Professional Documents

Culture Documents

Poleas At10

Poleas At10

Uploaded by

milaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Poleas At10

Poleas At10

Uploaded by

milaCopyright:

Available Formats

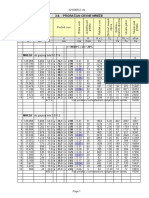

Pulleys for Metric Polyurethane

AT10 Belts

Pulley Types Catalogue No.

Teeth

Pulley

Type

Pitch Circle Min.

Bore

Max.

Bore

Ouside

Diameter

Flange

Dia.

Pulley

Width

Bore

Length

Hub

Dia.

Approx.

Weight

No. Dia.

The Pulley types referred to in Z dp d d do A F L M kg

tables are as drawings below. 10mm Pitch Pulleys for 16mm Wide Belt Ref. 16T10

16AT10

Suffix ‘F’ indicates pulley has

flanges. 16 AT10-15 15 1F 47.75 8 20 45.9 51 21 31 31 0.12

16 AT10-16 16 1F 50.93 8 23 49.1 54 21 31 35 0.14

Std. Pulleys can be reworked 16 AT10-18 18 1F 57.30 8 26 55.4 60 21 31 40 0.17

to customers bore and 16 AT10-19 19 1F 60.48 8 28 58.6 66 21 31 44 0.19

keywaying requirements. 16 AT10-20 20 1F 63.66 8 30 61.8 66 21 31 46 0.21

16 AT10-22 22 1F 70.03 8 34 68.2 75 21 31 52 0.26

16 AT10-24 24 1F 76.39 8 38 74.5 83 21 31 58 0.29

16 AT10-25 25 1F 79.58 8 39 77.7 83 21 31 60 0.31

16 AT10-26 26 1F 82.76 8 39 80.9 87 21 31 60 0.36

16 AT10-27 27 1F 85.94 8 39 84.1 91 21 31 60 0.37

16 AT10-28 28 1F 89.13 8 39 87.2 93 21 31 60 0.40

16 AT10-30 30 1F 95.49 8 39 93.6 97 21 31 60 0.44

16 AT10-32 32 1F 101.86 10 42 100.0 106 21 31 65 0.49

16 AT10-36 36 1F 114.59 10 45 112.7 120 21 31 70 0.63

16 AT10-40 40 1F 127.32 10 52 125.4 135

_ 21 31 80 0.77

L 16 AT10-44 44 1 140.06 10 57 138.2 _ 21 31 88 1.00

F 16 AT10-48 48 1 152.79 16 62 150.9 _ 21 31 95 1.09

16 AT10-60 60 1 190.99 16 72 189.1 21 31 110 1.70

10mm Pitch Pulleys for 25mm Wide Belt Ref. 25AT10

25 AT10-15 15 1F 47.75 8 21 45.9 51 30 40 32 0.16

25 AT10-16 16 1F 50.93 8 23 49.1 54 30 40 35 0.18

25 AT10-18 18 1F 57.30 8 26 55.4 60 30 40 40 0.23

25 AT10-19 19 1F 60.48 8 28 58.6 66 30 40 44 0.25

dp

do

M

d

25 AT10-20 20 1F 63.66 8 30 61.8 66 30 40 46 0.28

25 AT10-22 22 1F 70.03 8 34 68.2 75 30 40 52 0.34

25 AT10-24 24 1F 76.39 8 38 74.5 83 30 40 58 0.39

25 AT10-25 25 1F 79.58 8 39 77.7 83 30 40 60 0.42

25 AT10-26 26 1F 82.76 8 39 80.9 87 30 40 60 0.48

25 AT10-27 27 1F 85.94 8 39 84.1 91 30 40 60 0.54

25 AT10-28 28 1F 89.13 8 39 87.2 93 30 40 60 0.55

25 AT10-30 30 1F 95.49 8 39 93.6 97 30 40 60 0.64

Type 1 25 AT10-32 32 1F 101.86 10 42 100.0 106 30 40 65 0.69

25 AT10-36 36 1F 114.59 10 45 112.7 120 30 40 70 0.87

25 AT10-40 40 1F 127.32 10 52 125.4 135

_ 30 40 80 1.07

25 AT10-44 44 1 140.06 10 57 138.2 _ 30 40 88 1.35

25 AT10-48 48 1 152.79 16 62 150.9 _ 30 40 95 1.52

25 AT10-60 60 1 190.99 16 72 189.1 30 40 110 2.34

10mm Pitch Pulleys for 32mm Wide Belt Ref. 32AT10-

32 AT10-18 18 1F 57.30 10 26 55.4 60 37 47 40 0.26

L 32 AT10-19 19 1F 60.48 10 28 58.6 66 37 47 44 0.28

F 32 AT10-20 20 1F 63.66 12 30 61.8 66 37 47 46 0.32

32 AT10-22 22 1F 70.03 12 34 68.2 75 37 47 52 0.40

32 AT10-24 24 1F 76.39 12 38 74.5 83 37 47 58 0.48

32 AT10-25 25 1F 79.58 12 39 77.7 83 37 47 60 0.53

32 AT10-26 26 1F 82.76 12 39 80.9 87 37 47 60 0.57

32 AT10-27 27 1F 85.94 12 39 84.1 91 37 47 60 0.60

32 AT10-28 28 1F 89.13 12 39 87.2 93 37 47 60 0.64

32 AT10-30 30 1F 95.49 12 39 93.6 97 37 47 60 0.74

dp

do

A

100.0

d

32 AT10-32 32 1F 101.86 12 42 106 37 47 65 0.85

32 AT10-36 36 1F 114.59 16 45 112.7 120 37 47 70 1.07

32 AT10-40 40 1F 127.32 16 52 125.4 135

_ 37 47 80 1.32

32 AT10-44 44 1 140.06 16 57 138.2 _ 37 47 88 1.61

32 AT10-48 48 1 152.79 16 62 150.9 _ 37 47 95 1.93

32 AT10-60 60 1 190.99 16 72 189.1 37 47 110 3.00

10mm Pitch Pulleys for 50mm Wide Belt Ref. 50AT10

Type 1F

50 AT10-18 18 1F 57.30 10 26 55.4 60 56 66 40 0.43

50 AT10-19 19 1F 60.48 10 28 58.6 66 56 66 44 0.47

50 AT10-20 20 1F 63.66 12 30 61.8 66 56 66 46 0.52

50 AT10-22 22 1F 70.03 12 34 68.2 75 56 66 52 0.57

50 AT10-24 24 1F 76.39 12 38 74.5 83 56 66 58 0.74

50 AT10-25 25 1F 79.58 12 39 77.7 83 56 66 60 0.77

50 AT10-26 26 1F 82.76 12 39 80.9 87 56 66 60 0.82

50 AT10-27 27 1F 85.94 12 39 84.1 91 56 66 60 0.91

50 AT10-28 28 1F 89.13 12 39 87.2 93 56 66 60 0.96

50 AT10-30 30 1F 95.49 12 39 93.6 97 56 66 60 1.17

50 AT10-32 32 1F 101.86 12 42 100.0 106 56 66 65 1.30

All pulleys machined from 50 AT10-36 36 1F 114.59 16 45 112.7 120 56 66 70 1.64

aluminium for low weight and 50 AT10-40 40 1F 127.32 16 52 125.4 135

_ 56 66 80 2.00

inertia, and fitted as indicated 50 AT10-44 44 1 140.06 16 57 138.2 _ 56 66 88 2.36

with steel flanges. 50 AT10-48 48 1 152.79 16 62 150.9 _ 56 66 95 2.83

All dimensions in mm 50 AT10-60 60 1 190.99 16 72 189.1 56 66 110 4.37

Pulley Installation

Correct and accurate installation of Timing Drives is essential. Pulley alignment and shaft parallelism is very important as misalignment of

the drive will cause unequal loading across the belt width and edge wear of belt on flanges. Pulley alignment can be checked by placing a

straight edge against the outside edge of the pulleys and adjusting so contact made evenly across both pulleys.

The shafts should be located within a rigid framework, as any distortion under load could result in a reduction of centre distance which

will cause jumping of belt on pulley teeth. If idlers are used they must be locked firmly into position after correct belt tensioning.

Refer to page 10 for additional information on drive installation.

You might also like

- Technical Manual SABROEDocument288 pagesTechnical Manual SABROEyiannis1786% (14)

- Standard Holes and Tapping ChartDocument1 pageStandard Holes and Tapping ChartajaykrishnaaNo ratings yet

- FINAL - Predictive Maintenance in Garment IndustryDocument52 pagesFINAL - Predictive Maintenance in Garment IndustryAashish Kumar100% (1)

- Rab Bak Reservoir KMDocument78 pagesRab Bak Reservoir KMThales Yulianus100% (2)

- Road ConcretingDocument58 pagesRoad ConcretingHerbee ZevlagNo ratings yet

- PTB TrussDocument158 pagesPTB TrussRAJKOT AIRPORTNo ratings yet

- 188888Document1 page188888Sumit PatelNo ratings yet

- BBS For Pier Cap & Pedestal P7Document1 pageBBS For Pier Cap & Pedestal P7SAYAN SARKARNo ratings yet

- Versamatic MetalicaDocument12 pagesVersamatic MetalicaJahaziel VegaNo ratings yet

- At5 PBDocument1 pageAt5 PBOscar GonzalezNo ratings yet

- Bolt A325 A490 PDFDocument2 pagesBolt A325 A490 PDFmostapha soubraNo ratings yet

- Injection MouldingDocument11 pagesInjection Mouldingjogjayusuf4No ratings yet

- NDC Catalog 2002Document62 pagesNDC Catalog 2002Samuel FloresNo ratings yet

- Metric Low Head CapDocument1 pageMetric Low Head CapBala Lakshman0% (1)

- Vauxaire Catalog JS A Jet Slot Diffuser A4 210Wx297H PortraitDocument2 pagesVauxaire Catalog JS A Jet Slot Diffuser A4 210Wx297H PortraitThinh NguyenNo ratings yet

- 04 Se Za 940 1111 PDFDocument175 pages04 Se Za 940 1111 PDFАндрей СилаевNo ratings yet

- جولدن بايب لصنتعة المواسير البلاستيكDocument8 pagesجولدن بايب لصنتعة المواسير البلاستيكmostafaNo ratings yet

- Cylinder Id.80 Od.90 Rod.40 Stroke 1700-ModelDocument1 pageCylinder Id.80 Od.90 Rod.40 Stroke 1700-Modelbadai_boyZNo ratings yet

- Ansi b18 6 4 Self Tapping Head Type and Hole Size Data PDFDocument2 pagesAnsi b18 6 4 Self Tapping Head Type and Hole Size Data PDFjssimeNo ratings yet

- PRICE LIST CODE: FG0024/03/2021 W.E.F. 01/03/2021: Terms & ConditionsDocument1 pagePRICE LIST CODE: FG0024/03/2021 W.E.F. 01/03/2021: Terms & ConditionsJoshua GnanarajNo ratings yet

- L370 L370-M L370-W L370-MW L470 L470-M: SpecificationsDocument1 pageL370 L370-M L370-W L370-MW L470 L470-M: SpecificationsDumbo_balenoNo ratings yet

- Ipe 2Document5 pagesIpe 2Aboalmaail AlaminNo ratings yet

- psr60 AbbDocument4 pagespsr60 AbbEdwin SaynesNo ratings yet

- List of Job Work Rate List of P.Dass Forging (JW) DATE: - 25.06.2016Document92 pagesList of Job Work Rate List of P.Dass Forging (JW) DATE: - 25.06.2016Vikas KashyapNo ratings yet

- Jayson Guansing Dwg-A3-Size - PDF 2Document1 pageJayson Guansing Dwg-A3-Size - PDF 2ADONIS PLATINONo ratings yet

- Tapered Flange Channels: H (MM) B (MM) T (MM) T (MM) R (MM) R (MM) B (MM) D (MM) K (MM) S (%) A (CM) e (MM)Document5 pagesTapered Flange Channels: H (MM) B (MM) T (MM) T (MM) R (MM) R (MM) B (MM) D (MM) K (MM) S (%) A (CM) e (MM)ariffNo ratings yet

- Rotary Turbine Vibrator Series OT 4Document1 pageRotary Turbine Vibrator Series OT 4Kalaimadasamy SubramanianNo ratings yet

- Deck SlabDocument3 pagesDeck SlabPurnima SinghNo ratings yet

- Carbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesDocument1 pageCarbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesKamrul HasanNo ratings yet

- Jhonny 2Document1 pageJhonny 2WILMER JHONNY MARIN LINIANNo ratings yet

- Transom - 30°: For Rollers Series: MPS Belt Roller Transom Order CodesDocument1 pageTransom - 30°: For Rollers Series: MPS Belt Roller Transom Order CodesMarco Antonio FloresNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahNo ratings yet

- St. Helena Bridge PiDocument2 pagesSt. Helena Bridge PiKofi DanielNo ratings yet

- 3.6 Proracun Cevne Mreze Za RadijatoreDocument2 pages3.6 Proracun Cevne Mreze Za RadijatoreSrdjanNo ratings yet

- Barden - 107Document1 pageBarden - 107Linh LạiNo ratings yet

- Bbs StackerDocument6 pagesBbs StackerBhaskar KatraguntaNo ratings yet

- 6.2 DX Selection SheetDocument1 page6.2 DX Selection SheetSaaed EllalaNo ratings yet

- MOMENT CONNECTION-AISC-FLUSH-r5Document24 pagesMOMENT CONNECTION-AISC-FLUSH-r5raghav abudhabi0% (1)

- Pumps Calcul PP-RFDocument1 pagePumps Calcul PP-RFNghiaNo ratings yet

- HydrantDocument3 pagesHydrantadil.multi.bsNo ratings yet

- Panel Boards Exit 18Document21 pagesPanel Boards Exit 18sweitya004No ratings yet

- Precat Pile Capacity by Zahid VaiDocument3 pagesPrecat Pile Capacity by Zahid VaiEmdadul HuqNo ratings yet

- Bowex M, IDocument1 pageBowex M, Iorlahen.sulzerNo ratings yet

- ABC AutosavedDocument17 pagesABC AutosavedĐiện Điện TửNo ratings yet

- Solderin Gauge ToolDocument1 pageSolderin Gauge ToolJorge LatoucheNo ratings yet

- Slab K - II Level Slab Rebar CheckDocument8 pagesSlab K - II Level Slab Rebar CheckUMESH LAMICHHANENo ratings yet

- Columns Bar Schedule Block # 05Document1 pageColumns Bar Schedule Block # 05M ShahidNo ratings yet

- Bbsfor Slab: Along Shorter Span (Main Bar) KitchenDocument12 pagesBbsfor Slab: Along Shorter Span (Main Bar) KitchenAsr FlowerNo ratings yet

- CatalogDocument11 pagesCatalogAlonsoNo ratings yet

- Top Reinforcement Section A - A: (Each)Document1 pageTop Reinforcement Section A - A: (Each)Tarek AbulailNo ratings yet

- Af 60 Cu Iso 10Document1 pageAf 60 Cu Iso 10Marko BradvicaNo ratings yet

- Construction/ Channelization of Jumma Khwar Nullah (Pkg-1) : C O Ns T Ru C T I O NDocument5 pagesConstruction/ Channelization of Jumma Khwar Nullah (Pkg-1) : C O Ns T Ru C T I O Natif mehmoodNo ratings yet

- What Is The Difference Between A RTJDocument7 pagesWhat Is The Difference Between A RTJTejash NayakNo ratings yet

- Comprasion On 420 DWR Between 500DWRDocument10 pagesComprasion On 420 DWR Between 500DWRMojammel HaqueNo ratings yet

- Countersunk Socket Head Screws MetricDocument2 pagesCountersunk Socket Head Screws MetricSATHISHKUMAR MNo ratings yet

- bORED pILES 1Document1 pagebORED pILES 1AqilahNasihahNo ratings yet

- Design of PilesDocument3 pagesDesign of Pilesanabelle rosarioNo ratings yet

- Ancla Tubing in Ficha Tecnica-WeatherfordDocument3 pagesAncla Tubing in Ficha Tecnica-WeatherfordDaniel Eduardo Ramos RicardezNo ratings yet

- Sprocket80a enDocument2 pagesSprocket80a enfjnievesNo ratings yet

- Plate 70628-40E Turbocharger Compressor Wheel Diameter and Slip FactorDocument1 pagePlate 70628-40E Turbocharger Compressor Wheel Diameter and Slip FactorMax MaksNo ratings yet

- 06 - ChainDocument9 pages06 - ChainVick' CastroNo ratings yet

- Tanko S30 SpecificationDocument1 pageTanko S30 SpecificationJuan IglesiasNo ratings yet

- A Systemic Review of Functional Near-Infrared Spectroscopy For Stroke: Current Application and Future DirectionsDocument14 pagesA Systemic Review of Functional Near-Infrared Spectroscopy For Stroke: Current Application and Future DirectionsEricNo ratings yet

- Staad Foundation Advanced: Product Data SheetDocument2 pagesStaad Foundation Advanced: Product Data Sheetsofonias bezabehNo ratings yet

- Money and Monetary StandardsDocument40 pagesMoney and Monetary StandardsZenedel De JesusNo ratings yet

- Study of Ashtavinayaka Temples in MaharashtraDocument13 pagesStudy of Ashtavinayaka Temples in MaharashtraRahul RoyNo ratings yet

- Elco 345Document3 pagesElco 345fernandez_jhon4987100% (1)

- List of Multinational Companies With Research and Development Centres in IsraelDocument10 pagesList of Multinational Companies With Research and Development Centres in IsraelEDUARDONo ratings yet

- Second Periodical Test in Mathematics Vi S.Y. 2019-2020Document7 pagesSecond Periodical Test in Mathematics Vi S.Y. 2019-2020Jessmiel Labis100% (1)

- Catia Important Interview QuestionsDocument40 pagesCatia Important Interview QuestionsHarshwardhan Singh0% (1)

- Bulk Oil Circuit BreakerDocument3 pagesBulk Oil Circuit BreakerMudasurNo ratings yet

- MLM Engineering Sample Two Storey Residential Building-WBS Item/Description 1 General RequirementsDocument12 pagesMLM Engineering Sample Two Storey Residential Building-WBS Item/Description 1 General RequirementsNiño EvangelioNo ratings yet

- Steam Power Plant: Pros & Cons: What This Power Station Presents Advantages DisadvantagesDocument4 pagesSteam Power Plant: Pros & Cons: What This Power Station Presents Advantages Disadvantagesyanblade100% (2)

- Chapter 2.1Document152 pagesChapter 2.1Naoto MikaNo ratings yet

- Inflatable Packers and GroutingDocument7 pagesInflatable Packers and GroutingjasonlaiymNo ratings yet

- PHD0130 - Saurabh Rawat - 126602 - Ce - 2017Document313 pagesPHD0130 - Saurabh Rawat - 126602 - Ce - 2017Nadeesh PriyashanNo ratings yet

- Cobiax Slab TechnologyDocument2 pagesCobiax Slab TechnologykomalNo ratings yet

- Micom P438: Rail Catenary Protection Device P438/En M/Cf8Document652 pagesMicom P438: Rail Catenary Protection Device P438/En M/Cf8Peng GuoNo ratings yet

- Stochastic ProcessDocument610 pagesStochastic ProcesshopanzNo ratings yet

- IOT For SMEs - HandbookDocument58 pagesIOT For SMEs - HandbookbluesbankyNo ratings yet

- AcuitSign M8&M6&M5&M3 User's Manual 20141215 - CompressedDocument305 pagesAcuitSign M8&M6&M5&M3 User's Manual 20141215 - CompressedElectromedycal EQUIPO MEDICONo ratings yet

- ATT2100 & 2200 ManualDocument52 pagesATT2100 & 2200 ManualFranco SNo ratings yet

- TabernacleDocument126 pagesTabernacleVal100% (8)

- Contador Frecuencia 1-50Document4 pagesContador Frecuencia 1-50jose100% (2)

- Ch06 SlidesDocument73 pagesCh06 SlidesbeelzeburtonNo ratings yet

- Topic 1.3 Revision Practice (Ans)Document3 pagesTopic 1.3 Revision Practice (Ans)Mahina WongNo ratings yet

- CA VD4-31kA (EN) - 1VCP000001 PDFDocument52 pagesCA VD4-31kA (EN) - 1VCP000001 PDFkienNo ratings yet

- Lo3. Provide Information and Advice On A Destination, Product or Services Available at The DestinationDocument14 pagesLo3. Provide Information and Advice On A Destination, Product or Services Available at The Destinationverirowena28No ratings yet

- Darryl's Lunch MenuDocument2 pagesDarryl's Lunch MenuJenna Renée LumtscherNo ratings yet