Professional Documents

Culture Documents

POLYQuikP 480

POLYQuikP 480

Uploaded by

Robin carcamoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

POLYQuikP 480

POLYQuikP 480

Uploaded by

Robin carcamoCopyright:

Available Formats

Technical POLYQuik® P-480

Data Sheet Fast-setting Polyurea Coating

DESCRIPTION

POLYQuik® P-480 is a two-component, aromatic, sprayable, polyurea, elastomeric coating. It is used as a chemical-resistant,

waterproof, protective coating for both vertical and horizontal surfaces. It is resistant to corrosion and many chemicals,

including hydrogen sulfide, acids and hydrocarbon solvents. Use POLYQuik® P-480 where regular thermal or dynamic

movement is expected.

WHERE TO USE PACKAGING COLOR

• Primary and Secondary Containment 5-gal. pails (18.9L) Black, Gray, Tan

• Waterproofing–above or below grade 50-gal. drum (189 L)

*More colors and packaging options may be available. Contact your WVCO

• Wastewater–meets requirements of LA County representative and refer to the color palate for more information.

Willamette Valley • Protective Coatings–for concrete, wood, metal, steel YIELD

Company FEATURES AND BENEFITS 5-gallon bucket set (10 gal total) = 0.67 ft3

• Superior properties –excellent crack-bridging 50-gallon drum set (100 gal total) = 13.36 ft3

www.wilvaco.com Sprayed Yield*: 26 ft2 per gal or 3.8 gal per 100 ft2 at 60

• Two-component cure –sets in seconds

mil DFT(0.63 m2 per L at 1.5 mm DFT)

800.333.9826 • Serviceable within 1 hour –reduces facility downtime *assumes 100% transfer

• Excellent chemical resistance SHELF LIFE

SPECIFICATION COMPLIANCE AND APPROVALS 1 year when properly stored.

• Los Angeles County Sanitation (Grade 3 Redner test) STORAGE

• Washington Dept. of Ecology Toxicity Test (Pass) Store and ship this product in a clean, dry, low-humidity,

Partnering through • Dept. of Environmental Protection (Florida Approved) shaded or covered environment at 60 to 90° F (15 to 32° C).

service, innovation, and

integrity

TECHNICAL INFORMATION

Typical Properties Geomembrane Properties (GEOTEX® 1201 nonwoven)

VOC, lbs/gal (g/L), ASTM D 2369 0

Grab tensile strength, lbs (MPa), ASTM d751 653 (4.4)

Viscosity, cps, ASTM D 4878, resin / iso 500 / 400

-26 to 180 Grab elongation, %, ASTM D751 64

Service temperature, ° F (° C) (-32 to 82)

Immersion test for liners, Transformer oil, EPA Pass

Gel time, sec 6 9090A

Tack-free time, sec 30 Moisture vapor transmission, 1.1x10-8

cm/s (Perms), ASTM E 96 water method at 94 mils (1.6)

Tensile*, psi (MPa), ASTM D 412 2,500 (17)

Puncture resistance, lbs (kg), ASTM D 4833 233 (105)

Elongation*, %, ASTM D 412 480

Soil burial test, retention of 95% of properties, Pass

Hardness, Shore D, ASTM D 2240 45 ASTM D 3083

Tear*, pli (kN/m), ASTM D 1938 270 (47) Trapezoid tear, lbs (kg), ASTM D 4533 207 (94)

Tear Die C*, pli (kN/m), ASTM D 624 410 (72)

Processing Parameters

Abrasion resistance mg lost, H-18 wheel, 1kg, 1k 298

cycles, ASTM D 4060 Ratio by volume 1:1

Concrete adhesion, psi (MPa), ASTM D 4541 350 (2.4)

Application temp, ° F (° C) 20 to 120 (-7 to 50)

Crack bridging, 1/8" at 60 mils, ASTM C 836 Pass

Hydrostatic pressure, ASTM D 5385, Recommended thick., mils (mm) 20 to 125 (0.5 to 3.0)

231 (70)

0.060 in.(1.5mm); feet (meter) of water Heated Plural Component

Moisture vapor transmission g/24hr/m2 (Perms), 3.3 Meter equipment (30 Mesh Y-Strainer

ASTM E96, Desic. Method 90 mils or 2.2mm (0.48) Screens)

Puncture resistance*, lbs (kg), ASTM D 4833 130 (59) Impingement (40 Mesh

Gun requirement

Screens)

Discolors with no

UV resistance, ASTM C1442 Xenon Arc physical changes Spray pressure, psi (MPa) 2,000 to 3,000

(13.6 to 20.4)

*Properties achieved using specific dispensing equipment – Spray temperature, 150 to 180 (65 to 82)

Contact WVCO for more information. primary heaters and hose, °F (° C)

WILLAMETTE VALLEY COMPANY

APPLICATION www.wilvaco.com

SURFACE PREPARATION 3. Recommended geotextiles include: GEOTEX 1201 and GEOTEX 2x2HF info@wilvaco.com

CONCRETE (spray P-480 on the black side).

1. Priming is recommended; prime with POLYQuik® PolyPrime or other PROCESSING DIVISIONS

suitable primer. Contact WVCO representative for primer options, 1. Precondition material to at least 70°F (21°C) for 24 hours. Secure an

technical recommendations and before using on surfaces intended for air driven mixer with 3 folding blades in the center bung hole of the

WESTERN DIVISION

immersion service. Refer to primer technical data sheet for application and drum. Air driven mixer blade configuration: 8”blade - bottom, 6” blade -

cure time information. middle, and a 6” blade - top. Ensure the mixer is spinning clockwise at

1075 Arrowsmith Street

2. The surface being coated must be fully cured (28 days minimum), a speed adequate enough to thoroughly mix the resin. Mix for 30 PO Box 2280

structurally sound (200 psi or greater tensile strength according to ASTM minutes before spraying. Repeat above mixing instructions after every Eugene, OR 97402

D 7234), clean (ASTM D 4258), and dry (less than 5% surface moisture, 4 hours of operation. Avoid mixing for more than 30 minutes as air Tel 541.484.9621

ASTM E1907 and D4263). may become entrapped in the resin. Mixers are available through www.POLYQUIK.com

3. The surface must have low moisture vapor transmission (less than 3 lb/24 WVCO Precision Technologies. www.SPIKEFAST.com

hr/1000 ft2, RMA Test Method). 2. P-480 must be sprayed with a high pressure plural-component

4. Do not apply over concrete if vapor barrier is not present or unknown. proportioner. Contact WVCO representative for plural component EASTERN DIVISION

5. Profile surface according to ICRI Guide 03732 to a minimum of CSP 3 by proportioner recommendations and configurations. Proportioner should 6662 Marbut Road

abrasive blasting or hydroblasting. Remove contaminants before blasting. be able to heat resin and iso to 150-180°F (65-82°C).

Lithonia, GA 30058

6. Fill all voids and cracks between 0.06-0.50” (1.5-12.5 mm) with suitable 3. Proportioner must generate a minimum spray pressure of 2,000 psi

concrete filler. Contact your WVCO representative for filler options and (13.8 MPa), maintain a stable pressure during spray and keep minimal Tel 888.878.9826

technical recommendations. pressure differential between resin and iso – no more than 300 psi –

MIDWEST DIVISION

STEEL & OTHER METALS during application.

1. Steel and other metal surfaces must be cleaned before blasting according 4. Contact WVCO representative for high and low output application 1549 Hwy 2

to SSPC-SP1. Remove any sharp edges, weld splatters and other surface equipment. Equivalent applicator setups from other manufacturers are Two Harbors, MN 55616

imperfections. available. CAUTION: APPLICATOR OUTPUT MUST NOT EXCEED 75% Tel 218.834.3922

2. Blast according to SSPC-SP10 / NACE No. 2 Near White standard (0.003” OF METER OUTPUT.

(0.08 mm) profile). APPLICATION PRECISION TECHNOLOGIES DIVISION

3. Test the surface for non-visible soluble salt contamination according to 1. If priming, prime according to Surface Preparation guidelines. Refer to 675 McKinley Street

NACE 6G186. If necessary treat the surface with CHLOR*RID or primer technical data sheet for application and cure time information. Eugene, OR 97402

equivalent chloride remover until less than 3 mg/cm2 is detected. 2. Avoid blisters and poor adhesion by not applying coating when the Tel 541.484.2368

4. STEEL - Properly prepared steel does not require primer for some humidity is above 85%. Apply the coating when the substrate www.pre-tec.com

applications. Contact your WVCO representative before electing this temperature is stable or dropping. Minimize out-gassing and pinholes

option, as priming may be recommended for your application. Apply P-480 on concrete with primers, and with multiple thin applications of coating

SOUTHERN DIVISION

only if steel surface temperature is 5°F (3°C) above the dew point to avoid (10 mils or less per pass) on wood.

application over damp surface. Steel should be coated within the same 3. Clean surface of contaminants (i.e. dust, dirt). Surface may be blown 100 Dixie Mae Drive

day and before flash rusting reoccurs. with dry compressed air or tack cloth. PO Box 4450

5. PRIMING STEEL OR OTHER METALS – Apply POLYQuik® Epoxy Primer or 4. Spray P-480 in a consistent sweeping pattern, 15-20 mils per pass as a Pineville, Louisiana 71361

PolyPrime only if metal surface temperature is 5° F (3°C) above the dew general guideline and maintaining a consistent distance from the Tel 318.640.5077

point to avoid application over damp surface. Refer to primer technical substrate. ALWAYS START AND STOP SPRAYING OFF TARGET TO

data sheet for application and cure time information. Contact your WVCO AVOID BLISTERING. SUBSIDIARIES

representative for approval before using other primers or using on surfaces 5. Apply an optional texture coat over the surface to create a uniform

intended for immersion service. appearance. CANADIAN WILLAMETTE

6. For aluminum and galvanized metals, contact your WVCO representative 6. Recoat without surface preparation is possible within 12 hours of

19081- 27th Avenue

for additional information. application at 70°F (21°C). After 12 hours, mechanically abrade the

GEOTEXTILE SURFACES surface and clean with acetone or POLYQuik® Cleaner. Recoat with P-

Surrey BC V3S 5T1

1. P-480 is applied to the heat treated side of non-woven polypropylene 480 within one hour of cleaning. Tel. 800.663.4298

geotextiles. Choose the geotextile weight based on application. Contact 7. For color stability, aliphatic topcoats may be used. Contact WVCO

your WVCO Representative before using other types of geotextiles. representative for topcoat options and technical recommendations. ECLECTIC PRODUCTS INC.

Protect geotextile surfaces from damage before applying coating. CLEANING & MAINTENANCE Corporate Office

Minimize wrinkles when laying out geotextile. Only walk on geotextile • Use POLYQuik® Cleaner to clean applicators and parts after every use. 1075 Arrowsmith Street

while applying coating to prevent scuffing or frayed surfaces. Do not immerse the entire applicator in Cleaner. Eugene, OR 97402

2. Apply coating over entire geotextile before adhering it to perimeter • CLEAN Y-STRAINERS REGULARLY. Tel 541.284.4667

surfaces. Use the coating to bond geotextile to perimeter surface after • Contact WVCO representative for pump flushing and long term storage www.eclecticproducts.com

the entire area has cured for 60 minutes, or else bury the coated geotextile stability recommendations.

in a trench surrounding the application area. IDAHO MILL & GRAIN

445 North 430 West Hwy

HEALTH AND SAFETY PO Box188

Before handling, you should become familiar with the Material Safety Data Sheet (MSDS) regarding the risks and safe use of this Malad City, Idaho 83252

product. To obtain an MSDS please call 800-333-9826 or send an email to: msds@wilvaco.com. Tel 208.766.2206

TAPEL WILLAMETTE LTD. S.A.

Av. Estero La Posada 3625 Parque

Industrial Coronel Coronel, Chile

Tel 011.56.41.928.100

www.tapel.cl

DISCLAIMER OF WARRANTY

TEST RESULTS ARE TO BE CONSIDERED AS REPRESENTATIVE OF CURRENT PRODUCTION AND SHOULD NOT BE TREATED AS SPECIFICATIONS. WHILE ALL THE INFORMATION PRESENTED IN THIS

DOCUMENT IS BELIEVED TO BE RELIABLE AND TO REPRESENT THE BEST AVAILABLE DATA ON THESE PRODUCTS, NO GUARANTEE, WARRANTY, OR REPRESENTATION IS MADE, INTENDED, OR

IMPLIED AS TO THE CORRECTNESS OR SUFFICIENCY OF ANY INFORMATION, OR AS TO THE SUITABILITY OF ANY CHEMICAL COMPOUNDS FOR ANY PARTICULAR USE, OR THAT ANY CHEMICAL

COMPOUNDS OR USE THEREOF ARE NOT SUBJECT TO A CLAIM BY A THIRD PARTY FOR INFRINGEMENT OF ANY PATENT OR OTHER INTELLECTUAL PROPERTY RIGHT. EACH USER SHOULD CONDUCT

A SUFFICIENT INVESTIGATION TO ESTABLISH THE SUITABILITY OF ANY PRODUCT FOR ITS INTENDED USE. Revision Date: Sept 2014

PROPER APPLICATION IS THE RESPONSILBITY OF THE USER. AS WITH ANY PRODUCT THE USE OF THE THIS PRODUCT IN A GIVEN APPLICATION MUST BE TESTED (INCLUDING BUT NOT LIMITED TO

FIELD TESTING) IN ADVANCE BY THE USER TO DETERMINE SUITIBILITY. TESTING IS THE REQUIREMENT OF BOTH ENGINEERS AND CONTRACTORS ALIKE. WVCO DOES NOT WARRANT THE

APPLICATION UNDER ANY OR ALL CIRCUMSTANCES.

You might also like

- Hi Solid PolyurethaneDocument4 pagesHi Solid PolyurethaneafvasquezNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Climaveneta Mainternance Check ListDocument2 pagesClimaveneta Mainternance Check ListNhật Phong Nguyễn100% (1)

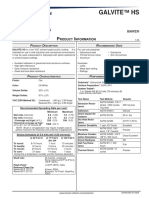

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Dow Corning AllGuard Silicone Elastomeric CoatingDocument4 pagesDow Corning AllGuard Silicone Elastomeric Coatinggpax42No ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- SAN - KUMHO - 350-HW - TDS FDocument4 pagesSAN - KUMHO - 350-HW - TDS FakshayNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Styrolution PS 1290/1291: General Purpose Polystyrene (GPPS)Document2 pagesStyrolution PS 1290/1291: General Purpose Polystyrene (GPPS)DiegoTierradentroNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Corian Exterior Cladding: Technical BulletinDocument6 pagesCorian Exterior Cladding: Technical BulletinnaheedahmedNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Polygomma EPDM Pond Liner BrochureDocument4 pagesPolygomma EPDM Pond Liner Brochurepolygomma Industries Pvt. LtdNo ratings yet

- DENSO SeaShield HDPE OutercoverDocument1 pageDENSO SeaShield HDPE OutercoverJorge QuintanaNo ratings yet

- Terluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Jose VillarrealNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

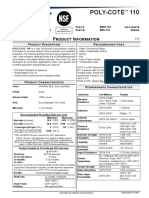

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- Styroflex 2G66: Styrene Butadiene Copolymer (SBC)Document3 pagesStyroflex 2G66: Styrene Butadiene Copolymer (SBC)Ronaldo CamargoNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- 351 - Pe HD Sabic b5933Document2 pages351 - Pe HD Sabic b5933oussama messadiNo ratings yet

- Deckorators WPC Properties: Property Test Method ResultDocument1 pageDeckorators WPC Properties: Property Test Method ResultCarlos CardenasNo ratings yet

- BinanizincspecsDocument6 pagesBinanizincspecsJimmy ThomasNo ratings yet

- H6105JUDocument1 pageH6105JUhunghiepvanNo ratings yet

- Quintolubric® 888 68Document2 pagesQuintolubric® 888 68Cédric LOUISNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Nukote Har: DescriptionDocument4 pagesNukote Har: DescriptionMarco Dos Santos NevesNo ratings yet

- Polygomma EPDM Roofing Membrane CatalogueDocument4 pagesPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNo ratings yet

- TPC 7240Document1 pageTPC 7240babarancho56No ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Dupont Styrofoam Brand Highload 40, 60 and 100 Xps Foam InsulationDocument4 pagesDupont Styrofoam Brand Highload 40, 60 and 100 Xps Foam InsulationAhmed AbdelazizNo ratings yet

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Technical Data Sheet Foam - EPDM - 1404: REV. 002 REV. DATE: 09/30/18 ISO 9001:2015 - ISO/IEC 17025:2017Document1 pageTechnical Data Sheet Foam - EPDM - 1404: REV. 002 REV. DATE: 09/30/18 ISO 9001:2015 - ISO/IEC 17025:2017Sameer SaxenaNo ratings yet

- Tairilac Abs Resin: Formosa Chemicals & Fibre CorporationDocument1 pageTairilac Abs Resin: Formosa Chemicals & Fibre CorporationRodrigo LoraNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- Protective & Marine Coatings: MetalatexDocument4 pagesProtective & Marine Coatings: MetalatexAna CabreraNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- 226NDocument2 pages226NUmaibalanNo ratings yet

- Ajedium Films (Solvay)Document3 pagesAjedium Films (Solvay)hyper meshNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- Resin - ABS Tairalac PDFDocument3 pagesResin - ABS Tairalac PDFDiegoTierradentroNo ratings yet

- Miratech GT500: Technical Data SheetDocument3 pagesMiratech GT500: Technical Data SheetNicolás CanoNo ratings yet

- Carboguard 1207 PDSDocument4 pagesCarboguard 1207 PDSmartinbeyerNo ratings yet

- Fast Clad HB Acrylic: Protective & Marine CoatingsDocument4 pagesFast Clad HB Acrylic: Protective & Marine CoatingsAna CabreraNo ratings yet

- TDS 140N - TipicosDocument2 pagesTDS 140N - TipicosCris AranzNo ratings yet

- Styrolux 684D SBC Ineos TDS enDocument3 pagesStyrolux 684D SBC Ineos TDS enfabianmendez2875No ratings yet

- S1005 TairiproDocument1 pageS1005 TairiproJacquelin DelgadoNo ratings yet

- 9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMDocument2 pages9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMqcsupNo ratings yet

- TDS Pe 202 SP4808Document2 pagesTDS Pe 202 SP4808Desri AkbarNo ratings yet

- Hdpe V1160 TDS 20230908Document2 pagesHdpe V1160 TDS 20230908phanplastic299No ratings yet

- Geomembrane Technical DataDocument1 pageGeomembrane Technical DataYusufAliMuktiNo ratings yet

- PORON 4790-92-25041 P Extra SoftSlow ReboundSupportedDocument2 pagesPORON 4790-92-25041 P Extra SoftSlow ReboundSupportedkarpagsNo ratings yet

- DSMTS-0111.5 NiAlMo Powders PDFDocument3 pagesDSMTS-0111.5 NiAlMo Powders PDFJosua Cavin WijayaNo ratings yet

- Native ElementsDocument3 pagesNative ElementsDattaraj JawdekarNo ratings yet

- Troubleshooting: A Guide For Injection MoldersDocument145 pagesTroubleshooting: A Guide For Injection Molderssam54mxNo ratings yet

- Jaundice - BILIRUBINDocument103 pagesJaundice - BILIRUBINshar12100% (3)

- BS-476 Part 21Document23 pagesBS-476 Part 21MiniEscort75% (4)

- Yio Chu Kang Secondary Sec 1 SA2 2020 ScienceDocument21 pagesYio Chu Kang Secondary Sec 1 SA2 2020 ScienceBecky ChungNo ratings yet

- Lesson Plan: Cosmetology I: Chemical Hair Relaxer Retouch ©2003 Texas Trade and Industrial Education 1Document8 pagesLesson Plan: Cosmetology I: Chemical Hair Relaxer Retouch ©2003 Texas Trade and Industrial Education 1Lady WellsNo ratings yet

- SWatch Bharat PDFDocument12 pagesSWatch Bharat PDFsachin saxenaNo ratings yet

- Schneider Electric Industries: Date: Wednesday, July 14, 2021Document2 pagesSchneider Electric Industries: Date: Wednesday, July 14, 2021David MolinaNo ratings yet

- Drying and Curing Time: Technical Data Sheet Jotaprime 500Document1 pageDrying and Curing Time: Technical Data Sheet Jotaprime 500TamerTamerNo ratings yet

- (CSEC Chemistry) Section B Notes and ESQsDocument45 pages(CSEC Chemistry) Section B Notes and ESQsNathaniel WhyteNo ratings yet

- Ramireddy Subbarami Reddy Engineering College Kadanuthala: Department of Civil EngineeringDocument38 pagesRamireddy Subbarami Reddy Engineering College Kadanuthala: Department of Civil Engineeringmegha srivastavaNo ratings yet

- 5 6145242896493707317 PDFDocument19 pages5 6145242896493707317 PDFIhtisham Ul HaqNo ratings yet

- Epcon G5 Adhesive Summary Brochure 584364Document2 pagesEpcon G5 Adhesive Summary Brochure 584364William MercadoNo ratings yet

- INDESIT W143 User Guide PDFDocument16 pagesINDESIT W143 User Guide PDFgabi_george_1No ratings yet

- AFV Modeller - Issue 08 - 5 - Naked Desperation Part 2Document17 pagesAFV Modeller - Issue 08 - 5 - Naked Desperation Part 2András Huszti100% (2)

- Foam Performance of A New HMS-PP-paperDocument5 pagesFoam Performance of A New HMS-PP-paperDebabrata MukhopadhyayNo ratings yet

- Sika Separol WDocument11 pagesSika Separol WStacey HarperNo ratings yet

- SRPS en 15004-5 FM200Document18 pagesSRPS en 15004-5 FM200Antonije100% (1)

- Viral DNA RNA Nucleic Acid Extraction Kit (Magnetic - Bead Method) - Ver 01 - 20200106Document5 pagesViral DNA RNA Nucleic Acid Extraction Kit (Magnetic - Bead Method) - Ver 01 - 20200106RuniNo ratings yet

- BIOL 2406 - Lab Review - Sp22 PDFDocument12 pagesBIOL 2406 - Lab Review - Sp22 PDFM ArNo ratings yet

- Scheme of Salt AnalysisDocument8 pagesScheme of Salt AnalysisAz Ahmed100% (1)

- جهاز قياس الناقلية - EnglishDocument13 pagesجهاز قياس الناقلية - EnglishAhmad A ShamiNo ratings yet

- Electrochemical MachiningDocument16 pagesElectrochemical MachiningParthiban SoundarrajanNo ratings yet

- BTEXDocument7 pagesBTEXECRDNo ratings yet

- American Survival Guide - Summer 2014Document132 pagesAmerican Survival Guide - Summer 2014marcelloassuncao75% (4)

- PDF Paradigms in Green Chemistry and Technology 1St Edition Angelo Albini Ebook Full ChapterDocument53 pagesPDF Paradigms in Green Chemistry and Technology 1St Edition Angelo Albini Ebook Full Chapteralexander.boyd500100% (2)

- Brochure MosselmanDocument12 pagesBrochure Mosselmanvcoranm100% (1)

- Treatments For Nuclear ContaminationDocument8 pagesTreatments For Nuclear Contaminationcappy262No ratings yet