Professional Documents

Culture Documents

SABIC® LLDPE - 218WJ - Global - Technical - Data - Sheet

SABIC® LLDPE - 218WJ - Global - Technical - Data - Sheet

Uploaded by

Lê Đình QuânOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SABIC® LLDPE - 218WJ - Global - Technical - Data - Sheet

SABIC® LLDPE - 218WJ - Global - Technical - Data - Sheet

Uploaded by

Lê Đình QuânCopyright:

Available Formats

SABIC® LLDPE 218WJ

LINEAR LOW DENSITY POLYETHYLENE

DESCRIPTION

218WJ is a butene Linear Low Density Polyethylene TNPP free grade suitable for general‐purpose packaging. It is easy to

process giving good tensile properties, impact strength and optical properties. 218WJ contains slip and antiblock additives.

TYPICAL APPLICATIONS

Lamination film, thin liners, shopping bags, carrier bags, garbage bags, coextruded films, consumer packaging and other general-purpose applications.

TYPICAL PROPERTY VALUES Revision 20211108

PROPERTIES TYPICAL VALUES UNITS TEST METHODS

POLYMER PROPERTIES

Melt Flow Rate (MFR)

at 190°C and 2.16 kg 2 g/10 min ASTM D1238

Density 918 kg/m³ ASTM D1505

FORMULATION

Slip agent - -

Anti block agent - -

MECHANICAL PROPERTIES

(1)

Dart Impact Strength 85 g/µm ASTM D1709

(1)

OPTICAL PROPERTIES

Haze 13 % ASTM D1003

Gloss

at 60° 80 - ASTM D2457

(1)

FILM PROPERTIES

Tensile Properties

stress at break, MD 35 MPa ASTM D882

stress at break, TD 29 MPa ASTM D882

strain at break, MD 700 % ASTM D882

strain at break, TD 750 % ASTM D882

stress at yield, MD 12 MPa ASTM D882

stress at yield, TD 10 MPa ASTM D882

1% secant modulus, MD 220 MPa ASTM D882

1% secant modulus, TD 260 MPa ASTM D882

Elmendorf Tear Strength

MD 130 g ASTM D1922

TD 320 g ASTM D1922

THERMAL PROPERTIES

Vicat Softening Point 98 °C ASTM D1525

(1) Mechanical properties have been measured by producing 30 μ film with 2.5 BUR using 100% 218NJ.

PROCESSING CONDITIONS

© 2023 Copyright by SABIC. All rights reserved

Typical processing conditions for 218WJ are:

Melt temperature: 185 - 205°C, Blow up ratio: 2.0 - 3.0

STORAGE AND HANDLING

Polyethylene resin should be stored in a manner to prevent a direct exposure to sunlight and/or heat. The storage area should also be dry and preferably

1% secant modulus, MD 220 MPa ASTM D882

1% secant modulus, TD 260 MPa ASTM D882

Elmendorf Tear Strength

MD 130 g ASTM D1922

TD 320 g ASTM D1922

THERMAL PROPERTIES

Vicat Softening Point 98 °C ASTM D1525

(1) Mechanical properties have been measured by producing 30 μ film with 2.5 BUR using 100% 218NJ.

PROCESSING CONDITIONS

Typical processing conditions for 218WJ are:

Melt temperature: 185 - 205°C, Blow up ratio: 2.0 - 3.0

STORAGE AND HANDLING

Polyethylene resin should be stored in a manner to prevent a direct exposure to sunlight and/or heat. The storage area should also be dry and preferably

do not exceed 50°C. SABIC would not give warranty to bad storage conditions which may lead to quality deterioration such as color change, bad smell

and inadequate product performance. It is advisable to process PE resin within 6 months after delivery.

DISCLAIMER

Any sale by SABIC, its subsidiaries and affiliates (each a “seller”), is made exclusively under seller’s standard conditions of sale (available upon request) unless agreed

otherwise in writing and signed on behalf of the seller. While the information contained herein is given in good faith, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED,

INCLUDING MERCHANTABILITY AND NONINFRINGEMENT OF INTELLECTUAL PROPERTY, NOR ASSUMES ANY LIABILITY, DIRECT OR INDIRECT, WITH RESPECT TO THE

PERFORMANCE, SUITABILITY OR FITNESS FOR INTENDED USE OR PURPOSE OF THESE PRODUCTS IN ANY APPLICATION. Each customer must determine the suitability of seller

materials for the customer’s particular use through appropriate testing and analysis. No statement by seller concerning a possible use of any product, service or design is

intended, or should be construed, to grant any license under any patent or other intellectual property right.

© 2023 Copyright by SABIC. All rights reserved

You might also like

- Effects ManualDocument213 pagesEffects Manualliamsutd99No ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- STB5100 Electric Wiring DiagramDocument10 pagesSTB5100 Electric Wiring Diagramsea13100% (2)

- Sabic® Ldpe Hp4024Wn: Low Density PolyethyleneDocument2 pagesSabic® Ldpe Hp4024Wn: Low Density PolyethyleneTOMALO FREENo ratings yet

- Lldpe - Sabic® Lldpe - 118NJ PDFDocument2 pagesLldpe - Sabic® Lldpe - 118NJ PDFNilay TanrıverNo ratings yet

- SABIC® LDPE - HP0323NN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP0323NN - Global - Technical - Data - SheetRubenMurguiaNo ratings yet

- LDBF2 HP2023J SabicDocument2 pagesLDBF2 HP2023J SabicDiana SarmientoNo ratings yet

- Ldpe HP4025ZN TDSDocument2 pagesLdpe HP4025ZN TDSmittalplaschemNo ratings yet

- 219ZJDocument2 pages219ZJAziz AlaghbariNo ratings yet

- Ldpe HP0723JNDocument2 pagesLdpe HP0723JNChu ChuNo ratings yet

- SABIC® LLDPE - 218WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 218WJA - Americas - Technical - Data - Sheetdiana sarmientoNo ratings yet

- SABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetJosiola MariledoNo ratings yet

- SABIC® LLDPE_118WJA_Americas_Technical_Data_Sheet (1)Document2 pagesSABIC® LLDPE_118WJA_Americas_Technical_Data_Sheet (1)Kelly ConradoNo ratings yet

- Special Characteristics:: Innoplus Ll7420DDocument1 pageSpecial Characteristics:: Innoplus Ll7420DFahad MohamedNo ratings yet

- TDS - LD 2023 CC PDFDocument1 pageTDS - LD 2023 CC PDFYasir SiddiquiNo ratings yet

- Aramco PP HP30EGDocument2 pagesAramco PP HP30EGSayed FathyNo ratings yet

- Aramco PP CP390NA: PolypropyleneDocument1 pageAramco PP CP390NA: PolypropylenesubakialamNo ratings yet

- LF410 (영문)Document1 pageLF410 (영문)coordinador.comercialNo ratings yet

- Aramco F2111 PDFDocument1 pageAramco F2111 PDFhillaireNo ratings yet

- Riblene FF20Document2 pagesRiblene FF20Stefan PopaNo ratings yet

- Aramco PP CP390NK TDS REV 01012019Document1 pageAramco PP CP390NK TDS REV 01012019AthonioMourinhoNo ratings yet

- LL7410D1Document1 pageLL7410D1Nitin MaheshwariNo ratings yet

- Sabic 37MK10Document2 pagesSabic 37MK10Chu ChuNo ratings yet

- PDS Aramco PP CP390N Rev 20180116Document1 pagePDS Aramco PP CP390N Rev 20180116Bogdan ShevchenkoNo ratings yet

- Technical Datasheet: Product DescriptionDocument1 pageTechnical Datasheet: Product Descriptionالجزائرية انفست بلاستNo ratings yet

- Aramco PP CP245NK TDS REV 01012019Document1 pageAramco PP CP245NK TDS REV 01012019AthonioMourinhoNo ratings yet

- SABIC® PP - 312MK40 - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 312MK40 - Global - Technical - Data - SheetSayed RehanNo ratings yet

- Aramco PP CP90NK TDS REV 01012019Document1 pageAramco PP CP90NK TDS REV 01012019AthonioMourinhoNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- H T NH A Lldpe 1002en TdsDocument1 pageH T NH A Lldpe 1002en TdsChu ChuNo ratings yet

- C1809PJ 02 Technical Data Sheet 20240227105023Document1 pageC1809PJ 02 Technical Data Sheet 20240227105023phanplastic299No ratings yet

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 5271K - Global - Technical - Data - SheetjituniNo ratings yet

- ASTM UT404 Eng 240223Document1 pageASTM UT404 Eng 240223MERVENo ratings yet

- SABIC® PP - 528K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 528K - Global - Technical - Data - SheetjituniNo ratings yet

- Hdi0653u1 Enus AstmDocument1 pageHdi0653u1 Enus AstmJonathan GuadarramaNo ratings yet

- 400 00285139en Innate st50 Precision Packaging Resin TdsDocument3 pages400 00285139en Innate st50 Precision Packaging Resin Tdsteguh.budi.uNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- TDS BB120 Eng 220216Document1 pageTDS BB120 Eng 220216QcNo ratings yet

- Certene™ Llbf-218aDocument1 pageCertene™ Llbf-218aJose FernandezNo ratings yet

- Aramco PP CP160NK TDS REV 01012019Document1 pageAramco PP CP160NK TDS REV 01012019AthonioMourinhoNo ratings yet

- Dow Elite 5400G TDSDocument2 pagesDow Elite 5400G TDSAli RazuNo ratings yet

- Marpol® LDF 720 CSBDocument1 pageMarpol® LDF 720 CSBDiana SarmientoNo ratings yet

- Technical Datasheet 2102TX00: 1) Product DescriptionDocument1 pageTechnical Datasheet 2102TX00: 1) Product DescriptionjavadmohammadiNo ratings yet

- Bapolene 200fDocument2 pagesBapolene 200fDiana SarmientoNo ratings yet

- Aramco PP HP30G Rev 20180116Document1 pageAramco PP HP30G Rev 20180116wulan kantiasihNo ratings yet

- Lotte Chemical Titan TITANLENE LDF201FG Low Density PolyethyleneDocument2 pagesLotte Chemical Titan TITANLENE LDF201FG Low Density PolyethyleneMamdouhNo ratings yet

- Application:: High Stiffness Blown & Cast Film, Blending, LaminationDocument1 pageApplication:: High Stiffness Blown & Cast Film, Blending, Laminationmohamad mostafaviNo ratings yet

- Cynpol LL0118-1Document1 pageCynpol LL0118-1Jorge MedinaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data Sheetnadaelbeltagy4No ratings yet

- Exxon LD 100 BWDocument2 pagesExxon LD 100 BWAli KüçükNo ratings yet

- Linear Low Density Polyethylene: LL 22402 (Basell Grade: 22402)Document1 pageLinear Low Density Polyethylene: LL 22402 (Basell Grade: 22402)Jaime222No ratings yet

- Exceed™ XP 8318MJ: Performance PolymerDocument2 pagesExceed™ XP 8318MJ: Performance PolymerMaram YasserNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetLeductoan LeNo ratings yet

- SABIC® PP - 513MN40 - Global - Technical - Data - SheetDocument2 pagesSABIC® PP - 513MN40 - Global - Technical - Data - SheetmeshaktimanNo ratings yet

- ExxonMobil HTA 001HDDocument1 pageExxonMobil HTA 001HDakshayNo ratings yet

- ASTM FL7100U Eng 240223Document1 pageASTM FL7100U Eng 240223MERVENo ratings yet

- Certene™ Llhc-318aDocument1 pageCertene™ Llhc-318aJose FernandezNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Aramco PP HP40G Rev 20180116Document1 pageAramco PP HP40G Rev 20180116wulan kantiasihNo ratings yet

- Halene - H : Technical Data SheetDocument1 pageHalene - H : Technical Data SheetIshah KaziNo ratings yet

- CAPART GuidelinesDocument178 pagesCAPART GuidelinesGops100% (1)

- Bridge Replacement Project Development Process: Scdot Bridge Design ManualDocument50 pagesBridge Replacement Project Development Process: Scdot Bridge Design ManualSamuel EsparteroNo ratings yet

- Grade 10 Science PointersDocument2 pagesGrade 10 Science PointersHendrix Antonni AmanteNo ratings yet

- Bahay KuboDocument13 pagesBahay KuboArianne Joy Quiba DullasNo ratings yet

- Geronimo Z. Velasco - IOMDocument4 pagesGeronimo Z. Velasco - IOMGazelle Joy UlalanNo ratings yet

- Daniel Rosenberg GravitasDocument28 pagesDaniel Rosenberg GravitasKaren MiradNo ratings yet

- School Grade Level Teacher Emerson M. Punzalan Learning Area Teaching Dates and Time QuarterDocument6 pagesSchool Grade Level Teacher Emerson M. Punzalan Learning Area Teaching Dates and Time QuarterEarl Caesar Quiba PagunsanNo ratings yet

- Distributor - Perkins Extended Life Coolant PresentationDocument11 pagesDistributor - Perkins Extended Life Coolant PresentationPritish147No ratings yet

- A Technical Report AmadiDocument51 pagesA Technical Report Amadiscrewball's animesNo ratings yet

- Portico Design 1Document5 pagesPortico Design 1Asr FlowerNo ratings yet

- Rectangular Break Line: 1. Purpose and DescriptionDocument5 pagesRectangular Break Line: 1. Purpose and DescriptionNico InfanteNo ratings yet

- 1.BEAM TO BEAM CONNECTION-BOLTS 1RV17CV134-Model - MergedDocument14 pages1.BEAM TO BEAM CONNECTION-BOLTS 1RV17CV134-Model - MergedFAHD ABDUL RAHMANNo ratings yet

- Macbook All-In-One For Dummies Cheat Sheet: Mac Os X Finder Keyboard ShortcutsDocument1 pageMacbook All-In-One For Dummies Cheat Sheet: Mac Os X Finder Keyboard ShortcutsRyuzaki LawlietNo ratings yet

- Hindusthan College of Engineering & Technology - HICET: Consolidated ReportDocument4 pagesHindusthan College of Engineering & Technology - HICET: Consolidated Reportkumaresanm MCET-HICETNo ratings yet

- 3.4 - Burning in A KilnDocument4 pages3.4 - Burning in A KilnIrshad Hussain100% (1)

- 1 s2.0 S0263876216304695 MainDocument8 pages1 s2.0 S0263876216304695 MainEva Olvera CoelloNo ratings yet

- PHEONWJ-M-SPE-0021 1 Piping Fabrication & InstallationDocument22 pagesPHEONWJ-M-SPE-0021 1 Piping Fabrication & InstallationIksan Adityo Mulyo100% (1)

- Lenovo B40Document96 pagesLenovo B40Alberto JiménezNo ratings yet

- Kerala Public Service Commission NotificationDocument6 pagesKerala Public Service Commission NotificationHareesh RaghavanNo ratings yet

- Case 1: Soil: Project Title: Prince Majed Palace Design of Underground Water TankDocument5 pagesCase 1: Soil: Project Title: Prince Majed Palace Design of Underground Water TankafvilavilanoriegaNo ratings yet

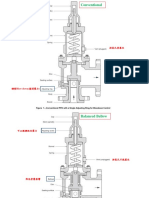

- PSV FigureDocument118 pagesPSV Figure李天No ratings yet

- Autocad Mechanical EssentialsDocument3 pagesAutocad Mechanical EssentialsJigar Patel's100% (1)

- Zorrozaurre Master Plan: Press ReleaseDocument4 pagesZorrozaurre Master Plan: Press ReleasegmaNo ratings yet

- Welding Map and Monitoring Field Weld Actifity Bbe Tahap 2Document13 pagesWelding Map and Monitoring Field Weld Actifity Bbe Tahap 2Cak NhassNo ratings yet

- NZS 3101-2006 PT-SL Example 001Document6 pagesNZS 3101-2006 PT-SL Example 001Fredy Sandro Rosas FloresNo ratings yet

- RAYCHEM - EPKT Terminations: Termination Systems For Polymeric and MIND Paper Insulated Cables From 7.2kV Up To 36kVDocument1 pageRAYCHEM - EPKT Terminations: Termination Systems For Polymeric and MIND Paper Insulated Cables From 7.2kV Up To 36kVStephen BridgesNo ratings yet

- Service Life and Durability of Reinforced Concrete StructuresDocument184 pagesService Life and Durability of Reinforced Concrete StructuresGiovanni Medrano67% (3)

- Effectiveness of Durian Peel As Biomass BriquetteDocument103 pagesEffectiveness of Durian Peel As Biomass BriquetteEvan Kristofer De Castro100% (2)