Professional Documents

Culture Documents

Ass ThermoMETER CTL en

Ass ThermoMETER CTL en

Uploaded by

gerard boonenCopyright:

Available Formats

You might also like

- SM JCB 3CX 4CX 328739808-9803-3280-9 PDFDocument1,212 pagesSM JCB 3CX 4CX 328739808-9803-3280-9 PDFСергей Ганкевич97% (32)

- MCTC ArdDocument2 pagesMCTC ArdMohammed Sajid80% (5)

- Beckhoff Main Catalog 2016 PDFDocument1,009 pagesBeckhoff Main Catalog 2016 PDFChi Lac PhungNo ratings yet

- AN5506-02-FG (F1G) GPON Optical Network Unit User Manual (Version A) - 1511784409Document2 pagesAN5506-02-FG (F1G) GPON Optical Network Unit User Manual (Version A) - 1511784409Hagyo Jozsef100% (1)

- Procedures or Subprograms: ObjectivesDocument65 pagesProcedures or Subprograms: ObjectivesFebwin VillaceranNo ratings yet

- Thermometre Frontal Sans Contact NoticeDocument4 pagesThermometre Frontal Sans Contact Noticeimane hallisNo ratings yet

- WA MelchiorriDocument70 pagesWA MelchiorriAbhishek DharNo ratings yet

- Plakat FESTO CPX MPA VTSADocument2 pagesPlakat FESTO CPX MPA VTSAtadNo ratings yet

- Poster PA 2015 en A1Document1 pagePoster PA 2015 en A1Dalat TigonNo ratings yet

- 2000 - Marchal - Al - 4D Analogue Modelling - NewInsight - PosterDocument2 pages2000 - Marchal - Al - 4D Analogue Modelling - NewInsight - PosterRobert BlaireauNo ratings yet

- Tan 2001Document6 pagesTan 2001t123medNo ratings yet

- 2021 Figo (India MCA) Tapa de PunteriasDocument8 pages2021 Figo (India MCA) Tapa de PunteriasReneNo ratings yet

- Instrument Hookup 10Document1 pageInstrument Hookup 10Wael ZakariaNo ratings yet

- Batteries: Color Code For Schematic LinesDocument2 pagesBatteries: Color Code For Schematic LinesIsaac NewtonNo ratings yet

- Dball-Chrysler-Rsr en Ig Me20130118Document29 pagesDball-Chrysler-Rsr en Ig Me20130118Mat JonesNo ratings yet

- Control Solenid Main Mod Control Circuit High P0963Document4 pagesControl Solenid Main Mod Control Circuit High P0963Christian Ramos Alarcon100% (1)

- DMKNXDocument2 pagesDMKNXSupuran RichardoNo ratings yet

- SEBoKv1.0 FinalDocument852 pagesSEBoKv1.0 Finalh_bekhitNo ratings yet

- 564shj22-01-Gym-Tc-100 R1Document1 page564shj22-01-Gym-Tc-100 R1IbrahimUnesNo ratings yet

- TNA TemplateDocument4 pagesTNA TemplateSwapon KumarNo ratings yet

- Apple's CSAM Detection MechanismDocument12 pagesApple's CSAM Detection MechanismMike WuertheleNo ratings yet

- Rapid Object Detection Using A Boosted Cascade of Simple FeaturesDocument9 pagesRapid Object Detection Using A Boosted Cascade of Simple FeaturesYuvraj NegiNo ratings yet

- Inovacne Am400 Cpu1608tn NPN PLC Cpu Product Note English 20 4 20Document2 pagesInovacne Am400 Cpu1608tn NPN PLC Cpu Product Note English 20 4 20Manova JNo ratings yet

- 324D, 325D and 329D Excavator Electrical System: Area ADocument4 pages324D, 325D and 329D Excavator Electrical System: Area AHarry KimNo ratings yet

- Triaxial Test CoggleDocument1 pageTriaxial Test CoggleAndika PerbawaNo ratings yet

- Combivert: Instruction ManualDocument36 pagesCombivert: Instruction Manualruisengo100% (1)

- In Edit State:save Key: 0.4mV/V 6mV/VDocument5 pagesIn Edit State:save Key: 0.4mV/V 6mV/VJulian HortaNo ratings yet

- FX 2n 4 Da Function PDFDocument8 pagesFX 2n 4 Da Function PDFTrần Thanh TiếnNo ratings yet

- VALMEX Structure FDocument2 pagesVALMEX Structure Fanas1984No ratings yet

- GRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsDocument1 pageGRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsJason DaNny FloResNo ratings yet

- 00 F 5 Sebk 320Document40 pages00 F 5 Sebk 320Mr.K chNo ratings yet

- App x86 ServerDocument11 pagesApp x86 ServerOnur FilizoğluNo ratings yet

- Frequency Inverter Convertidor de Frecuencia Inversor de FrequênciaDocument13 pagesFrequency Inverter Convertidor de Frecuencia Inversor de FrequênciamikeNo ratings yet

- SCADA Network ArchitectureDocument1 pageSCADA Network ArchitectureSlick72No ratings yet

- MideaDocument74 pagesMideaivanNo ratings yet

- T&MT Connector: This Portion of The Schematic Shows Components Needed For PHY To Operate in A HS Peripheral ApplicationDocument1 pageT&MT Connector: This Portion of The Schematic Shows Components Needed For PHY To Operate in A HS Peripheral ApplicationЮрий ВетровNo ratings yet

- Digium Failover Appliances Application BriefDocument3 pagesDigium Failover Appliances Application Briefmaple4VOIPNo ratings yet

- Pe 324DDocument4 pagesPe 324DNss Nery100% (1)

- SOUTH Operation ManualDocument236 pagesSOUTH Operation ManualPrashanth Reddy TummuluriNo ratings yet

- Coolmay TK Series User ManualDocument2 pagesCoolmay TK Series User ManualSeferino CampazNo ratings yet

- Accesspro4 InstalaciónDocument2 pagesAccesspro4 InstalaciónJuan Pablo SosaNo ratings yet

- XA2624 QIQI DatasheetDocument5 pagesXA2624 QIQI DatasheetjunclarcNo ratings yet

- Poster CPX VTSA-F-CB EN136116 202111 V01 Screen-MDocument2 pagesPoster CPX VTSA-F-CB EN136116 202111 V01 Screen-MBenjie DucutNo ratings yet

- Uen R 24490001Document12 pagesUen R 24490001Martin Carhuaz AcunaNo ratings yet

- ENGLISH Operating Instructions ManualDocument1 pageENGLISH Operating Instructions ManualRay ZerNo ratings yet

- User'S Guide: JY992D65501CDocument8 pagesUser'S Guide: JY992D65501CAbdulrehmanNo ratings yet

- 966H and 972H Wheel Loader With Steel Mill Electrical SystemDocument6 pages966H and 972H Wheel Loader With Steel Mill Electrical SystemmohamedNo ratings yet

- Simbología de Instrumentación SENATIDocument1 pageSimbología de Instrumentación SENATINavarro Zavala AntonyNo ratings yet

- 564shj22-01-Gym-Tc-101 R1Document1 page564shj22-01-Gym-Tc-101 R1IbrahimUnesNo ratings yet

- D9T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pagesD9T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsfernandoNo ratings yet

- ASIC Implementation of Shared LUT Based Distributed Arithmetic in FIR FilterDocument4 pagesASIC Implementation of Shared LUT Based Distributed Arithmetic in FIR Filtermuneeb rahmanNo ratings yet

- Intel® Workstation Board S5520SC Quick Start User's Guide 1 2Document1 pageIntel® Workstation Board S5520SC Quick Start User's Guide 1 2BleyaNo ratings yet

- licM08V Eng PDFDocument2 pageslicM08V Eng PDFFeeze WdsNo ratings yet

- EVC302L EVCFittingDocument2 pagesEVC302L EVCFittingrenimoNo ratings yet

- 《Mctc Ard C系列电梯应急救援装置用户手册》 英文19010431 b00Document2 pages《Mctc Ard C系列电梯应急救援装置用户手册》 英文19010431 b00kolwin .chindwinNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: MathFrom EverandInstant Assessments for Data Tracking, Grade 4: MathRating: 5 out of 5 stars5/5 (2)

- Instant Assessments for Data Tracking, Grade 4: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 4: Language ArtsRating: 5 out of 5 stars5/5 (1)

- XSupport Jan - Jun 2012Document214 pagesXSupport Jan - Jun 2012arcman17No ratings yet

- MSX125 - 6 - Electric Starter System - 8Document10 pagesMSX125 - 6 - Electric Starter System - 8Teddy KhantNo ratings yet

- CL-NG-6460-002-023 Checklist For CT Rev00Document2 pagesCL-NG-6460-002-023 Checklist For CT Rev00WajahatNo ratings yet

- AVK Group of CompaniesDocument4 pagesAVK Group of CompaniesSathishkumar DhamodaranNo ratings yet

- VRF-SLB005-EN 10 2low PDFDocument48 pagesVRF-SLB005-EN 10 2low PDFJesus DavalosNo ratings yet

- Model1 EDDocument2 pagesModel1 EDskrtamilNo ratings yet

- CHJV04I04P0176Document16 pagesCHJV04I04P0176chemistryjournalNo ratings yet

- PMT-MS-018 Rev.00 - Method of Statement For Chpping and Coring WworksDocument4 pagesPMT-MS-018 Rev.00 - Method of Statement For Chpping and Coring Wworksromeo arazaNo ratings yet

- Fuzzy Based Transformer Less Grid Connected PV System: I J I R S E TDocument6 pagesFuzzy Based Transformer Less Grid Connected PV System: I J I R S E TskrtamilNo ratings yet

- L.D. College of Engineering, Ahmedabad MID-Semester Examination Feb-2021 M.E. (CAD/CAM) Semester-IDocument2 pagesL.D. College of Engineering, Ahmedabad MID-Semester Examination Feb-2021 M.E. (CAD/CAM) Semester-Ibrijesh garasiyaNo ratings yet

- TestDocument3 pagesTestmohanNo ratings yet

- Peppers - CABLE GLANDDocument1 pagePeppers - CABLE GLANDcahyo SNo ratings yet

- Thermodyamics R07Document9 pagesThermodyamics R07hhjjNo ratings yet

- VmsfaqDocument368 pagesVmsfaqMridul MitraNo ratings yet

- SOP Tracked ExcavatorDocument2 pagesSOP Tracked ExcavatordaneyenzNo ratings yet

- Slides.D13A. Presentation. enDocument10 pagesSlides.D13A. Presentation. enAlex PakitoNo ratings yet

- Particular Spec For Geocell - Industrial Plots - East RailwayDocument4 pagesParticular Spec For Geocell - Industrial Plots - East RailwayThameem SharaafNo ratings yet

- Case Study - Ipt Maznur F2002, Akmal F2022Document29 pagesCase Study - Ipt Maznur F2002, Akmal F2022Akmal AzharNo ratings yet

- SyllabusDocument57 pagesSyllabusYasin ArslanNo ratings yet

- Glass KilnsDocument16 pagesGlass Kilnsspaceskipper100% (1)

- Cutler-Hammer: Learning Module 2: Fundamentals of ElectricityDocument39 pagesCutler-Hammer: Learning Module 2: Fundamentals of ElectricityobeNo ratings yet

- Construction of Building Housing & SewerageDocument69 pagesConstruction of Building Housing & SewerageHadi Anwar100% (1)

- Hvac Research Paper TopicsDocument4 pagesHvac Research Paper Topicsgsrkoxplg100% (1)

- AB 14 para Tranzystorow DarlingtonaDocument23 pagesAB 14 para Tranzystorow DarlingtonavengalamahenderNo ratings yet

- Cpx-fb13 - CPX Profibus DPDocument166 pagesCpx-fb13 - CPX Profibus DPAriel BruniNo ratings yet

- MOBO Basic PartsDocument17 pagesMOBO Basic PartsJohara Mundas DiocolanoNo ratings yet

- Sunera Technologies Pvt. LTD.: Standard Operating Procedure TemplateDocument14 pagesSunera Technologies Pvt. LTD.: Standard Operating Procedure Templatesastrylanka_1980No ratings yet

- Specification For Temperature Element/Instrument: S T E / IDocument14 pagesSpecification For Temperature Element/Instrument: S T E / Iamini_mohi100% (1)

- CFSD Data SheetDocument62 pagesCFSD Data Sheettrija_mrNo ratings yet

- U Per Zte Umts Uni-Pos Netmax Introduction v1.30 20150312Document44 pagesU Per Zte Umts Uni-Pos Netmax Introduction v1.30 20150312Frans RapetsoaNo ratings yet

Ass ThermoMETER CTL en

Ass ThermoMETER CTL en

Uploaded by

gerard boonenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ass ThermoMETER CTL en

Ass ThermoMETER CTL en

Uploaded by

gerard boonenCopyright:

Available Formats

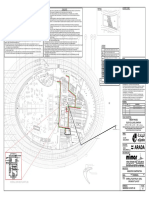

Intended Use Laser Class Mechanical Installation 110 (4.

33)

92 (3.62) 22 (.87)

The thermoMETER CTL is designed for use in industrial and laboratory appli- The thermoMETER CTL sensor works with a double laser sight at a wave- The CTL features a metric M48x1.5 thread and can be directly installed into

4 (.16)

4 (.16) 13 (.51)

cations. It is used for non-contact temperature measurement. length of 635 nm (visible/red). existing mounting devices by using this thread or by using the hexagonal nut

The system must only be operated within the limits specified in the technical The warning sign below is attached to the controller: (default) and fixed mounting bracket (default). M12x1.5

data, see operating instructions, Chap 2. The system must be used in such a

Ø

Avoid rough mechanical force on the sensor.

4.

way that no persons are endangered or machines are damaged in the event

70 (2.76)

LASER

LASER LIGHT

LASER LIGHT

LIGHT

>> Destruction of the system

(.94)

DODO

NOT

NOTSTARE

NOT STARE INTOBEAM

STARE INTO BEAM

of malfunction or total failure of the system. Take additional precautions for

DO INTO BEAM

47 (1.85)

24

CLASS

CLASS 222 LASER

CLASS LASER

LASER

safety and damage prevention in case of safety-related applications.

23 (.91)

< 1< mW

1 mW/ 500

/ 500--650

650 nm

nm

Do not look deliberately into the laser beam! Close 100 (3.94)

(1.97 dia.)

ENEN60825

608251:1:2014

(.16)

2014

(.91)

Warnings

23

your eyes, or immediately turn away if the laser beam 8 (.31)

4

THIS PRODUCT COMPLIES WITH

COMPLIES21 CFR

COMPLIES WITH

WITH 1040.10AND

21 CFR 1040.11

CFR1040.10

1040.10

1040.10 AND

AND

COMPLIES WITH 21 AND

Ø50

EXCEPT FORFORCONFORMANCE

Connect the power supply and the display/output device according to the

1040.11

1040.11

1040.11 EXCEPT

EXCEPT

EXCEPT

WITH

FOR

FOR

IEC

CONFORMANCE

CONFORMANCE

CONFORMANCE

60825-1

ED.ED. 3., hits the eye.

52

WITHWITH

WITH IEC IEC

IEC 60825-1

60825-1

60825-1 ED.

ED. 3.,3.,

3.,AS

ASDESCRIBED

AS

DESCRIBED

DESCRIBED

AS DESCRIBED ININ

DATED

DATED

DATED

DATED

IN

LASER

IN LASER

LASER

LASER

MAY

MAY

MAY

MAY

NOTICE

NOTICE

NOTICE

NOTICE

8, 2019.

8,2019.

8, 2019.

2019.

NO.NO.

NO.

NO. 56,56,

56,

56, 13 4 30

safety regulations for electrical equipment. 89 (3.50)

WS

(.51) (.16) (1.18)

(1.94 dia.)

(2.17 dia.)

M48x1.5

>> Risk of injury, damage to or destruction of the sensor and/or the controller max. 120 (4.72)

Notes on CE Marking

Ø49.3

Avoid shocks and impacts to the sensor and the controller.

Ø55

The following apply to the thermoMETER CTL measuring system: Fig. 2 Dimensional drawing of controller, dimensions in mm, not to scale

>> Damage to or destruction of the sensor and/or the controller

-- EU Directive 2014/30/EU The mounting bracket is included in the scope of delivery.

Avoid rough mechanical force on the sensor. -- EU Directive 2011/65/EU, “RoHS” Category 9 M 12 x 1.5

>> Damage to or destruction of the sensor

(.54 dia.)

The sensor satisfies the requirements if the guidelines in the operating instruc- Cable gland

46.27

13.73

tions are maintained in installation and operation. 30 4 (.16) 57

.)

The supply voltage must not exceed the specified limits.

dia

R3.

(1.82)

( .5

85.5 (1.18) (2.24) 8.5 ia.)

Proper Environment

Ø6

>> Damage to or destruction of the sensor and/or controller. Ø4.91 d

50 .26

3

R5

(3.37) (1

-- Protection class: 135°

(1.97)

Protect the sensor cable against damage.

60°

87 (3.43)

Sensor: IP 65 (NEMA 4) Fig. 1 Dimensional drawing of CTL sensor, dimensions in mm, not to scale R28

>> Destruction of the sensor, failure of the measuring device

ia.)

Controller: IP 65 (NEMA 4) The optical path of the beam must be free of any obstructions. °

6d

Never fold the sensor cable and do not bend it in tight radii. The minimum -- Ambient temperature: 49 (1.93) 90

0

>> Deviation in measurement, inaccurate measured result

Ø6

(2.3

bending radius is 14 mm (static). Dynamic movement is not permitted. Sensor: -20 °C ... +85 °C (-4 °F ... +185 °F) 60 (2.36)

>> Damage to sensor cable, failure of the measuring device (+50 °C (+122 °F) when laser is on) Please enable the integrated double laser to precisely align the sensor with

Controller: 0 ... +85 °C (+32 °F ... +185 °F) 1 the object; see operating instructions. Fig. 3 Dimensional drawing of mounting bracket, dimensions in mm, not to

Avoid exposure of sensor (both optics and housing) to cleaning agents that -- Storage temperature:

contain solvents. scale

Sensor: -40 °C ... +85 °C (-40 °F ... +185 °F)

>> Damage to or destruction of the sensor Controller: -40 °C ... +85 °C (-40 °F ... +185 °F) The sensor can be adjusted on 2 axes by using the adjustable mounting

-- Humidity: 10 ... 95 %, non-condensing bracket; see also operating instructions, Optional Accessories.

Avoid abrupt changes in ambient temperature.

>> Inaccurate or incorrect measurements Unpacking/Included in Delivery

-- 1 thermoMETER CTL sensor and sensor cable

MICRO-EPSILON MESSTECHNIK GmbH & Co. KG

-- 1 Controller You can download a PDF of the detailed operating instructions from our Koenigbacher Str. 15

-- 1 Mounting nut and fixed mounting bracket website: 94496 Ortenburg / Germany

-- 1 Assembly instructions Tel. +49 8542 / 168-0 / Fax +49 8542 / 168-90

http://www.micro-epsilon.de/download/manuals/man--thermoMETER-CTL--en.pdf X9771197-A022030HDR

e-mail info@micro-epsilon.com

1) With temperatures < 0 °C, display function is not guaranteed any more. www.micro-epsilon.com *X9771197-A02*

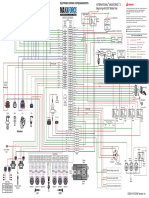

Electrical Installation Pin Assignments for CTLM Models Ground Connection

Pin Explanation A plug connector (jumper) is located on the bottom of the motherboard.

Cable Connection Depending on the position, the ground terminals (GND supply voltage/output)

+8 ... 36 VDC Power supply

The default version is shipped with sensor cables (connection between sen- are connected to the housing ground of the controller, see Fig. 6, see Fig. 8.

GND Power supply ground (0 V)

sor and controller). To prevent ground loops and related signal interference, it may be necessary

GND Internal input and output ground (0 V) to separate this connection in an industrial environment.

To connect the thermoMETER CTL, open the controller cover (4 screws).

AL2 Alarm 2 (open collector output) To do so, remove the board in order to switch the jumper on the back of

The screw terminal connections for connecting the cables are located in the OUT-TC Analog output for thermocouple (J or K) the board by removing the 2 screw connections.

bottom of the controller.

OUT-mV/mA Analog output for object temperature (mV or mA) Please push the jumper into the appropriate position, see Fig. 7, see

Pin Assignments for CTL/CTLF/CTLC/CTLG Models F1-F3 Function inputs Fig. 9.

Pin

+8 - 36 VDC

GND

Explanation

Power supply

Power supply ground (0 V)

GND

3V SW

GND

Ground (0 V)

PINK/power supply for laser (+)

PINK/power supply for laser (-)

i When using the thermocouple output, separation of the ground con-

nection GND - housing is recommended in principle.

Fig. 6 Plug Fig. 7 Plug

GND Internal input and output ground (0 V) BROWN Temperature probe for sensor (NTC) connector connector

OUT-AMB Analog output for sensor temperature (mV) WHITE Sensor ground (jumper), (jumper),

OUT-TC Analog output for thermocouple (J or K) GREEN Power supply (sensor) GND to GND - open; Assembly Instructions

YELLOW Detector signal housing; CTL, CTLF,

OUT-mV/mA Analog output for object temperature (mV or mA) thermoMETER CTL

CTL, CTLF, CTLC, CTLG

F1-F3 Function inputs CTLC, CTLG models

AL2 Alarm 2 (open collector output) models

3V SW PINK/power supply for laser (+)

GND GRAY/power supply for laser (-)

BROWN Temperature probe (sensor) (NTC)

WHITE Ground sensor Fig. 8 Plug Fig. 9 Plug

connector connector

GREEN Power supply sensor

Fig. 5 Open CTLM controller (jumper), (jumper),

YELLOW Detector signal GND - open;

with terminal connections GND to

CTLM models

housing;

Power Supply

CTLM models

Please use a power supply unit with an output voltage of 8 - 36 VDC that

provides at least 160 mA current. Residual ripple should be no more than

200 mV.

Never apply voltage to the analog outputs.

Position

>> Destruction of the output

Cable gland

Fig. 4 Open CTL/CTLF/ thermoMETER CTL is not a two-wire sensor! Board

CTLC/CTLG controller with

terminal connections

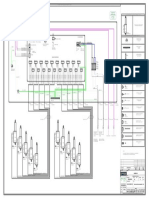

Sensor Cable Installation Inputs and Outputs Digital Interfaces Alarms

The controller’s M12x1.5 cable gland is suitable for cables with an outer The description of the optional digital interfaces is available in the operating The thermoMETER CTL features the following alarm functions:

Analog Outputs instructions. The following interfaces are available: USB, RS232, RS485, Profi-

diameter of 3 to 5 mm. For all alarms (alarm 1, alarm 2, output channels 1 and 2 when used as alarm

Remove the cable insulation (40 mm power supply, 50 mm signal out- The thermoMETER CTL features 1 or 2 output channels. bus, CAN BUS interface, Ethernet, Modbus RTU outputs), a 2 K hysteresis has been permanently set.

puts, 60 mm function inputs). Never apply voltage to the analog outputs. Function Inputs Output channels 1 and 2 (channel 2 only for CTL, CTLG)

Shorten the shielding braid to approx. 5 mm and unravel the shielding The thermoMETER CTL is not a two-wire sensor!

>> Destruction of the output The three function inputs F1 to F3 can only be programmed by using the To be activated, the corresponding output channel must be switched to digital

wires.

CompactConnect software. mode. You can do so only by using the CompactConnect software

Remove approx. 4 mm of the individual core insulations and tin the core

ends. Output channel 1 Function inputs Description Visual alarms

Push the compression screw, washers and the cable screw connection’s This output is used to output the object temperature. The programming keys F1 (digital) Trigger (a 0 V level at F1 resets holding functions)

are used to select the output signal. Output channel 1 can also be pro- These alarms cause the color of the LCD display to change and are available

rubber seal one after another onto the prepared cable end according to F2 (analog)

grammed as an alarm output by using the CompactConnect software. External emissivity [0 - 10 V: 0 V e = 0.1; 9 V by using the optional relay interface. Alarm 2 can additionally be used on pin

the figure, see Fig. 10.

e = 1; 10 V e = 1.1] AL2 on the controller as open collector output [24 V/50 mA].

Spread the shielding braids and affix the cable shield between two metal Output signal Range Connection pin on CT board F3 (analog) External ambient temperature compensation/the The factory default definitions of the alarms are:

discs.

Voltage 0 ... 5 V OUT-mV/mA range can be scaled by using the CompactCon-

Insert the cable into the cable gland until the stop. nect software. Alarm 1 Normally closed/low alarm

Voltage 0 - 10 V OUT-mV/mA

Tightly screw on the cap. Alarm 2 Normally open/high alarm

Current 0 - 20 mA OUT-mV/mA [0 - 10 V: -40 - 900 °C/preset range: -20 - 200 °C]

Individual cores can now be attached to the appropriate screw terminal con- Current 4 - 20 mA OUT-mV/mA F1 - F3 (digital) Emissivity (digital selection using table) Both alarms affect the color settings of the LCD display:

nections based on their colors. An unconnected input is interpreted as follows:

Thermocouple TC J OUT-TC BLUE Alarm 1 active

i Only use shielded ca- Thermocouple TC K OUT-TC F1 = high level

RED Alarm 2 active

i

Pressing screw bles! The sensor must F2, F3 = low level

Metal washer Please note that, depending on the output used, different connection High level: ≥ +3 V- +36 V GREEN No alarm active

Rubber washer be grounded!

pins (OUT-mV/mA or OUT-TC) are used. Low level: ≤ +0.4 V - -36 V For advanced settings, such as defining them as low or high alarm

(by changing normally open/closed) or selecting the signal source [TObject,

034J - PQKE - 0JKH

Output channel 2 (only for CTL, CTLG models) THead, TBox], a digital interface (e.g., USB, RS232) and the CompactConnect

The sensor temperature [-20 ... 180 °C as 0 ... 5 V or 0 ... 10 V signal] is output software are required.

to the OUT AMB connection pin. Output channel 2 can also be programmed

Shield

as an alarm output by using the software. Here the object temperature

TObject or controller temperature TBox can also be used as an alarm source Ratio D = Distance From Device Front Edge to Measured Object/S = Spot Size

Fig. 10 Cable installation

instead of the sensor temperature THead. The size of the object to be measured and the optical resolution of the IR thermometer determine the maximum distance between sensor and object. To avoid

measuring errors, the measured object should completely fill the field of vision of the sensor's optical system. This means, the spot must always be at least as

large as or smaller than the measured object.

D 0 150 300 450 600 750 900 1050 1200 1350 1500 1800 2100 2400

S 20 19.5 19 18.5 18 17.5 17 16.5 16 20.5 25 34 43 52

Fig. 12 Example for model CTL-SF75

Additional D/S ratios are available in the operating instructions.

Operation Display Mode (example) Settings range Display Mode (example) Settings range CompactConnect Software

After the supply voltage is applied, the sensor starts an initialization routine 142CA Current object temperature Cannot be changed M 01 Multidrop address [1] 01 ... 32 Place the CompactConnect installation CD into the corresponding drive

and shows INIT on the display for a few seconds. Next, the object tempera- (only with RS485 interface) on your PC or download the software from our website at: https://www.

MV5 Signal output in output channel 1 0 - 20 = 0 - 20 mA/

ture is displayed. The color of the display lighting changes depending on the B 9.6 Baud rate in kBaud [9.6] 9.6/19.2/38.4/57.6/115.2 kBaud micro-epsilon.de/download/software/thermoMETER-CompactConnect/.

[0 - 5 V] 4 - 20 = 4 - 20 mA/

alarm settings. If Autorun has been enabled on your computer, the installation wizard starts

MV5 = 0 - 5 V/ Error Messages automatically. Otherwise, please start CDsetup.exe on the CD-ROM.

Configuring the Sensor MV10 = 0 - 10 V/

TCJ = thermocouple output The error messages below may appear on the thermoMETER CTL display: Please follow the instructions in the wizard until the installation has been

The programming keys , and allow the configuration of the sensor completed.

type J/ CTL, CTLF, CTLC-4, CTLC-2, CTLC-6, CTLG models

on site. The display shows the current measurement or the selected func-

TCK = thermocouple output OVER Object temperature too high After installation, the CompactConnect software is available on your desktop

tion. The key moves you to the desired function, and change the

type K UNDER Object temperature too low (as a program icon) and in the start menu.

function parameters - a settings change is applied immediately. If no key

is pressed for more than 10 seconds, the display automatically switches to E0.970 Emissivity [0.970] 0.100 ... 1.100 If you want to uninstall the software, please use Uninstall in the start menu.

^^^CH Sensor temperature too high

showing the calculated object temperature (according to the selected signal T1.000 Transmission [1.000] 0.100 ... 1.100 vvvCH Sensor temperature too low A detailed description of the software is available on the CompactConnect

processing). A 0.2 Mean signal output [0.2 s] A---- = inactive/ software CD.

0.1 ... 999.9 s CTLM-1, CTLM-2, CTLM-3, CTLM-5 models

When the key is pressed, you automatical- System Requirements

1st digit -- Windows XP, Windows Vista, Windows 7, 8 and 10

ly reach the last function called. P---- Maximum signal output [inactive] P---- = inactive/ 0.1 ... 999.9 0x No error -- At least 128 MByte RAM

The “maximum search” and “minimum s/P oo oo oo oo = infinite -- USB interface

1x Sensor probe short-circuited after ground (bn)

search” signal processing functions cannot be V---- Minimum signal output [inactive] V---- = inactive/ 0.1 ... 999.9 s/V -- CD-ROM drive

oo oo oo oo = infinite 2x Box temperature too low

selected concurrently. -- Hard drive with at least 30 MByte storage space

u 0.0 Temperature range lower limit Depending on model/inactive 4x Box temperature too high

[0 °C] for TCJ and TCK output 6x Box temperature probe interrupted Main Functions

Mode Up Down Fig. 11 Display and programming keys n 500.0 Temperature range lower limit 8x Box temperature probe short-circuited after ground -- Visual depiction and

[500 °C] recording of temperature

Restoring Factory Setting [ 0.00 Output signal lower limit [0 V] According to the range of the 2nd digit measurements for later

To reset the thermoMETER CTL to factory-set parameters, first press the selected output x0 No error analysis and documenta-

] 5.00 Output signal upper limit [5 V]

key and then the key and hold both for 3 seconds. x2 Object temperature too high tion

U °C Temperature unit [° C] °C/°F -- Setting all sensor param-

x4 Sensor temperature too low

For confirmation, RESET appears on the display. eters and remote sensor

/ 30.0 Lower alarm limit [30 °C] Depending on model x8 Sensor temperature too high monitoring

Display Mode (example) Settings range // 100.0 Upper alarm limit [100 °C] Depending on model -- Programming signal pro-

xC Sensor temperature probe interrupted (bn)

S ON Laser sighting [On] ON/OFF XHEAD Ambient temperature compen- XHEAD = sensor temperature/ cessing functions

142.3C Object temperature (after signal Cannot be changed sation -40.0 - 900.0 °C (for LT) as fixed -- Scaling outputs and setting

processing) [142.3 °C] [sensor temperature] value for compensation/press- parameters for function

ing and at the same inputs

127CH Sensor temperature [127 °C] Cannot be changed

25CB Box temperature [25 °C] Cannot be changed

time switches back to XHEAD

(sensor temperature) i A detailed description of the commands is available on the Compact-

Connect software CD in the folder: \Commands.

You might also like

- SM JCB 3CX 4CX 328739808-9803-3280-9 PDFDocument1,212 pagesSM JCB 3CX 4CX 328739808-9803-3280-9 PDFСергей Ганкевич97% (32)

- MCTC ArdDocument2 pagesMCTC ArdMohammed Sajid80% (5)

- Beckhoff Main Catalog 2016 PDFDocument1,009 pagesBeckhoff Main Catalog 2016 PDFChi Lac PhungNo ratings yet

- AN5506-02-FG (F1G) GPON Optical Network Unit User Manual (Version A) - 1511784409Document2 pagesAN5506-02-FG (F1G) GPON Optical Network Unit User Manual (Version A) - 1511784409Hagyo Jozsef100% (1)

- Procedures or Subprograms: ObjectivesDocument65 pagesProcedures or Subprograms: ObjectivesFebwin VillaceranNo ratings yet

- Thermometre Frontal Sans Contact NoticeDocument4 pagesThermometre Frontal Sans Contact Noticeimane hallisNo ratings yet

- WA MelchiorriDocument70 pagesWA MelchiorriAbhishek DharNo ratings yet

- Plakat FESTO CPX MPA VTSADocument2 pagesPlakat FESTO CPX MPA VTSAtadNo ratings yet

- Poster PA 2015 en A1Document1 pagePoster PA 2015 en A1Dalat TigonNo ratings yet

- 2000 - Marchal - Al - 4D Analogue Modelling - NewInsight - PosterDocument2 pages2000 - Marchal - Al - 4D Analogue Modelling - NewInsight - PosterRobert BlaireauNo ratings yet

- Tan 2001Document6 pagesTan 2001t123medNo ratings yet

- 2021 Figo (India MCA) Tapa de PunteriasDocument8 pages2021 Figo (India MCA) Tapa de PunteriasReneNo ratings yet

- Instrument Hookup 10Document1 pageInstrument Hookup 10Wael ZakariaNo ratings yet

- Batteries: Color Code For Schematic LinesDocument2 pagesBatteries: Color Code For Schematic LinesIsaac NewtonNo ratings yet

- Dball-Chrysler-Rsr en Ig Me20130118Document29 pagesDball-Chrysler-Rsr en Ig Me20130118Mat JonesNo ratings yet

- Control Solenid Main Mod Control Circuit High P0963Document4 pagesControl Solenid Main Mod Control Circuit High P0963Christian Ramos Alarcon100% (1)

- DMKNXDocument2 pagesDMKNXSupuran RichardoNo ratings yet

- SEBoKv1.0 FinalDocument852 pagesSEBoKv1.0 Finalh_bekhitNo ratings yet

- 564shj22-01-Gym-Tc-100 R1Document1 page564shj22-01-Gym-Tc-100 R1IbrahimUnesNo ratings yet

- TNA TemplateDocument4 pagesTNA TemplateSwapon KumarNo ratings yet

- Apple's CSAM Detection MechanismDocument12 pagesApple's CSAM Detection MechanismMike WuertheleNo ratings yet

- Rapid Object Detection Using A Boosted Cascade of Simple FeaturesDocument9 pagesRapid Object Detection Using A Boosted Cascade of Simple FeaturesYuvraj NegiNo ratings yet

- Inovacne Am400 Cpu1608tn NPN PLC Cpu Product Note English 20 4 20Document2 pagesInovacne Am400 Cpu1608tn NPN PLC Cpu Product Note English 20 4 20Manova JNo ratings yet

- 324D, 325D and 329D Excavator Electrical System: Area ADocument4 pages324D, 325D and 329D Excavator Electrical System: Area AHarry KimNo ratings yet

- Triaxial Test CoggleDocument1 pageTriaxial Test CoggleAndika PerbawaNo ratings yet

- Combivert: Instruction ManualDocument36 pagesCombivert: Instruction Manualruisengo100% (1)

- In Edit State:save Key: 0.4mV/V 6mV/VDocument5 pagesIn Edit State:save Key: 0.4mV/V 6mV/VJulian HortaNo ratings yet

- FX 2n 4 Da Function PDFDocument8 pagesFX 2n 4 Da Function PDFTrần Thanh TiếnNo ratings yet

- VALMEX Structure FDocument2 pagesVALMEX Structure Fanas1984No ratings yet

- GRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsDocument1 pageGRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsJason DaNny FloResNo ratings yet

- 00 F 5 Sebk 320Document40 pages00 F 5 Sebk 320Mr.K chNo ratings yet

- App x86 ServerDocument11 pagesApp x86 ServerOnur FilizoğluNo ratings yet

- Frequency Inverter Convertidor de Frecuencia Inversor de FrequênciaDocument13 pagesFrequency Inverter Convertidor de Frecuencia Inversor de FrequênciamikeNo ratings yet

- SCADA Network ArchitectureDocument1 pageSCADA Network ArchitectureSlick72No ratings yet

- MideaDocument74 pagesMideaivanNo ratings yet

- T&MT Connector: This Portion of The Schematic Shows Components Needed For PHY To Operate in A HS Peripheral ApplicationDocument1 pageT&MT Connector: This Portion of The Schematic Shows Components Needed For PHY To Operate in A HS Peripheral ApplicationЮрий ВетровNo ratings yet

- Digium Failover Appliances Application BriefDocument3 pagesDigium Failover Appliances Application Briefmaple4VOIPNo ratings yet

- Pe 324DDocument4 pagesPe 324DNss Nery100% (1)

- SOUTH Operation ManualDocument236 pagesSOUTH Operation ManualPrashanth Reddy TummuluriNo ratings yet

- Coolmay TK Series User ManualDocument2 pagesCoolmay TK Series User ManualSeferino CampazNo ratings yet

- Accesspro4 InstalaciónDocument2 pagesAccesspro4 InstalaciónJuan Pablo SosaNo ratings yet

- XA2624 QIQI DatasheetDocument5 pagesXA2624 QIQI DatasheetjunclarcNo ratings yet

- Poster CPX VTSA-F-CB EN136116 202111 V01 Screen-MDocument2 pagesPoster CPX VTSA-F-CB EN136116 202111 V01 Screen-MBenjie DucutNo ratings yet

- Uen R 24490001Document12 pagesUen R 24490001Martin Carhuaz AcunaNo ratings yet

- ENGLISH Operating Instructions ManualDocument1 pageENGLISH Operating Instructions ManualRay ZerNo ratings yet

- User'S Guide: JY992D65501CDocument8 pagesUser'S Guide: JY992D65501CAbdulrehmanNo ratings yet

- 966H and 972H Wheel Loader With Steel Mill Electrical SystemDocument6 pages966H and 972H Wheel Loader With Steel Mill Electrical SystemmohamedNo ratings yet

- Simbología de Instrumentación SENATIDocument1 pageSimbología de Instrumentación SENATINavarro Zavala AntonyNo ratings yet

- 564shj22-01-Gym-Tc-101 R1Document1 page564shj22-01-Gym-Tc-101 R1IbrahimUnesNo ratings yet

- D9T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pagesD9T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsfernandoNo ratings yet

- ASIC Implementation of Shared LUT Based Distributed Arithmetic in FIR FilterDocument4 pagesASIC Implementation of Shared LUT Based Distributed Arithmetic in FIR Filtermuneeb rahmanNo ratings yet

- Intel® Workstation Board S5520SC Quick Start User's Guide 1 2Document1 pageIntel® Workstation Board S5520SC Quick Start User's Guide 1 2BleyaNo ratings yet

- licM08V Eng PDFDocument2 pageslicM08V Eng PDFFeeze WdsNo ratings yet

- EVC302L EVCFittingDocument2 pagesEVC302L EVCFittingrenimoNo ratings yet

- 《Mctc Ard C系列电梯应急救援装置用户手册》 英文19010431 b00Document2 pages《Mctc Ard C系列电梯应急救援装置用户手册》 英文19010431 b00kolwin .chindwinNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: MathFrom EverandInstant Assessments for Data Tracking, Grade 4: MathRating: 5 out of 5 stars5/5 (2)

- Instant Assessments for Data Tracking, Grade 4: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 4: Language ArtsRating: 5 out of 5 stars5/5 (1)

- XSupport Jan - Jun 2012Document214 pagesXSupport Jan - Jun 2012arcman17No ratings yet

- MSX125 - 6 - Electric Starter System - 8Document10 pagesMSX125 - 6 - Electric Starter System - 8Teddy KhantNo ratings yet

- CL-NG-6460-002-023 Checklist For CT Rev00Document2 pagesCL-NG-6460-002-023 Checklist For CT Rev00WajahatNo ratings yet

- AVK Group of CompaniesDocument4 pagesAVK Group of CompaniesSathishkumar DhamodaranNo ratings yet

- VRF-SLB005-EN 10 2low PDFDocument48 pagesVRF-SLB005-EN 10 2low PDFJesus DavalosNo ratings yet

- Model1 EDDocument2 pagesModel1 EDskrtamilNo ratings yet

- CHJV04I04P0176Document16 pagesCHJV04I04P0176chemistryjournalNo ratings yet

- PMT-MS-018 Rev.00 - Method of Statement For Chpping and Coring WworksDocument4 pagesPMT-MS-018 Rev.00 - Method of Statement For Chpping and Coring Wworksromeo arazaNo ratings yet

- Fuzzy Based Transformer Less Grid Connected PV System: I J I R S E TDocument6 pagesFuzzy Based Transformer Less Grid Connected PV System: I J I R S E TskrtamilNo ratings yet

- L.D. College of Engineering, Ahmedabad MID-Semester Examination Feb-2021 M.E. (CAD/CAM) Semester-IDocument2 pagesL.D. College of Engineering, Ahmedabad MID-Semester Examination Feb-2021 M.E. (CAD/CAM) Semester-Ibrijesh garasiyaNo ratings yet

- TestDocument3 pagesTestmohanNo ratings yet

- Peppers - CABLE GLANDDocument1 pagePeppers - CABLE GLANDcahyo SNo ratings yet

- Thermodyamics R07Document9 pagesThermodyamics R07hhjjNo ratings yet

- VmsfaqDocument368 pagesVmsfaqMridul MitraNo ratings yet

- SOP Tracked ExcavatorDocument2 pagesSOP Tracked ExcavatordaneyenzNo ratings yet

- Slides.D13A. Presentation. enDocument10 pagesSlides.D13A. Presentation. enAlex PakitoNo ratings yet

- Particular Spec For Geocell - Industrial Plots - East RailwayDocument4 pagesParticular Spec For Geocell - Industrial Plots - East RailwayThameem SharaafNo ratings yet

- Case Study - Ipt Maznur F2002, Akmal F2022Document29 pagesCase Study - Ipt Maznur F2002, Akmal F2022Akmal AzharNo ratings yet

- SyllabusDocument57 pagesSyllabusYasin ArslanNo ratings yet

- Glass KilnsDocument16 pagesGlass Kilnsspaceskipper100% (1)

- Cutler-Hammer: Learning Module 2: Fundamentals of ElectricityDocument39 pagesCutler-Hammer: Learning Module 2: Fundamentals of ElectricityobeNo ratings yet

- Construction of Building Housing & SewerageDocument69 pagesConstruction of Building Housing & SewerageHadi Anwar100% (1)

- Hvac Research Paper TopicsDocument4 pagesHvac Research Paper Topicsgsrkoxplg100% (1)

- AB 14 para Tranzystorow DarlingtonaDocument23 pagesAB 14 para Tranzystorow DarlingtonavengalamahenderNo ratings yet

- Cpx-fb13 - CPX Profibus DPDocument166 pagesCpx-fb13 - CPX Profibus DPAriel BruniNo ratings yet

- MOBO Basic PartsDocument17 pagesMOBO Basic PartsJohara Mundas DiocolanoNo ratings yet

- Sunera Technologies Pvt. LTD.: Standard Operating Procedure TemplateDocument14 pagesSunera Technologies Pvt. LTD.: Standard Operating Procedure Templatesastrylanka_1980No ratings yet

- Specification For Temperature Element/Instrument: S T E / IDocument14 pagesSpecification For Temperature Element/Instrument: S T E / Iamini_mohi100% (1)

- CFSD Data SheetDocument62 pagesCFSD Data Sheettrija_mrNo ratings yet

- U Per Zte Umts Uni-Pos Netmax Introduction v1.30 20150312Document44 pagesU Per Zte Umts Uni-Pos Netmax Introduction v1.30 20150312Frans RapetsoaNo ratings yet