Professional Documents

Culture Documents

JOPAR catalog -最新

JOPAR catalog -最新

Uploaded by

thihuedoanCopyright:

Available Formats

You might also like

- QCP KOC-VME 1221006120-PART 1 Rev 2Document49 pagesQCP KOC-VME 1221006120-PART 1 Rev 2Alireza GolpesarNo ratings yet

- Firm Profile FormatDocument13 pagesFirm Profile FormatSURANA1973No ratings yet

- ZTZG CatalogueDocument12 pagesZTZG Catalogueajay.dinkar.pingleNo ratings yet

- SMACO Tube Mill LineDocument5 pagesSMACO Tube Mill LineIshtiaq bhatti Ishtiaq bhattiNo ratings yet

- DWT Babcock en MailingDocument68 pagesDWT Babcock en MailingMileNo ratings yet

- Ss Engineering Works: GST No.: 27AUTPN0369A1ZIDocument19 pagesSs Engineering Works: GST No.: 27AUTPN0369A1ZIFCP GHUGENo ratings yet

- 2021 WEIDA CatalogueDocument48 pages2021 WEIDA Cataloguefikrismart77No ratings yet

- Capacity Verification Run at Rate IpaDocument9 pagesCapacity Verification Run at Rate IpaAnonymous VRspXsmNo ratings yet

- Perforator Auger Boring Bro 23Document17 pagesPerforator Auger Boring Bro 23Jehan2No ratings yet

- UntitledDocument13 pagesUntitledabhishek purkarNo ratings yet

- Piping & Engineering Piping & Engineering: BJ BJDocument28 pagesPiping & Engineering Piping & Engineering: BJ BJWilson Xavier Orbea BrachoNo ratings yet

- Overseas Assignment 4th DecDocument3 pagesOverseas Assignment 4th DecKh HafezNo ratings yet

- Bengal PresentationDocument37 pagesBengal PresentationManish KumarNo ratings yet

- Buew 27.12.2023Document24 pagesBuew 27.12.2023Amit SinghNo ratings yet

- .Trashed 1716806683 Unidrilltech Drill Bits For MiningDocument9 pages.Trashed 1716806683 Unidrilltech Drill Bits For MiningAhmed HajiNo ratings yet

- 2024RAYMAX CatalogDocument18 pages2024RAYMAX CatalogSot DesignNo ratings yet

- WULC - 14 - 1000-G. Selgi SAIPEM New Developments in High Pressure Equipment Design FeaturesDocument9 pagesWULC - 14 - 1000-G. Selgi SAIPEM New Developments in High Pressure Equipment Design FeaturesadityadhNo ratings yet

- Catalogo RexcomachDocument21 pagesCatalogo RexcomachCarlos LopezNo ratings yet

- Kova Brochure 2019Document12 pagesKova Brochure 2019Jainam ShahNo ratings yet

- Apollo Upvc PipesDocument8 pagesApollo Upvc PipesAkshat Engineers Private LimitedNo ratings yet

- M S & M, I .: Achine Pecialty Anufacturing NCDocument20 pagesM S & M, I .: Achine Pecialty Anufacturing NCLuis QuiñelNo ratings yet

- Ef Co CatalogDocument24 pagesEf Co CatalogHayderr HassNo ratings yet

- Special Purpose Machine: Automotive Services andDocument24 pagesSpecial Purpose Machine: Automotive Services andSajed ul Haque SadmanNo ratings yet

- QCP KOC-VME 1221006120-PART 1 Rev 3Document49 pagesQCP KOC-VME 1221006120-PART 1 Rev 3Alireza Golpesar100% (1)

- Marcello FantoniDocument29 pagesMarcello FantoniAnonymous q9c7KY1vNo ratings yet

- Northern EnterprisesDocument35 pagesNorthern EnterprisesJagdev SinghNo ratings yet

- Vimax Company ProfileDocument7 pagesVimax Company ProfilemarketingNo ratings yet

- Structural Steel Fabrication Division AUG-2017Document29 pagesStructural Steel Fabrication Division AUG-2017structural steel trendsNo ratings yet

- MECH Valves SubmittalDocument254 pagesMECH Valves Submittalm.rukhsarNo ratings yet

- Fabrication of Hydraulic Pipe Bending Machine PDFDocument2 pagesFabrication of Hydraulic Pipe Bending Machine PDFAndrew100% (1)

- OTC 6 External Axis SolutionsDocument4 pagesOTC 6 External Axis Solutionsr rajeshNo ratings yet

- Unitech Profile Part 1Document33 pagesUnitech Profile Part 1Muthu kumaranNo ratings yet

- Enlistment FormDocument6 pagesEnlistment FormUNITED SWITCHGEAR SALES TEAMNo ratings yet

- Project PrasadDocument64 pagesProject PrasadTejas BhosaleNo ratings yet

- Nirmala Industrial Services: Company ProfileDocument9 pagesNirmala Industrial Services: Company ProfileSaravanan DevarajanNo ratings yet

- Catalogue of Octg / Line Pipe: Hengyang Valin Steel Tube Co.,LtdDocument28 pagesCatalogue of Octg / Line Pipe: Hengyang Valin Steel Tube Co.,LtdnebotNo ratings yet

- Technical Equipment Plant: New Opportunity For YouDocument28 pagesTechnical Equipment Plant: New Opportunity For YouNurlanNo ratings yet

- Drilltech Oilfield Company IntroductionDocument84 pagesDrilltech Oilfield Company IntroductionAdhie WaelacxhNo ratings yet

- Vapi CompaniesDocument11 pagesVapi CompaniesRahul PratapNo ratings yet

- Royal Steel Catalouge PDFDocument30 pagesRoyal Steel Catalouge PDFAsHish RaulNo ratings yet

- CBS Industry Company Limited: uPVC Window Making MachineDocument18 pagesCBS Industry Company Limited: uPVC Window Making MachineMohd DaudNo ratings yet

- Wujing Products 2023Document30 pagesWujing Products 2023Nicole WuNo ratings yet

- SHORT COMPANY PROFILE SSS-wonderslideDocument10 pagesSHORT COMPANY PROFILE SSS-wonderslideMuhammad ZakiNo ratings yet

- Aliva Product Catalogue WebDocument24 pagesAliva Product Catalogue WebquioxxNo ratings yet

- Industrial Case Study Report atDocument14 pagesIndustrial Case Study Report atamitdhakateNo ratings yet

- IjkjkDocument12 pagesIjkjkfareesyaNo ratings yet

- Robit Top Hammer Product Catalogue 11 2021 LowresDocument120 pagesRobit Top Hammer Product Catalogue 11 2021 Lowressindy leeNo ratings yet

- DataSheet SP 240 EC LC SO - Diaphragm Pump GasDocument3 pagesDataSheet SP 240 EC LC SO - Diaphragm Pump Gaskrasus95No ratings yet

- Report On Industrial Training AT Dee Piping Systems Prithla (Palwal)Document20 pagesReport On Industrial Training AT Dee Piping Systems Prithla (Palwal)Amit PatelNo ratings yet

- Mapal 2016Document416 pagesMapal 2016isuntxoNo ratings yet

- DRK Vendor Presentation FY (2022-23)Document42 pagesDRK Vendor Presentation FY (2022-23)Laxmikant JoshiNo ratings yet

- RadiatorDocument54 pagesRadiatorPavithra Agastiswaran50% (2)

- Wuzhou & Foowell Latest Profile PDFDocument77 pagesWuzhou & Foowell Latest Profile PDFAmiti AlisaNo ratings yet

- Multitek PPTDocument29 pagesMultitek PPTcsusheelaNo ratings yet

- Product Catalogue2Document43 pagesProduct Catalogue2RAMODSNo ratings yet

- Final 2Document22 pagesFinal 2prasad moreNo ratings yet

- Drop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsFrom EverandDrop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsRating: 5 out of 5 stars5/5 (1)

- Production Engineering - Jig And Tool DesignFrom EverandProduction Engineering - Jig And Tool DesignRating: 3.5 out of 5 stars3.5/5 (3)

- Statistical Quality Control PPT 3 2Document18 pagesStatistical Quality Control PPT 3 2Baljeet Singh100% (1)

- Grade 7 Sample Class ProgramDocument1 pageGrade 7 Sample Class ProgramRaymart EstabilloNo ratings yet

- The Ape-Man: His Kith and KinDocument128 pagesThe Ape-Man: His Kith and KinamitrupaniNo ratings yet

- Alice Becker-Ho, The Language of Those in The KnowDocument4 pagesAlice Becker-Ho, The Language of Those in The KnowIntothepill Net100% (1)

- Justin Bieber Is - Famous Singer.: (You Must Read Out The Whole Sentence.)Document2 pagesJustin Bieber Is - Famous Singer.: (You Must Read Out The Whole Sentence.)Irene De la FuenteNo ratings yet

- Dynamics of Machinery Oral Question BankDocument22 pagesDynamics of Machinery Oral Question BankSurajKahateRajputNo ratings yet

- Sun Pharma ProjectDocument26 pagesSun Pharma ProjectVikas Ahuja100% (1)

- The DJ Test: Personalised Report and Recommendations For Alex YachevskiDocument34 pagesThe DJ Test: Personalised Report and Recommendations For Alex YachevskiSashadanceNo ratings yet

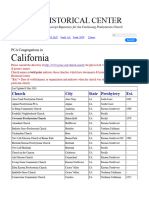

- PCA Churches in CaliforniaDocument4 pagesPCA Churches in CaliforniaLIGHT GNo ratings yet

- Comparison of Starbucks With The Coffee BeanDocument16 pagesComparison of Starbucks With The Coffee BeanshaiNo ratings yet

- Yohe Nitsumi: GH 15.00 GH 15.00 GH 15.00Document3 pagesYohe Nitsumi: GH 15.00 GH 15.00 GH 15.00lYNX GHNo ratings yet

- VHDL Processes: Cwru Eecs 318Document24 pagesVHDL Processes: Cwru Eecs 318KarThikNo ratings yet

- Nuclear PhysicsDocument85 pagesNuclear PhysicsKy2ST3z4No ratings yet

- Sliding Doors Standard Sizes NSWDocument3 pagesSliding Doors Standard Sizes NSWCorey WardNo ratings yet

- Code of Ethics For Professional TeachersDocument12 pagesCode of Ethics For Professional TeachersJean GuyuranNo ratings yet

- Collections and Recollections by Russell, George William Erskine, 1853-1919Document202 pagesCollections and Recollections by Russell, George William Erskine, 1853-1919Gutenberg.org100% (1)

- Petitioner vs. VS.: Third DivisionDocument12 pagesPetitioner vs. VS.: Third DivisionAnonymous QR87KCVteNo ratings yet

- Conditional Sentence and Passive VoiceDocument2 pagesConditional Sentence and Passive Voicedebietamara larentikaNo ratings yet

- InglesDocument5 pagesInglesJessi mondragonNo ratings yet

- Philo ExamDocument2 pagesPhilo ExamJohn Albert100% (1)

- Ahad NaamahDocument2 pagesAhad NaamahedoolawNo ratings yet

- Will or Going To 90069Document2 pagesWill or Going To 90069Dragana ZafirovskaNo ratings yet

- Note On F3 SC C2 TransportationDocument4 pagesNote On F3 SC C2 Transportationgan tong hock a.k.a ganosNo ratings yet

- Amy Gaines - Amigurumi Matryoshka Dolls (C)Document7 pagesAmy Gaines - Amigurumi Matryoshka Dolls (C)John Eduardo Henriquez BorbonNo ratings yet

- Bent Mag-Dec 2009Document80 pagesBent Mag-Dec 2009EcarvalhoStad0% (3)

- Piano Solo XXDocument6 pagesPiano Solo XXschweyermatthieuNo ratings yet

- Basket 1159913 DataDocument13 pagesBasket 1159913 DataMartin SuchomelNo ratings yet

- Maternal and Infant Care Beliefs Aeta Mothers in PhilippinesDocument8 pagesMaternal and Infant Care Beliefs Aeta Mothers in PhilippinesChristine Joy MolinaNo ratings yet

- En 12245 (2022) (E)Document9 pagesEn 12245 (2022) (E)David Chirinos100% (1)

- Naet Basic 15 GuideDocument6 pagesNaet Basic 15 Guidesissicarranza100% (1)

JOPAR catalog -最新

JOPAR catalog -最新

Uploaded by

thihuedoanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JOPAR catalog -最新

JOPAR catalog -最新

Uploaded by

thihuedoanCopyright:

Available Formats

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

电子画册 官网二维码 Website

地址:广东省佛山市南海区狮山镇招大创业 Add: Zhaoda Industrial Park,Shishan Town,

园创业北路 Nanhai Distrrict, Foshan City,52800, China.

电话:0757-81082366 Tel: +86-0757-81082366

传真:0757-81082377 Fax: +86-0757-81082377

邮箱:info@itubemill.com Email: sales@itubemill.com

网址:www.jopar279.com Web: www.joparr.com 佛山市中牌机械有限公司

全国服务热线:400-8383-818 Mob: +86-139 2992 2994 Contact:Eric Xiao Foshan Jopar Machinery Co.,Ltd.

全新自动化升级

Brand New Automatic Upgrade

实现更高效更便捷的使用操作

电动调节 模具共用 省时高效

Achieve More EffIcient And Convenient Operation

Electrical Control Mould Sharing High EffIciency

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

CONTENTS

产品目录

通用型制管机

STANDARD TUBE MILL

07

加强型制管机

STRONGER TUBE MILL

09

精密型制管机

PRECIOUS TUBE MILL

11

不锈钢工业制管机

INDUSTRIAL TUBE MILL

13

大口径制管机

LARGE DIAMETER TUBE MILL

15

高频直缝焊管机

ERW/HF TUBE MILL

17

在线内焊缝去除装置

INSIDE BEAD REMOVE MACHINE

19

在线光亮退火

IN-LINE ANNEALING MACHINE

20

圆管抛光机

ROUND TUBE POLISHING MACHINE

21

方/矩形管抛光机

SQUARE & RECTANGLE TUBE POLISHING MACHINE

22

制管机模具

PIPE MOULD

23

钢管压花机

PIPE / TUBE EMBOSSING MACHINE

24

自动上料-切管机

PIPE CUTTING MACHINE WITH AUTOMATIC UPLOADING SYSTEM

25

管端倒角机

PIPE CHAMFERING MACHINE

26

P01 www.jopar279.com www.jopar279.com P02

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

COMPANY PROFILE

公司简介

佛山市中牌机械有限公司是一家集研发、设计、生产、销售,配套服务于一体的专业不锈钢管整厂设备制造商。

公司实行现代化管理,引进精密型机械加工设备,不断创新,产品质量和完善的售后服务为公司赢得了大批忠实客

户,产品销售于南美、东欧、印度、印尼、日本、韩国、马来西亚、泰国等国家和地区的装饰、汽车、卫浴、管输等送行业中等到

广泛的运用。

主打产品:不锈钢制管机、在线焊缝内整平设备、在线光亮退火设备、抛光机、高频机、压花机、焊管模具等,为客户提

供专业的建厂规划解决方案以及钥匙工程。

秉承“创新共赢”的企业理念,中牌机械努力打造具有国际竞争力的综合性不锈钢厂设备综合型公司,期待与您的合

作。

Foshan Jopar Machinery Co., Ltd. is a professional manufacturer of stainless steel tube equipment,concentrating

on the research and development, design, production, sales and supporting service.

Focus on continuous innovation, product quality and after-sales service, and it let us gain the large number

of loyal customers. Our products are sold to South America, Eastern Europe, India, Indonesia, Japan, Korea,

Malaysia, Thailand and other countries and regions of decoration, automobile, sanitary ware, pipe and industries

medium to a wide range of application.

Main products : Tube Mill, Stainless Steel Pipe Making Machine, Inside Bead Remove Machine, In-line Bright

Annealing Machine, Polishing Machine, ERW Tube Mill, Pipe Embossing Machine,Roll Sets & Mould, etc., Providing

customers with professional factory planning solutions and turnkey project.

We have always insisted on the company of "Innovation and win-win".Jopar Machinery Co., Ltd. strives to build a

comprehensive stainless steel plant equipment company with international competitiveness and looks forward

to cooperating with you.

P03 www.jopar279.com www.jopar279.com P04

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

HONOR CERTIFICATE

荣誉证书

P05 www.jopar279.com www.jopar279.com P06

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

细节展示 PRODUCT DETAILS

STANDARD TUBE MILL 高 高 高

通用型制管机 精度 效率 节能

应用范围 APPLICATION

主要适用于装饰、工业制品、家电用不锈钢及碳钢(圆管、方管、异型管)的生产中。

Mainly used for the production of decoration,industrial products,appliances stainless steel and carbon steel tube(round tube,

square tube,special tube).

性能优势 PRODUCT ADVANTAGES

技术参数 TECHNICAL PARAMETERS

专业用材:外观采用优质不锈钢工程材质,持久耐用。

精细结构:采用高科技精细电机结构设计,性能稳定,节能环保。 直径

型号 水平轴直径 立轴直径 厚度 主电机 尺寸

使用便捷:人性化操作系统设计,轻松易学,操作简便。 Out Diameter

Model Horizontal Shaft Size Vertical Shaft Size Thickness Drive Motor Dimension

Range

品质保障:产品通过ISO9001国际质量管理体系认证,高品质,名牌保障。

Professional material:its appearance is made up of superior stainless steel engineering material,having the advantage of durability. ZP-40S 40mm 25mm Φ6-32mm 0.2-1.0mm 5.5kW 20m*1.0m

Precise structure:it uses the high tech design of elaborate motor structure,having the advantage of stable performance,energy ZP-40 40mm 25mm Φ8-51mm 0.3-1.8mm 7.5kW 21.5m*1.1m

conservation and environment protection.

ZP-40L 40mm 25mm Φ12-64mm 0.3-2.0mm 11kW 21.5m*1.1m

Easy operation:its humanizing design of operating system makes it have advantage of learn ability and easy operation.

Quality assurance:the products have passed the ISO9001 international quality management system certification, having the ZP-50 50mm 30mm Φ25-76mm 0.3-2.0mm 11kW 24m*1.2m

advantage of high quality and prestige.

ZP-60 60mm 40mm Φ50-114mm 0.3-2.5mm 15kW 26m*1.4m

生产流程 PRODUCTION PROCESS ZP-80 80mm 50mm Φ89-168mm 0.8-3.5mm 18.5kW 32m*2.3m

专业采用全自动化生产流程:经开卷、打商标、成型、焊接、打磨、定径、校直、定尺、切断、接料等连续成型工艺。

ZP-100 100mm 60mm Φ114-219mm 1.0-5.0mm 22kW 36m*2.5m

Automatic production processes:After the technology of decoiling, branding, molding, welding, grinding, sizing, alignment, cut-to-

length, abscission, splicing and so on. OFFERING THE PROFESSIONAL WELDED TUBE SOLUTIONS

P07 www.jopar279.com www.jopar279.com P08

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

细节展示 PRODUCT DETAILS

STRONGER TUBE MILL 高 高 高

加强型制管机 精度 效率 节能

生产流程 PRODUCTION PROCESS

应用范围 APPLICATION 自动化生产流程:经开卷、清洗装置、进料导向、成型、焊接、外焊缝打磨、整形定径、定径、校直、定尺、切断(盘卷)等连续成型工艺。

主要适用于生产不锈钢管。 在化工、医药、酒厂、石油、食品、汽车、造纸、空调等诸多行业得到广泛应用。 Uncoiling, cleaning, guidance, molding, welding, outside welded grinding, sizing, alignment, cut off, run out table.

Mainly used for the production of stainless steel tube, be widely used in many areas, such as:chemical engineering, medicine,

petroleum, food, automobile, paper-making industry, air conditioning and so on.

技术参数 TECHNICAL PARAMETERS

性能优势 PRODUCT ADVANTAGES 直径

型号 水平轴直径 立轴直径 厚度 主电机

Out Diameter 尺寸 Dimension

专业用材:外观采用优质不锈钢工程材质,持久耐用。 Model Horizontal Shaft Size Vertical Shaft Size Thickness Drive Motor

Range

精细结构:采用高科技精细电机结构设计,性能稳定,节能环保。

ZP-S40 40mm 30mm Φ8-51mm 0.3-2.2mm 7.5kW+7.5kW 29m*1.5m

使用便捷:人性化操作系统设计,轻松易学,操作简便。

品质保障:产品通过ISO9001国际质量管理体系认证,高品质,名牌保障。 ZP-S50 50mm 30mm Φ25-76mm 0.4-2.5mm 11kW+11kW 32m*1.5m

Material:

its appearance is made up of superior stainless steel engineering material,having the advantage of durability.

ZP-S60 60mm 40mm Φ50-114mm 0.5-3.0mm 15kW+15kW 35m*1.8m

Precise structure:it uses the high-tech design of elaborate motor structure, haing the advantage of stable performance, energy

conservation and environment protection. ZP-S80 80mm 50mm Φ89-168mm 0.8-4.0mm 18.5kW+18.5kW 40m*2.5m

Easy operation:its humanizing design of operating system makes it have the advantage of learn ability and easy operation. ZP-S100 100mm 60mm Φ114-219mm 1.0-6.0mm 30kW+30kW 43m*2.5m

Quality assurance:the products have passed the ISO9001 international quality management system certification, having the

advantage of high quality and prestige. OFFERING THE PROFESSIONAL WELDED TUBE SOLUTIONS

P09 www.jopar279.com www.jopar279.com P10

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

细节展示 PRODUCT DETAILS

PRECIOUS TUBE MILL 高 高 高

精密型制管机 精度 效率 节能

应用范围 APPLICATION

生产流程 PRODUCTION PROCESS

主要适用于生产不锈钢管。 在化工、医药、酒厂、石油、食品、汽车、造纸、空调等诸多行业得到广泛应用。 自动化生产流程:经开卷、清洗装置、进料导向、成型、焊接、外焊缝打磨、整形定径、定径、校直、定尺、切断(盘卷)、等连续成型工艺。

Mainly used for the production of industrial stainless steel tube, be widely used in many areas, such as:chemical engineering, After the technology of continuous formation including decoiling, cleaning equipment, feed orientation, molding, welding, in-line

medicine, winery, petroleum, food, automobile, paper-making industry, air conditioning and so on. inside welded bead controlling , outside welded grinding , shaping and sizing, solution treatment , final sizing, alignment , flaw

detection, spraying code, cut-to-length, abscission (pony roll), splicing and so on.

性能优势 PRODUCT ADVANTAGES

专业用材:外观采用优质不锈钢工程材质,持久耐用。

技术参数 TECHNICAL PARAMETERS

精细结构:采用高科技精细电机结构设计,性能稳定,节能环保。

直径

使用便捷:人性化操作系统设计,轻松易学,操作简便。 型号 水平轴直径 立轴直径 厚度 主电机

Out Diameter 尺寸 Dimension

品质保障:产品通过ISO9001国际质量管理体系认证,高品质,名牌保障。 Model Horizontal Shaft Size Vertical Shaft Size Thickness Drive Motor

Range

Professional material:its appearance is made up of superior stainless steel engineering material,having the advantage of durability.

ZP-P40 40mm 25mm Φ8-51mm 0.5-2.0mm 7.5kW+7.5kW 29m*1.5m

Precise structure:it uses high-tech the design of elaborate motor structure, having the advantage of stable performance, energy

conservation and envizronment protection. ZP-P50 50mm 30mm Φ25-76mm 0.5-3.0mm 11kW+11kW 32m*1.5m

ZP-P60 60mm 40mm Φ50-114mm 0.6-3.5mm 15kW+15kW 35m*1.8m

Easy operation:its humanizing design of operating system makes it have the advantage of learn ability and easy operation.

ZP-P80 80mm 50mm Φ89-168mm 1.0-4.5mm 18.5kW+18.5kW 40m*2.5m

Quality assurance:the products have passed the ISO9001 international quality management system certification, having the

advantage of high quality and prestige. ZP-P100 100mm 60mm Φ114-219mm 1.0-5.0mm 22kW+22kW 43m*3.0m

OFFERING THE PROFESSIONAL WELDED TUBE SOLUTIONS

P11 www.jopar279.com www.jopar279.com P12

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

细节展示 PRODUCT DETAILS

INDUSTRIAL TUBE MILL 高 高 高

不锈钢工业制管机 精度 效率 节能

技术参数 TECHNICAL PARAMETERS

产品描述 PRODUCT DESCRIPTION 直径

型号 水平轴直径 立轴直径 厚度 主电机

Out Diameter 尺寸 Dimension

不锈钢工业制管机主要用于生产工业用不锈钢管,由于不锈钢焊管技术的成熟,很多领域已经取代无缝管。

其在化工、医药、酒厂、石油、食品、 Model Horizontal Shaft Size Vertical Shaft Size Thickness Drive Motor

汽车、造纸、空调等行业运用广泛。

Range

Front7.5kW

The machine is manufacturing stainless steel industrial pipes/tubes widely applied in Mechanical Structure, Construction, Medical ZP-I40 40mm 25mm Φ8-51mm 0.5-2.0mm 29m*1.5m

use, Refrigeration, Food and Beverage handling equipment, Heating elements/Heat exchange, Drilling and Exploration platforms. Rear7.5kW

Aerospace and Nuclear industry etc. Front11kW

ZP-I50 50mm 30mm Φ25-63mm 0.5-3.0mm 32m*1.5m

Rear11kW

自动化生产流程 PRODUCT PROCESSES ZP-I60 60mm 40mm Φ50-114mm 0.6-3.5mm

Front15kW

35m*1.8m

Rear15kW

开卷、进料导向、成型、焊接、内焊缝处理、外焊缝打磨、整形定径、固垎处理、终定径、校直、探伤、喷码、定尺、切断、下料等连续成型工艺。 结构 Front18.5kW

ZP-I80 80mm 50mm Φ89-168mm 1.0-4.5mm 40m*2.5m

精细,操作简便,专业制造,高品质。 Rear18.5kW

Single or double side uncoiler- leveling section -forming section-welding stage -in-line inside weld bead remove section Front22kW

ZP-I100 100mm 60mm Φ114-219mm 1.0-5.0mm 43m*3.0m

-outside welding bead grind section -first sizing section -in-line annealing section - final sizing section and straightening section Rear22kW

-nondestructive testing -marking stage- fixed length-cut off-end-product upload stage. OFFERING THE PROFESSIONAL WELDED TUBE SOLUTIONS

P13 www.jopar279.com www.jopar279.com P14

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

细节展示 PRODUCT DETAILS

LARGE DIAMETER TUBE MILL 高 高 高

大口径制管机 精度 效率 节能

技术参数 TECHNICAL PARAMETERS

直径

型号 水平轴直径 立轴直径 厚度 主电机 尺寸

应用范围 APPLICATION Model Horizontal Shaft Size Vertical Shaft Size

Out Diameter

Thickness Drive Motor Dimension

Range

主要适用于工业管道,在食品管道、饮料厂、酒厂、天然气、污水处理管、石油、通风用管、建筑、桥梁、航空等诸多行业得到广泛应用。

ZP-S100 100mm 50 Φ127-219mm 2.0-6.0mm 30(kW)*2 36m*2.6m

Mainly used for industrial pipes. They are widely used in food pipes, beverage factory, winery, natural gas, sewage treatment pipe,

oil pipe, ventilation pipe, construction, bridge, aviation and many other industries. ZP-S110 110mm 70 Φ219-325mm 3.0-8.0mm 45(kW)*2 45m*4.0m

自动化生产流程 PRODUCT PROCESSES

ZP-S120 120mm 75 Φ273-355mm 4.0-10.0mm 55(kW)*2 48m*4.5m

开卷→成型→内焊缝整平→外焊缝处理→在线黑退火→定径调直→涡轮探伤→切割→成品料架。 ZP-S130 130mm 80 Φ325-426mm 5.0-12.0mm 75(kW)*2 55m*5m

Double Uncoiler →Forming Section → Outside Weld Grinding Machine → Black Annealing → Sizing Unit And Straightener → In-Line

Eddy Current Flaw Detector → Cutting Unit → Run-Out Table. ZP-S150 150mm 85 Φ377-530mm 5.0-12.0mm 95(kW)*2 59m*5.5m

ZP-S160 160mm 90 Φ426-630mm 6.0-14.0mm 110(kW)*2 63m*6m

P15 www.jopar279.com www.jopar279.com P16

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

细节展示 PRODUCT DETAILS

ERW/HF TUBE MILL 高 高 高

高频直缝焊管机 精度 效率 节能

技术参数 TECHNICAL PARAMETERS

产品描述 PRODUCT DESCRIPTION

水平轴直径 立轴直径 直径

高频直缝焊管机主要用于生产普碳钢管的生产,运用在家具、建筑、装潢、汽车、造纸、空调等行业运用广泛。 型号 Model 厚度 Thickness

Horizontal Shaft Size Vertical Shaft Size Out Diameter Range

Mainly used for the production of stainless steel tube, be widely used in many areas,such as:chemical engineering, medicine,

petroleum, food, automobile, paper-making industry, air conditioning and so on. ERW25 7-25mm 0.2-1.0mm 20*20mm 0.6mm

自动化生产流程 PRODUCT PROCESSES

ERW32 7-32mm 0.25-1.2mm 25*25mm 0.8mm

ERW38 8-38mm 0.3-1.5mm 30*30mm 1.0mm

经开卷、进料导向、成型、高频焊接、外焊缝去除、冷却、定径、校直、定尺、电脑飞锯切断、下料等连续成型工艺。 结构精细、操作简便、专业制造、

高品质。 ERW52 8-52mm 0.4-1.8mm 40*40mm 1.5mm

Single or double side uncoiler -leveling section -forming section -HF welding stage -outside weld bead remove section -sizing

section and straightening section -cut off -end product upload section. ERW64 10-64mm 0.4-2.2mm 50*50mm 1.8mm

ERW76 16-76mm 0.5-2.5mm 60*60mm 2.0mm

ERW114 38-114mm 0.6-3.5mm 100*100mm 2.5mm

OFFERING THE PROFESSIONAL WELDED TUBE SOLUTIONS

P17 www.jopar279.com www.jopar279.com P18

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

INSIDE BEAD REMOVE MACHINE IN-LINE ANNEALING MACHINE

在线内焊缝去除装置 在线光亮退火

高 高 高 高 高 高

精度 效率 节能 精度 效率 节能

应用范围

应用范围 APPLICATION

APPLICATION

主要适用于生产工业用不锈钢管。

主要适用于不锈钢无缝管生产,并广泛应用于饮用水水管、石油、化工、核电、锅炉、视频、医药等行业。

Mainly used for the production of industrial stainless steel tube.

Mainly used for the production of industrial stainless steel seamless tube, be widely used in many areas,such as:petroleum,

chemical, engineering, nuclear power, boiler,food, medicine and so on.

性能优势

性能优势 PRODUCT ADVANTAGES

PRODUCT ADVANTAGES

专业用材:外观采用优质不锈钢工程材质,持久耐油,抗腐蚀性强。

专业用材:外观采用优质不锈钢工程材质,持久耐用。 精细结构:采用高科技精细电机结构设计,性能稳定,节能环保,极好地解决了在线黑色固溶再酸洗或是离线光亮固溶带来的环境危害。

精细结构:采用高科技精细电机结构设计;性能稳定,节能环保。 使用便捷:人性化操作系统,轻松易学,操作简便。

使用便捷:人性化操作系统设计,轻松易学,操作简便。 品质保障:产品通过ISO9001国际质量管理体系认证,高品质,名牌保障。

品质保障:产品通过ISO9001国际质量管理体系认证,高品质,名牌保障。

Professional material:its appearance is made up of superior stainless steel engineering materials,having the advantage of durability

Professional materials :its appearance is made up of superior stainless steel engineering materials, having the advantage of and corrosion resistance.It can solve the environmental harm of repickling of in-line black solid solution or off-line bright annealing.

durability.

Precise structure :it uses the high-tech elaborate motor structure,having the advantage of stable performance,energy conservation

Precise structure :it uses the high-tech design of elaborate motor structure, having the advantage of stable performance,energy and environment protection.

conservation and environment protection.

Easy operation :its humanizing design of operating system makes it have the advantage of learn ability and easy operation.

Easy operation :its humanizing design of operation system makes it have the advantage of learn ability and easy operation.

Quality assurance:the products have passed the ISO9001 international quality management system certification, having the advantage

Quality assurance :the products have passed the ISO9001 international quality management system certification, having the of high quality and prestige.

advantage of high quality and prestige.

生产流程 生产流程 PRODUCTION PROCESS

PRODUCTION PROCESS

专业采用全自动化生产流程:即内置芯棒利用轧辊对不锈钢焊管进行滚压的往复式自动滚压装置,通过控制滚压强度和道次,使不锈钢焊管 将不锈钢焊管用感应加热线圈加热到固溶所需温度,完成奥氏体的均质化即固溶过程。 经水套1进口端石墨冷却夹具极冷,将温度降至800℃下,

内外焊缝整平,彻底去除内外焊缝余高,达到与母材平齐的要求。 防止碳,铬析出以保住固溶化效果。经水套1在550~750℃之间进行保温,给铬提供充足的扩散时间,有效消除贫铬区。同时,550℃~750℃虽为

Automated production processes :the built-in mandrel utilizes roller to make stainless welded pipe roll and stitch automatically and 不锈钢敏化区,但水套2石墨冷却夹具对焊管的急速冷却阻断了不锈钢敏化的时间效应,避免出现敏化结果。经水套2冷却后的钢管温度应低于

circularly. In order to meet the abreast requirement with parent metal,it controls the strength and frequency of rolling for in -line 130℃。

inside welded bead controlling and outsize welded grinding of the stainless steel welded pipe and completely removing surplus It employs induction heating coil to make the stainless steel welded pipe achieve the required temperature of solid solution and

height of seam. complete the homogenizing solution of austenite .In order to prevent carbon or chromium from separating out and keep solutionizing

result , its fixture will cold snap by the first water jacket graphite cooler to cool to below 800℃. The first water jacket keeps the

temperature 500℃ and 750℃ is weld decay area of stainless steel, but the second water jacket and graphite cooler can stop its time

effect and avoid sensitizing results. The temperature of steel tube after cooling of the second water jacket must below 130℃.

P19 www.jopar279.com www.jopar279.com P20

FOCUS ON R&D 专注研发与制造焊管整厂设备

SQUARE & RECTANGLE

THE HIGH-TECH WELDED TUBE MACHINERY

ROUND TUBE POLISHING MACHINE TUBE POLISHING MACHINE

圆管抛光机 方/矩形管抛光机

高 高 高 高 高 高

精度 效率 节能 精度 效率 节能

细节展示 PRODUCT DETAILS

细节展示 PRODUCT DETAILS

技术参数 TECHNICAL PARAMETERS

技术参数 TECHNICAL PARAMETERS

磨头轴轴径 抛管范围 磨头轴轴径 抛管范围

磨头电机功率 总功率 抛光速度 主机尺寸 磨头电机功率 总功率 抛光速度 主机尺寸

型号 Model Diameter Of Head Polishing 型号 Model Diameter Of Head Polishing

Driving Motor Total Power Speed (L*W)Dimension Driving Motor Total Power Speed (L*W)Dimension

Spindle Range Spindle Range

8 磨头圆抛光机 32 磨头方管抛光机

0-20 F10*F10- 0-30

8 Heads Round Tube 4kW*8 29.5kW Φ36mm Φ8-Φ51mm 5300*1250mm 32 Heads Square Polishing 4kW*32 130.2kW Φ36mm 11700*1550mm

m/min F90*F90 m/min

Polishing Machine Machine

10 磨头圆抛光机 36 磨头方管抛光机

0-20 F10*F10- 0-30

10 Heads Round Tube 4kW*10 45.5kW Φ36mm Φ12-Φ76mm 6500*1300mm 36 Heads Square Polishing 4kW*18+5.5kW*18 175kW Φ36mm 13100*1550mm

m/min F90*F90 m/min

Polishing Machine Machine

10 磨头大圆抛光机 12 磨头钢管拉丝抛光机

0-18 F10*F10- 0-30

10Heads Big Tube 5.5kW*10 60.5kW Φ36mm Φ38-Φ114mm 7200*1550mm 12 Heads Tube Hair Line 5.5kW*12 68.2kW Φ36mm 6500*1550mm

m/min F90*F90 m/min

Round Polishing Machine Polishing Machine

10 磨头工业管抛光机 32 磨头水蜡方管抛光机

0-15 F10*F10- 0-30

10 Heads Industrial Round 7.5kW*10 82.5kW Φ36mm Φ89-Φ219mm 7500*1600mm 32 Heads Liquid Wax 4kW*32 130.2kW Φ36mm 11700*1550mm

m/min F90*F90 m/min

Tube Polishing Machine Square Polishing Machine

10 磨头水蜡抛光机

0-18

10 Heads Liquid Wax 5.5kW*10 60.5kW Φ36mm Φ38-Φ114mm 7200*1550mm

m/min

Polishing Machine

P21 www.jopar279.com www.jopar279.com P22

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

PIPE MOULD 高 高 高 PIPE / TUBE EMBOSSING MACHINE

制管机模具 精度 效率 节能 钢管压花机

高 高 高

精度 效率 节能

技术参数 TECHNICAL PARAMETERS

规格 材质 公差范围 硬度

型号 Model

Specification Material Tolerance ranges Hardness

圆管 Round Tube Φ5 - 630mm Cr12MoV/SKD11/D2 圆度:±0.05mm Roundess:±0.05mm 60-65HRC 性能优势 PRODUCT ADVANTAGES

方管 Square Tube S10*10 - 450*450mm Cr12MoV/SKD11/D2 平面度:±0.04mm Flatness:±0.04mm 60-65HRC

不锈钢设备压花机又称不锈钢花管成型机、对不锈钢、铁、铝等管材进行各种加工扁花、圆形花、工艺花、大头花、鸡蛋花等花型。

扁管 Rectangle Tube R20*10 - 400*100mm Cr12MoV/SKD11/D2 圆度:±0.04mm Flatness:±0.04mm 60-65HRC

可加工的管径范围( 6-114毫米)

,厚度(0.2-3.0毫米)。

该不锈钢压花机具有加工质量好、成本低、效率高的特点,是加工各种管材花管的理想选择。

应用范围 APPLICATION

Stainless steel embossing machine, also known as stainless steel flower pipe forming machine,is mainly used for embossing

stainless steel pipe,iron pipe, aluminum pipe and so on. The embossing machine can variety of flower shapes,such as flat flower,

包括圆管、方管、梅花管、扁管、椭圆管、扇形管、多角形管、单双槽型管、门框管、异型管等模具。 round flower, craft flower,bulk flower, egg flower,etc.

Including round pipe, square pipe, torx pipe, oblate tube, oval tube, polygon tube, single and double groove tube, frame tube, Workable diameter of pipe range from (6-114)mm, pipe Thickness from (0.2-3.0)mm. With good processing quality, lower cost and

special pipe and so on. high efficiency, the embossing machine is an ideal choice for clients to process various kinds of flower pipes.

性能优势 PRODUCT ADVANTAGES 技术参数 TECHNICAL PARAMETERS

专业用材:选用优质模具钢Cr12MoV/SKD11/D2为原材料、耐磨性高、韧性强、抗高压、高硬度、淬透性强。

精细做工:采用日本数控系统加工、精密极高、有效解决方管成型面不平、角度差、制管过程中产生的拉伤、起皱、指纹、机械纹、对角、凹角等现象; 型号 Model EM25 EM50 EM76 EM114

并使形位公差圆度在0.05mm以内;方管对角不超出±0.05mm。

品质保障:产品通过ISO9001国际质量管理体系认证,高品质,名牌保障。 模具尺寸 Mould Dimension(mm) 35*300*55 50*300*75 70*400*60 90*650*70

Professional Material: it is made up of superior die steel Cr12MoV/SKD11/D2, having the advantage of abrasive resistance, tenacity,

crushing resistance, hardness and hardenability. 加工范围 Process Scope(mm) Φ12-Φ25 Φ16-Φ51 Φ25-Φ76 Φ38-Φ114

Precise Structure: it employs Japanese numerical control system to process products and has high precision, effectively solving 工件壁厚 Process Thickness(mm) 0.2-1.5 0.2-2.0 0.4-7.5 0.7-3.0

the phenomenon of irregular die land, differential seat angle, pulling, corrugation, fingerprint, mechanical texture, opposite angle,

concave angle during tubulation. It can keep the geometric tolerance below 0.05mm and opposite angle less than ±0.05mm. 成型长度 Process Lenth(mm) 290 290 360 600

Quality Assurance: the products have passed the ISO9001 international quality management system certification, having the 成型时间 Time Of Forming (Second) 3-12 3-20 8-30 10-40

advantage of high quality and prestige.

生产流程

主电机 Main Motor Power(kw) 3 4 7.5 11

PRODUCTION PROCESS

主轴转速 Rotation Rate Of Axis(Rpm) 300 200 200 200

经原材采集、材料检测、锻炼、锯床、车床、钻床、车床、数控精车、磨床、淬火、硬度检测、内外磨加工、试验、装箱等制造工序。

After the manufacturing process of raw materials collection, materials testing, exercise, turning lathe, drilling, CNC precision turning, 设备总量 Gross Weight (kg) 1500 2000 3000 5000

grinding, quenching, hardness test, internal and external grinding, test, boxing and so on.

P23 www.jopar279.com www.jopar279.com P24

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

PIPE CUTTING MACHINE WITH

AUTOMATIC UPLOADING SYSTEM PIPE CHAMFERING MACHINE

自动上料-切管机 管端倒角机

高 高 高 高 高 高

精度 效率 节能 精度 效率 节能

技术参数 TECHNICAL PARAMETERS

型号 Model 76CNC 100CNC

送料伺服马达 Pipe Feeding Servo Motor 1.5kW 1.5kW

尾料伺服马达 Pipe Pulling Servo Motor 0.75kW 0.75kW

主轴驱动马达 Spindle Driving Motor 3kW 4kW

上料架上料减速马达

1.1kW 1.1kW

Uploading Gear Motor For Uploading Table

上料架上料减速马达

0.75kW 0.75kW

Feeding Gear Motor For Uploading Table

液压驱动马达 Hydraulic Drive Motor NO 2.2kW

切削液马达 Cutting Liquid Motor 0.15kW 0.15kW

滚珠丝杆和伺服马达 滚珠丝杆和伺服马达

送料驱动方式 Method Of Feeding System

Ball Screw And Servo Motor Ball Screw And Servo Motor

滚珠丝杆和伺服马达 滚珠丝杆和伺服马达

尾料驱动方式 Method Of Pulling System

Ball Screw And Servo Motor Ball Screw And Servo Motor

主轴转速 Speed Of The Spindle 52-104r/min 30-130r/min

锯片尺寸 Size Of Saw Blade HSSΦ250-Φ325mm HSSΦ250-Φ375mm

锯片参数 Parameter Of Saw Blade 2*Φ11*PCD63mm 2*Φ11*PCD63mm 技术参数 TECHNICAL PARAMETERS

原材料长度 Raw Material Length 6000mm or Customized 6000mm or Customized

送料长度 Feeding Length 30-1000mm Per Trip, Can Feeding Many Trip 30-1000mm Per Trip, Can Feeding Many Trip 型号 Model EM25 EM114

料头损耗 Waste Of Before Cutting 10-20mm 10-20mm 模具尺寸 Mould Dimension 2HP*4P 2HP*4P

料头损耗 Waste Of Before Cutting 20-30mm 20-30mm 加工范围 Process Scope(mm) Φ12-Φ55mm Φ55-Φ100mm

Hydraulic System 5-8kg/cm2 25-35kg/cm2 工件壁厚 Process Thickness(mm) 5-8kg/cm 2

5-8kg/cm2

1. 标准刀头 :Φ20-Φ51mm

Weight Of Machine 1500kg 2050kg Standard Tool Bit For Range:Φ12-Φ55mm

成形长度 Process Lenth(mm)

2. 小刀头 :Φ9-Φ18mm

Machine Size 7500*2200*1550mm 8200*2500*1900mm Small Tool Bit For Range :Φ9-Φ18mm

P25 www.jopar279.com www.jopar279.com P26

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

OUR SERVICE

服务项目

THE MOST PROFESSIONAL PROVIDER OF INDUSTRY APPLICATION SOLUTIONS EXAMINATION & INSPECTION

最专业的行业应用解决方案提供商 检测、检验

厂房规划 PROJECT FOR FACTORY

压扁试验:

是用以检验金属管压扁到规定尺寸的变形性能,并显示其缺陷的一种试验方法。将试样放在两个平行板之间,用压力机或其他方法,均匀地压至

厂房选择:为您的厂房设计提供科学建议。 有关的技术条件规定的压扁距,检查试样弯曲变形处,如无裂缝、裂口或焊缝开裂,即认为合格。

机组排列方式:机组采用纵向排列方式,流水线生产,提高生产效率,节省空间。 扩口试验:

相关辅助设备:装运手推车、供水系统、抽风系统、补焊机、切割机、包装台架子、钢带架存放架、水泵、手动打磨机、电子吊称、电子地称、仓库料 是检验金属管端扩口工艺的变形性能的一种方法。在进行扩口试验时,将具有一定锥度的顶芯压入金属管试样一端,使其均匀地扩张到有关技术

架、空压机、航车。 条件规定的扩口率,然后检查扩口处是否有裂纹等缺陷,以判定合格与否。

Plant design: We can provide scientific advice for your design of plant. 无损探伤:

Arrangement for machine: we suggest the machines to be arranged lengthwise, helping you realize assembly line production, 无损探伤是在不损坏工件或原材料工作状态的前提下,对被检查部件的表面和内部质量进行检查的一种测试手段。

improve production efficiency and save space. 水压试验:

Relevant auxiliary equipment should be provided in the factory such as follows: Wheel barrow, water supply system, ventilation 水压试验是利用水压进行精力测定岩石变形特性指标的一种方法。在岩体中开挖一圆形试侗,在试侗试验段一端部以混凝土盖板封闭起来,用高

systems, complement welder, cutter, packing table shelf, steel tape storage racks, water pump, manual grinding machine, electronic 压水泵将水压入试侗内,使试侗岩体表面受到均匀的水压力而引起岩石变形,测试试侗半径或直径的变化,然后根据压力和变形的关系,计算出

hanging said, warehouse rack, air compressor, crane. 岩石的变形模量和弹性抗力系数。

生产服务

侵蚀试验:

PRODUCTION SERVICES 经双方规定和协议的侵蚀方法,进行钢管和焊缝的侵蚀检验,不得有晶间侵蚀倾向。

翻边试验:

为您提供科学的生产管理制度。 Scientific system for production. 利用模具使金属管的边缘形成有一定角度的直壁或凸缘的成型方法翻边,检验其缺陷的方法。

为您提供专业的生产规划。 Professional production planning. 其他类型的检验:

为您提供专业的生产经验。 Professional production experience. 根据客户特殊要求进行试验。

为您培训专业的技术人员。 Professional technical staff training.

为您推荐专业的制管专家及厂长。 Flattening Test:

Acquaint yourself with tube expert and factory director. It is atest method of tube/pipe defects by flattening process.the sample was placed between two parallel plates,use the press machine

提供我司(客户)工厂不锈钢管生产线参观机会。

A visit to stainless steel pipe production line. or other methods,even pressure to the relevant tecnical requirements of flattening distance,to check sample of bending deformation,

其他不锈钢项目事项。 if no cracks,nicks cracking,or weld cracking,that the samples are qualified.

Other items about stainless steel.

销售服务 SALE SERVICES

Flaring Test:

It is a test method of tube/pipe defects of deformation properties of the metal tubes and flaring process. Put the taper core ressed into

one end of the metal tube, it evenly expansion to the relevant technical requirements of the flaring rate, then check flared at the cracks

为您提供专业的行业知识与销售技巧。 Professional industrial knowledge and sales skill.

and other defects, in order to determine whether are qualified or not.

为您提供成熟的销售经验。 Proven sales experience.

Nondestructive Testing:

为您解决生产过程中的疑问及难题。 Solutions for questions and problems encountered by the production. It is a test method of tube/pipe defects and cracks of the inside metal tubes. The NDT is a test of inspecting the surface and internal

如有需要,可协助您申请佛山营业执照,也可为您联系佛山本 We can apply business license and the manufacturer for stainless steel quality premise by not damaging the workpiece or the working state of raw materials.

地不锈钢厂家,授权您在当地生产与销售佛山牌不锈钢管。 in Foshan if necessary that you are authorized to manufacture and sales

stainless steel pipe. Hydrostatic Pressure Test:

售后服务 AFTER-SALES SERVICE

It is a test method of tube/pipe defects of the metal tubes water press test. Using the high pressure water inject the water into the

specimen, so that the surface of the metal tube is subjected to a uniform water pressure caused by rock deformation, test the radius

and diameter change of the test sample, in order to determine whether are qualified or not according to the relationship between

负责设备的安装与调试。 Installation and debugging for equipment. pressure and deformation.

提供机械安装、操作、维护等方面的技术文件及技术支持。 Technical support for installation, operation and maintain, etc.

Erosion Test:

提供设备的主要元件清单。 Main part lists for machine are offered. It is a test method of tube/pipe defects of the metal tubes by chemical attack. Erosion test of metal tube and weld inspection, the tubes

提供一年保修期(设备保修范围内、人为损坏不保、易损件不保)。 A year's guarantee is provided(Man-made damage and wearing shall not have the erosion tendency to intergranular.

提供保修期后的有偿维护与检修。 parts can no be maintained during the warranty).

Flange Test:

Compensation for maintenance and repair. It is a test method of tube/pipe defects of the metal tubes and flange process. Process the edge of the metal tube/pipe for forming a

certain angle straight-wall or flange, in order to determine whether are qualified or not.

THEORETICAL METHOD TO CALCULATE THE WEIGHT OF STAINLESS STEEL

常用不锈钢理论重量的计算方法

Other Types Of Testing:

Tested in accordance with the special requirements of the customers.

不锈钢板分条计算方式: Stainless steel strips

圆管: (外径-厚度)×3.14159+厚度 Round tube: (Size-Wall thickness)×3.14159+Wall Thickness

方管:边长×4-(厚度×2) Square tube: Side length×4-(Wall Thickness×2)

301、304、321等铬镍不锈钢管: Chromium nickel stainless steel tube/pipe like 301/304/321

(外径-壁厚)×壁厚×0.02491×长度=kg (Size-Wall thickness)×Wall thickness×0.02491×length=kg

316、316L等铬镍钼不锈钢管: Chromium nickel stainless steel tube/pipe like 316/316L

(外径-壁厚)×壁厚×0.02507×长度=kg (Size-Wall Thickness)×Wall Thickness×0.02507×length=kg

不锈钢板理论重量: THeoretical weight for stainless steel strips

FOCUS ON R&D 专注研发与制造焊管整厂设备

重量=壁厚×宽度×长度×密度值 Weight=Wall Thickness×width×length×density

密度和钢种 Density and grade of steel.

密度 Density(kg/cm3) 钢种 Grade Of Steel THE HIGH-TECH WELDED TUBE MACHINERY

7.93 201/202/301/302/304/304L/305/321

7.75 405/410/420

7.98 309S/310S/316S/316L/347

P27 www.jopar279.com www.jopar279.com P28

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

OUR ADVANTAGE

我们的优势

PROFESSIONAL SERVICE TEAM

专业服务团队

黄工,拥有20年以上的制管调机以及出国安装调试经验,目前负责海外地区机器安装,调试以及培训工作。

Mr.Huang, he has more than 20 years experience of running tube mills and installation, now in charge of our international

installation, debugging, and teaching.

魏工,拥有15年以上的制管调机以及出国安装调试经验,目前负责海外地区机器安装,调试工作。

Mr.Wei, he has more than 15 years running experience of running tube mills and installation, now in charge of our international

installation, debugging.

张工,拥有20年以上的制管调机以及国内安装调试经验,目前负责国内地区机器安装,调试以及培训工作。

Mr. Zhang, he had more than 20 years experience of running tube mills and installation, now in charge of our domestic installation,

debugging, and teaching.

陈工,拥有15年以上的制管调机以及国内安装调试经验,目前负责国内地区机器安装,调试工作。

Mr. Chen, he has more than 15 years running experience of running tube mills and installation, now in charge of our domestic

installation, debugging.

蓝工,拥有10年以上的制管调机以及国内安装调试经验,目前负责国内地区机器安装,调试工作。

Mr. Lan, he has more than 10 years running experience of running tube mills and installation, now in charge of our domestic

installation, debugging.

CORPORATION WITH THE ZHUHAI CAMPUS, BEIJING INSTITUTE OF TECHNOLOGY

我司与北京理工大学珠海学院展开校企合作。

学校推荐部分优秀学生过来我公司学习和实践,我们的团队也同时学习其理论以及调研能力,大家一起共同成长。

Some recommended students came our company to learn and practice, our team also can learn each other and grow up together.

CUSTOMER RESPONSIVENES

客户响应能力

我们一直以来把应用先进的技术实现客户需求作为自己不懈的奋斗目标。 对于客户的各种需求与问题都将予以高度重视,并努力帮助客户实

现和解决。

We are committed to Committed to application of advanced technology to achieve the customer demand, we are also pay attention

our customer request and the problem, and try our best to help customers achieve and solve the problem.

PRODUCTS AND TECHNOLOGY RESEARCH AND DEVELOPMENT CAPABILITIE

产品和技术研发能力

我们有自己的研发团队5人,不断的改进产品设计,同时也为客户的厂房排布提供专业的设计。

We have our own R&D team 5 persons, Continuously improve product design, also work out the best solutions for our customer’s

workshop arrangement.

WE HAVE PROFESSIONAL QUALITY CONTROL PERSONNEL AND ELECTRICAL ENGINEER

我们有专业的质检人员和电气工程师

机器的每个加工部件和外购产品都必须经过质检人员的检查方可入库,我们采用产品质量负责制度来约束质检人员,产品不合格予以报废或

者退货,每季度按时清理报废产品。

Each processing machine parts and outsourcing products must inspected by QC personnel before storage, and we constrained our

QC personnel by the responsibility system, the substandard products will be go back to scrap or return to the supplier, we cleaning

discarded products on time quarterly.

CUSTOMER CASE

每一台机器发货前都必须试机,及时发现问题以及配件缺失的,可以最大程度避免问题出现。 客户案例

Each machine must be try running and test before delivery, and find out the problem and missing parts in time, and maximize to

avoid the problems arised in our customer’s factory.

RESOURCE INTEGRATION ABILITY

资源整合能力

我们有丰富的为客户提供交钥匙工程的经验,大部分的合作伙伴都有五年以上的合作经验,我们清楚如何让每个环节工作完美衔接,对于整

个项目我们统筹全部服务。

We had many experiences to offer our customer with the Turn-Key Project, and we cooperate with most our parners more than 5

years, we know each section work perfectly, and we will take responsible to every item of this protects.

P29 www.jopar279.com www.jopar279.com P30

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

PARTNER

合作伙伴

品质值得信赖

助您提升经济效益 降低成本

QUALITY IS TRUSTWORTHY

HELP YOU IMPROVE ECONOMIC EFFICIENCY

AND REDUCE THE COSTS

兴中成不锈钢

XINGZHONGCHENG STAINLESS STEEL

P31 www.jopar279.com www.jopar279.com P32

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

CUSTOMERS

客户见证

GLOBAL

全球

PARTNER

伙伴

VALUE

价值

P33 www.jopar279.com www.jopar279.com P34

FOCUS ON R&D 专注研发与制造焊管整厂设备

THE HIGH-TECH WELDED TUBE MACHINERY

PRODUCTS

SHOW

专业引领未来 产品展示

Look To The Future

全国服务热线

400-8383-818

P35 www.jopar279.com www.jopar279.com P36

You might also like

- QCP KOC-VME 1221006120-PART 1 Rev 2Document49 pagesQCP KOC-VME 1221006120-PART 1 Rev 2Alireza GolpesarNo ratings yet

- Firm Profile FormatDocument13 pagesFirm Profile FormatSURANA1973No ratings yet

- ZTZG CatalogueDocument12 pagesZTZG Catalogueajay.dinkar.pingleNo ratings yet

- SMACO Tube Mill LineDocument5 pagesSMACO Tube Mill LineIshtiaq bhatti Ishtiaq bhattiNo ratings yet

- DWT Babcock en MailingDocument68 pagesDWT Babcock en MailingMileNo ratings yet

- Ss Engineering Works: GST No.: 27AUTPN0369A1ZIDocument19 pagesSs Engineering Works: GST No.: 27AUTPN0369A1ZIFCP GHUGENo ratings yet

- 2021 WEIDA CatalogueDocument48 pages2021 WEIDA Cataloguefikrismart77No ratings yet

- Capacity Verification Run at Rate IpaDocument9 pagesCapacity Verification Run at Rate IpaAnonymous VRspXsmNo ratings yet

- Perforator Auger Boring Bro 23Document17 pagesPerforator Auger Boring Bro 23Jehan2No ratings yet

- UntitledDocument13 pagesUntitledabhishek purkarNo ratings yet

- Piping & Engineering Piping & Engineering: BJ BJDocument28 pagesPiping & Engineering Piping & Engineering: BJ BJWilson Xavier Orbea BrachoNo ratings yet

- Overseas Assignment 4th DecDocument3 pagesOverseas Assignment 4th DecKh HafezNo ratings yet

- Bengal PresentationDocument37 pagesBengal PresentationManish KumarNo ratings yet

- Buew 27.12.2023Document24 pagesBuew 27.12.2023Amit SinghNo ratings yet

- .Trashed 1716806683 Unidrilltech Drill Bits For MiningDocument9 pages.Trashed 1716806683 Unidrilltech Drill Bits For MiningAhmed HajiNo ratings yet

- 2024RAYMAX CatalogDocument18 pages2024RAYMAX CatalogSot DesignNo ratings yet

- WULC - 14 - 1000-G. Selgi SAIPEM New Developments in High Pressure Equipment Design FeaturesDocument9 pagesWULC - 14 - 1000-G. Selgi SAIPEM New Developments in High Pressure Equipment Design FeaturesadityadhNo ratings yet

- Catalogo RexcomachDocument21 pagesCatalogo RexcomachCarlos LopezNo ratings yet

- Kova Brochure 2019Document12 pagesKova Brochure 2019Jainam ShahNo ratings yet

- Apollo Upvc PipesDocument8 pagesApollo Upvc PipesAkshat Engineers Private LimitedNo ratings yet

- M S & M, I .: Achine Pecialty Anufacturing NCDocument20 pagesM S & M, I .: Achine Pecialty Anufacturing NCLuis QuiñelNo ratings yet

- Ef Co CatalogDocument24 pagesEf Co CatalogHayderr HassNo ratings yet

- Special Purpose Machine: Automotive Services andDocument24 pagesSpecial Purpose Machine: Automotive Services andSajed ul Haque SadmanNo ratings yet

- QCP KOC-VME 1221006120-PART 1 Rev 3Document49 pagesQCP KOC-VME 1221006120-PART 1 Rev 3Alireza Golpesar100% (1)

- Marcello FantoniDocument29 pagesMarcello FantoniAnonymous q9c7KY1vNo ratings yet

- Northern EnterprisesDocument35 pagesNorthern EnterprisesJagdev SinghNo ratings yet

- Vimax Company ProfileDocument7 pagesVimax Company ProfilemarketingNo ratings yet

- Structural Steel Fabrication Division AUG-2017Document29 pagesStructural Steel Fabrication Division AUG-2017structural steel trendsNo ratings yet

- MECH Valves SubmittalDocument254 pagesMECH Valves Submittalm.rukhsarNo ratings yet

- Fabrication of Hydraulic Pipe Bending Machine PDFDocument2 pagesFabrication of Hydraulic Pipe Bending Machine PDFAndrew100% (1)

- OTC 6 External Axis SolutionsDocument4 pagesOTC 6 External Axis Solutionsr rajeshNo ratings yet

- Unitech Profile Part 1Document33 pagesUnitech Profile Part 1Muthu kumaranNo ratings yet

- Enlistment FormDocument6 pagesEnlistment FormUNITED SWITCHGEAR SALES TEAMNo ratings yet

- Project PrasadDocument64 pagesProject PrasadTejas BhosaleNo ratings yet

- Nirmala Industrial Services: Company ProfileDocument9 pagesNirmala Industrial Services: Company ProfileSaravanan DevarajanNo ratings yet

- Catalogue of Octg / Line Pipe: Hengyang Valin Steel Tube Co.,LtdDocument28 pagesCatalogue of Octg / Line Pipe: Hengyang Valin Steel Tube Co.,LtdnebotNo ratings yet

- Technical Equipment Plant: New Opportunity For YouDocument28 pagesTechnical Equipment Plant: New Opportunity For YouNurlanNo ratings yet

- Drilltech Oilfield Company IntroductionDocument84 pagesDrilltech Oilfield Company IntroductionAdhie WaelacxhNo ratings yet

- Vapi CompaniesDocument11 pagesVapi CompaniesRahul PratapNo ratings yet

- Royal Steel Catalouge PDFDocument30 pagesRoyal Steel Catalouge PDFAsHish RaulNo ratings yet

- CBS Industry Company Limited: uPVC Window Making MachineDocument18 pagesCBS Industry Company Limited: uPVC Window Making MachineMohd DaudNo ratings yet

- Wujing Products 2023Document30 pagesWujing Products 2023Nicole WuNo ratings yet

- SHORT COMPANY PROFILE SSS-wonderslideDocument10 pagesSHORT COMPANY PROFILE SSS-wonderslideMuhammad ZakiNo ratings yet

- Aliva Product Catalogue WebDocument24 pagesAliva Product Catalogue WebquioxxNo ratings yet

- Industrial Case Study Report atDocument14 pagesIndustrial Case Study Report atamitdhakateNo ratings yet

- IjkjkDocument12 pagesIjkjkfareesyaNo ratings yet

- Robit Top Hammer Product Catalogue 11 2021 LowresDocument120 pagesRobit Top Hammer Product Catalogue 11 2021 Lowressindy leeNo ratings yet

- DataSheet SP 240 EC LC SO - Diaphragm Pump GasDocument3 pagesDataSheet SP 240 EC LC SO - Diaphragm Pump Gaskrasus95No ratings yet

- Report On Industrial Training AT Dee Piping Systems Prithla (Palwal)Document20 pagesReport On Industrial Training AT Dee Piping Systems Prithla (Palwal)Amit PatelNo ratings yet

- Mapal 2016Document416 pagesMapal 2016isuntxoNo ratings yet

- DRK Vendor Presentation FY (2022-23)Document42 pagesDRK Vendor Presentation FY (2022-23)Laxmikant JoshiNo ratings yet

- RadiatorDocument54 pagesRadiatorPavithra Agastiswaran50% (2)

- Wuzhou & Foowell Latest Profile PDFDocument77 pagesWuzhou & Foowell Latest Profile PDFAmiti AlisaNo ratings yet

- Multitek PPTDocument29 pagesMultitek PPTcsusheelaNo ratings yet

- Product Catalogue2Document43 pagesProduct Catalogue2RAMODSNo ratings yet

- Final 2Document22 pagesFinal 2prasad moreNo ratings yet

- Drop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsFrom EverandDrop Forging, Die Sinking and Machine Forming of Steel - Modern Shop Practice, Processes, Methods, Machines, Tools and DetailsRating: 5 out of 5 stars5/5 (1)

- Production Engineering - Jig And Tool DesignFrom EverandProduction Engineering - Jig And Tool DesignRating: 3.5 out of 5 stars3.5/5 (3)

- Statistical Quality Control PPT 3 2Document18 pagesStatistical Quality Control PPT 3 2Baljeet Singh100% (1)

- Grade 7 Sample Class ProgramDocument1 pageGrade 7 Sample Class ProgramRaymart EstabilloNo ratings yet

- The Ape-Man: His Kith and KinDocument128 pagesThe Ape-Man: His Kith and KinamitrupaniNo ratings yet

- Alice Becker-Ho, The Language of Those in The KnowDocument4 pagesAlice Becker-Ho, The Language of Those in The KnowIntothepill Net100% (1)

- Justin Bieber Is - Famous Singer.: (You Must Read Out The Whole Sentence.)Document2 pagesJustin Bieber Is - Famous Singer.: (You Must Read Out The Whole Sentence.)Irene De la FuenteNo ratings yet

- Dynamics of Machinery Oral Question BankDocument22 pagesDynamics of Machinery Oral Question BankSurajKahateRajputNo ratings yet

- Sun Pharma ProjectDocument26 pagesSun Pharma ProjectVikas Ahuja100% (1)

- The DJ Test: Personalised Report and Recommendations For Alex YachevskiDocument34 pagesThe DJ Test: Personalised Report and Recommendations For Alex YachevskiSashadanceNo ratings yet

- PCA Churches in CaliforniaDocument4 pagesPCA Churches in CaliforniaLIGHT GNo ratings yet

- Comparison of Starbucks With The Coffee BeanDocument16 pagesComparison of Starbucks With The Coffee BeanshaiNo ratings yet

- Yohe Nitsumi: GH 15.00 GH 15.00 GH 15.00Document3 pagesYohe Nitsumi: GH 15.00 GH 15.00 GH 15.00lYNX GHNo ratings yet

- VHDL Processes: Cwru Eecs 318Document24 pagesVHDL Processes: Cwru Eecs 318KarThikNo ratings yet

- Nuclear PhysicsDocument85 pagesNuclear PhysicsKy2ST3z4No ratings yet

- Sliding Doors Standard Sizes NSWDocument3 pagesSliding Doors Standard Sizes NSWCorey WardNo ratings yet

- Code of Ethics For Professional TeachersDocument12 pagesCode of Ethics For Professional TeachersJean GuyuranNo ratings yet

- Collections and Recollections by Russell, George William Erskine, 1853-1919Document202 pagesCollections and Recollections by Russell, George William Erskine, 1853-1919Gutenberg.org100% (1)

- Petitioner vs. VS.: Third DivisionDocument12 pagesPetitioner vs. VS.: Third DivisionAnonymous QR87KCVteNo ratings yet

- Conditional Sentence and Passive VoiceDocument2 pagesConditional Sentence and Passive Voicedebietamara larentikaNo ratings yet

- InglesDocument5 pagesInglesJessi mondragonNo ratings yet

- Philo ExamDocument2 pagesPhilo ExamJohn Albert100% (1)

- Ahad NaamahDocument2 pagesAhad NaamahedoolawNo ratings yet

- Will or Going To 90069Document2 pagesWill or Going To 90069Dragana ZafirovskaNo ratings yet

- Note On F3 SC C2 TransportationDocument4 pagesNote On F3 SC C2 Transportationgan tong hock a.k.a ganosNo ratings yet

- Amy Gaines - Amigurumi Matryoshka Dolls (C)Document7 pagesAmy Gaines - Amigurumi Matryoshka Dolls (C)John Eduardo Henriquez BorbonNo ratings yet

- Bent Mag-Dec 2009Document80 pagesBent Mag-Dec 2009EcarvalhoStad0% (3)

- Piano Solo XXDocument6 pagesPiano Solo XXschweyermatthieuNo ratings yet

- Basket 1159913 DataDocument13 pagesBasket 1159913 DataMartin SuchomelNo ratings yet

- Maternal and Infant Care Beliefs Aeta Mothers in PhilippinesDocument8 pagesMaternal and Infant Care Beliefs Aeta Mothers in PhilippinesChristine Joy MolinaNo ratings yet

- En 12245 (2022) (E)Document9 pagesEn 12245 (2022) (E)David Chirinos100% (1)

- Naet Basic 15 GuideDocument6 pagesNaet Basic 15 Guidesissicarranza100% (1)