Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsOil Refineries

Oil Refineries

Uploaded by

Mishi KhanDifferent types of Refineries

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Case Study - Strategic Management - ChevronDocument66 pagesCase Study - Strategic Management - ChevronThanos PitatzisNo ratings yet

- Design and Development of 15ooobpd Modular RefineryDocument13 pagesDesign and Development of 15ooobpd Modular RefinerySamuel Hugos100% (3)

- IOCL Haldia Refinery Summer Training ReportDocument47 pagesIOCL Haldia Refinery Summer Training ReportAmit Datta70% (10)

- SHELL OIL CompanyDocument19 pagesSHELL OIL Companysonu_saisNo ratings yet

- Biggest ORDocument10 pagesBiggest ORexport importNo ratings yet

- Economy Brass Parts: Reliance Industries RefineryDocument3 pagesEconomy Brass Parts: Reliance Industries Refinery16SA125.KaranThakkarNo ratings yet

- Economy Brass Parts: Reliance Industries RefineryDocument3 pagesEconomy Brass Parts: Reliance Industries Refinery16SA125.KaranThakkarNo ratings yet

- Oman's Key IndustriesDocument9 pagesOman's Key IndustriesibrahimkhansahilNo ratings yet

- ReportDocument41 pagesReportGaurav ChawdaNo ratings yet

- GFTDocument15 pagesGFTMeera PanchalNo ratings yet

- Barauni RefineryDocument10 pagesBarauni RefineryRajiv KalraNo ratings yet

- IOCL Complete ReportDocument43 pagesIOCL Complete ReportSanjiv KumarNo ratings yet

- Global Major Oil & Gas FieldsDocument6 pagesGlobal Major Oil & Gas FieldsG Vishwanath ReddyNo ratings yet

- Iocl ProfileDocument20 pagesIocl ProfileNupur Rajendra PanditNo ratings yet

- WPC Guide To Petrochemicals and Refining - FinalDocument116 pagesWPC Guide To Petrochemicals and Refining - FinalvasucristalNo ratings yet

- Our Company OrpicDocument6 pagesOur Company OrpicErik AlfiandyNo ratings yet

- Iocl Haldia ReportDocument99 pagesIocl Haldia ReportSnehasisDasNo ratings yet

- INDIAN OI1 LAtestDocument101 pagesINDIAN OI1 LAtestTruly SelenatorNo ratings yet

- Coal BedDocument17 pagesCoal BedPRIYAH CoomarasamyNo ratings yet

- Top Oil & Gas CompaniesDocument7 pagesTop Oil & Gas CompaniesUtpalSahaNo ratings yet

- The Success of ShellDocument12 pagesThe Success of ShellAyezza Margarette BaranganNo ratings yet

- 337TO 003 World's Largest FLNG PreludeDocument9 pages337TO 003 World's Largest FLNG PreludeRamNo ratings yet

- Summer Project OilDocument84 pagesSummer Project OilAbhishek GuptaNo ratings yet

- Indian Oil Corporation LTDDocument11 pagesIndian Oil Corporation LTDsaz786chemicalNo ratings yet

- Iocl Summer Training ReportDocument67 pagesIocl Summer Training Reportrahulmayank71% (7)

- ArlDocument68 pagesArlAtta Ur Rehman100% (1)

- Oil Refinery - WikipediaDocument23 pagesOil Refinery - WikipediaArjit Kumar100% (1)

- Reliance PetroleumDocument15 pagesReliance PetroleumHarsh PatelNo ratings yet

- The Essar Group: A ProfileDocument10 pagesThe Essar Group: A ProfileewfsdNo ratings yet

- Oil and Gas Company ProfileDocument2 pagesOil and Gas Company ProfileChandrashekharCSKNo ratings yet

- Oil and Gas Company Profile PDFDocument2 pagesOil and Gas Company Profile PDFChandrashekharCSKNo ratings yet

- Final Report,,,ChevronDocument21 pagesFinal Report,,,ChevronemonenjoyNo ratings yet

- Functionalities of NalcoDocument26 pagesFunctionalities of NalcoSmrutiranjan ParidaNo ratings yet

- Nigerian Refineries - Histories, Problems and Possible SolutionDocument17 pagesNigerian Refineries - Histories, Problems and Possible Solutionmexx4u2nvNo ratings yet

- Expansions and New-Build Smelter ProjectsDocument4 pagesExpansions and New-Build Smelter ProjectsajaydhageNo ratings yet

- A Report On Institutional Training Undergone at Oil and Natural Gas Corporation (Ongc)Document55 pagesA Report On Institutional Training Undergone at Oil and Natural Gas Corporation (Ongc)muthurajNo ratings yet

- Ali DaDocument8 pagesAli DaBudhaditya GoswamiNo ratings yet

- Chevron at A GlanceDocument7 pagesChevron at A GlancebarclaybarrNo ratings yet

- API FinalDocument39 pagesAPI FinalMuhammad KhizerNo ratings yet

- I0c Training ReportDocument99 pagesI0c Training ReportmantelpokaNo ratings yet

- Reliance Petroleum LTDDocument65 pagesReliance Petroleum LTDneerajbajoliyaNo ratings yet

- Vocational Training Report, Indian Oil Corporation Limited, Gujarat RefineryDocument43 pagesVocational Training Report, Indian Oil Corporation Limited, Gujarat Refineryjhashashank26883% (12)

- Reliance Industrial Report)Document48 pagesReliance Industrial Report)Piyush AbhishekNo ratings yet

- LNG Brochure PDFDocument12 pagesLNG Brochure PDFrezarizqi09No ratings yet

- MBA Project 3rd Sem 1Document76 pagesMBA Project 3rd Sem 1prantideka20No ratings yet

- 2014 Saudi Aramco Facts FiguresDocument28 pages2014 Saudi Aramco Facts Figuresm.aNo ratings yet

- Oil Refinery PDFDocument28 pagesOil Refinery PDFHemant KumarNo ratings yet

- Oil RefineryDocument28 pagesOil RefineryHemant KumarNo ratings yet

- Who We Are: Board of DirectorsDocument12 pagesWho We Are: Board of DirectorsRam Krishn PandeyNo ratings yet

- Assignment On Shell LogisticsDocument7 pagesAssignment On Shell LogisticsAravind Sethumadhavan100% (1)

- Suncor EnergyDocument9 pagesSuncor EnergyVivarodNo ratings yet

- Iocl ReportDocument51 pagesIocl ReportChandanKumarSinghNo ratings yet

- GULFDocument33 pagesGULFJORDAN FREENo ratings yet

- FloatingDocument33 pagesFloatingJORDAN FREENo ratings yet

- IOCL Report 2011Document56 pagesIOCL Report 2011Ajay ShekhawatNo ratings yet

- Short HistoryDocument2 pagesShort HistoryMírŽʌ TʌłhʌNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- german application fee free universitiesDocument6 pagesgerman application fee free universitiesMishi KhanNo ratings yet

- List of Chemicals & MSDSDocument1 pageList of Chemicals & MSDSStansilous Tatenda NyagomoNo ratings yet

- Isenthalpic processDocument3 pagesIsenthalpic processMishi KhanNo ratings yet

- Experiment # 4: ObjectiveDocument2 pagesExperiment # 4: ObjectiveMishi KhanNo ratings yet

- LOM GuidelineDocument1 pageLOM GuidelineMishi KhanNo ratings yet

- 2k17che17 AssignmentDocument6 pages2k17che17 AssignmentMishi KhanNo ratings yet

- Bunker Requisition Form - VLCC1Document1 pageBunker Requisition Form - VLCC1shipdesigner088No ratings yet

- Rekap Hasil Analisa Batubara Mingguan PLTU Sulbagut-1 2 X 50 MWDocument1 pageRekap Hasil Analisa Batubara Mingguan PLTU Sulbagut-1 2 X 50 MWmuhbayusaputroiNo ratings yet

- Conventional Power Plants EUDocument137 pagesConventional Power Plants EUMadhusudhan SrinivasanNo ratings yet

- Oil and GasDocument7 pagesOil and GasMARYNo ratings yet

- CoalInventory 2019 PDFDocument25 pagesCoalInventory 2019 PDFg.subhadeep6890No ratings yet

- Specifications Guide: Americas Crude OilDocument21 pagesSpecifications Guide: Americas Crude OilAbdurahman JumaNo ratings yet

- Alcance Proyecto CartagenaDocument3 pagesAlcance Proyecto CartagenamarraezNo ratings yet

- M R I C, & P, I E: Petroleum Planning & Analysis CellDocument11 pagesM R I C, & P, I E: Petroleum Planning & Analysis CellSushobhan DasNo ratings yet

- Asia-Pacific/Arab Gulf Marketscan: Volume 39 / Issue 65 / April 2, 2020Document21 pagesAsia-Pacific/Arab Gulf Marketscan: Volume 39 / Issue 65 / April 2, 2020Donnie HavierNo ratings yet

- API 614 Lubrication, Shaft-Sealing, and Control-Oil Systems and Auxiliares For Petroleum, Chemical and Gas Industry ServicesDocument206 pagesAPI 614 Lubrication, Shaft-Sealing, and Control-Oil Systems and Auxiliares For Petroleum, Chemical and Gas Industry ServicesOzzy Fake100% (4)

- 10740-Tecna Caso: Mdm2015 Planta de Tratamiento de Crudo Borde Montuoso Vista O&G / Aleph MidstreamDocument1 page10740-Tecna Caso: Mdm2015 Planta de Tratamiento de Crudo Borde Montuoso Vista O&G / Aleph MidstreamsantiagoNo ratings yet

- Unconventional ResourcesDocument2 pagesUnconventional ResourcesTaimoor HassanNo ratings yet

- Overview Petrol Basins IndiaDocument22 pagesOverview Petrol Basins IndiaShilpa PatilNo ratings yet

- EPIC Shale Oil Presentation FINAL 4.13.151Document24 pagesEPIC Shale Oil Presentation FINAL 4.13.151Anonymous NmOXutCKNo ratings yet

- North OilDocument3 pagesNorth OilcassandraargentumNo ratings yet

- Petroleum Geology of PakistanDocument26 pagesPetroleum Geology of PakistanSyed Hashim HussainNo ratings yet

- Unit Tag No Description MakeDocument8 pagesUnit Tag No Description MakeAnkit PandeyNo ratings yet

- Active OperatorsDocument7 pagesActive OperatorsGhulam MurtazaNo ratings yet

- 2013 List of China's CBM Fields and CBM Bearing StructuresDocument2 pages2013 List of China's CBM Fields and CBM Bearing StructuresarapublicationNo ratings yet

- Oil World Production 2030Document53 pagesOil World Production 2030Alberto NavasNo ratings yet

- Amended OutturnDocument15 pagesAmended OutturnfpaulrrNo ratings yet

- Crude Oil GradesDocument5 pagesCrude Oil GradesibrahimkhansahilNo ratings yet

- Sandrea Mexico Paper July 2019 FINAL 1Document20 pagesSandrea Mexico Paper July 2019 FINAL 1civalerick549No ratings yet

- Meeting Mingguan Pembangunan Epf Lokasi Jati Asri, Akasia Bagus Dan Bambu BesarDocument38 pagesMeeting Mingguan Pembangunan Epf Lokasi Jati Asri, Akasia Bagus Dan Bambu BesarAditya FathurachmanNo ratings yet

- Fossil FuelDocument52 pagesFossil FuelRejean PadreNo ratings yet

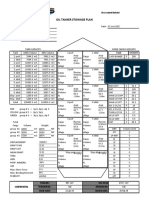

- Group 4 RDF 027 Oil Tanker Stowage Plan Rev 1.0 EditableDocument1 pageGroup 4 RDF 027 Oil Tanker Stowage Plan Rev 1.0 Editablegidjuns abs100% (1)

- Texcal Compro 2Document16 pagesTexcal Compro 2fitriyadi.bisnisNo ratings yet

- (DBBV) Reference ListDocument13 pages(DBBV) Reference ListCassy AbulenciaNo ratings yet

- Oil and Gas December 2023Document45 pagesOil and Gas December 2023akky.vns2004No ratings yet

- Refinery Balance PresentationDocument16 pagesRefinery Balance PresentationSiddharth sHARMANo ratings yet

Oil Refineries

Oil Refineries

Uploaded by

Mishi Khan0 ratings0% found this document useful (0 votes)

1 views8 pagesDifferent types of Refineries

Original Title

oil refineries

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDifferent types of Refineries

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views8 pagesOil Refineries

Oil Refineries

Uploaded by

Mishi KhanDifferent types of Refineries

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 8

Six largest oil refineries of the world

Petrochemicals can be found everywhere, from

the clothes we wear, our laptops and mobile

phones to cleaning products, fertilisers, and

packaging. As a report by the International Energy

Agency states, petrochemical feedstock is

responsible for 12 per cent of global oil

requirements, and this is set to grow as demand

for fertilisers, plastics, and other products

increases.

The sheer scale and complexity of refineries

involve astonishing feats of engineering and

require in-depth expertise from initial conception

straight through to commissioning and operation.

So where are 6 of the biggest refineries in the

world that contribute to making our world as we

know it?

Jamnagar Refinery, Reliance Industries – India

The Jamnagar Refinery, commissioned in July 1999,

is a private sector crude oil refinery and the largest

refinery in the world, with a capacity of 1.24 million

barrels of oil per day. It’s owned by Reliance

Industries Limited and is located in Jamnagar,

Gujarat, India.

The whole complex now consists of a fully

integrated petroleum refinery, a petrochemicals

complex, captive power plants, a captive port,

related infrastructure, and a small town that houses

its 2,500 employees and which has over 7,500 acres

of land. If one were to link all the pipes of the

refinery one after the other, they would link India

from North to South.

When it was completed by Bechtel in 2000, it was

already the largest ever petrochemical and refinery

complex in the world to be built from nothing. It

was then expanded in 2008, through an investment

of more than 6 billion USD, with a second adjacent

refinery, nearly doubling its initial capacity.

When construction was at its peak, the project

involved more than 70,000 employees. Bechtel also

created a virtual company that employed about

2,800 professionals across 19 offices worldwide.

Construction of the second refinery required more

than 200,000 supplier and engineering documents,

4 million metres of piping, over 1.5 million cubic

metres of concrete, and 4,400 pieces of major

equipment, whilst the worksite covered an area

bigger than London.

Ulsan Refinery, SK Energy – South Korea

The Ulsan Refinery, owned by SK Energy, is located

in Ulsan, South Korea. As of 2006, the refinery

reached a capacity of 1.12 million barrels per day. It

produces liquefied petroleum gas, gasoline, diesel,

jet fuel, and asphalt. The refinery and wider

business currently employ more than 2,600 people.

Ulsan is the country’s seventh largest metropolitan

city and is considered the powerhouse of South

Korea. It’s at the heart of the country’s Industrial

District.

On top of one of the world’s largest refineries,

Ulsan is home to the largest automobile assembly

plant in the world, operated by Hyundai Motor

Company and has the world’s largest shipyard,

operated by Hyundai Heavy Industries.

Paraguaná Refinery Complex, PDVSA – Venezuela

The Paraguaná Refinery Complex is a crude oil

refinery located in Venezuela, with a total

processing capacity of 971 thousand barrels a day.

It’s currently the third-largest oil refinery in the

world, after the Jamnagar and Ulsan refineries.

The whole complex was created by combining three

existing refineries: the Amuay Refinery, the Bajo

Grande Refinery, and the Cardón Refinery.

Operated by the state-owned company Petróleos

de Venezuela (PDVSA), the Paraguaná Refinery

Complex is responsible for 71 per cent of

Venezuela’s refining capacity.

The Cardon Refinery was owned by Shell and

started operations in 1949. The Amuay Refinery was

then built by Creole Petroleum in 1950 and the Bajo

Grande Refinery in 1956 by Richmond

(now Chevron). The combined crude oil processing

capacity of the Cardon and the Amuay refineries is

955,000 barrels per day, whilst the Bajo Grande

asphalt plant is capable of processing 16,000 barrels

per day of crude.

Yeosu Refinery, GS Caltex – South Korea

The Yeosu Refinery is the second biggest in South

Korea, with a total capacity of 730,000 barrels per

day. It’s operated by GS Caltex (jointly owned

by Chevron and GS Group) and produces gasoline,

diesel, jet fuel, fuel oil, and sulphur. GS Caltex

supplies more than one-third of Korea's oil needs

and exports more than 50% of its products.

In 2007, GS Caltex invested 1.5 billion USD to build,

what was at the time, the world’s largest vacuum

distillation unit, a hydrocracker, and base oil plant.

This dramatically increased GS Caltex's heavy-oil

cracking ability.

More recently, GS Caltex announced that it had

successfully switched from low-sulphur fuel oil

(LSFO) to liquified natural gas (LNG) for the

operation of the Yeosu refinery, in a bid to reduce

their CO2 emissions. They are expecting this

transition to reduce the refinery’s CO2 emissions by

over 19% and particular matter emissions (such as

sulphur oxides and nitrogen oxides) by more than

30%.

Onsan Refinery, S-Oil – South Korea

The Onsan Refinery, owned by S-Oil, is also located

in Ulsan in South Korea. It has a total processing

capacity of 669 thousand barrels per day.

S-Oil first started commercial operation of its crude

oil distillation unit in 1980. Since then, there have

been two expansions. S-Oil now has three crude

distillation units and have become a key player for

hard oil provision in the Asia-Pacific region.

In 2005, they also started exporting Ultra Low

Sulphur Gasoline (ULSG) of below 10ppm sulphur

contents to Japan, following strict environmental

regulations. S-Oil has focused a lot of its energy on

producing and exporting high-quality environment-

friendly oil products around the world, including

Europe, Asia, the US, and Oceania.

Singapore Refinery, ExxonMobil - Singapore

The Singapore Refinery, owned by ExxonMobil, has

a total processing capacity of 605 thousand barrels

per day. Located on Jurong Island in Singapore, it’s

ExxonMobil’s biggest refinery.

The refinery originally consisted of two sites

connected by pipelines. There was one refinery site

on Pioneer Road, which was commissioned by

Mobil in 1966. The other refining facility was

located at the Pulau Ayer Chawan site,

commissioned by Esso in 1970. When Esso and

Mobil merged in 1999 to become ExxonMobil, the

new company started operating both sites as a

single refinery complex.

There are currently plans for an expansion to

produce more higher-value lube products from fuel

oil. Final Investment Decision (FID) was made and

engineering, procurement, and construction

contracts for the expansion were awarded by

ExxonMobil in April 2019. This expansion is

expected to cost about 2.9 billion USD. Completion

is expected for 2023. Such an expansion will, of

course, create a whole host of new jobs for

engineers and other industry experts.

This expansion project will increase the refinery’s

low-sulphur clean fuel output by 48 thousand

barrels per day. It will also increase ExxonMobil’s

base stocks of high-quality automotive and engine

oil lubricants by 20 thousand barrels per day.

You might also like

- Case Study - Strategic Management - ChevronDocument66 pagesCase Study - Strategic Management - ChevronThanos PitatzisNo ratings yet

- Design and Development of 15ooobpd Modular RefineryDocument13 pagesDesign and Development of 15ooobpd Modular RefinerySamuel Hugos100% (3)

- IOCL Haldia Refinery Summer Training ReportDocument47 pagesIOCL Haldia Refinery Summer Training ReportAmit Datta70% (10)

- SHELL OIL CompanyDocument19 pagesSHELL OIL Companysonu_saisNo ratings yet

- Biggest ORDocument10 pagesBiggest ORexport importNo ratings yet

- Economy Brass Parts: Reliance Industries RefineryDocument3 pagesEconomy Brass Parts: Reliance Industries Refinery16SA125.KaranThakkarNo ratings yet

- Economy Brass Parts: Reliance Industries RefineryDocument3 pagesEconomy Brass Parts: Reliance Industries Refinery16SA125.KaranThakkarNo ratings yet

- Oman's Key IndustriesDocument9 pagesOman's Key IndustriesibrahimkhansahilNo ratings yet

- ReportDocument41 pagesReportGaurav ChawdaNo ratings yet

- GFTDocument15 pagesGFTMeera PanchalNo ratings yet

- Barauni RefineryDocument10 pagesBarauni RefineryRajiv KalraNo ratings yet

- IOCL Complete ReportDocument43 pagesIOCL Complete ReportSanjiv KumarNo ratings yet

- Global Major Oil & Gas FieldsDocument6 pagesGlobal Major Oil & Gas FieldsG Vishwanath ReddyNo ratings yet

- Iocl ProfileDocument20 pagesIocl ProfileNupur Rajendra PanditNo ratings yet

- WPC Guide To Petrochemicals and Refining - FinalDocument116 pagesWPC Guide To Petrochemicals and Refining - FinalvasucristalNo ratings yet

- Our Company OrpicDocument6 pagesOur Company OrpicErik AlfiandyNo ratings yet

- Iocl Haldia ReportDocument99 pagesIocl Haldia ReportSnehasisDasNo ratings yet

- INDIAN OI1 LAtestDocument101 pagesINDIAN OI1 LAtestTruly SelenatorNo ratings yet

- Coal BedDocument17 pagesCoal BedPRIYAH CoomarasamyNo ratings yet

- Top Oil & Gas CompaniesDocument7 pagesTop Oil & Gas CompaniesUtpalSahaNo ratings yet

- The Success of ShellDocument12 pagesThe Success of ShellAyezza Margarette BaranganNo ratings yet

- 337TO 003 World's Largest FLNG PreludeDocument9 pages337TO 003 World's Largest FLNG PreludeRamNo ratings yet

- Summer Project OilDocument84 pagesSummer Project OilAbhishek GuptaNo ratings yet

- Indian Oil Corporation LTDDocument11 pagesIndian Oil Corporation LTDsaz786chemicalNo ratings yet

- Iocl Summer Training ReportDocument67 pagesIocl Summer Training Reportrahulmayank71% (7)

- ArlDocument68 pagesArlAtta Ur Rehman100% (1)

- Oil Refinery - WikipediaDocument23 pagesOil Refinery - WikipediaArjit Kumar100% (1)

- Reliance PetroleumDocument15 pagesReliance PetroleumHarsh PatelNo ratings yet

- The Essar Group: A ProfileDocument10 pagesThe Essar Group: A ProfileewfsdNo ratings yet

- Oil and Gas Company ProfileDocument2 pagesOil and Gas Company ProfileChandrashekharCSKNo ratings yet

- Oil and Gas Company Profile PDFDocument2 pagesOil and Gas Company Profile PDFChandrashekharCSKNo ratings yet

- Final Report,,,ChevronDocument21 pagesFinal Report,,,ChevronemonenjoyNo ratings yet

- Functionalities of NalcoDocument26 pagesFunctionalities of NalcoSmrutiranjan ParidaNo ratings yet

- Nigerian Refineries - Histories, Problems and Possible SolutionDocument17 pagesNigerian Refineries - Histories, Problems and Possible Solutionmexx4u2nvNo ratings yet

- Expansions and New-Build Smelter ProjectsDocument4 pagesExpansions and New-Build Smelter ProjectsajaydhageNo ratings yet

- A Report On Institutional Training Undergone at Oil and Natural Gas Corporation (Ongc)Document55 pagesA Report On Institutional Training Undergone at Oil and Natural Gas Corporation (Ongc)muthurajNo ratings yet

- Ali DaDocument8 pagesAli DaBudhaditya GoswamiNo ratings yet

- Chevron at A GlanceDocument7 pagesChevron at A GlancebarclaybarrNo ratings yet

- API FinalDocument39 pagesAPI FinalMuhammad KhizerNo ratings yet

- I0c Training ReportDocument99 pagesI0c Training ReportmantelpokaNo ratings yet

- Reliance Petroleum LTDDocument65 pagesReliance Petroleum LTDneerajbajoliyaNo ratings yet

- Vocational Training Report, Indian Oil Corporation Limited, Gujarat RefineryDocument43 pagesVocational Training Report, Indian Oil Corporation Limited, Gujarat Refineryjhashashank26883% (12)

- Reliance Industrial Report)Document48 pagesReliance Industrial Report)Piyush AbhishekNo ratings yet

- LNG Brochure PDFDocument12 pagesLNG Brochure PDFrezarizqi09No ratings yet

- MBA Project 3rd Sem 1Document76 pagesMBA Project 3rd Sem 1prantideka20No ratings yet

- 2014 Saudi Aramco Facts FiguresDocument28 pages2014 Saudi Aramco Facts Figuresm.aNo ratings yet

- Oil Refinery PDFDocument28 pagesOil Refinery PDFHemant KumarNo ratings yet

- Oil RefineryDocument28 pagesOil RefineryHemant KumarNo ratings yet

- Who We Are: Board of DirectorsDocument12 pagesWho We Are: Board of DirectorsRam Krishn PandeyNo ratings yet

- Assignment On Shell LogisticsDocument7 pagesAssignment On Shell LogisticsAravind Sethumadhavan100% (1)

- Suncor EnergyDocument9 pagesSuncor EnergyVivarodNo ratings yet

- Iocl ReportDocument51 pagesIocl ReportChandanKumarSinghNo ratings yet

- GULFDocument33 pagesGULFJORDAN FREENo ratings yet

- FloatingDocument33 pagesFloatingJORDAN FREENo ratings yet

- IOCL Report 2011Document56 pagesIOCL Report 2011Ajay ShekhawatNo ratings yet

- Short HistoryDocument2 pagesShort HistoryMírŽʌ TʌłhʌNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- german application fee free universitiesDocument6 pagesgerman application fee free universitiesMishi KhanNo ratings yet

- List of Chemicals & MSDSDocument1 pageList of Chemicals & MSDSStansilous Tatenda NyagomoNo ratings yet

- Isenthalpic processDocument3 pagesIsenthalpic processMishi KhanNo ratings yet

- Experiment # 4: ObjectiveDocument2 pagesExperiment # 4: ObjectiveMishi KhanNo ratings yet

- LOM GuidelineDocument1 pageLOM GuidelineMishi KhanNo ratings yet

- 2k17che17 AssignmentDocument6 pages2k17che17 AssignmentMishi KhanNo ratings yet

- Bunker Requisition Form - VLCC1Document1 pageBunker Requisition Form - VLCC1shipdesigner088No ratings yet

- Rekap Hasil Analisa Batubara Mingguan PLTU Sulbagut-1 2 X 50 MWDocument1 pageRekap Hasil Analisa Batubara Mingguan PLTU Sulbagut-1 2 X 50 MWmuhbayusaputroiNo ratings yet

- Conventional Power Plants EUDocument137 pagesConventional Power Plants EUMadhusudhan SrinivasanNo ratings yet

- Oil and GasDocument7 pagesOil and GasMARYNo ratings yet

- CoalInventory 2019 PDFDocument25 pagesCoalInventory 2019 PDFg.subhadeep6890No ratings yet

- Specifications Guide: Americas Crude OilDocument21 pagesSpecifications Guide: Americas Crude OilAbdurahman JumaNo ratings yet

- Alcance Proyecto CartagenaDocument3 pagesAlcance Proyecto CartagenamarraezNo ratings yet

- M R I C, & P, I E: Petroleum Planning & Analysis CellDocument11 pagesM R I C, & P, I E: Petroleum Planning & Analysis CellSushobhan DasNo ratings yet

- Asia-Pacific/Arab Gulf Marketscan: Volume 39 / Issue 65 / April 2, 2020Document21 pagesAsia-Pacific/Arab Gulf Marketscan: Volume 39 / Issue 65 / April 2, 2020Donnie HavierNo ratings yet

- API 614 Lubrication, Shaft-Sealing, and Control-Oil Systems and Auxiliares For Petroleum, Chemical and Gas Industry ServicesDocument206 pagesAPI 614 Lubrication, Shaft-Sealing, and Control-Oil Systems and Auxiliares For Petroleum, Chemical and Gas Industry ServicesOzzy Fake100% (4)

- 10740-Tecna Caso: Mdm2015 Planta de Tratamiento de Crudo Borde Montuoso Vista O&G / Aleph MidstreamDocument1 page10740-Tecna Caso: Mdm2015 Planta de Tratamiento de Crudo Borde Montuoso Vista O&G / Aleph MidstreamsantiagoNo ratings yet

- Unconventional ResourcesDocument2 pagesUnconventional ResourcesTaimoor HassanNo ratings yet

- Overview Petrol Basins IndiaDocument22 pagesOverview Petrol Basins IndiaShilpa PatilNo ratings yet

- EPIC Shale Oil Presentation FINAL 4.13.151Document24 pagesEPIC Shale Oil Presentation FINAL 4.13.151Anonymous NmOXutCKNo ratings yet

- North OilDocument3 pagesNorth OilcassandraargentumNo ratings yet

- Petroleum Geology of PakistanDocument26 pagesPetroleum Geology of PakistanSyed Hashim HussainNo ratings yet

- Unit Tag No Description MakeDocument8 pagesUnit Tag No Description MakeAnkit PandeyNo ratings yet

- Active OperatorsDocument7 pagesActive OperatorsGhulam MurtazaNo ratings yet

- 2013 List of China's CBM Fields and CBM Bearing StructuresDocument2 pages2013 List of China's CBM Fields and CBM Bearing StructuresarapublicationNo ratings yet

- Oil World Production 2030Document53 pagesOil World Production 2030Alberto NavasNo ratings yet

- Amended OutturnDocument15 pagesAmended OutturnfpaulrrNo ratings yet

- Crude Oil GradesDocument5 pagesCrude Oil GradesibrahimkhansahilNo ratings yet

- Sandrea Mexico Paper July 2019 FINAL 1Document20 pagesSandrea Mexico Paper July 2019 FINAL 1civalerick549No ratings yet

- Meeting Mingguan Pembangunan Epf Lokasi Jati Asri, Akasia Bagus Dan Bambu BesarDocument38 pagesMeeting Mingguan Pembangunan Epf Lokasi Jati Asri, Akasia Bagus Dan Bambu BesarAditya FathurachmanNo ratings yet

- Fossil FuelDocument52 pagesFossil FuelRejean PadreNo ratings yet

- Group 4 RDF 027 Oil Tanker Stowage Plan Rev 1.0 EditableDocument1 pageGroup 4 RDF 027 Oil Tanker Stowage Plan Rev 1.0 Editablegidjuns abs100% (1)

- Texcal Compro 2Document16 pagesTexcal Compro 2fitriyadi.bisnisNo ratings yet

- (DBBV) Reference ListDocument13 pages(DBBV) Reference ListCassy AbulenciaNo ratings yet

- Oil and Gas December 2023Document45 pagesOil and Gas December 2023akky.vns2004No ratings yet

- Refinery Balance PresentationDocument16 pagesRefinery Balance PresentationSiddharth sHARMANo ratings yet