Professional Documents

Culture Documents

Epc Pip Cal 0001

Epc Pip Cal 0001

Uploaded by

mb.pipingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epc Pip Cal 0001

Epc Pip Cal 0001

Uploaded by

mb.pipingCopyright:

Available Formats

Purpose

The purpose of this document is to provide guidance in the assessment of Wall thicknes by

calculation for all pressure equipment manufactured by WGPSN under the requirements of the PED.

Scope

This form applies to the UK Region, for pressure equipment procured, manufactured or assembled

within the EU or EEA.

Glossary of Terms

References

Note: These references are subject to change. Utilise the iMAP search engine for the latest applicable references.

PED Compliance, ENG-PRC-1108

Originating,

ASME B31.3Checking, Approval and Authorisation of Engineering and Design Documentation, ENG-

Abbreviations

Bar g Gauge Pressure in Bar

deg C Degrees Celcius

ins Inch

mm Millimetre

PED Pressure Equipment Directive

psi Pressure in pounds per square inch

wt Wall thickness

Roles & Responsibilities

As per ENG-PRC-1108

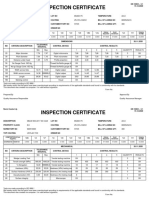

UK - Pressure Equipment Directive Wall thickness Calculation

Pipe Data Pipe Size

nb Nominal Bore ins 0.50 0.75 1.00 1.50 2.00 3.00 4.00 6.00 8.00 10.00 12.00 14.00 16.00 18.00 20.00 24.00 Ref Note

D Outside Diameter mm 21.30 26.70 33.40 48.30 60.30 88.90 114.30 168.30 219.10 273.10 323.90 355.60 406.40 457.00 508.00 609.60

D Outside Diameter ins 0.84 1.05 1.31 1.90 2.37 3.50 4.50 6.63 8.63 10.75 12.75 14.00 16.00 18.00 20.00 24.00

Pressure Data

P Pressure Bar g 19.6 19.6 19.6 19.6 19.6 19.6 19.6 19.6 19.6 19.6 19.6 19.6 19.6 19.6 19.6 19.6 7

P Pressure psi 284.2 284.2 284.2 284.2 284.2 284.2 284.2 284.2 284.2 284.2 284.2 284.2 284.2 284.2 284.2 284.2

From B31.3

S Stress Value psi 19998 19998 19998 19998 19998 19998 19998 19998 19998 19998 19998 19998 19998 19998 19998 19998 2, 7

E Quality Factor - 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 3

W Weld Joint Factor - 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 4

Y Coefficient - 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 5

t Pressure Design Thickness ins 0.01 0.01 0.01 0.01 0.02 0.02 0.03 0.05 0.06 0.08 0.09 0.10 0.11 0.13 0.14 0.17 1

t Pressure Design Thickness mm 0.15 0.19 0.24 0.34 0.43 0.63 0.81 1.19 1.55 1.93 2.29 2.51 2.87 3.23 3.59 4.31

Allowances & Tolerances

c Erosion / Corr allow mm 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

c Thread allowance mm 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Design Thickness

tm Minimum Required Thickness mm 1.15 1.19 1.24 1.34 1.43 1.63 1.81 2.19 2.55 2.93 3.29 3.51 3.87 4.23 4.59 5.31 6

Actual Thickness

Sch ANSI B36.10 - 80 80 80 80 40 40 40 40 20 20 20 20 20 20 20 20

T Wall Thickness mm 3.73 3.91 4.55 5.08 3.91 5.49 6.02 7.11 6.35 6.35 6.35 7.92 7.92 7.92 9.53 9.53

tol Negative Tolerance (wt) % 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50%

T(less tol) Wall Thickness less Tolerance mm 3.26 3.42 3.98 4.45 3.42 4.80 5.27 6.22 5.56 5.56 5.56 6.93 6.93 6.93 8.34 8.34

Wall Thickness Check (T(less tol)- tm) 2.11 2.23 2.75 3.10 2.00 3.18 3.46 4.03 3.01 2.63 2.27 3.42 3.06 2.70 3.75 3.03

Notes Legend User Input Asset Job No

1 t = PD / 2(SEW + PY) per ASME B31.3 Section 304.1.2 (a) Auto Calc

Various Various

2 ASME B31.3 Table A1 Pipe Class / 11412 (See also Note 6) Job Title

3 ASME B31.3 Table A-1B

Spec

CS, 150#, 1mm CA,Non-Sour

Various

4 ASME B31.3 Section 302.3.5(e) Title

5 ASME B31.3 Table 304.1.1

Wall Thickness Calculation

6 tm = t + c per ASME B31.3 304.1.1(a)

(Pipe Spec 11412 @ 19.6 Bar g / 150 deg C)

7 Calculation based on the following Design Conditions - C1 21/6/22 AJLH NJDP NJDP Document No. Rev

See Below

Rev Date By Chkd Appd EPC-PIP-CAL-0001-01 C1

19.6 Barg (Max Press Rating of Spec) & Allowable stress value S at 150 Deg C

Form No: ENG-FRM-1192 © 2017 Wood Group Limited

Rev/Date: C1 14-Aug-2017 This document is uncontrolled once printed. Check iMAP for the current version.

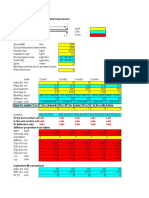

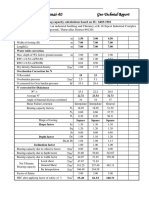

UK - Pressure Equipment Directive Wall thickness Calculation

Pipe Data Pipe Size

nb Nominal Bore ins 16.00 18.00 20.00 24.00 30.00 36.00 42.00 48.00 Ref Note

D Outside Diameter mm 406.40 457.00 508.00 610.00 762.00 914.00 1067.00 1219.00

D Outside Diameter ins 16.00 18.00 20.00 24.02 30.00 35.98 42.01 47.99

Pressure Data

P Pressure Bar g 19.6 19.6 19.6 19.6 19.6 19.6 19.6 19.6 7

P Pressure psi 284.2 284.2 284.2 284.2 284.2 284.2 284.2 284.2

From B31.3

S Stress Value psi 21700 21700 21700 21700 21700 21700 21700 21700 2, 7

E Quality Factor - 1 1 1 1 1 1 1 1 3

W Weld Joint Factor - 1 1 1 1 1 1 1 1 4

Y Coefficient - 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 5

t Pressure Design Thickness ins 0.10 0.12 0.13 0.16 0.20 0.23 0.27 0.31 1

t Pressure Design Thickness mm 2.65 2.98 3.31 3.97 4.96 5.95 6.95 7.94

Allowances & Tolerances

c Erosion / Corr allow mm 1 1 1 1 1 1 1 1

c Thread allowance mm 0 0 0 0 0 0 0 0

Design Thickness

tm Minimum Required Thickness mm 3.65 3.98 4.31 4.97 5.96 6.95 7.95 8.94 6

Actual Thickness

Sch ANSI B36.10 - 20 20 20 20 10 10 STD STD

T Wall Thickness mm 7.92 7.92 9.53 9.53 7.92 7.92 9.53 9.53

tol Negative Tolerance (wt) % 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50%

T(less tol) Wall Thickness less Tolerance mm 6.93 6.93 8.34 8.34 6.93 6.93 8.34 8.34

Wall Thickness Check (T(less tol)- tm) 3.28 2.95 4.03 3.37 0.97 -0.02 0.39 -0.60

Notes Legend User Input Asset Job No

1 t = PD / 2(SEW + PY) per ASME B31.3 Section 304.1.2 (a) Auto Calc

Various Various

2 ASME B31.3 Table A1 Pipe Class / 11412 (See also Note 6) Job Title

3 ASME B31.3 Table A-1B

Spec

CS, 150#, 1mm CA,Non-Sour

Various

4 ASME B31.3 Section 302.3.5(e) Title

5 ASME B31.3 Table 304.1.1

Wall Thickness Calculation

6 tm = t + c per ASME B31.3 304.1.1(a)

(Pipe Spec 11412 @ 19.6 Bar g / 38 deg C)

7 Calculation based on the following Design Conditions - C1 21/6/22 AJLH NJDP NJDP Document No. Rev

See Below

Rev Date By Chkd Appd EPC-PIP-CAL-0001-02 C1

19.6 Barg (Max Press Rating of Spec) & 38 deg C ( Max Temp for given value of 'S')

Form No: ENG-FRM-1192 © 2017 Wood Group Limited

Rev/Date: C1 14-Aug-2017 This document is uncontrolled once printed. Check iMAP for the current version.

UK - Pressure Equipment Directive Wall thickness Calculation

Pipe Data Pipe Size

nb Nominal Bore ins 16.00 18.00 20.00 24.00 30.00 36.00 42.00 48.00 Ref Note

D Outside Diameter mm 406.40 457.00 508.00 610.00 762.00 914.00 1067.00 1219.00

D Outside Diameter ins 16.00 18.00 20.00 24.02 30.00 35.98 42.01 47.99

Pressure Data

P Pressure Bar g 15.8 15.8 15.8 15.8 15.8 15.8 15.8 15.8 7

P Pressure psi 229.1 229.1 229.1 229.1 229.1 229.1 229.1 229.1

From B31.3

S Stress Value psi 20586 20586 20586 20586 20586 20586 20586 20586 2, 7

E Quality Factor - 1 1 1 1 1 1 1 1 3

W Weld Joint Factor - 1 1 1 1 1 1 1 1 4

Y Coefficient - 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 5

t Pressure Design Thickness ins 0.09 0.10 0.11 0.13 0.17 0.20 0.23 0.27 1

t Pressure Design Thickness mm 2.25 2.53 2.81 3.38 4.22 5.06 5.91 6.75

Allowances & Tolerances

c Erosion / Corr allow mm 1 1 1 1 1 1 1 1

c Thread allowance mm 0 0 0 0 0 0 0 0

Design Thickness

tm Minimum Required Thickness mm 3.25 3.53 3.81 4.38 5.22 6.06 6.91 7.75 6

Actual Thickness

Sch ANSI B36.10 - 20 20 20 20 10 10 STD STD

T Wall Thickness mm 7.92 7.92 9.53 9.53 7.92 7.92 9.53 9.53

tol Negative Tolerance (wt) % 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50% 12.50%

T(less tol) Wall Thickness less Tolerance mm 6.93 6.93 8.34 8.34 6.93 6.93 8.34 8.34

Wall Thickness Check (T(less tol)- tm) 3.68 3.40 4.52 3.96 1.71 0.87 1.43 0.59

Notes Legend User Input Asset Job No

1 t = PD / 2(SEW + PY) per ASME B31.3 Section 304.1.2 (a) Auto Calc

Various Various

2 ASME B31.3 Table A1 Pipe Class / 11412 (See also Note 6) Job Title

3 ASME B31.3 Table A-1B

Spec

CS, 150#, 1mm CA,Non-Sour

Various

4 ASME B31.3 Section 302.3.5(e) Title

5 ASME B31.3 Table 304.1.1

Wall Thickness Calculation

6 tm = t + c per ASME B31.3 304.1.1(a)

(Pipe Spec 11412 @ 15.8 Bar g / 150 deg C)

7 Calculation based on the following Design Conditions - C1 21/6/22 AJLH NJDP NJDP Document No. Rev

See Below

Rev Date By Chkd Appd EPC-PIP-CAL-0001-03 C1

15.8 Barg ( Press Rating of Spec at 150 deg C) & 150 deg C (Max Temp for given value of 'S')

Form No: ENG-FRM-1192 © 2017 Wood Group Limited

Rev/Date: C1 14-Aug-2017 This document is uncontrolled once printed. Check iMAP for the current version.

You might also like

- Hume Pipe BOQ For QuoteDocument4 pagesHume Pipe BOQ For Quotebsenthil78No ratings yet

- Epc Pip Cal 0002Document3 pagesEpc Pip Cal 0002mb.pipingNo ratings yet

- PT Paver Strength CalculationsDocument3 pagesPT Paver Strength CalculationsEr Narayan ApawatNo ratings yet

- Correction To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsDocument2 pagesCorrection To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsTimNo ratings yet

- 6 Typical Purlins With DesignDocument1 page6 Typical Purlins With DesignajitgijareNo ratings yet

- Kyodo Pipe Producs SpecificationDocument3 pagesKyodo Pipe Producs SpecificationTengku MunzirNo ratings yet

- Area of SteelDocument26 pagesArea of Steelaqib.syed1011No ratings yet

- Diseño de ColumnasDocument4 pagesDiseño de ColumnasLuiz Fernando Alarcon RojasNo ratings yet

- General Information: 2.1. ConcreteDocument4 pagesGeneral Information: 2.1. ConcreteWilliam ProvidoNo ratings yet

- NOZZLEDocument4 pagesNOZZLEHarshil TejaniNo ratings yet

- Shear Deflection Shear Shear Deflection Shear: M/BD M/BDDocument11 pagesShear Deflection Shear Shear Deflection Shear: M/BD M/BDHafeel Ahamed Ashraf AliNo ratings yet

- Jing Niu TDSDocument1 pageJing Niu TDSPg ChongNo ratings yet

- BBBarBrochure - 2011 05 30 PDFDocument7 pagesBBBarBrochure - 2011 05 30 PDFKS LeeNo ratings yet

- K-511-V, FLW SWTDocument2 pagesK-511-V, FLW SWTamir shokrNo ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- Distribution of Lateral Pressure Due To Surcharge With DepthDocument18 pagesDistribution of Lateral Pressure Due To Surcharge With DepthuhopeNo ratings yet

- Description VA Meters Size of Wire Z/305 AMP VD %VDDocument3 pagesDescription VA Meters Size of Wire Z/305 AMP VD %VDJM AndresNo ratings yet

- LKIF in Line Strainers Product LeafletDocument3 pagesLKIF in Line Strainers Product LeafletGisela ViskaNo ratings yet

- VALFLON Sheet Gasket: Valqua No. 7010 Food Product Name VALFLON Pure PTFE GasketDocument4 pagesVALFLON Sheet Gasket: Valqua No. 7010 Food Product Name VALFLON Pure PTFE GasketMỹ Phạm AnhNo ratings yet

- Cmax in N/MM Vucmax in KN Min PT% ReqdDocument1 pageCmax in N/MM Vucmax in KN Min PT% Reqdd4891No ratings yet

- Figure UG-34 Forged HeadDocument8 pagesFigure UG-34 Forged Headmiteshpatel191No ratings yet

- TM 215461 SRTDocument3 pagesTM 215461 SRTömer cılızNo ratings yet

- T M B D Z M: Pitting StrengthDocument6 pagesT M B D Z M: Pitting StrengthprasannaNo ratings yet

- TM 210728 SRTDocument3 pagesTM 210728 SRTömer cılızNo ratings yet

- Design of Sectons For LoadDocument12 pagesDesign of Sectons For LoadE Santosh KumarNo ratings yet

- Builtup SectionDocument4 pagesBuiltup SectionSuhas MangaloreNo ratings yet

- Victaulic Firelock Fittings: 1.0 Product DescriptionDocument4 pagesVictaulic Firelock Fittings: 1.0 Product Descriptionmido2112No ratings yet

- Comparison of Retaining StructureDocument7 pagesComparison of Retaining StructureAccrete GurgaonNo ratings yet

- CBA of TanksDocument25 pagesCBA of TanksNithinNo ratings yet

- New CPVC Brochure 004Document12 pagesNew CPVC Brochure 004murtadha ahmedNo ratings yet

- C662-70 (2010) Standard Specification For Impervious Graphite Pipe and ThreadingDocument4 pagesC662-70 (2010) Standard Specification For Impervious Graphite Pipe and Threadingastewayb_964354182No ratings yet

- Chapter 10. Piping WorkDocument29 pagesChapter 10. Piping WorkSastra Winata100% (1)

- Din 3021Document18 pagesDin 3021Valerio AmetranoNo ratings yet

- Centricast CL 1520 Data SheetDocument6 pagesCentricast CL 1520 Data SheetOlmer Romero MendezNo ratings yet

- D265T063Document6 pagesD265T063adhyharmonypngNo ratings yet

- Bab Iii Hasil Perhitungan Dan Pembahasan III-1 Bab Iii Hasil Perhitungan Dan PembahasanDocument7 pagesBab Iii Hasil Perhitungan Dan Pembahasan III-1 Bab Iii Hasil Perhitungan Dan PembahasanNisrina HuttiNo ratings yet

- Maintenance Specifications: 6.1. Tightening TorqueDocument9 pagesMaintenance Specifications: 6.1. Tightening TorqueWshop2 AdminNo ratings yet

- Pipeline Thickness CalculationDocument1 pagePipeline Thickness CalculationUmer KhanNo ratings yet

- Tacos para TubosDocument21 pagesTacos para TubosPedro SantiagoNo ratings yet

- Pickled and Oiled Steel CoilsDocument36 pagesPickled and Oiled Steel CoilsX800XLNo ratings yet

- Kształtki 001 002 003 006 10.03Document4 pagesKształtki 001 002 003 006 10.03Jacek GorgolNo ratings yet

- BD - R - ROOFING & CEILINGDocument4 pagesBD - R - ROOFING & CEILINGMuthusamy Arumugam100% (1)

- Slickwall 20 Ipi001 Inspection ReportDocument2 pagesSlickwall 20 Ipi001 Inspection ReportRino SutrisnoNo ratings yet

- D 1587 - 94 Rde1odctukve PDFDocument6 pagesD 1587 - 94 Rde1odctukve PDFLupita CarelyNo ratings yet

- Diseño Puente Compuesto de Vigas-I Puente 8.00 Datos Superestructura MaterialesDocument12 pagesDiseño Puente Compuesto de Vigas-I Puente 8.00 Datos Superestructura MaterialesJesús Rodríguez RodríguezNo ratings yet

- Civil Engineering Material Q.T.ODocument10 pagesCivil Engineering Material Q.T.ONaison StanleyNo ratings yet

- Built Up Box PlatesDocument16 pagesBuilt Up Box Platesvrajan1988No ratings yet

- 14399-3 Bolt Tech89 PDFDocument2 pages14399-3 Bolt Tech89 PDFHüseyin VarolNo ratings yet

- Presentation of Die DesignDocument33 pagesPresentation of Die DesignIsrar EqubalNo ratings yet

- Concrete Calculation For T1Document1 pageConcrete Calculation For T1Goku SaitoNo ratings yet

- Triaxial Test Data Sheet MEGA IDocument121 pagesTriaxial Test Data Sheet MEGA ILao Nong NgoNo ratings yet

- Gauge (Ga) Standard Steel Thickness (Inches) Galvanized Steel Thickness (Inches) Aluminum Thickness (Inches)Document8 pagesGauge (Ga) Standard Steel Thickness (Inches) Galvanized Steel Thickness (Inches) Aluminum Thickness (Inches)Elan David Sánchez MendezNo ratings yet

- M Hamza 338848Document20 pagesM Hamza 338848hamzaNo ratings yet

- Structural Steelwork Design CheckDocument3 pagesStructural Steelwork Design CheckChong Wee LinNo ratings yet

- Schedule 40 Cast Iron Pipe Wall Thickness - SCH 40 Cast Iron Pipe Size - Cast Iron Schedule 40 Pipe DimensionsDocument7 pagesSchedule 40 Cast Iron Pipe Wall Thickness - SCH 40 Cast Iron Pipe Size - Cast Iron Schedule 40 Pipe Dimensions13393m210No ratings yet

- Decon (Screw) WH SeriesDocument2 pagesDecon (Screw) WH Serieszuigh899gNo ratings yet

- Raw Data TorsionDocument2 pagesRaw Data TorsionHanif SaufiNo ratings yet

- Ki NG Do M o F Thai L And: EDI CT OF GovernmentDocument14 pagesKi NG Do M o F Thai L And: EDI CT OF Government翁偉晟No ratings yet

- Geonix, Chennai-40 Geonix, Chennai-40 Geonix, Chennai-40 Geonix, Chennai-40Document1 pageGeonix, Chennai-40 Geonix, Chennai-40 Geonix, Chennai-40 Geonix, Chennai-40Abhijeet OundhakarNo ratings yet

- Page 1 of 1Document2 pagesPage 1 of 1mb.pipingNo ratings yet

- MESC Description 772041.904.1Document2 pagesMESC Description 772041.904.1mb.pipingNo ratings yet

- Mesc Text For 77.00.35.008.1Document2 pagesMesc Text For 77.00.35.008.1mb.pipingNo ratings yet

- Page 1 of 0Document1 pagePage 1 of 0mb.pipingNo ratings yet

- GEG 206-1 Rev.0Document63 pagesGEG 206-1 Rev.0mb.pipingNo ratings yet

- Mesc 766579.210.1Document1 pageMesc 766579.210.1mb.pipingNo ratings yet

- Mesc 771334.009.1Document2 pagesMesc 771334.009.1mb.pipingNo ratings yet

- Mesc 766510.316.1Document1 pageMesc 766510.316.1mb.pipingNo ratings yet

- Page 1 of 0Document1 pagePage 1 of 0mb.pipingNo ratings yet

- MESC Description 76.31.39.208.1Document1 pageMESC Description 76.31.39.208.1mb.pipingNo ratings yet

- Page 1 of 1Document2 pagesPage 1 of 1mb.pipingNo ratings yet

- MESC Description 76.65.80.404.1Document1 pageMESC Description 76.65.80.404.1mb.pipingNo ratings yet

- MESC Description 76.65.79.208.1Document1 pageMESC Description 76.65.79.208.1mb.pipingNo ratings yet

- MESC Description 771033.005.1Document2 pagesMESC Description 771033.005.1mb.pipingNo ratings yet

- Tur SMN 800 1100Document5 pagesTur SMN 800 1100Cesar MessiasNo ratings yet

- Jamboeditora Os Sussurros Do Caos Rastejante 623512c6870de e PDF FreeDocument2 pagesJamboeditora Os Sussurros Do Caos Rastejante 623512c6870de e PDF FreeTabacudo RoooidNo ratings yet

- Value-Based Strategy For Industrial Products: John L. Forbis and T. MehtaDocument19 pagesValue-Based Strategy For Industrial Products: John L. Forbis and T. MehtaHarshali ShreyaNo ratings yet

- Olympus THMDocument10 pagesOlympus THMfaket48881No ratings yet

- Installation Instructions: Electric Gauges 2-1/16" and 2-5/8"Document2 pagesInstallation Instructions: Electric Gauges 2-1/16" and 2-5/8"HanNo ratings yet

- Lab NoDocument8 pagesLab NoAli MohsinNo ratings yet

- Chess Life 93-06Document49 pagesChess Life 93-06Oscar Estay T.No ratings yet

- Conversion Factors: Dimension Metric Metric/EnglishDocument2 pagesConversion Factors: Dimension Metric Metric/EnglishMilton CesarNo ratings yet

- NPTEL Phase II - Civil Engineering - NOC - GPS SURVEYINGDocument1 pageNPTEL Phase II - Civil Engineering - NOC - GPS SURVEYINGAmit KumarNo ratings yet

- A Survey of Punjabi Language Translation Using OCR and MLDocument9 pagesA Survey of Punjabi Language Translation Using OCR and MLgkaurbe21No ratings yet

- Wejiz Plastic Factory Design ReportDocument36 pagesWejiz Plastic Factory Design ReportMikuNo ratings yet

- HDL and FPGA Ch05 HVT 2024 RTL Combinational CircuitsDocument44 pagesHDL and FPGA Ch05 HVT 2024 RTL Combinational CircuitsVy TungNo ratings yet

- Film Documentary Script Writing Process Ijariie1273 Volume 1 14 Page 7 12Document6 pagesFilm Documentary Script Writing Process Ijariie1273 Volume 1 14 Page 7 12Kevin SmithNo ratings yet

- MJD122 889583Document8 pagesMJD122 889583Mahmoud Elpop ElsalhNo ratings yet

- DGSDocument11 pagesDGSsridhar kumar singh100% (1)

- Yoram Koren ContentsDocument8 pagesYoram Koren ContentsMadhu SudhanNo ratings yet

- Auma - Selection BasisDocument4 pagesAuma - Selection BasisVed Singh TomarNo ratings yet

- Module - 4: 8051 Timers and Serial PortDocument37 pagesModule - 4: 8051 Timers and Serial PortPramod PatilNo ratings yet

- Pseudowire Concepts and Troubleshooting PDFDocument10 pagesPseudowire Concepts and Troubleshooting PDFEze Alexander IkNo ratings yet

- BRM 2021 - 22 Outline Sec A B C eDocument8 pagesBRM 2021 - 22 Outline Sec A B C eEkalavya ChaudhuriNo ratings yet

- MySQL Database AdministrationDocument93 pagesMySQL Database AdministrationKISHAN KUMARNo ratings yet

- Integer Programming (IP) : Prof. Yong Won Seo (Seoyw@cau - Ac.kr) College of Business Administration, CAUDocument53 pagesInteger Programming (IP) : Prof. Yong Won Seo (Seoyw@cau - Ac.kr) College of Business Administration, CAUk leeNo ratings yet

- Lesson Plan MechatronicsDocument2 pagesLesson Plan MechatronicsChetan GhatageNo ratings yet

- Strategic Management Course Outline SUKCM 0220Document4 pagesStrategic Management Course Outline SUKCM 0220Niswarth TolaNo ratings yet

- Crepe Paper As An Alternative Ink For Ballpoint PenDocument5 pagesCrepe Paper As An Alternative Ink For Ballpoint Penchelsea kayle licomes fuentesNo ratings yet

- Design, Engineering and Evaluation of Refractory Liners For Slagging GasifiersDocument89 pagesDesign, Engineering and Evaluation of Refractory Liners For Slagging Gasifiersfzl123007No ratings yet

- GOMO Complete Document February 2020 2 242Document1 pageGOMO Complete Document February 2020 2 242RICROD71No ratings yet

- 2A Introduction EDP AuditDocument98 pages2A Introduction EDP AuditnasrciaNo ratings yet

- Solidworks 2017 Intermediate SkillsDocument40 pagesSolidworks 2017 Intermediate SkillsMajd HusseinNo ratings yet

- EON15 Parts ListDocument1 pageEON15 Parts ListDaniel FloresNo ratings yet