocument18 pagesAdvance Building ServicesashishNo ratings yet

- Modelling Simulation and Performance Analysis of PV Array Under Different Shading Conditions Ijariie23628Document7 pagesModelling Simulation and Performance Analysis of PV Array Under Different Shading Conditions Ijariie23628ntsuandihNo ratings yet

- Electronic Card Lock System Final Year Ece Project ReportDocument17 pagesElectronic Card Lock System Final Year Ece Project ReportSunny Prasanth100% (3)

- Automatic Railway Gate Controller Project ReportDocument32 pagesAutomatic Railway Gate Controller Project ReportAbhijeet Pareek71% (7)

- Design and Implementation of Mini Ups SystemDocument11 pagesDesign and Implementation of Mini Ups SystemGhilman HabibNo ratings yet

- Gyan Ganga Institute of Technology & Science, Jabalpur (MP) : Approved by AICTE New Delhi & Govt. of M.PDocument12 pagesGyan Ganga Institute of Technology & Science, Jabalpur (MP) : Approved by AICTE New Delhi & Govt. of M.PDebashish MukherjeeNo ratings yet

- Presentation 1Document24 pagesPresentation 1Nabeel KhanNo ratings yet

- IE Project Report Group 3Document9 pagesIE Project Report Group 3john jkillerzsNo ratings yet

- Remote Control LED: Final ProjectDocument18 pagesRemote Control LED: Final ProjectNoman MustafaNo ratings yet

- Introduction To Basic Electronics, Electronic Components and ProjectsDocument29 pagesIntroduction To Basic Electronics, Electronic Components and Projectsajay chaudharyNo ratings yet

- Timeport Alternative EnergyDocument7 pagesTimeport Alternative Energytimeport24No ratings yet

- Using Flyback Diodes in Relays Prevents Electrical Noise in Your CircuitsDocument12 pagesUsing Flyback Diodes in Relays Prevents Electrical Noise in Your CircuitsjackNo ratings yet

- A Project Report ONDocument15 pagesA Project Report ONshiv infotechNo ratings yet

- Physics Project TKDocument24 pagesPhysics Project TKsimantini hazraNo ratings yet

- Electronic EyeDocument14 pagesElectronic EyeHajarath Prasad Abburu100% (1)

- Environment Monitoring System Table of Content: WorkingDocument6 pagesEnvironment Monitoring System Table of Content: WorkingAmit sonkerNo ratings yet

- Semiconductor Efficiency Comparison Between Discrete Devices and Integrated Devices Submitted by Waleed Abrar (2018-EE-061) Section (B)Document16 pagesSemiconductor Efficiency Comparison Between Discrete Devices and Integrated Devices Submitted by Waleed Abrar (2018-EE-061) Section (B)Sudais PastaNo ratings yet

- Components of Substation CdsDocument12 pagesComponents of Substation CdsSaradaprasan DasNo ratings yet

- ESP8266 Based Appliance Control Using Wifi: NAME OF THE STUDENTDocument31 pagesESP8266 Based Appliance Control Using Wifi: NAME OF THE STUDENTGurhans Pal SinghNo ratings yet

- Chapter One Smps InverterDocument10 pagesChapter One Smps Inverterolawale gbadeboNo ratings yet

- A Synopsis Report ON Speed Control of DC Motor Using Arduino Microcontroller Board and PWMDocument14 pagesA Synopsis Report ON Speed Control of DC Motor Using Arduino Microcontroller Board and PWMsaikumarNo ratings yet

- 14 Basic Electrical Components & Their FunctionsDocument10 pages14 Basic Electrical Components & Their FunctionsBrian ByengaboNo ratings yet

- ديعس دجام ءاقرو:مسلاا ةيناثلا ةلحرملا CAD/CAM:عرف فارشاب ذاتسلأا: بيبش نسح ءلاعDocument6 pagesديعس دجام ءاقرو:مسلاا ةيناثلا ةلحرملا CAD/CAM:عرف فارشاب ذاتسلأا: بيبش نسح ءلاعBatool MagedNo ratings yet

- Chapter 1: Introduction: Automatic Brake Failure IndicatorDocument21 pagesChapter 1: Introduction: Automatic Brake Failure IndicatorYatishchandra BMNo ratings yet

- PCB Design and Assembly For Power SuppliesDocument6 pagesPCB Design and Assembly For Power SuppliesMuhammed İkablNo ratings yet

- Automatic Street Light Control and FaultDocument6 pagesAutomatic Street Light Control and FaultJagabandhu KarNo ratings yet

- AJES Vol.7 No.1 January June 2018 pp.6 9Document4 pagesAJES Vol.7 No.1 January June 2018 pp.6 9vishal kambleNo ratings yet

- Name: Usman Rasheed Section: A ID: 14019019062 Course: Engg - Ethics Assignment:Electronic Components Submitted To: Sir Khalid AsgharDocument12 pagesName: Usman Rasheed Section: A ID: 14019019062 Course: Engg - Ethics Assignment:Electronic Components Submitted To: Sir Khalid AsgharUsman RasheedNo ratings yet

- P.E.S. College of Engineering, Aurangabad.: Project ReportDocument25 pagesP.E.S. College of Engineering, Aurangabad.: Project ReportShaikh Ibrahim0% (1)

- Next Generation Alternative Energy Storage Using Super Capacitors/ultra CapacitorsDocument25 pagesNext Generation Alternative Energy Storage Using Super Capacitors/ultra CapacitorsKonda Snigdha100% (1)

- Automatic Grass Cutter MachineDocument33 pagesAutomatic Grass Cutter MachineDebashishParidaNo ratings yet

- Report On RelayDocument27 pagesReport On RelayDeepakVyas67% (3)

- CSC - 121 - LN - 1 - 20192020Document9 pagesCSC - 121 - LN - 1 - 20192020nlovestimNo ratings yet

- Department of Electronics and InstrumentationDocument15 pagesDepartment of Electronics and InstrumentationRajeshwariNo ratings yet

- Export DocumentDocument37 pagesExport DocumentEunjeru EspedidoNo ratings yet

- Research Paper 22 MayDocument10 pagesResearch Paper 22 Mayviju143No ratings yet

- Design of Buck DC-DC Converter Space ApplicationDocument7 pagesDesign of Buck DC-DC Converter Space ApplicationIJRASETPublicationsNo ratings yet

- Solar Wireless Electric Vehicle Charging SystemDocument5 pagesSolar Wireless Electric Vehicle Charging Systemsubhamkumar01122000No ratings yet

- 18 IR Smart Street Light PRJ FileDocument25 pages18 IR Smart Street Light PRJ FileANCHAL MISHRANo ratings yet

- Automatic Phase ChangerDocument17 pagesAutomatic Phase ChangerganeshNo ratings yet

- Sri Vasavi Engineering College: 132/33 KV Substation YernagudemDocument34 pagesSri Vasavi Engineering College: 132/33 KV Substation Yernagudemsathya naiduNo ratings yet

- Fpe Final PournimaDocument12 pagesFpe Final Pournimadigi mitraNo ratings yet

- Power Generation Using Footstep-310Document5 pagesPower Generation Using Footstep-310LavanyaNo ratings yet

- Phone Charger Using Sun Tracking Solar PanelDocument6 pagesPhone Charger Using Sun Tracking Solar PanelIJRASETPublicationsNo ratings yet

- Temperature Distribution Along A Constant Cross Sectional Area FinDocument7 pagesTemperature Distribution Along A Constant Cross Sectional Area FinFawaz PartoNo ratings yet

- 2nd Year ExamDocument4 pages2nd Year ExamFares HaifNo ratings yet

- Basic PULSE Labshop TutorialDocument52 pagesBasic PULSE Labshop TutorialSufyan AzamNo ratings yet

- 18 - Creating The Persistence Layer With TopLinkDocument42 pages18 - Creating The Persistence Layer With TopLinksuresh1130No ratings yet

- Voltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Document5 pagesVoltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Moustafa NassarNo ratings yet

- Reseach Heat Waves G1Document13 pagesReseach Heat Waves G1rogieevemurilloNo ratings yet

- Basic Macroeconomics Module Part 2Document206 pagesBasic Macroeconomics Module Part 2Ikrima ibn abdisaNo ratings yet

- React On What Is Asserted LP EDITED AND FINAL To Be PrintedDocument8 pagesReact On What Is Asserted LP EDITED AND FINAL To Be PrintedEUNICE RIVAS100% (3)

- Documentary: Mind Over Money: 1 2 3 4 5 6 7 8 9 10 A X X X B X X C X X X D X XDocument1 pageDocumentary: Mind Over Money: 1 2 3 4 5 6 7 8 9 10 A X X X B X X C X X X D X XCARLOTA MALDONADO MARTINNo ratings yet

- Pr1 q2 Modules 17 To 18Document37 pagesPr1 q2 Modules 17 To 18Nv SdNo ratings yet

- S006 - Suicide in An Airpla PDFDocument19 pagesS006 - Suicide in An Airpla PDFruso1900No ratings yet

- En Cours 2018 Lepl1102Document2 pagesEn Cours 2018 Lepl1102Airton MotaNo ratings yet

- Class 10 Economics PDFDocument104 pagesClass 10 Economics PDFanirudhNo ratings yet

- 【奥纬咨询】Will Web3 Reinvent Insurance - 【洞见研报DJyanbao.com】Document39 pages【奥纬咨询】Will Web3 Reinvent Insurance - 【洞见研报DJyanbao.com】dafei sunNo ratings yet

- Understanding Regression Equations Interpreting Regression Tables PDFDocument20 pagesUnderstanding Regression Equations Interpreting Regression Tables PDFCaro SánchezNo ratings yet

- D. A Framework For Every Stage of The Collection and Analysis of DataDocument4 pagesD. A Framework For Every Stage of The Collection and Analysis of DataShenna LimNo ratings yet

- Imaginarium - Byju's - Amazing FactsDocument47 pagesImaginarium - Byju's - Amazing Factsaryankumawat40No ratings yet

- Avantaje+ DezavantajeDocument23 pagesAvantaje+ DezavantajeFlori FlorentinaNo ratings yet

- Church Social BrochureDocument14 pagesChurch Social BrochureOmosegbon tunmiseNo ratings yet

- Vacuum PumpDocument126 pagesVacuum PumpJessicalba Lou100% (3)

- HeadofficeDocument6 pagesHeadofficeTikoo AdityaNo ratings yet

- Wind LoadDocument13 pagesWind LoadHimani NagarNo ratings yet

- Chapter 16 PSK DemodDocument18 pagesChapter 16 PSK DemodberkahNo ratings yet

- Jsa Removal Fixing InsulationDocument2 pagesJsa Removal Fixing InsulationAprilia Rizki Ardila63% (8)

- As 4649-1999 Brake Shoe Assemblies and Disc Brake Pad Assemblies - AttachmentDocument7 pagesAs 4649-1999 Brake Shoe Assemblies and Disc Brake Pad Assemblies - AttachmentSAI Global - APACNo ratings yet

- Hongleong StatementDocument43 pagesHongleong StatementHaziq “AjiBoy” MhnBzNo ratings yet

- El Pop Ocho Viola GuitarDocument13 pagesEl Pop Ocho Viola GuitarGabriel BiscagliaNo ratings yet