Professional Documents

Culture Documents

Alloy MAster Link

Alloy MAster Link

Uploaded by

Kailin JuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alloy MAster Link

Alloy MAster Link

Uploaded by

Kailin JuCopyright:

Available Formats

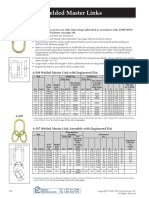

Alloy Master Links

Ratings below are for use with chain slings fabricated in accordance

A-342 with ASME B30.9. For other applications, see page 159. A-345

• Alloy Steel – Quenched and Tempered.

• Individually Proof Tested with certification. (See page 159 for Proof Test values.)

• Proof Tested with 60% inside width special fixtures sized to prevent localized

point loading per ASTM A-952. Reference page 269.

• Meets or exceeds all requirements of ASME B30.26 including identification,

ductility, design factor, proof load and temperature requirements.

Importantly, these links meet other critical performance requirements

including fatigue life, impact properties and material traceability, not

addressed by ASME B30.26.

• Forgings have a Product Identification Code (PIC) for material traceability,

along with the size, the name Crosby and USA in raised lettering.

• Selected sizes designated with “W” in the size column have enlarged inside

dimensions to allow additional room for sling hardware and crane hook.

• Incorporates patented QUIC-CHECK® deformation indicators.

A-342 Alloy Master Links

Dimensions

Size Chain Size Single Leg Double Leg (in.)

WLL WLL

WLL WLL Based on Based on

Based on Based on Grade 80 Grade 100

A-342 Weight Grade 80 Grade 100 Chain 60° Chain 60°

Accessories

Stock Each Chain Chain Sling Angle Sling Angle Deformation

Chain &

(in.) (mm) No. (lbs.) (in.) (mm) (lbs.)* (lbs.)* (lbs.)* (lbs.)* A B C Indicator

1/4 7 3500 4300 6100 7400

1/2W 13W 1014266 1.3 .62 2.80 5.00 3.50

5/16 8 4500 5700 - -

5/8 16 1014280 1.5 5/16 8 4500 5700 7800 - .62 3.00 6.00 3.50

5/16 8 4500 5700 - 9900

3/4W 19W 1014285 2.0 .73 3.20 6.00 4.00

3/8 10 7100 8800 12300 -

3/8 10 7100 8800 12300 15200

7/8W 22W 1014319 3.3 .88 3.75 6.38 4.50

1/2 13 12000 15000 - -

1/2 13 12000 15000 20800 26000

1W 26W 1014331 6.1 1.10 4.30 7.50 5.50

5/8 16 18100 22600 - -

5/8 16 18100 22600 31300 39100

1-1/4W 32W 1014348 12.0 1.33 5.50 9.50 7.00

3/4 20 28300 35300 - -

3/4 20 28300 35300 49000 61100

1-1/2W 38W 1014365 18.6 1.61 5.90 10.50 7.50

7/8 22 34200 42700 - -

7/8 22 - - 59200 74000

1-3/4 44 1014388 25.2 1.75 6.00 12.00 7.50

1 26 47700 59700 - -

1 26 - - 82600 103400

2 51 1014404 37.0 2.00 7.00 14.00 9.00

1-1/4 32 72300 90400 - -

2-1/4 57 1014422 54.1 1-1/4 32 - - 125200 - 2.25 8.00 16.00 10.00

2-1/2 63 1014468 68.5 1-1/4 32 72300 90400 125200 156600 2.5 8.38 16.00 11.00

* Chain slings require that the Minimum Ultimate Load be 4 times the Working Load Limit. Refer to page 159 to determine products actual

Ultimate Load. Proof Test Load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9-1.4 for the chain size and number

of legs. See chart on page 234 for other sling angles.

A-345 Master Link Assembly with Engineered Flat for Use with S-1325A coupler link

Three and Dimensions

Size Chain Size Four Leg Sling (in.)

WLL WLL

Based on Based on

Grade 80 Grade 100

Chain Chain Engineered

A-345 Weight 60° Sling 60° Sling Flat for

Stock Each Angle Angle Deformation S-1325

(in.) (mm) No. (lbs.) (in.) (mm) (lbs.)* (lbs.)* A B C D E F G Indicator (in.) — (mm)

3/4W 19W 1014739 3.51/4 7 9100 11200 .73 3.20 6.00 .56 3.35 1.77 .30 4.00 1/4”-5/16”, 7-8mm

7/8W 22W 1014742 4.8

5/16 8 11700 14800 .88 3.75 6.38 .56 3.35 1.77 .30 4.50 -

1W 26W 1014766 9.33/8 10 18400 22900 1.10 4.30 7.50 .75 3.94 2.36 .33 5.50 3/8”, 10mm

1-1/4W 32W 1014779 15.8

1/2 13 31200 39000 1.33 5.50 9.50 1.00 6.30 3.54 .51 7.00 1/2”, 13mm

1-1/2W 38W 1014807 34.1

5/8 16 47000 58700 1.61 5.90 10.50 1.25 7.09 3.94 .65 7.50 5/8”, 16mm

1-3/4 44 1014810 46.7

3/4 20 73500 91700 1.75 6.00 12.00 1.50 6.00 4.00 - 7.50 No Flat

7/8 22 88900 110900 2.25 8.00 16.00 1.88 8.00 5.50 - 10.00 No Flat

2-1/4 57 1014845 97

1 26 123900 155100 2.25 8.00 16.00 1.88 8.00 5.50 - 10.00 No Flat

3-1/4 83 1014986 255 1-1/4 32 187800 234900 3.25 10.00 20.00 2.50 11.25 8.00 - 13.50 No Flat

* Chain slings require that the Minimum Ultimate Load be 4 times the Working Load Limit. Refer to page 159 to determine products actual Ultimate Load. Proof Test

Load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9-1.4 for the chain size and number of legs. See chart on page 234 for other sling angles.

Copyright © 2013 The Crosby Group LLC 237

All Rights Reserved

You might also like

- MSDS For PN 3000671, Beacon Replacement Kit (Part 1) PDFDocument15 pagesMSDS For PN 3000671, Beacon Replacement Kit (Part 1) PDFAndrianoNo ratings yet

- 2016 Colorado Design Snow LoadsDocument108 pages2016 Colorado Design Snow LoadsKevin Nathaniel100% (1)

- A 906 - A 906m - 99 - Qtkwni9bota2ts1sruqDocument8 pagesA 906 - A 906m - 99 - Qtkwni9bota2ts1sruqZam DresNo ratings yet

- Axial Piston Pumps For Open Circuits in Mobile, Industrial and Marine ApplicationsDocument36 pagesAxial Piston Pumps For Open Circuits in Mobile, Industrial and Marine ApplicationsKamal Solanki100% (1)

- Proof Coil Chain Grade 30: Working Load Limit: 800 To 10,600 LbsDocument1 pageProof Coil Chain Grade 30: Working Load Limit: 800 To 10,600 LbsCristhian TaipeNo ratings yet

- Engineering Chains For The Sugar Mill IndustryDocument52 pagesEngineering Chains For The Sugar Mill IndustryJEARGTO123100% (1)

- 15 KV Cable Data SheetDocument8 pages15 KV Cable Data SheetanilNo ratings yet

- FT Eslabon Maestro A342Document1 pageFT Eslabon Maestro A342fernando.solarNo ratings yet

- N Product Overview: Y-H Series Three Phase Marine Asynchronous Motor (Frame Size80 355)Document10 pagesN Product Overview: Y-H Series Three Phase Marine Asynchronous Motor (Frame Size80 355)Tutunaru SergNo ratings yet

- Victaulic OGS-200 Grooved End Fittings: 1.0 Product DescriptionDocument13 pagesVictaulic OGS-200 Grooved End Fittings: 1.0 Product DescriptionCinthya Yesenia Cruz MedinaNo ratings yet

- Gear Pumps: Product RangeDocument4 pagesGear Pumps: Product RangeEng-Mohammed SalemNo ratings yet

- 76 Herc Alloy Chain 800 BrochureDocument1 page76 Herc Alloy Chain 800 BrochuredhaniezhanNo ratings yet

- A342 Alloy Master LinkDocument4 pagesA342 Alloy Master LinkKailin JuNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetAbdelaziz RagabNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetHilman NabilNo ratings yet

- FUSE03Document1 pageFUSE03PukraDastNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetluaiNo ratings yet

- Calculations Based On Motor HPDocument4 pagesCalculations Based On Motor HPAhmed SweetNo ratings yet

- MasterlinkDocument1 pageMasterlinkAndreyNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheetkiki270977No ratings yet

- Master Rigger Reference Material: Crane Institute CertificationDocument3 pagesMaster Rigger Reference Material: Crane Institute CertificationKintali VinodNo ratings yet

- Cable Sizing Calculations.Document4 pagesCable Sizing Calculations.Shijumon KpNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetAudi TresnawanNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetAriel DimacaliNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetSudara RandombageNo ratings yet

- Calculations Based On Motor HPDocument4 pagesCalculations Based On Motor HPNaim ZeinounNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetBernadette SimbahanNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheethimachalam baluNo ratings yet

- Calculations Based On Motor HPDocument4 pagesCalculations Based On Motor HPafaqueNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetMohammad Ather SiddiquiNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetAlamgir ReazNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheetkoyangi jagiyaNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetShubham BaderiyaNo ratings yet

- Grade 30 Proof Coil ChainDocument1 pageGrade 30 Proof Coil Chainrisiana_limuriaNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheetarun kumarNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetAbdul ajisNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetJAIDEEP BNNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetsdgafgafdhadNo ratings yet

- Material HandlingDocument10 pagesMaterial HandlingEric BaretteNo ratings yet

- Cable Size Calculations: Input Data Calculated ValuesDocument4 pagesCable Size Calculations: Input Data Calculated ValuesMark DomalaonNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetRichard TorrivillaNo ratings yet

- Cable Size Calculations: Input Data Calculated ValuesDocument4 pagesCable Size Calculations: Input Data Calculated ValuesAkashGauravNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetYsun Herrera BacaniNo ratings yet

- Calculations Based On Motor HP Cable-Size-SpreadsheetDocument4 pagesCalculations Based On Motor HP Cable-Size-SpreadsheetIwan TristiawanNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetRichard AGNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheetashish yadavNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheetpradeep.selvarajan100% (1)

- Cable Size CalculationsDocument4 pagesCable Size CalculationsDiego BurneoNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheeterwin pumayNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetSravan SimhadriNo ratings yet

- Calculations Based On Motor HPDocument4 pagesCalculations Based On Motor HPAsif Zahidul HaqNo ratings yet

- Conditioned Cut Wire: For Shot Peening ApplicationsDocument2 pagesConditioned Cut Wire: For Shot Peening ApplicationsAshok MalkudNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetRajendra LabadeNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheetbram87No ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations Spreadsheetamerinvest007No ratings yet

- Calculations Based On Motor HPDocument4 pagesCalculations Based On Motor HPAqua TechNo ratings yet

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetRicardo MCNo ratings yet

- 6.2 Cable Size Calculations SpreadsheetDocument4 pages6.2 Cable Size Calculations SpreadsheetMijba TalukderNo ratings yet

- Cable Size CalculatorDocument4 pagesCable Size CalculatorRashid Akbar KaimKhaniNo ratings yet

- Calculations Based On Motor HPDocument4 pagesCalculations Based On Motor HPDessouki Samak100% (1)

- Cable Size Calculations SpreadsheetDocument4 pagesCable Size Calculations SpreadsheetkhalidNo ratings yet

- Takeuchi TB216 SlabCalcs - GOODDocument34 pagesTakeuchi TB216 SlabCalcs - GOODKailin JuNo ratings yet

- Calculation Lateral Force - Screw Jack - KJDocument3 pagesCalculation Lateral Force - Screw Jack - KJKailin JuNo ratings yet

- 1.3.1 Brokk 110 - SlabCalcs - GOODDocument28 pages1.3.1 Brokk 110 - SlabCalcs - GOODKailin JuNo ratings yet

- Lateral Soil Pressure - Example - KJDocument4 pagesLateral Soil Pressure - Example - KJKailin JuNo ratings yet

- Bracket Facrication DrawingDocument1 pageBracket Facrication DrawingKailin JuNo ratings yet

- Demo Plan Requirements CommDocument112 pagesDemo Plan Requirements CommKailin JuNo ratings yet

- Application of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectDocument7 pagesApplication of Buoyancy-Power Generator For Compressed Air Energy Storage Using A Fluid-Air Displacement System - ScienceDirectJoel Stanley TylerNo ratings yet

- Halimatus Islamiah Analisis Jurnal Internasional K3Document3 pagesHalimatus Islamiah Analisis Jurnal Internasional K3TussNo ratings yet

- StatementOfAccount 6316692309 21072023 222045Document17 pagesStatementOfAccount 6316692309 21072023 222045Asekar AlagarsamyNo ratings yet

- Rikki Tikki Tavi Story Lesson PlanDocument3 pagesRikki Tikki Tavi Story Lesson Planapi-248341220No ratings yet

- ESSAYDocument7 pagesESSAYKaren OliveraNo ratings yet

- Themelis Ulloa LandfillDocument15 pagesThemelis Ulloa LandfillHenry Bagus WicaksonoNo ratings yet

- 11a - Advanced - Turkish Grammar - NotesDocument79 pages11a - Advanced - Turkish Grammar - Notesfardousa ibNo ratings yet

- Oma TS MLP V3 - 2 20110719 ADocument128 pagesOma TS MLP V3 - 2 20110719 AkennychanklNo ratings yet

- Factory Physics PrinciplesDocument20 pagesFactory Physics Principlespramit04100% (1)

- Arithmetic 1Document15 pagesArithmetic 1arman malikNo ratings yet

- DorkDocument5 pagesDorkJeremy Sisto ManurungNo ratings yet

- LG+47ln5700 47ln570t 47ln570y 47ln5710 Chassis lb33bDocument119 pagesLG+47ln5700 47ln570t 47ln570y 47ln5710 Chassis lb33bmidominguez0% (1)

- EXAM COG-622: IBM Cognos 10 BI AdministratorDocument16 pagesEXAM COG-622: IBM Cognos 10 BI AdministratorSaptarshi Dey0% (1)

- Telegram DocumeDocument21 pagesTelegram Documemilli birhanuNo ratings yet

- CyberbullyingDocument8 pagesCyberbullyingapi-433558817No ratings yet

- Gershwin George Rhapsody in Blue For Sax Quartet 64734Document113 pagesGershwin George Rhapsody in Blue For Sax Quartet 64734Jessica HowardNo ratings yet

- Comfort ZoneDocument4 pagesComfort Zonesigal ardanNo ratings yet

- Kepler Problem - Wikipedia, The Free Encyclopedia PDFDocument4 pagesKepler Problem - Wikipedia, The Free Encyclopedia PDFrizal123No ratings yet

- DAPA Teams Spider DiagramDocument2 pagesDAPA Teams Spider DiagramEduardoJaimeNo ratings yet

- 1.2 FMCC221 - Introduction To International Businesss - Part 1Document19 pages1.2 FMCC221 - Introduction To International Businesss - Part 1Bernie D. TeguenosNo ratings yet

- ManualeDelphi IngleseDocument86 pagesManualeDelphi IngleseoxooxooxoNo ratings yet

- Bayley ReviewDocument12 pagesBayley ReviewagNo ratings yet

- Ascariasis Ada GambarDocument4 pagesAscariasis Ada GambarninaNo ratings yet

- Jobdesc Project Officer Intern TRACK SDGsDocument2 pagesJobdesc Project Officer Intern TRACK SDGssocmed gistiNo ratings yet

- Natural Gas - Pipe SizingDocument6 pagesNatural Gas - Pipe SizinglekakasNo ratings yet

- L550 19MY MB XC-EN V1j DX PDFDocument88 pagesL550 19MY MB XC-EN V1j DX PDFAnonymous gMgeQl1SndNo ratings yet

- ME-458 Turbomachinery: Muhammad Shaban Lecturer Department of Mechanical EngineeringDocument113 pagesME-458 Turbomachinery: Muhammad Shaban Lecturer Department of Mechanical EngineeringAneeq Raheem50% (2)

- In Re Plagiarism Case Against Justice Del CastilloDocument112 pagesIn Re Plagiarism Case Against Justice Del CastilloRaffyLaguesmaNo ratings yet

- Quiz For Western Lit.Document25 pagesQuiz For Western Lit.donnie4workingNo ratings yet