Professional Documents

Culture Documents

Specification 300

Specification 300

Uploaded by

Arbaaz KhanCopyright:

Available Formats

You might also like

- 10 VESDA-E VEP TDS AQ IE LoresDocument2 pages10 VESDA-E VEP TDS AQ IE LoresAdel AdhiganaNo ratings yet

- Data SheetsDocument2 pagesData SheetsRobinson DuraiNo ratings yet

- Vesda-E Vep: Product NameDocument2 pagesVesda-E Vep: Product NameIFCI 3 RojoNo ratings yet

- Specification 331Document4 pagesSpecification 331arthasolution.23No ratings yet

- Simplex Vesda-E Ves Idnet Aspirating Smoke Detectors With Idnet CommunicationsDocument6 pagesSimplex Vesda-E Ves Idnet Aspirating Smoke Detectors With Idnet CommunicationsVivekNo ratings yet

- VEP-A00-P - VEP With LEDs 4 PipesDocument1 pageVEP-A00-P - VEP With LEDs 4 PipesNicu NicuNo ratings yet

- Specification 340Document3 pagesSpecification 340Arbaaz KhanNo ratings yet

- DN 61029Document4 pagesDN 61029Alek Freire DíazNo ratings yet

- 16 VESDA-E Product Brochure A4 LoresDocument8 pages16 VESDA-E Product Brochure A4 LoresvinayakNo ratings yet

- 14 VESDA-E VEA TDS A4 IE LoresDocument2 pages14 VESDA-E VEA TDS A4 IE LoresmuktiNo ratings yet

- ARTS Datasheet Rev13Document4 pagesARTS Datasheet Rev13Rafi YusohNo ratings yet

- 16 Vesda VLC Tds A4 Ie LoresDocument2 pages16 Vesda VLC Tds A4 Ie LoresIVAN ANDRES PizarroNo ratings yet

- Xtralis TrainingDocument315 pagesXtralis TrainingMelina TreminioNo ratings yet

- Vesda e AsdDocument8 pagesVesda e AsdKarthick BellanNo ratings yet

- Vesda VLF-250Document2 pagesVesda VLF-250Ever BradiNo ratings yet

- 01 Vesda Vlc-Ex Tds A4 Ie LoresDocument2 pages01 Vesda Vlc-Ex Tds A4 Ie LoresVladimir BukaricaNo ratings yet

- Data Sheet IVS-282: Innovation in Radar Technology Innovation in Radar TechnologyDocument5 pagesData Sheet IVS-282: Innovation in Radar Technology Innovation in Radar TechnologyNord RamosNo ratings yet

- 1 062 Qatar ReferenceDocument6 pages1 062 Qatar ReferenceChetankumar ChaudhariNo ratings yet

- SPS-1000V-5 SPS-1000V-5: Radar Warning System Radar Warning SystemDocument2 pagesSPS-1000V-5 SPS-1000V-5: Radar Warning System Radar Warning SystemadrianioantomaNo ratings yet

- 004 Essse-Ti Mancinelli HelpyAir EnglDocument13 pages004 Essse-Ti Mancinelli HelpyAir EnglKemal DemNo ratings yet

- EVTracII v1-1Document4 pagesEVTracII v1-1Iulian TudoracheNo ratings yet

- Rsi ERTBDocument2 pagesRsi ERTBSelva KumaraNo ratings yet

- Aq200 Series Flyer 2.0enDocument2 pagesAq200 Series Flyer 2.0enAlexandre MorenoNo ratings yet

- Tools8000 HandbuchDocument8 pagesTools8000 HandbuchLuca HeydeNo ratings yet

- Multilin F60: Grid SolutionsDocument9 pagesMultilin F60: Grid SolutionsSathishNo ratings yet

- FIMER - VSN700 Data Logger - EN - Rev - B - ENDocument4 pagesFIMER - VSN700 Data Logger - EN - Rev - B - ENWilliam BuitragoNo ratings yet

- 19 VESDA VLP TDS AQ IE LoresDocument2 pages19 VESDA VLP TDS AQ IE LoresNassim FouchalNo ratings yet

- VESDA-E TrainingDocument119 pagesVESDA-E TrainingMelina TreminioNo ratings yet

- 12 VESDA-E VEP TDS A4 IE LoresDocument2 pages12 VESDA-E VEP TDS A4 IE Loresarmand isakhNo ratings yet

- Dok Fly Mru4 2eDocument4 pagesDok Fly Mru4 2eAníbal FloresNo ratings yet

- Aquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterDocument48 pagesAquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterAmol BorikarNo ratings yet

- 40394-DataSheet Watchdog Scout WEBDocument2 pages40394-DataSheet Watchdog Scout WEBtoninoleNo ratings yet

- 9 - Dir Oc - Ef Protn. - f60Document8 pages9 - Dir Oc - Ef Protn. - f60govindarulNo ratings yet

- 33728_07_VESDA-E_VES_TDS_A4_IE_loresDocument2 pages33728_07_VESDA-E_VES_TDS_A4_IE_loresMr. Yoso MysteryNo ratings yet

- Multilin f60 Brochure en 12595j LTR 201806 r002Document8 pagesMultilin f60 Brochure en 12595j LTR 201806 r002ghostrider1098No ratings yet

- Centrix BR enDocument12 pagesCentrix BR en오재명No ratings yet

- Taptrans enDocument2 pagesTaptrans enRanderson MoraisNo ratings yet

- Tektronix Tds3054b DatasheetDocument9 pagesTektronix Tds3054b Datasheetangelo_lopez1993No ratings yet

- Sensa Power Datasheets PDFDocument8 pagesSensa Power Datasheets PDFDoan Anh TuanNo ratings yet

- Multilin 750/760: Grid SolutionsDocument10 pagesMultilin 750/760: Grid SolutionsJaime BertinNo ratings yet

- 11 VESDA-E VEP TDS A4 IE LoresDocument2 pages11 VESDA-E VEP TDS A4 IE Loresjonas paladioNo ratings yet

- Multilin F60 Brochure en 12595L LTR 202007 R001Document9 pagesMultilin F60 Brochure en 12595L LTR 202007 R001nabNo ratings yet

- Vallen AMSY-6: The Acoustic Emission CompanyDocument6 pagesVallen AMSY-6: The Acoustic Emission CompanyMaria Cristina DijmarescuNo ratings yet

- Ifm Octavis Brochure 2013 ZaDocument12 pagesIfm Octavis Brochure 2013 ZasandeshshivaNo ratings yet

- Multilin 750760-1-2Document2 pagesMultilin 750760-1-2joseangelmarinNo ratings yet

- Kelman Multitrans: GE Grid SolutionsDocument2 pagesKelman Multitrans: GE Grid SolutionsDaniel RizzoNo ratings yet

- SKVARANDocument12 pagesSKVARANmaaz ahmadNo ratings yet

- Universal Recloser Control: Key BenefitsDocument6 pagesUniversal Recloser Control: Key BenefitsNetaxion CelularNo ratings yet

- 18 Vesda Vls Tds Aq Ie LoresDocument2 pages18 Vesda Vls Tds Aq Ie LoressureshNo ratings yet

- Dual Input Monitor Module 6007Document1 pageDual Input Monitor Module 6007Vanhalen BlancoNo ratings yet

- OV-1000 V2 Optical Time Domain Reflectometer: Features and BenefitsDocument8 pagesOV-1000 V2 Optical Time Domain Reflectometer: Features and BenefitsOptiNetwork c.a.No ratings yet

- Servopro Multiexact 4100 1Document9 pagesServopro Multiexact 4100 1Jose Armando TemoNo ratings yet

- Factsheet Ric290 2018-08 en WebDocument2 pagesFactsheet Ric290 2018-08 en WebAndres AlvarezNo ratings yet

- 9110D Portable Vibration Calibrator Datasheet DS 0103Document2 pages9110D Portable Vibration Calibrator Datasheet DS 0103Adhitya ReNo ratings yet

- Iris Power PDA-IV: Periodic On-Line Partial Discharge Monitoring Using A Portable Instrument For Hydro GeneratorsDocument4 pagesIris Power PDA-IV: Periodic On-Line Partial Discharge Monitoring Using A Portable Instrument For Hydro Generatorsle hoai NamNo ratings yet

- Avx 10k Flight Line Test Set Selection Guides enDocument8 pagesAvx 10k Flight Line Test Set Selection Guides enhrga hrgaNo ratings yet

- MP85A FASTpress Industrial Amplifier - 447Document12 pagesMP85A FASTpress Industrial Amplifier - 447Alta MirNo ratings yet

- Product Overview Virtual Fiber 2022-OCT-05Document49 pagesProduct Overview Virtual Fiber 2022-OCT-05Filipe RangelNo ratings yet

- Evd4 Circuit BreakerDocument12 pagesEvd4 Circuit BreakeralkilanyNo ratings yet

- Multisensor Instrumentation 6σ Design: Defined Accuracy Computer-Integrated Measurement SystemsFrom EverandMultisensor Instrumentation 6σ Design: Defined Accuracy Computer-Integrated Measurement SystemsNo ratings yet

- Policy On Determining Material SubsidiariesDocument4 pagesPolicy On Determining Material SubsidiariesArbaaz KhanNo ratings yet

- Unit 3Document31 pagesUnit 3Arbaaz KhanNo ratings yet

- UG Prospectus 2024-25Document94 pagesUG Prospectus 2024-25Arbaaz KhanNo ratings yet

- 105 India NagpurDocument1 page105 India NagpurArbaaz KhanNo ratings yet

- Agni Agforion2zDocument16 pagesAgni Agforion2zArbaaz KhanNo ratings yet

- DBMS SolutionsDocument8 pagesDBMS SolutionsSourav DuttaNo ratings yet

- Sure Short Questions Business Studies Class-Xii (Commerce)Document35 pagesSure Short Questions Business Studies Class-Xii (Commerce)JaspreetNo ratings yet

- SIMATIC MV500 - ImageDocument3 pagesSIMATIC MV500 - ImageValter PileriNo ratings yet

- 1682767499958249annual Report 2022-CompressedDocument131 pages1682767499958249annual Report 2022-Compresseddanke22No ratings yet

- 2 2024 School Census ADVANCE Questionnaire Pre-PriDocument18 pages2 2024 School Census ADVANCE Questionnaire Pre-Prifrecymile46No ratings yet

- COst CHapter 1Document26 pagesCOst CHapter 1christoper laurenteNo ratings yet

- Advisory Circular: Federal Aviation AdministrationDocument22 pagesAdvisory Circular: Federal Aviation AdministrationMohamed OsamaNo ratings yet

- NI-LabVIEW For ECG Signal ProcessingDocument5 pagesNI-LabVIEW For ECG Signal Processingamhosny64No ratings yet

- Regaining SL - 1Document23 pagesRegaining SL - 1shanNo ratings yet

- Xavs400 800Document22 pagesXavs400 800MANEP100% (1)

- RevitKeynotes NZLDocument50 pagesRevitKeynotes NZLPranshu LondaseNo ratings yet

- Using Stock Warrants As Consideration - AOL Vs Google (08!31!14)Document4 pagesUsing Stock Warrants As Consideration - AOL Vs Google (08!31!14)pyrosriderNo ratings yet

- EAB 2604 Automation in Agriculture Report 1 8-Bit Led ModuleDocument10 pagesEAB 2604 Automation in Agriculture Report 1 8-Bit Led ModuleRedzuan KamarudinNo ratings yet

- Iexpenses Training ManualDocument52 pagesIexpenses Training Manualoraclemans100% (4)

- Respiratory Treatments Poster June2022v1Document2 pagesRespiratory Treatments Poster June2022v1Jade ProvidenceNo ratings yet

- Accenture Corporate Crisis ManagementDocument16 pagesAccenture Corporate Crisis Managementmukosino100% (1)

- Project Report On Sky Vision Tours & Travels LTDDocument38 pagesProject Report On Sky Vision Tours & Travels LTDrishadNo ratings yet

- Ty vs. CADocument15 pagesTy vs. CAOjay OnofreNo ratings yet

- Yima Clothing Wholesale Market - An Exploration of Zhanxi Clothing Market Area - Business in GuangzhDocument5 pagesYima Clothing Wholesale Market - An Exploration of Zhanxi Clothing Market Area - Business in GuangzhjacksparrowNo ratings yet

- An Adaptive Neural Spike Detector With Threshold - Locked LoopDocument23 pagesAn Adaptive Neural Spike Detector With Threshold - Locked LoopAbhishek SinghaniaNo ratings yet

- Bodor Nest Tube ManualDocument22 pagesBodor Nest Tube ManualNam NguyenNo ratings yet

- SOP For Cleaning of Clean Area (Sterile Area) - Pharmaceutical GuidelinesDocument2 pagesSOP For Cleaning of Clean Area (Sterile Area) - Pharmaceutical GuidelinesRupesh Naidu100% (1)

- UNDP Skopje: Innovation StoriesDocument32 pagesUNDP Skopje: Innovation StoriesUNDP in Europe and Central Asia100% (1)

- Bulk Bag Filler Brochure WWDocument8 pagesBulk Bag Filler Brochure WWTran Anh LeNo ratings yet

- HP HPE6-A70 March 2023-v1.2Document33 pagesHP HPE6-A70 March 2023-v1.2CCIEHOMERNo ratings yet

- Latest LogDocument6 pagesLatest Logportillolucasnahuel867No ratings yet

- Service: FABIA 2000Document52 pagesService: FABIA 2000Mantenimientos IndustrialesNo ratings yet

- Legal Ethics - Re - Investigation and Report Concerning Samuel Ancheta, Jr. - Ramos, DDocument3 pagesLegal Ethics - Re - Investigation and Report Concerning Samuel Ancheta, Jr. - Ramos, DMax RamosNo ratings yet

- Tax 1 DigestsDocument165 pagesTax 1 DigestsJm Palisoc100% (5)

- Bronson at Home Advanced Illness Management ProgramDocument15 pagesBronson at Home Advanced Illness Management Programapi-262307733No ratings yet

Specification 300

Specification 300

Uploaded by

Arbaaz KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification 300

Specification 300

Uploaded by

Arbaaz KhanCopyright:

Available Formats

VESDA-E VEP

The VESDA-E VEP series of smoke detectors

bring the latest and most advanced

detection technology to provide very early

warning and the best nuisance alarm

rejection to a wide range of applications.

Built on the Flair detection technology and years of application experience, VEP

detectors achieve consistent performance over their lifetime via absolute

calibration. In addition, the VEP delivers a range of revolutionary features that

provide user value.

FLAIR DETECTION TECHNOLOGY

Flair is the revolutionary new detection chamber that forms the core of VESDA-E

VEP, providing better detection, fewer nuisance alarms, higher stability, increased

longevity and particle characterisation. Direct imaging of the sampled particles

using a CMOS imager combined with multiple photo-diodes allow vastly more data

that can be used to derive actionable information about the observed particles

using analytics.

INSTALLATION, COMMISSIONING AND OPERATION

VESDA-E VEP is equipped with a powerful aspirator that enables use of a total of

130m (427ft) of sampling pipe in the one pipe model and 560m (1,837ft) of pipe

in the four pipe model. Out of box operation is made possible with AutoConfig

which allows airflow normalisation and AutoLearn Smoke and Flow to be initiated

from within the detector. VEP is fully supported by the ASPIRE and Xtralis VSC

software applications which facilitate ease of pipe network design, system

commissioning and maintenance.

VESDAnet™

VESDA devices communicate on VESDAnet which provides a robust bi-directional

communication network allowing continued redundant operation even during

single point wiring failures. VESDAnet enables primary reporting, centralized

configuration, control, maintenance and monitoring.

ETHERNET AND WIFI CONNECTIVITY

VESDA-E detectors offer Ethernet and WiFi connectivity as standard features. The

detector can be added to a corporate network, allowing WiFi enabled tablet devices

and PC’s installed with Xtralis monitoring and configuration software to connect

wirelessly to the detector via the network.

BACKWARD COMPATIBILITY

VESDA-E VEP is compatible with existing VESDA installations. The detector

occupies the same mounting footprint, pipe, conduit and electrical connector

positioning as VESDA VLP. VEP is also compatible with existing VESDAnet

installations allowing monitoring of both VESDA-E and legacy detectors via the

latest iVESDA application.

FEATURES AND BENEFITS

• One and four pipe • Four alarm • Smart on-board • Referencing to • Ethernet for

models for different levels and a wide filter retains accommodate connectivity with

applications sensitivity range dust count and external Xtralis software

deliver optimum remaining filter environmental for configuration,

• Flair detection

protection for the life for predictable conditions to secondary

technology

widest range of maintenance minimise nuisance monitoring and

delivers reliable

applications alarms maintenance

very early warning • Extensive event log

in a wide range of • Intuitive LCD icon (20,000 events) for • Fully backward • Industry first.

environments with display provides event analysis and compatible with Aspirating detector

minimal nuisance instant status system diagnostics VLP and VESDAnet secondary

alarms information for monitoring and

• AutoLearn™ • Remote monitoring

immediate response maintenance via

• Multi stage smoke and flow for with iVESDA for

WiFi

filtration and • Flow fault reliable and rapid system review

optical protection thresholds per port commissioning and proactive • USB for PC

with clean air accommodate maintenance configuration, and

• Two programmable

barriers ensures varying airflow firmware upgrade

GPIs (1 monitored) • Field replaceable

lifetime detection conditions using a memory

for flexible remote sub-assemblies

performance stick

control enable faster service

and maximum

uptime

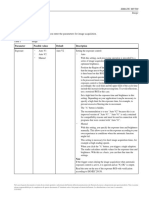

VESDA-E VEP Technical Specification

PART NUMBERS LISTINGS / APPROVALS *

DESCRIPTION ORDER CODE UL

VESDA-E VEP with LEDs, 1 pipe VEP-A00-1P ULC

FM

VESDA-E VEP with LEDs, 4 pipe VEP-A00-P

ActiveFire

VESDA-E VEP with 3.5” Display, 4 pipe VEP-A10-P

Mounting Bracket VSP-960 CE

SPARE PARTS VdS

VESDA-E Exhaust adaptor US VSP-961 Class A (40 holes / Fire 1 =

0.028% obs/m)

VESDA-E Filter VSP-962

Class B (80 holes / Fire 1 =

EN 54-20,

VESDA-E Filter - 20 Pieces VSP-962-20 0.027% obs/m)

ISO 7240-20

Four Pipe VEP Class C (100 holes / Fire 1 =

VESDA-E Aspirator VSP-963

0.056% obs/m)

VESDA-E Smoke Detection Chamber VSP-964 (Classification of any

configuration is determined

VESDA-E Sampling Module VSP-965 using ASPIRE.)

*These Listings/Approvals are owned

APPROVAL COMPLIANCE by Xtralis, a Honeywell company.

They are for the products covered in

Please refer to the Product Guide for details regarding compliant design,

this document.

installation and commissioning.

Regional approvals listings and regulatory compliance vary between product

models. Refer to www.xtralis.com for the latest product approvals matrix.

SPECIFICATION 3.5’’ DISPLAY

One Pipe VEP Four Pipe VEP

Supply Voltage 18 - 30 VDC (24 V Nominal)

Power Consumption @ 24 VEP-A10[Zone Number]

VEP-A00-1P VEP-A00-P VEP-A10-P Zone Name

VDC

Aspirator Setting Fixed 1 5 1 5 0.1100%/m

Power (Quiescent) 8.8 W 7.0 W 8.8 W 8.2 W 10.0 W

Power (in alarm) 9.6 W 7.8 W 9.6 W 10.4 W 11.6 W

Dimensions 350 mm x 225 mm x 135 mm (13.8 in x 8.9 in x 5.3 in)

Weight 4.0 kg (8.8 lb) 4.0 kg (8.8 lb) 4.1 kg (9.0 lb)

Operating Conditions Ambient: 0°C to 39°C (32°F to 102°F)

Sampled Air: -20°C to 60°C (-4°F to 140°F)

Tested to: -20°C to 55°C (-4°F to 131°F)

UL: -20°C to 50°C (-4°F to 122°F)

Humidity: 10% to 95% RH, non-condensing SYMBOL LED

Area Coverage 1,000 m2 (10,760 sq. ft) 2,000 m2 (21,520 sq. ft)

Fire 2

Min Airflow Per Pipe 15 l/m

Fire 1

Pipe Length (Linear)

100 m (328 ft) 280 m (919 ft) Action

Alert

Pipe Length (Branched) 130 m (427 ft) 560 m (1,837 ft)

Disabled

Pipe Lengths 1 Pipe 1 Pipe 2 Pipe 3 Pipe 4 Pipe

Depending On 100 m 110 m 100 m 80 m 70 m Fault

Number Of Pipes In Use (328 ft) (361 ft) (328 ft) (262 ft) (230 ft)

Power

StaX PSU PSU, Auto Pipe Clean

Smoke and Alarm

No. Of Holes (A/B/C) 30/40/45 40/80/100 Threshold Levels

Computer Design Tool ASPIRE Detector OK

Pipe Inlet: External diameter 25 mm or 1.05 in (3/4 in IPS) Detector Fault

Exhaust: External diameter 25 mm or 1.05 in (3/4 in IPS) via adaptor

Relays 7 programmable relays (latching or non-latching states) Aspirator Fault

Contacts rated 2 A @ 30 VDC (Resistive)

Airflow Fault

IP Rating IP40

Power Fault

Cable Access 4 x 26 mm (1.02 in) cable entries

Cable Termination 4 x 26 mm (1.02 in) cable entries Filter Fault

Dynamic Range 0.001% to 32% obs/m (0.0003% to 10% obs/ft) Smoke Chamber Fault

Sensitivity Range 0.005 to 20% obs/m (0.0016% to 6.25% obs/ft)

VESDAnet Fault

Threshold Setting Range Alert: 0.005% to 2.0% obs/m (0.0016% to 0.625% obs/ft)

Action: 0.005% to 2.0% obs/m (0.0016% to 0.625% obs/ft)

StaX Module Fault

Fire1: 0.010% to 2.0% obs/m (0.0031% to 0.625% obs/ft)

Fire2: 0.020% to 20.0% obs/m (0.0063% to 6.25% obs/ft)

Software Features Event log: Up to 20,000 events

Smoke level, user actions, alarms and faults with time and date stamp

AutoLearn: Detector learns Alarm Thresholds and Flow Fault thresholds by

monitoring the environment.

For more information

Contact your Business Manager

All technical data is correct at the time of

publication and is subject to changes without

Honeywell notice. All trademarks acknowledged.

Installation information: In order to

140 Waterside Road ensure full functionality, refer to the

installation instructions as supplied.

Hamilton Industrial Park

Leicester, LE5 1TN VESDA-E-VEP I V.02 I 04./20

Tel: +44 (0) 203 409 1779 © 2020 Honeywell International Inc.

You might also like

- 10 VESDA-E VEP TDS AQ IE LoresDocument2 pages10 VESDA-E VEP TDS AQ IE LoresAdel AdhiganaNo ratings yet

- Data SheetsDocument2 pagesData SheetsRobinson DuraiNo ratings yet

- Vesda-E Vep: Product NameDocument2 pagesVesda-E Vep: Product NameIFCI 3 RojoNo ratings yet

- Specification 331Document4 pagesSpecification 331arthasolution.23No ratings yet

- Simplex Vesda-E Ves Idnet Aspirating Smoke Detectors With Idnet CommunicationsDocument6 pagesSimplex Vesda-E Ves Idnet Aspirating Smoke Detectors With Idnet CommunicationsVivekNo ratings yet

- VEP-A00-P - VEP With LEDs 4 PipesDocument1 pageVEP-A00-P - VEP With LEDs 4 PipesNicu NicuNo ratings yet

- Specification 340Document3 pagesSpecification 340Arbaaz KhanNo ratings yet

- DN 61029Document4 pagesDN 61029Alek Freire DíazNo ratings yet

- 16 VESDA-E Product Brochure A4 LoresDocument8 pages16 VESDA-E Product Brochure A4 LoresvinayakNo ratings yet

- 14 VESDA-E VEA TDS A4 IE LoresDocument2 pages14 VESDA-E VEA TDS A4 IE LoresmuktiNo ratings yet

- ARTS Datasheet Rev13Document4 pagesARTS Datasheet Rev13Rafi YusohNo ratings yet

- 16 Vesda VLC Tds A4 Ie LoresDocument2 pages16 Vesda VLC Tds A4 Ie LoresIVAN ANDRES PizarroNo ratings yet

- Xtralis TrainingDocument315 pagesXtralis TrainingMelina TreminioNo ratings yet

- Vesda e AsdDocument8 pagesVesda e AsdKarthick BellanNo ratings yet

- Vesda VLF-250Document2 pagesVesda VLF-250Ever BradiNo ratings yet

- 01 Vesda Vlc-Ex Tds A4 Ie LoresDocument2 pages01 Vesda Vlc-Ex Tds A4 Ie LoresVladimir BukaricaNo ratings yet

- Data Sheet IVS-282: Innovation in Radar Technology Innovation in Radar TechnologyDocument5 pagesData Sheet IVS-282: Innovation in Radar Technology Innovation in Radar TechnologyNord RamosNo ratings yet

- 1 062 Qatar ReferenceDocument6 pages1 062 Qatar ReferenceChetankumar ChaudhariNo ratings yet

- SPS-1000V-5 SPS-1000V-5: Radar Warning System Radar Warning SystemDocument2 pagesSPS-1000V-5 SPS-1000V-5: Radar Warning System Radar Warning SystemadrianioantomaNo ratings yet

- 004 Essse-Ti Mancinelli HelpyAir EnglDocument13 pages004 Essse-Ti Mancinelli HelpyAir EnglKemal DemNo ratings yet

- EVTracII v1-1Document4 pagesEVTracII v1-1Iulian TudoracheNo ratings yet

- Rsi ERTBDocument2 pagesRsi ERTBSelva KumaraNo ratings yet

- Aq200 Series Flyer 2.0enDocument2 pagesAq200 Series Flyer 2.0enAlexandre MorenoNo ratings yet

- Tools8000 HandbuchDocument8 pagesTools8000 HandbuchLuca HeydeNo ratings yet

- Multilin F60: Grid SolutionsDocument9 pagesMultilin F60: Grid SolutionsSathishNo ratings yet

- FIMER - VSN700 Data Logger - EN - Rev - B - ENDocument4 pagesFIMER - VSN700 Data Logger - EN - Rev - B - ENWilliam BuitragoNo ratings yet

- 19 VESDA VLP TDS AQ IE LoresDocument2 pages19 VESDA VLP TDS AQ IE LoresNassim FouchalNo ratings yet

- VESDA-E TrainingDocument119 pagesVESDA-E TrainingMelina TreminioNo ratings yet

- 12 VESDA-E VEP TDS A4 IE LoresDocument2 pages12 VESDA-E VEP TDS A4 IE Loresarmand isakhNo ratings yet

- Dok Fly Mru4 2eDocument4 pagesDok Fly Mru4 2eAníbal FloresNo ratings yet

- Aquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterDocument48 pagesAquamaster 4 Few4 and Fet4: Electromagnetic FlowmeterAmol BorikarNo ratings yet

- 40394-DataSheet Watchdog Scout WEBDocument2 pages40394-DataSheet Watchdog Scout WEBtoninoleNo ratings yet

- 9 - Dir Oc - Ef Protn. - f60Document8 pages9 - Dir Oc - Ef Protn. - f60govindarulNo ratings yet

- 33728_07_VESDA-E_VES_TDS_A4_IE_loresDocument2 pages33728_07_VESDA-E_VES_TDS_A4_IE_loresMr. Yoso MysteryNo ratings yet

- Multilin f60 Brochure en 12595j LTR 201806 r002Document8 pagesMultilin f60 Brochure en 12595j LTR 201806 r002ghostrider1098No ratings yet

- Centrix BR enDocument12 pagesCentrix BR en오재명No ratings yet

- Taptrans enDocument2 pagesTaptrans enRanderson MoraisNo ratings yet

- Tektronix Tds3054b DatasheetDocument9 pagesTektronix Tds3054b Datasheetangelo_lopez1993No ratings yet

- Sensa Power Datasheets PDFDocument8 pagesSensa Power Datasheets PDFDoan Anh TuanNo ratings yet

- Multilin 750/760: Grid SolutionsDocument10 pagesMultilin 750/760: Grid SolutionsJaime BertinNo ratings yet

- 11 VESDA-E VEP TDS A4 IE LoresDocument2 pages11 VESDA-E VEP TDS A4 IE Loresjonas paladioNo ratings yet

- Multilin F60 Brochure en 12595L LTR 202007 R001Document9 pagesMultilin F60 Brochure en 12595L LTR 202007 R001nabNo ratings yet

- Vallen AMSY-6: The Acoustic Emission CompanyDocument6 pagesVallen AMSY-6: The Acoustic Emission CompanyMaria Cristina DijmarescuNo ratings yet

- Ifm Octavis Brochure 2013 ZaDocument12 pagesIfm Octavis Brochure 2013 ZasandeshshivaNo ratings yet

- Multilin 750760-1-2Document2 pagesMultilin 750760-1-2joseangelmarinNo ratings yet

- Kelman Multitrans: GE Grid SolutionsDocument2 pagesKelman Multitrans: GE Grid SolutionsDaniel RizzoNo ratings yet

- SKVARANDocument12 pagesSKVARANmaaz ahmadNo ratings yet

- Universal Recloser Control: Key BenefitsDocument6 pagesUniversal Recloser Control: Key BenefitsNetaxion CelularNo ratings yet

- 18 Vesda Vls Tds Aq Ie LoresDocument2 pages18 Vesda Vls Tds Aq Ie LoressureshNo ratings yet

- Dual Input Monitor Module 6007Document1 pageDual Input Monitor Module 6007Vanhalen BlancoNo ratings yet

- OV-1000 V2 Optical Time Domain Reflectometer: Features and BenefitsDocument8 pagesOV-1000 V2 Optical Time Domain Reflectometer: Features and BenefitsOptiNetwork c.a.No ratings yet

- Servopro Multiexact 4100 1Document9 pagesServopro Multiexact 4100 1Jose Armando TemoNo ratings yet

- Factsheet Ric290 2018-08 en WebDocument2 pagesFactsheet Ric290 2018-08 en WebAndres AlvarezNo ratings yet

- 9110D Portable Vibration Calibrator Datasheet DS 0103Document2 pages9110D Portable Vibration Calibrator Datasheet DS 0103Adhitya ReNo ratings yet

- Iris Power PDA-IV: Periodic On-Line Partial Discharge Monitoring Using A Portable Instrument For Hydro GeneratorsDocument4 pagesIris Power PDA-IV: Periodic On-Line Partial Discharge Monitoring Using A Portable Instrument For Hydro Generatorsle hoai NamNo ratings yet

- Avx 10k Flight Line Test Set Selection Guides enDocument8 pagesAvx 10k Flight Line Test Set Selection Guides enhrga hrgaNo ratings yet

- MP85A FASTpress Industrial Amplifier - 447Document12 pagesMP85A FASTpress Industrial Amplifier - 447Alta MirNo ratings yet

- Product Overview Virtual Fiber 2022-OCT-05Document49 pagesProduct Overview Virtual Fiber 2022-OCT-05Filipe RangelNo ratings yet

- Evd4 Circuit BreakerDocument12 pagesEvd4 Circuit BreakeralkilanyNo ratings yet

- Multisensor Instrumentation 6σ Design: Defined Accuracy Computer-Integrated Measurement SystemsFrom EverandMultisensor Instrumentation 6σ Design: Defined Accuracy Computer-Integrated Measurement SystemsNo ratings yet

- Policy On Determining Material SubsidiariesDocument4 pagesPolicy On Determining Material SubsidiariesArbaaz KhanNo ratings yet

- Unit 3Document31 pagesUnit 3Arbaaz KhanNo ratings yet

- UG Prospectus 2024-25Document94 pagesUG Prospectus 2024-25Arbaaz KhanNo ratings yet

- 105 India NagpurDocument1 page105 India NagpurArbaaz KhanNo ratings yet

- Agni Agforion2zDocument16 pagesAgni Agforion2zArbaaz KhanNo ratings yet

- DBMS SolutionsDocument8 pagesDBMS SolutionsSourav DuttaNo ratings yet

- Sure Short Questions Business Studies Class-Xii (Commerce)Document35 pagesSure Short Questions Business Studies Class-Xii (Commerce)JaspreetNo ratings yet

- SIMATIC MV500 - ImageDocument3 pagesSIMATIC MV500 - ImageValter PileriNo ratings yet

- 1682767499958249annual Report 2022-CompressedDocument131 pages1682767499958249annual Report 2022-Compresseddanke22No ratings yet

- 2 2024 School Census ADVANCE Questionnaire Pre-PriDocument18 pages2 2024 School Census ADVANCE Questionnaire Pre-Prifrecymile46No ratings yet

- COst CHapter 1Document26 pagesCOst CHapter 1christoper laurenteNo ratings yet

- Advisory Circular: Federal Aviation AdministrationDocument22 pagesAdvisory Circular: Federal Aviation AdministrationMohamed OsamaNo ratings yet

- NI-LabVIEW For ECG Signal ProcessingDocument5 pagesNI-LabVIEW For ECG Signal Processingamhosny64No ratings yet

- Regaining SL - 1Document23 pagesRegaining SL - 1shanNo ratings yet

- Xavs400 800Document22 pagesXavs400 800MANEP100% (1)

- RevitKeynotes NZLDocument50 pagesRevitKeynotes NZLPranshu LondaseNo ratings yet

- Using Stock Warrants As Consideration - AOL Vs Google (08!31!14)Document4 pagesUsing Stock Warrants As Consideration - AOL Vs Google (08!31!14)pyrosriderNo ratings yet

- EAB 2604 Automation in Agriculture Report 1 8-Bit Led ModuleDocument10 pagesEAB 2604 Automation in Agriculture Report 1 8-Bit Led ModuleRedzuan KamarudinNo ratings yet

- Iexpenses Training ManualDocument52 pagesIexpenses Training Manualoraclemans100% (4)

- Respiratory Treatments Poster June2022v1Document2 pagesRespiratory Treatments Poster June2022v1Jade ProvidenceNo ratings yet

- Accenture Corporate Crisis ManagementDocument16 pagesAccenture Corporate Crisis Managementmukosino100% (1)

- Project Report On Sky Vision Tours & Travels LTDDocument38 pagesProject Report On Sky Vision Tours & Travels LTDrishadNo ratings yet

- Ty vs. CADocument15 pagesTy vs. CAOjay OnofreNo ratings yet

- Yima Clothing Wholesale Market - An Exploration of Zhanxi Clothing Market Area - Business in GuangzhDocument5 pagesYima Clothing Wholesale Market - An Exploration of Zhanxi Clothing Market Area - Business in GuangzhjacksparrowNo ratings yet

- An Adaptive Neural Spike Detector With Threshold - Locked LoopDocument23 pagesAn Adaptive Neural Spike Detector With Threshold - Locked LoopAbhishek SinghaniaNo ratings yet

- Bodor Nest Tube ManualDocument22 pagesBodor Nest Tube ManualNam NguyenNo ratings yet

- SOP For Cleaning of Clean Area (Sterile Area) - Pharmaceutical GuidelinesDocument2 pagesSOP For Cleaning of Clean Area (Sterile Area) - Pharmaceutical GuidelinesRupesh Naidu100% (1)

- UNDP Skopje: Innovation StoriesDocument32 pagesUNDP Skopje: Innovation StoriesUNDP in Europe and Central Asia100% (1)

- Bulk Bag Filler Brochure WWDocument8 pagesBulk Bag Filler Brochure WWTran Anh LeNo ratings yet

- HP HPE6-A70 March 2023-v1.2Document33 pagesHP HPE6-A70 March 2023-v1.2CCIEHOMERNo ratings yet

- Latest LogDocument6 pagesLatest Logportillolucasnahuel867No ratings yet

- Service: FABIA 2000Document52 pagesService: FABIA 2000Mantenimientos IndustrialesNo ratings yet

- Legal Ethics - Re - Investigation and Report Concerning Samuel Ancheta, Jr. - Ramos, DDocument3 pagesLegal Ethics - Re - Investigation and Report Concerning Samuel Ancheta, Jr. - Ramos, DMax RamosNo ratings yet

- Tax 1 DigestsDocument165 pagesTax 1 DigestsJm Palisoc100% (5)

- Bronson at Home Advanced Illness Management ProgramDocument15 pagesBronson at Home Advanced Illness Management Programapi-262307733No ratings yet