Professional Documents

Culture Documents

Meenakshi Sundar - CV

Meenakshi Sundar - CV

Uploaded by

Rakesh WinmeenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Meenakshi Sundar - CV

Meenakshi Sundar - CV

Uploaded by

Rakesh WinmeenCopyright:

Available Formats

MEENAKSHI SUNDAR T.

S

Mail ID: tsm.sundar@gmail.com;

Phone No: +91 9940163004

DOB: 06.07.1994

Current Location: Bangalore

Designation : Process Engineer

SUMMARY

Degree qualified Process Engineer having 7 years of process engineering experience in upstream &

Downstream Oil & Gas, chemical industries. Have experience on Feasibility Study, pre-FEED, Front End

Engineering Design (FEED) and Detail Engineering Design.

Performed process activities includes P&ID, PFD, Material balance, Line sizing, Control Valve Sizing, Various

schedule preparation (Line list, Equipment list, tie-in list), PDS, Pumps sizing, C&E preparation, Vendor offer

reviews, HAZOP close out reports. Skilled in HTRI and Aspen Hysys works.

EDUCATION :

2012 – 2016 Degree in Chemical Engineering (B.Tech) from AC tech Anna University

BRIEF OF RESPONSIBLITIES UNDERTAKEN

• Hydraulic Study including line sizing, Pressure drop calculation and Pump Calculation (using API 14E)

• Control Valve and PSV Sizing (using API RP 520)

• Heat Exchanger design Calculation (using HTRI)

• Preparation of Heat and Mass Balance Process Flow Diagram

• Preparation of Piping and Instrumentation Diagram -verifying and confirming

• Process Data Sheet and Technical bid analysis Preparation for Static and Rotary equipment

• Feasibility study of Required Plants and specified area.

• Preparation of Process Description, Design Basis.

• Interaction with the vendor for procurement assistance.

TECHNICAL SOFTWARE SKILLS :

• HTRI, Aspen HYSYS, Hycal (for pumps, lines and CV) AUTOCAD, MATLAB, MS-Word, MS-Excel

EXPERIENCE HIGHLIGHTS

2022 - Present Process Engineer, Worley, Bangalore, India

Worked on Green Hydrogen pilot plant and detailed engineering for SRU/TGT plant

Prepared PFD, P&ID’s, process data sheet for Tanks, Heat Exchangers, Pumps, Hydraulic

Calculation for the entire Unit

2022 – 2022 Process Engineer, Saipem India projects Pvt, LTD Chennai.

Worked on Onshore Gas Treatment Plant

Prepared process data sheet for Tanks, Heat Exchangers, Pumps, Hydraulic Calculation for

Lines, pumps and control Valves, Performed Aspen HYSYS simulation for the given material

balance

2016 - 2022 Process Engineer, Protech Consultants, Chennai

Worked on Caustic Soda Plants

Material Balance, PFD& PID Preparation, Line sizing and Pump sizing Calculations, Equipment

list, Process datasheet preparation for various Equipments, Vender Documents Review and

Approve, Procurement Control (Direct Contact with Vendors), Technical Bid Analysis of

vendors, Operation manual, Control &interlock description preparation,HTRI.

EXPERIENCE DETAIL

Sep 2022 – Present - Worley India Private Limited, Bangalore

1. GREEN HYDROGEN PLANT (PILOT PLANT)

Client- Shell-Banglore- Hydrogen generation capacity of 29 kg/h at 20-40 mbarG and ambient

temperature

Prepared Utility consumption with line hydraulics, Design Basis, Process Description, Process Flow

Diagrams, preparation of PID, PFD and MSD.Technical specification for Package units Like ion DM and ultra

filteration unit, Boiler Unit, Chilled Water Unit, De-oxo Unit, Prepared process data sheets and Enquiry and

for Heat Exchangers, pumps, providing Data’s for instruments, cross checking vendor docs.

2. SULFUR RECOVERY UNITS AND TAIL GAS RECOVER UNIT (DETAILED ENGINEERING)

Client- Saudi Aramco- SRU/TGT Unit in Yanbu Refinery

Updated pump hydraulics and crosschecked , Updated of PID and PFD for the detailed engineering. Updated

process data sheets for Heat Exchangers, pumps, providing Data’s for instruments, cross checking vendor

docs.

May 2022 – Sep 2022 - Saipem India projects Pvt, LTD Chennai

1. ONSHORE GAS TREATMENT PLANT

Client -Quiluma & Maboqueiro, ENI Angola , Italy - To gather gas and hydrocarbon liquid from NAG

PFD, P&ID mark-up preparations for proposal. Updating Relevant process documents like sizing calculations,

Equipment lists, Guarantee sheet preparation for utilities. Vendor documents review. Prepared process

data sheet for Tanks, Heat Exchangers, Pumps, Hydraulic Calculation for pumps and control Valves.

Verifying Stream data’s and cases Using aspen hysys simulations. Verifying the Back pressure cases Using

Flare-net.

Feb 2016 – Apr 2022 - Protech Consultants, Chennai

1. FORCED ETHYLENE DI-CHLORIDE REACTOR SYSTEM

Client - Chemplast Sanmar Limited, Karaikal - 400 TPD of HCl Neutralization using Caustic Soda

Stoichiometry of the reaction to PFD and MHB, Line hydraulics, PHE design, Pump Design Prepared process

data sheet for PSV, Heat Exchangers, Pumps, Chilled Water System, providing Data’s for instruments.

2. HCl NEUTRALIZATION PLANT

Client - Chemplast Sanmar Limited, Mettur - 250 TPD of HCl Neutralization using Caustic Soda

Stoichiometry of the reaction to PFD, P&ID and MHB, Line hydraulics, PHE design, Pump Design Prepared

process data sheet for PSV, Heat Exchangers, Pumps, Chilled Water System, providing Data’s for

instruments.

3. PROJECT REPORTS FOR CAUSTIC SODA PLANTS

Clients - Avant Garde Systems and Controls (P) LTD, [30TPD]Chemfab Karaikkal Alkalis LTD, Meghmani

Fine chem ltd., [30000 MTPA]

Prepared Utility and Raw Materials consumption with line Sizing, Product Distribution, Basis, Process

Description, Budgetary Cost Estimate, Process Flow Diagrams, preparation of PID, PFD and network

diagrams, technical specification for Package units Like ion exchange unit, Precoat Filter Unit, Chilled Water

Unit, HCl Unit, Prepared process data sheets, Enquiry and Procurement for Heat Exchangers, pumps,

providing Data’s for instruments

4. CHLOROMETHANE & CHLORINE TONNER AND ISO CONTAINER FILLING PROJECT

Client - Punjab Alkalis and Chemicals Ltd., Punjab, Meghmani Fine chem ltd., dahej

Tonner filling and ISO Container filling study, expansion bottle sizing, Liquid Chlorine Pump Sizing,

Preparation of operating manual, providing Data’s for instruments, Line sizing, Valve sizing P&ID

Preparation, Piping and Isometrics checking

5. EXPANSION OF FUMED SILICA PLANT

Client - Cabot Sanmar Limited, Mettur -3700 TPA Capacity Expansion of Fumed Silica

Line Sizing, Preparation and designing of entire PID, and network diagrams, Prepared process data sheet for

PSV, Heat Exchangers, Pumps, Chilled Water System, Refrigeration System, providing Data’s for

instruments.

6.CALCIUM CHLORIDE PLANT

Client - Deepak Oman Industries LLC (177 TPD) Meghmani Fine chem ltd., (233 TPD)

Prepared Energy balance, Material balance, Design Basis and PFD, Prepared process data sheets, Enquiry for

Heat Exchangers, pumps and technical specification for Package units

7.HYDROGEN PEROXIDE PLANT

Client - Meghmani Fine chem ltd., dahej -30000 MTPA of Hydrogen Peroxide

Line Sizing, PFD, preparation of PID, and network diagrams Prepared process data sheet and technical bid

analysis for PSV, Heat Exchangers, pumps, filters, valves, Strainers, Steam traps, Sight Glass, Flame arrester

and procurement had been done

LANGUAGES

Tamil, English and Hindi (Basic).

CERTIFIED TRAINING &I NTERNSHIP

Submitted Report on Pump Hydraulics Learned Line Sizing techniques, Pump Hydraulics and Heat

Exchanger Sizing, performed pump hydraulics in unisim and Aspen HYSYS in Dimensional Academy,

Chennai and reciced a PG diploma certificate (October 2017)

Had comprehensive and assimilated study on distillation Unit, for a period of one week in CPCL, Manali

(June 2014)

Gained an onsite exposure to various quality tests associated with crude oil with insights on crude

extraction from oil rigs in ONGC, Kuthalam. (May 2014)

Two-week training in Orchid Chemicals, Kanathur on API (Active Pharmaceutical Ingredient) processing in

additions with the various physical processes associated with it. (January 2014)

Conducted a practical study and successfully designed a Heat Exchanger and performed all design

calculations in the production of phthalic anhydride where the feed ortho-xylene is pre-heated before it is

fed into the reactor for higher flow rate in Thirumalai Chemicals Ltd., Ranipet (May 2014)

PROJECTS IN ACADEMIC / EXTRA CURRICULAR ACHIEVEMENTS

Extraction Of Bio-Diesel from Municipal Waste by Trans-Esterification Process in A C Tech, Chennai

[October 2014]

Manufacture Of Vanillin from Oxidation of Lignin Obtained During Pulping of Wood in A C Tech, Chennai

[April 2016]

Logistics Head of Chemfluence,’15,’16 a national level symposium, Member of Indian Institute of

Chemical Engineers [IICHe]

School Pupil Leader for the academic year 2010-2011,2011-2012

NCC ‘C’ certificate holder, Parade Commander for the Independence Day held on 2013 and holding

Serjeant rank in NCC

Enduro Cyclist. Accomplished a milestone distance of 10000 Km (Avg.)

I hereby declare that the above mentioned information are accurate to the best of my knowledge and will

(Meenakshi Sundar. T. S)

You might also like

- Laboratory Methods of Organic ChemistryDocument449 pagesLaboratory Methods of Organic Chemistryapi-3723687100% (12)

- Ali Huzafa Sayyar - OriginalDocument3 pagesAli Huzafa Sayyar - OriginalMuhammad ShehzadNo ratings yet

- Naukri Rahulsureshbhisikar (18y 0m)Document4 pagesNaukri Rahulsureshbhisikar (18y 0m)iyswarya.govindarajNo ratings yet

- Hafiz M Abubakar - OriginalDocument4 pagesHafiz M Abubakar - OriginalMuhammad ShehzadNo ratings yet

- Resume-Process Engg (Abhay Bhoir)Document4 pagesResume-Process Engg (Abhay Bhoir)Abhay BhoirNo ratings yet

- Taus IfDocument3 pagesTaus IftausifkagziNo ratings yet

- Process Engineer-M UsmanDocument3 pagesProcess Engineer-M UsmanUsɱâñ MåâñNo ratings yet

- Adil CV LatestDocument4 pagesAdil CV LatestBurhanNo ratings yet

- Naukri Neehasareenshaik (6y 0m)Document2 pagesNaukri Neehasareenshaik (6y 0m)iyswarya.govindarajNo ratings yet

- Mubasher Javaid - OriginalDocument6 pagesMubasher Javaid - OriginalMuhammad ShehzadNo ratings yet

- PROCESS ENGINEER CV (06 Years Experience) .Document3 pagesPROCESS ENGINEER CV (06 Years Experience) .Shoaib JadoonNo ratings yet

- Naukri RajendraKumar (13y 0m)Document3 pagesNaukri RajendraKumar (13y 0m)iyswarya.govindarajNo ratings yet

- Sudhakar Vallala P. EnggDocument5 pagesSudhakar Vallala P. EnggAbo MalikNo ratings yet

- Arul 3 Years - ExpDocument9 pagesArul 3 Years - ExpsvrsamroseNo ratings yet

- Curriculum Vitae: Sairaj. D. GaonkarDocument4 pagesCurriculum Vitae: Sairaj. D. GaonkarDevam KengeNo ratings yet

- Vishnu Priya RamakrishnanDocument2 pagesVishnu Priya RamakrishnanarunashireenNo ratings yet

- Alex Resume-Updated Jan-19Document4 pagesAlex Resume-Updated Jan-19madhusudanan.asbNo ratings yet

- Serial No: 22507 Skills Keywords:: I Am Currently Available For WorkDocument6 pagesSerial No: 22507 Skills Keywords:: I Am Currently Available For Worksayed mohsen musavianNo ratings yet

- Sr. I&C Engineer Resume (Aamir Khan) - 1Document3 pagesSr. I&C Engineer Resume (Aamir Khan) - 1Mohammad UmarNo ratings yet

- Curriculum Vitae: Total Years of Experience - 12 YearsDocument4 pagesCurriculum Vitae: Total Years of Experience - 12 YearsnandakumarNo ratings yet

- Megh Resume Experienced - R2 EMDocument3 pagesMegh Resume Experienced - R2 EMMegh JoshiNo ratings yet

- Piping Sudhagar CVDocument4 pagesPiping Sudhagar CVshivvaramNo ratings yet

- Adil CV Latest PDFDocument4 pagesAdil CV Latest PDFMuhammad Adil KhanNo ratings yet

- Jit Ghosh Resume latestDocument3 pagesJit Ghosh Resume latestjit ghoshNo ratings yet

- CV (1)Document5 pagesCV (1)SachinNo ratings yet

- Mechanical Engineer-Abdul Rehman CVDocument4 pagesMechanical Engineer-Abdul Rehman CVAbdul RehmanNo ratings yet

- Amit R. Gawade - CVDocument4 pagesAmit R. Gawade - CVSachinNo ratings yet

- Dewaker Subramani CVDocument3 pagesDewaker Subramani CViNFINITY & bEYOND RaoNo ratings yet

- Resume - Gaurav Maheshwari - Lead Process EngineerDocument3 pagesResume - Gaurav Maheshwari - Lead Process Engineergauravtech1988No ratings yet

- A Mumbai 6.08 YrsDocument5 pagesA Mumbai 6.08 YrssagarisheavyNo ratings yet

- Suresh RESDocument10 pagesSuresh RESMATHIVANNANNo ratings yet

- Vikash Chandra: B Tech in Chemical Engineering (Senior Process Engineer)Document2 pagesVikash Chandra: B Tech in Chemical Engineering (Senior Process Engineer)Kushal ChatterjeeNo ratings yet

- CV - Venkatesh Ramachandran - SWPCDocument14 pagesCV - Venkatesh Ramachandran - SWPChusam riadNo ratings yet

- P E M - Epc P M - T - C E: - Lead Principal Engineer - Since May' 15 - June 21Document3 pagesP E M - Epc P M - T - C E: - Lead Principal Engineer - Since May' 15 - June 21soumya19800000000No ratings yet

- Niladri Bhattacharyya: Curriculum Vitae' Piping & Utility DesignerDocument4 pagesNiladri Bhattacharyya: Curriculum Vitae' Piping & Utility DesignermishtinilNo ratings yet

- Updated Resume 30.03.2022Document4 pagesUpdated Resume 30.03.2022rupesh moharirNo ratings yet

- Protech Corporate PresentationDocument30 pagesProtech Corporate PresentationKamalMuralikumarNo ratings yet

- Naukri GauravRameshJadhav (2y 3m)Document3 pagesNaukri GauravRameshJadhav (2y 3m)piyushsingNo ratings yet

- Process Design Course-PD01Document4 pagesProcess Design Course-PD01Junaid ParkerNo ratings yet

- Om C V EngineeringDocument3 pagesOm C V Engineeringsoumya19800000000No ratings yet

- Resume - A VenkatesanDocument5 pagesResume - A Venkatesanwasim92khanNo ratings yet

- C Ur R Ic Ulum Vitae: Career ObjectiveDocument4 pagesC Ur R Ic Ulum Vitae: Career ObjectiveNivrite ShopnochariNo ratings yet

- 5 Years 3 Months: Working Experience: Career ObjectiveDocument4 pages5 Years 3 Months: Working Experience: Career ObjectiveKrantikumar KolliNo ratings yet

- Asad ResumeDocument3 pagesAsad ResumeAsad AliNo ratings yet

- Piping Engineer - 24Document5 pagesPiping Engineer - 24sttc2007No ratings yet

- Jabeen Waheed: Senior Process EngineerDocument5 pagesJabeen Waheed: Senior Process EngineerGHOST PAKNo ratings yet

- Ghulam Mustafa - OriginalDocument4 pagesGhulam Mustafa - OriginalMuhammad ShehzadNo ratings yet

- Epc JDDocument3 pagesEpc JDAmeerHamzaNo ratings yet

- Harshal C.Chole: Company ProfileDocument5 pagesHarshal C.Chole: Company ProfileHarshal CholeNo ratings yet

- Sennakesavan S: SynopsisDocument8 pagesSennakesavan S: SynopsisGandhi elumalaiNo ratings yet

- P Rama Krishna: SummaryDocument5 pagesP Rama Krishna: SummaryKrishna RamaNo ratings yet

- CV-P.gunasekaran Mech EnggDocument4 pagesCV-P.gunasekaran Mech Enggananth rajanNo ratings yet

- Jit Ghosh Resume Latest 2024Document3 pagesJit Ghosh Resume Latest 2024jit ghoshNo ratings yet

- Rajnish Resume 23.11.2023Document4 pagesRajnish Resume 23.11.2023Rajnish AnandNo ratings yet

- Mohsin Hashmi - ResumeDocument6 pagesMohsin Hashmi - ResumeMustafa AhsanNo ratings yet

- CV - Mohd Nadim - 01-06-2017Document6 pagesCV - Mohd Nadim - 01-06-2017Mohammad NadimNo ratings yet

- Process Engineer ResumeDocument4 pagesProcess Engineer ResumeDhamotharan ChinnaduraiNo ratings yet

- Curriculum Vitae: Om Prakash Mohanty Principal Commissioning Engineer (Lead)Document6 pagesCurriculum Vitae: Om Prakash Mohanty Principal Commissioning Engineer (Lead)soumya19800000000No ratings yet

- Rahul ResumeDocument2 pagesRahul ResumeAJAY1381No ratings yet

- CV, Process Engineer in Oil and Gas Looking GloballyDocument4 pagesCV, Process Engineer in Oil and Gas Looking Globallysayed mohsen musavianNo ratings yet

- PVC Vs Polyurethane A Tubing ComparisonDocument8 pagesPVC Vs Polyurethane A Tubing ComparisonAdnan SheikhNo ratings yet

- Pro Dryer: HaircareDocument11 pagesPro Dryer: HaircareIntan NurhaslindaNo ratings yet

- DescriereDocument80 pagesDescrieretitel0% (1)

- Chapter 13 The Periodic TableDocument9 pagesChapter 13 The Periodic TableTeck TieNo ratings yet

- Evaluation of Flexural Properties of BamDocument8 pagesEvaluation of Flexural Properties of Bamteshome enchalewNo ratings yet

- Ceramic Candle Filter: Suitable Conditions Advantages DisadvantagesDocument5 pagesCeramic Candle Filter: Suitable Conditions Advantages DisadvantagesVishal DhandeNo ratings yet

- DPP 7 Nsejs PDFDocument4 pagesDPP 7 Nsejs PDFAGNIBESH BHANJANo ratings yet

- Chemistry PAG 11.1 Learner v2.0Document3 pagesChemistry PAG 11.1 Learner v2.0CostaCoNo ratings yet

- International Standard: Cryogenic Vessels - Gas/materials CompatibilityDocument20 pagesInternational Standard: Cryogenic Vessels - Gas/materials CompatibilityMehdi Shahriari100% (1)

- Manish STUDYONAQUEOUSEXTRACTOFCitrusDocument5 pagesManish STUDYONAQUEOUSEXTRACTOFCitrusZurielle LuboaNo ratings yet

- Mab Capture Step Development Using Mabselect Sure LXDocument4 pagesMab Capture Step Development Using Mabselect Sure LXRohit ThakurNo ratings yet

- ASTM D 4377 - 00 (Reapproved 2006) PDFDocument7 pagesASTM D 4377 - 00 (Reapproved 2006) PDFJulian Felipe Noguera CruzNo ratings yet

- NTSE STAGE - I - 2020 - 2021 Tamil Nadu Part - I Mental Ability Test SolutionsDocument15 pagesNTSE STAGE - I - 2020 - 2021 Tamil Nadu Part - I Mental Ability Test SolutionsarbimbbNo ratings yet

- Margarine Hystorical AproachDocument12 pagesMargarine Hystorical AproachRiandi SaputraNo ratings yet

- Revision Test Series: (For NEET-2022) Test - 4 AnswersDocument12 pagesRevision Test Series: (For NEET-2022) Test - 4 AnswersAryan PanwarNo ratings yet

- Treatment of Industrial WastewaterDocument25 pagesTreatment of Industrial WastewaterdzikreeNo ratings yet

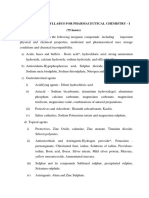

- DPHARM - 1Y - 12T - Pharm - Chemistry IDocument93 pagesDPHARM - 1Y - 12T - Pharm - Chemistry IPrathiNo ratings yet

- Change of Soil Organic Carbon With Depth Within Two Different CatenaDocument15 pagesChange of Soil Organic Carbon With Depth Within Two Different CatenaVarsity CornerNo ratings yet

- FR 2 Quantitative Determination of Copper Concentration in Aqueous Solution by Iodometric TitrationDocument6 pagesFR 2 Quantitative Determination of Copper Concentration in Aqueous Solution by Iodometric TitrationJeff Matthew Uayan75% (4)

- GT Series Gas Alarm Operation Manual: Hanwei Electronics Co.,LtdDocument7 pagesGT Series Gas Alarm Operation Manual: Hanwei Electronics Co.,LtdpenjualgasNo ratings yet

- Industrial PharmacyDocument9 pagesIndustrial PharmacyMr nobodyNo ratings yet

- RBD Tallow PrintDocument37 pagesRBD Tallow PrinthibreNo ratings yet

- Comparison Table Between Steel Grades in GOST and Other Countries, International Standard. GOST Nearest Equivalents, GOST Steel Grade Analogues PDFDocument7 pagesComparison Table Between Steel Grades in GOST and Other Countries, International Standard. GOST Nearest Equivalents, GOST Steel Grade Analogues PDFznovak77100% (1)

- Check Valves: CV, CH, CO, CA, COA, CL and CW SeriesDocument17 pagesCheck Valves: CV, CH, CO, CA, COA, CL and CW SeriesEdwin ArguelloNo ratings yet

- TRM259 Corrosion Inhibitors For Reinforced ConcreteDocument3 pagesTRM259 Corrosion Inhibitors For Reinforced ConcreteTuanNo ratings yet

- Nils Herlenius: IEC 60296 (Ed. 4) From A Transformer Oil Manufacturer's PerspectiveDocument6 pagesNils Herlenius: IEC 60296 (Ed. 4) From A Transformer Oil Manufacturer's Perspectivetaufiqishak09No ratings yet

- 80005233ENDocument8 pages80005233ENSemeer AliNo ratings yet

- LAS SHS GenBio1 MELC 3 Q2 Week-2Document8 pagesLAS SHS GenBio1 MELC 3 Q2 Week-2Anthony CañasNo ratings yet

- BP500C MSDSDocument3 pagesBP500C MSDSMiguel GonzalezNo ratings yet