Professional Documents

Culture Documents

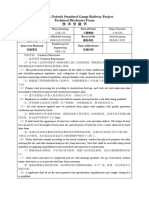

Steel Bar Raw Materials and Processing Quality Inspection Batch Quality Acceptance Records

Steel Bar Raw Materials and Processing Quality Inspection Batch Quality Acceptance Records

Uploaded by

lamin tun0 ratings0% found this document useful (0 votes)

1 views6 pagesOriginal Title

3

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views6 pagesSteel Bar Raw Materials and Processing Quality Inspection Batch Quality Acceptance Records

Steel Bar Raw Materials and Processing Quality Inspection Batch Quality Acceptance Records

Uploaded by

lamin tunCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 6

Steel bar raw materials and processing quality inspection

batch quality acceptance records

Project No.:

Bid 3 of the

The name of the construction and The name of the

unit (sub-unit) installation project division (subdivision) 08# Box change

duration of the photovoltaic project

field area

The name of the line 08# box transformer

Reinforcement works Acceptance site

project foundation cushion cap

Project

General contractor Huaneng Ruicheng Integrated Energy Co., Ltd

Leader

Mao

Project

Construction unit PowerChina Guizhou Engineering Co., Ltd Daik

Leader

un

Subcontract

Fang

Subcontracting units Hunan Yihe Engineering Co., Ltd ed Projects

Siwu

Head

Professiona

The name and number Liu

l Foreman

of the construction DL/T 5210.1-2021 Guiy

(Constructo

execution standard u

r)

Self-

inspecti

seri on Check

Categ al Inspection uni record the

Quality standards

ory numb items t of the resul

er construc ts

tion

unit

When the steel bar enters the site, the test

pieces should be extracted for yield strength,

tensile strength, elongation, bending

Raw

1 performance and quality deviation inspection

material

according to the provisions of the current

sampling

national standards, and the test results should

meet the provisions of the corresponding

standards

When the formed steel bar enters the site, the

test piece should be extracted for yield

strength, tensile strength, elongation and

host quality deviation inspection, and the test

Formed

contr results should meet the provisions of the

steel bars

ol current national relevant standards. For formed

2 are

item steel bars made of hot-rolled steel bars, when a

inspected

eye representative of the construction unit or

in the

supervision unit is stationed in the factory to

factory

supervise the production process and provide a

third-party inspection report on the mechanical

properties of the raw steel bar, only the

quality deviation inspection can be carried out

Frame For structures with seismic fortification

structures requirements, the performance of longitudinal

3 with stress reinforcement should meet the design

seismic requirements; sign, the longitudinal stressed

requiremen ordinary reinforcement in the frame and

diagonal bracing members (including flight

sections) designed for the first, second and

third seismic grades shall be

HRB400B, HRB500E, HRBF400E or HRBFS00E rein

forcements. The measured value of the total

elongation under its strength and maximum

tensile force shall comply with the following

ts provisions:( the ratio of the measured value of

tensile strength to the measured value of

service strength shall not be less than 1.252),

the ratio of the measured value of yield

strength of steel bars to the standard value

of strength shall not be greater than 130

(3), and the total measured value of maximum

tensile force shall not be less than 9%.

(1) Smooth round bars, should not be less

than 2.5 times the diameter

(2) 400MPa grade aided steel bar, should not be

The inner

less than 4 times the diameter of the steel bar.

diameter

(3) 500MPa grade aided steel bar, when the

of the arc

diameter is less than 28mm, should not be less

4 at which

than 6 times of the diameter of the steel bar,

the

when the diameter is 28mm and above, should

stressed

not be less than 7 times of the diameter of the

rebar is

steel bar.

bent

(4) The stirrup bend should not be less than

the diameter of the longitudinally stressed

reinforcement

The length

of the When the end of the round steel bar is made

5 straight at 180°, the length of the straight section of

section the hook should not be less than 3 times the

after diameter

bending

The ends of stirrups and tension bars should be

hooked according to the design requirements, and

should meet the following requirements:

(1) For general structural components, the

bending angle of the rib hook should not be less

than 90°, and the length of the straight

section after bending should not be less

than 5 times the diameter of the rib; For

structural components with seismic fortification

host requirements or special design requirements, the

contr bending angle of the stirrup hook should not be

ol less than 135, and the length of the straight

item 6 Stirrup section after bending should not be less

eye end hook than 10 times the diameter of the rib

(2) ooks should not be less than 135, the

length of the straight section after folding

should not be less than 5 times the diameter of

the rib to the general structural member, and

the structural member with fortification

requirements should not be less than 10 times

the diameter of the rib.

(3) The bending angle of the hook at both ends

of the rib shall not be less than 135 °, and

the straight length after folding shall comply

with the relevant provisions of paragraph 1

of this article

The reel After straightening the coiled steel bar, the

7 rebar is mechanical properties and quality deviation

straighten should be tested, and its strength should meet

the provisions of the current national

standards, and the elongation and quality

deviation after breaking should be in line with

ed

the provisions of the GB50204 of the Code for

Acceptance of Construction Quality of Concrete

Structure Engineering

Rebar The steel bar should be straight and undamaged,

1 surface and there should be no cracks, oil stains,

quality granular or flake rust on the surface

Appearance

quality

and

2 dimensiona It should comply with the provisions of the

l design and the relevant national standards

deviations

of formed

rebar

The

appearance

One quality of

kind mechanical

item connection

3 It should comply with the provisions of the

eye of steel

current relevant national standards

bars,

reinforcem

ent plates

and pre-

parts

The net size of the

full length of the ±10 mm

Rebar stressed reinforcement

process along the length

4 ing

The bending position ±20 mm

deviati

of the bent rebar

ons

Net size inside ±5 mm

stirrups

The

results

of the

inspectio Construction unit Project Professional Quality

n of the Project Professional Engineer: Check the results Inspector:

general YYYYYYYYYYYYYYYYY YYYYYYYYYYYYYYYYY

contracto

r

Acceptanc

e

conclusio

n of the Professional Supervision Engineer:

supervisi

YYYYYYYYYYYYYYYYY

on unit

Steel bar raw materials and processing quality inspection

batch quality acceptance records

Project No.:

The name of the Bid 3 of the The name of the 08# Box change

construction and

unit (sub-unit) installation project division (subdivision)

duration of the photovoltaic project

field area

The name of the line 08# box transforms the

Reinforcement works Acceptance site

project main body of the foundation

Project

General contractor Huaneng Ruicheng Integrated Energy Co., Ltd

Leader

Mao

Project

Construction unit PowerChina Guizhou Engineering Co., Ltd Daik

Leader

un

Subcontract

Fang

Subcontracting units Hunan Yihe Engineering Co., Ltd ed Projects

Siwu

Head

Professiona

The name and number Liu

l Foreman

of the construction DL/T 5210.1-2021 Guiy

(Constructo

execution standard u

r)

Self-

inspecti

seri on Check

Categ al Inspection uni record the

Quality standards

ory numb items t of the resul

er construc ts

tion

unit

host When the steel bar enters the site, the test

contr pieces should be extracted for yield strength,

ol tensile strength, elongation, bending

Raw

item 1 performance and quality deviation inspection

material

eye according to the provisions of the current

sampling

national standards, and the test results should

meet the provisions of the corresponding

standards

When the formed steel bar enters the site, the

test piece should be extracted for yield

strength, tensile strength, elongation and

quality deviation inspection, and the test

Formed

results should meet the provisions of the

steel bars

current national relevant standards. For formed

2 are

steel bars made of hot-rolled steel bars, when a

inspected

representative of the construction unit or

in the

supervision unit is stationed in the factory to

factory

supervise the production process and provide a

third-party inspection report on the mechanical

properties of the raw steel bar, only the

quality deviation inspection can be carried out

3 Frame For structures with seismic fortification

structures requirements, the performance of longitudinal

with stress reinforcement should meet the design

seismic requirements; sign, the longitudinal stressed

requiremen ordinary reinforcement in the frame and

ts diagonal bracing members (including flight

sections) designed for the first, second and

third seismic grades shall be

HRB400B, HRB500E, HRBF400E or HRBFS00E rein

forcements. The measured value of the total

elongation under its strength and maximum

tensile force shall comply with the following

provisions:( the ratio of the measured value of

tensile strength to the measured value of

service strength shall not be less than 1.252),

the ratio of the measured value of yield

strength of steel bars to the standard value

of strength shall not be greater than 130

(3), and the total measured value of maximum

tensile force shall not be less than 9%.

(1) Smooth round bars, should not be less

than 2.5 times the diameter

(2) 400MPa grade aided steel bar, should not be

The inner

less than 4 times the diameter of the steel bar.

diameter

(3) 500MPa grade aided steel bar, when the

of the arc

diameter is less than 28mm, should not be less

4 at which

than 6 times of the diameter of the steel bar,

the

when the diameter is 28mm and above, should

stressed

not be less than 7 times of the diameter of the

rebar is

steel bar.

bent

(4) The stirrup bend should not be less than

the diameter of the longitudinally stressed

reinforcement

The length

of the When the end of the round steel bar is made

5 straight at 180°, the length of the straight section of

section the hook should not be less than 3 times the

after diameter

bending

The ends of stirrups and tension bars should be

hooked according to the design requirements, and

should meet the following requirements:

(1) For general structural components, the

bending angle of the rib hook should not be less

than 90°, and the length of the straight

section after bending should not be less

than 5 times the diameter of the rib; For

structural components with seismic fortification

requirements or special design requirements, the

bending angle of the stirrup hook should not be

less than 135, and the length of the straight

host 6 Stirrup section after bending should not be less

contr end hook than 10 times the diameter of the rib

ol (2) oks should not be less than 135, the

item length of the straight section after folding

eye should not be less than 5 times the diameter of

the rib to the general structural member, and

the structural member with fortification

requirements should not be less than 10 times

the diameter of the rib.

(3) The bending angle of the hook at both ends

of the rib shall not be less than 135 °, and

the straight length after folding shall comply

with the relevant provisions of paragraph 1

of this article

After straightening the coiled steel bar, the

mechanical properties and quality deviation

should be tested, and its strength should meet

The reel

the provisions of the current national

7 rebar is

standards, and the elongation and quality

straighten

deviation after breaking should be in line with

ed

the provisions of the GB50204 of the Code for

Acceptance of Construction Quality of Concrete

Structure Engineering

Rebar The steel bar should be straight and undamaged,

One 1 surface and there should be no cracks, oil stains,

kind quality granular or flake rust on the surface

item

2 Appearance It should comply with the provisions of the

eye

quality design and the relevant national standards

and

dimensiona

l

deviations

of formed

rebar

The

appearance

quality of

mechanical

connection

3 It should comply with the provisions of the

of steel

current relevant national standards

bars,

reinforcem

ent plates

and pre-

parts

The net size of the

full length of the ±10 mm

Rebar stressed reinforcement

process along the length

4 ing

The bending position ±20 mm

deviati

of the bent rebar

ons

Net size inside ±5 mm

stirrups

The

results

of the

inspectio Construction unit Project Professional Quality

n of the Project Professional Engineer: Check the results Inspector:

general YYYYYYYYYYYYYYYYY YYYYYYYYYYYYYYYYY

contracto

r

Acceptanc

e

conclusio

n of the Professional Supervision Engineer:

supervisi

YYYYYYYYYYYYYYYYY

on unit

You might also like

- Erection Tower Method StatementDocument23 pagesErection Tower Method StatementJatmiko Purwo Saputro100% (2)

- 2006-Post-Tensioning Manual - 6th Edition PDFDocument370 pages2006-Post-Tensioning Manual - 6th Edition PDFArdiaTiaraR93% (14)

- Specification For Structural Steelworks PDFDocument58 pagesSpecification For Structural Steelworks PDFfarahazura80% (5)

- ITP - Steel ErectionDocument10 pagesITP - Steel ErectionGhayas RanjhaNo ratings yet

- Procedure For RCC - PCC WorksDocument5 pagesProcedure For RCC - PCC WorksBhargav Bbvs100% (2)

- Method Statement of GE Module InstallationDocument10 pagesMethod Statement of GE Module InstallationAshiqur Rahman ZituNo ratings yet

- Experience ReportDocument11 pagesExperience ReportXiaoman Tu100% (1)

- Poster DIN EN 1090-1 ENG Final PDFDocument1 pagePoster DIN EN 1090-1 ENG Final PDFlth770310No ratings yet

- Reinforcement Installation Inspection Batch Quality Acceptance RecordDocument9 pagesReinforcement Installation Inspection Batch Quality Acceptance Recordlamin tunNo ratings yet

- Eng 钢筋安装检验批Document9 pagesEng 钢筋安装检验批lamintun109.110.111No ratings yet

- IQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFDocument11 pagesIQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFAli MajeedNo ratings yet

- Dave Cheung - Supervisor (Welding)Document3 pagesDave Cheung - Supervisor (Welding)Dave CheungNo ratings yet

- Earthwork Excavation Inspection Batch Quality Acceptance RecordDocument2 pagesEarthwork Excavation Inspection Batch Quality Acceptance Recordlamin tunNo ratings yet

- Temporary Detour at Lebak Bulus: Construction of Mass Rapid Transit JakartaDocument7 pagesTemporary Detour at Lebak Bulus: Construction of Mass Rapid Transit JakartaJosua Ferry ManurungNo ratings yet

- Performancebasedseismicevaluation IEI AUG2015Document11 pagesPerformancebasedseismicevaluation IEI AUG2015cinithaserc appuNo ratings yet

- Fabrication & Erection of Steel Works ChecklistDocument1 pageFabrication & Erection of Steel Works ChecklisttaghlubNo ratings yet

- TWJO-ITP-EMB-0003 Reva ITP For Retaining Wall RRR MethodDocument11 pagesTWJO-ITP-EMB-0003 Reva ITP For Retaining Wall RRR MethodBangkit SamosirNo ratings yet

- Application Note: Savcor India Private LTDDocument1 pageApplication Note: Savcor India Private LTDmusaNo ratings yet

- Mindmap The 9 Key Elements Video 03 Mechanical CompletionDocument1 pageMindmap The 9 Key Elements Video 03 Mechanical CompletionDavinci LeonardoNo ratings yet

- Análisis Comparativo Entre Pavimento Rígido y FlexibleDocument1 pageAnálisis Comparativo Entre Pavimento Rígido y FlexiblealvereNo ratings yet

- NTP-EDocument8 pagesNTP-Ekevinlow3No ratings yet

- Steel Structure Fabrication Work: Inspection and Test Plan (Itp)Document6 pagesSteel Structure Fabrication Work: Inspection and Test Plan (Itp)Togar Richard SihotangNo ratings yet

- Assessment of Mechanical Properties of Reinforcing Steel Used in Construction Works at F.C.T Abuja IJERTV2IS60547Document13 pagesAssessment of Mechanical Properties of Reinforcing Steel Used in Construction Works at F.C.T Abuja IJERTV2IS60547titiNo ratings yet

- Japan Reinforcing Bar Joints Institute: @seismicisolationDocument8 pagesJapan Reinforcing Bar Joints Institute: @seismicisolationDiego Leonel Suárez VásquezNo ratings yet

- Matrix of Responsibilities-RebarDocument1 pageMatrix of Responsibilities-Rebarldpolides90No ratings yet

- Project Title: Masalli-Astara Motorway Section B: H Hold Point: W - Witness Point: S - Surveillance: R - ReviewDocument2 pagesProject Title: Masalli-Astara Motorway Section B: H Hold Point: W - Witness Point: S - Surveillance: R - ReviewMirzojon MirzoevNo ratings yet

- MES - Construction Quality Manual - Rev - 0Document55 pagesMES - Construction Quality Manual - Rev - 0Ishaan ThakerNo ratings yet

- Performance Based Seismic Evaluation-IEI-AUG2015Document10 pagesPerformance Based Seismic Evaluation-IEI-AUG2015cinithaserc appuNo ratings yet

- Sample Draft Final Report (Iloilo)Document15 pagesSample Draft Final Report (Iloilo)A.B. CbmNo ratings yet

- General - Non-Destructive Testing of Steel Structure - RevDocument70 pagesGeneral - Non-Destructive Testing of Steel Structure - Revhlkhgljkh100% (1)

- Pany ProfileDocument31 pagesPany ProfilehungleteNo ratings yet

- Tech 43Document6 pagesTech 43chuljoong kangNo ratings yet

- Salt Design & Infra Services Pvt. LTD.: Audit AgencyDocument6 pagesSalt Design & Infra Services Pvt. LTD.: Audit AgencysaurabhNo ratings yet

- Steel Structure 1Document15 pagesSteel Structure 1Febriono AdiNo ratings yet

- Fixed Solar PV Bracket Inspection ReportDocument13 pagesFixed Solar PV Bracket Inspection ReportTariq Ali SialNo ratings yet

- 1) Method Statement For FORMWORK STEEL & CONCRETE WORKDocument7 pages1) Method Statement For FORMWORK STEEL & CONCRETE WORKMukesh PrajapatNo ratings yet

- Civil Structure Assessment ServicesDocument1 pageCivil Structure Assessment ServicesKashif Zaheer AlviNo ratings yet

- Qi 2020 IOP Conf. Ser. Earth Environ. Sci. 510 052071Document8 pagesQi 2020 IOP Conf. Ser. Earth Environ. Sci. 510 052071teo_tran_1No ratings yet

- Qaqc Section: Presented To QAQC Safety Session at Jakarta MRT Project July 15, 2017Document17 pagesQaqc Section: Presented To QAQC Safety Session at Jakarta MRT Project July 15, 2017Wildan Al BaihaqiNo ratings yet

- Inspection of Welded and Bolted JointsDocument26 pagesInspection of Welded and Bolted JointsmilesmiconNo ratings yet

- Rahul Yadav Resume-1Document4 pagesRahul Yadav Resume-1rahul yadavNo ratings yet

- Structural Audit - A Case Study of Educational BuildingDocument5 pagesStructural Audit - A Case Study of Educational BuildingCivil StructuralNo ratings yet

- NCR7830 - MegatwrmktncrkDocument127 pagesNCR7830 - MegatwrmktncrkAldrin Jonas EduarteNo ratings yet

- Mechanical (Projects)Document7 pagesMechanical (Projects)Nilesh SutradharNo ratings yet

- Generator Condition Assessment Rev4Document1 pageGenerator Condition Assessment Rev4Ary SSNo ratings yet

- Setting of Operation Limit For PrestressingDocument3 pagesSetting of Operation Limit For Prestressinganarose gersanivaNo ratings yet

- Pages From SCTT31-2Document1 pagePages From SCTT31-2Anh Quoc VuNo ratings yet

- Wa0000.Document6 pagesWa0000.Monirul Islam BadalNo ratings yet

- Fabrication Work For The Construction of Chenab Bridge Part IDocument2 pagesFabrication Work For The Construction of Chenab Bridge Part IIndra Mishra100% (2)

- Msds-5 & Associated Systems of BSP Bhilai Comments On Structural WorkDocument3 pagesMsds-5 & Associated Systems of BSP Bhilai Comments On Structural WorkSUDDHA CHAKRABARTYNo ratings yet

- QAP Highmast 42672 D6ac45Document2 pagesQAP Highmast 42672 D6ac45Kritika Chaudhary Chandra MohanNo ratings yet

- Cengiz Karakose: Welding/Piping/Tank InspectorDocument4 pagesCengiz Karakose: Welding/Piping/Tank Inspectorcengiz88No ratings yet

- Anchor Design ManualDocument388 pagesAnchor Design ManualJianhua WuNo ratings yet

- NCR903 - SantillanDocument60 pagesNCR903 - SantillanAldrin Jonas EduarteNo ratings yet

- 3 钢筋工程技术交底 (中英)Document14 pages3 钢筋工程技术交底 (中英)fightbymyselfNo ratings yet

- Quality Assurance PlanDocument2 pagesQuality Assurance Planpiyush singhNo ratings yet

- Anchor Design ManualDocument390 pagesAnchor Design ManualNIranjan BuddikaNo ratings yet

- Modelquality Assuranceplanforpot 1Document8 pagesModelquality Assuranceplanforpot 1mouni9301997No ratings yet

- Hand Book For Steel Structure Quality Control on SiteFrom EverandHand Book For Steel Structure Quality Control on SiteNo ratings yet

- Used Water SES 7 Testing 12feb2016Document9 pagesUsed Water SES 7 Testing 12feb2016Mark BenjieNo ratings yet

- 'Take Lessons From Traditional Techniques': COST CONSCIOUS: Architect, Benny KuriakoseDocument3 pages'Take Lessons From Traditional Techniques': COST CONSCIOUS: Architect, Benny KuriakoseTushar SharmaNo ratings yet

- Mast DesignDocument18 pagesMast DesignPoulomi BiswasNo ratings yet

- Zaha HadidDocument11 pagesZaha HadidSejal jalanNo ratings yet

- FF OVS Maggio 2016Document3 pagesFF OVS Maggio 2016extiscalinetNo ratings yet

- Part 3 - Concurrent Delays in Construction A Practical ApproachDocument3 pagesPart 3 - Concurrent Delays in Construction A Practical ApproachBen MusimaneNo ratings yet

- SatecDocument29 pagesSatecALEJANDRO CABRERANo ratings yet

- Construction of Mppschool Building at Ainapoor Tanda (V) of Doma (M)Document30 pagesConstruction of Mppschool Building at Ainapoor Tanda (V) of Doma (M)vanamgouthamNo ratings yet

- 1 - Introduction To Hydraulic StructuresDocument11 pages1 - Introduction To Hydraulic StructuresAwes OmarNo ratings yet

- 517Document4 pages517Nabeel AL-HakeemNo ratings yet

- Introduction To Geotechnical EngineeringDocument9 pagesIntroduction To Geotechnical EngineeringFritz NatividadNo ratings yet

- 2017 Prisma M Catalog - LVED210002EN (Web) 1Document272 pages2017 Prisma M Catalog - LVED210002EN (Web) 1Nguyễn Ngọc ChungNo ratings yet

- L-CKD Heavy Duty Industrial Gear OilDocument3 pagesL-CKD Heavy Duty Industrial Gear OilDavidNo ratings yet

- Folleto Xtrem Vs H07RNF - EngDocument2 pagesFolleto Xtrem Vs H07RNF - EngTeodor BochevNo ratings yet

- STULZ CyberAir 3PRO CW Brochure 2001 ENDocument20 pagesSTULZ CyberAir 3PRO CW Brochure 2001 ENIvan Rudolf De FretesNo ratings yet

- CCPU-Defect List #010-17.jan.2019 PDFDocument5 pagesCCPU-Defect List #010-17.jan.2019 PDFNhoek RenNo ratings yet

- Reinforced Concrete DesignDocument993 pagesReinforced Concrete DesignRizal RifdoNo ratings yet

- List - Approved Prequalified SubsDocument42 pagesList - Approved Prequalified SubsJAGUAR GAMINGNo ratings yet

- Electrical First QuarterDocument44 pagesElectrical First QuarterYemi Eshetu MeeNo ratings yet

- What Causes Water Pump FailureDocument16 pagesWhat Causes Water Pump FailureGeethika NayanaprabhaNo ratings yet

- Beg 362 Ci Year: III Semester: II: Foundation EngineeringDocument3 pagesBeg 362 Ci Year: III Semester: II: Foundation EngineeringAnil MarsaniNo ratings yet

- Diamondspark - 52 - BC - C Tehnical DataDocument1 pageDiamondspark - 52 - BC - C Tehnical DataLuka DrascicNo ratings yet

- V Packing SealDocument10 pagesV Packing SealBobby ArbianugrohoNo ratings yet

- SHORING FOR DEPTH 4.2mDocument6 pagesSHORING FOR DEPTH 4.2mMohammed RajapNo ratings yet

- Diversion HeadworkDocument24 pagesDiversion Headworksabin birbal100% (1)

- Re-Development Proposal Draft.Document10 pagesRe-Development Proposal Draft.Shubham SawantNo ratings yet

- By: Engr. Ronald John R. CajillaDocument1 pageBy: Engr. Ronald John R. CajillareynoldNo ratings yet

- Keystone K-Lok: High Performance Butterfly Valves Series 36 and 37Document16 pagesKeystone K-Lok: High Performance Butterfly Valves Series 36 and 37el_apache10No ratings yet