Professional Documents

Culture Documents

Chem Poxy Grout E999 Tds Am22319

Chem Poxy Grout E999 Tds Am22319

Uploaded by

Navid Hashemi0 ratings0% found this document useful (0 votes)

2 views2 pagesOriginal Title

Chem Poxy Grout e999 Tds Am22319

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views2 pagesChem Poxy Grout E999 Tds Am22319

Chem Poxy Grout E999 Tds Am22319

Uploaded by

Navid HashemiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

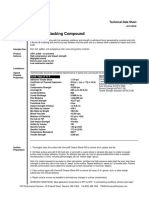

CHEM-POXY GROUT E999

Three Component High Strength

Structural Epoxy Grout

PRODUCT DESCRIPTION Technical Data for Mixed Parts

Property Value at 25°C ASTM Method

CHEM-POXY GROUT E999 is solvent-free 100% solids,

Gel Time (60 grams) 65 min. D-2471

moisture-insensitive three component, ultra-low creep,

Pot Life (10 Kg) 45 min. -

pumpable, high flow and non-shrink epoxy grout system. It is

Density, Lb/Gal (Kg/L) 16.7 (2) D-1475

formulated to be highly flowable for clearances down to 13mm.

Hardness (shore) 82 D D-2240

FIELDS OF APPLICATION Bond Strength to concrete, 620 (4.2) D-4541

Psi (MPa) Concrete failure Method A

CHEM-POXY GROUT E999 provides high strength and creep Bond Strength to steel, Psi (MPa) 120 (0.84) C-321

resistance combined with the highest effective bearing area in Water absorption 0.006% D-570

the industry. CHEM-POXY GROUT E999 is extensively used as Peak Exotherm, (10 Kg) 78°C D-2471

high strength grouting and under-filling of structural elements Coefficient of thermal expansion 6.34×10-5 C-531

in concrete, steel, metal stone etc. that is subject to heavy mm/mm.C

dynamic or static loads e.g.: Final Cure 7 days -

□ High-speed turbines and centrifuges.

□ Bridge bearings. Chemical Resistance: Tests are performed according the

□ Cranes and transport rails. ASTM D543 –Practice A (Immersion test for 7 days at 25°C)

□ Tie bars, holding down and fixing bolts.

□ Load bearing joints between pre-fabricated elements. The fully cured grout is resistant to:

□ Wide cracks >10mm in horizontal concrete surfaces.

□ In accessible holes and cavities in concrete. Water (Distilled, Tap, chlorinated, sewage, sea)

□ New and old machine base plates. Sulfuric acid* 50%wt

Citric Acid, 30% wt

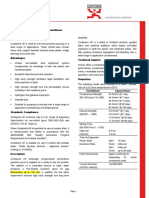

PRODUCT FEATURES Caustic Soda, 50%

□ High effective bearing area. Hydrochloric acid, 15%

□ Highly flowable. Diesel

□ Pumpable. Hydraulic Oil

□ Ultra-low creep. Isopropanol

□ High chemical and impact resistance. Refer to manufacturer for resistance of other reagents.

□ Precision non-shrink.

□ Provides an early high strength. APPLICATION DATA

□ Heat resistant up to 97C. Surface Preparation: prior to application, concrete shall be

□ Excellent adhesion to concrete, metal etc. at its designed strength and dimensional stability.

□ Grouting of effective bearing area from 3 to 75mm.

Concrete Substrates: the concrete must be clean, sound,

PACKAGING and free from oil and grease, curing compounds, mold

releasing agents and loosely adhering particles.

Packaging* Part A- Part B- Part C-

Resin Hardener Aggregate The surface should be scrabbled to remove any laitance and

(Lb/Kg) (Lb/Kg) (Lb/Kg) expose aggregates where possible, preparation of concrete

0.35 ft3 Kit 5.18 (2.35) 1.64 (0.74) 26.18 (11.88) surface should be carried out before the base plate is placed

0.5 ft3 Kit 7.85 (3.56) 2.49 (1.13) 39.66 (18.0) and aligned. Bolt pockets, gaps, wide horizontal cracks, etc.

*These packaging are convenient kits; add part B into part A, must be blown with oil free, clean compressed air to remove

mix thoroughly then add the mixture of A and B into Part C any dirt, debris and loose particles.

container and mix all parts thoroughly.

Steel Surfaces: the underside of the base plates’ machinery

TECHNICAL DATA bolts, etc. must be clean and free from oil, grease or rusting.

Technical Data for Mixed Parts Where possible, steel surfaces should be sandblasted to

Property Temperature Swedish Standard SA 2 1/2 to achieve bright metal.

25C 35C Degreasing shall be carried out thoroughly if any contamination

Compressive Strength ASTM C-579, 1 Day 13500 15700 of oils or grease, etc.

Psi (MPa) (92) (107)

Compressive Strength ASTM C-579, 3 Days 14800 16170 Formwork:

Psi (MPa) (101) (110) Before placing the formwork, ensure that the equipment

Compressive Strength ASTM C-579, 7 Days 15800 16900 and base plate is set and aligned. If any leveling shims are

Psi (MPa) (108) (115)

to be removed upon initial setting of the grout, apply a

Flexural Strength ASTM C-348, 7 Days 6040 6480

Psi (MPa) (41.1) (44.1) thin layer of release agent such as grease carefully for

easy removal.

Ensure the formwork is secure and firm as per the Mechanical pumping is possible (consult our technical

formwork design maintaining that the gap width between department)

the formwork and base plate is wider on the pouring side CLEANING

than the opposite side.

Use a strong detergent and water solution, ketones, lacquer

Formwork fixed around the base plate to contain the grout

thinner or similar solvent to clean surfaces, equipment and

must be as water tight as is practical to prevent grout loss.

tools before grout hardens. After the minimum required grout

Use release agents on the formwork for ease of form work

strengths have been achieved, in-service operation may begin.

release.

Spraying a very light mist of solvent before material becomes

Do not apply the grout when the contact surfaces

un-workable will finish the exposed surfaces.

temperature is less than +10C. Artificial heating may be

adopted if the ambient temperature is less than +10C. STORAGE

Store CHEM-POXY GROUT E999 in a dry and cool place in

Limitations: accordance with recommendations. Ideal temperatures are

Minimum substrate temperature + 10C between 21-27C. Prior to use, check all components for

Maximum permissible moisture content of 5% crystallization. Protect the material from freezing. Shelf Life:

substrate Two Years

Minimum adhesive strength of the pre- 1.5 N/mm2 SAFETY PRECAUTIONS

treated substrate

After full curing, the product is physiologically harmless. Keep

Minimum temperature of product for mixing + 15C

the resin and hardener away from the eyes, mouth and skin.

Minimum temperature for Curing + 10C

Do not inhale vapors. Uncured mixture can cause irritation of

Pre-requisites for Mixing: prior to mixing, CHEM-POXY the skin. The best precaution is to wear safety protective

GROUT E999 should be stored under cover and protected gloves, overall, mask and goggles while working. Skin

from extremes of temperatures, which may cause contamination should be immediately cleaned with soap and

inconsistent workability and cure times for the mixed material. plenty of water. The use of solvents should be avoided. If

Ideally, at least 24 hours before mixing, the estimated quantity resin and hardener splashes into the eyes, wash immediately

of the product should be maintained at approximately 20C. with running water. A Doctor must be visited in all cases.

Forced ventilation should be provided when working with

Mixing: stir component ‘A’ thoroughly prior to mixing hardener solvents.

component. TECHNICAL ASSISTANCE

Add Part ‘B’ hardener to Part ‘A’ resin completely and mix Please contact International Chem-Crete Corporation for

thoroughly using a low speed (max. 60 rpm) electric drill fitted Technical Personnel.

with mixing paddle. While mixing, slowly add Part ‘C’ silica WARRANTY

aggregate and mix from side to side and top to bottom until a

LIMITED WARRANTY: International Chem-Crete Inc.

fully homogeneous mixture of uniform grey color is obtained.

warrants that, at the time and place we make shipment, our

Mixing Time: approx. 5 minutes materials will be of good quality and will conform to our

Using a rubber hammer, tap the mixing pail until no air bubbles published specifications in force on the date of acceptance of

are seen to rise and the grout is level. the order.

DISCLAIMER: The information contained herein is included

Placing: for illustrative purposes only and, to the best of our knowledge,

Pour the prepared mixture immediately into the prepared is accurate and reliable. International Chem-Crete Inc. is not

surface or opening in such a manner that it has the under any circumstances liable to connection with the use of

shortest distance to flow. When under filling base plates, information. As International Chem-Crete Inc. has no control

pour grout from one side or from a corner. Grout must be over the use to which others may put its products, it is

poured continuously until the cavity is completely filled. recommended that the products be tested to determine the

Ensure the area to be grouted is not completely sealed so suitability for specific applications and/or our information is

that any displaced air can be expelled. Ensure evacuation valid in particular circumstances. Responsibility remains with

of entrapped air from voids. the architect or engineer, contractor and owner of the design,

Where placement depth of grout exceeds approx. 75 mm application and proper installation of each product. Specifier

application should be carried out in layers. Second layer and user shall determine the suitability of the product for

should be applied after 6 hours at 25C. specific application and assume all responsibility in connection

Protect the freshly placed grout from rain and dew for 4-6 therewith. AM22319.

hours. Formwork can be carefully removed after the grout

reaches its initial setting approx. after 6 hours.

Manufactured By:

International Chem-Crete Inc., 800 Security Row, Richardson, TX 75081, U.S.A

Tel: (972) 671-6477, Fax: (972) 238-0307

contactus@chem-crete.com www.chem-crete.com

You might also like

- Dow Corning 993 Product InfoDocument4 pagesDow Corning 993 Product InfoLloyd R. PonceNo ratings yet

- Presentation On Ohm's Law and Its Microscopic ViewDocument13 pagesPresentation On Ohm's Law and Its Microscopic ViewTAHIR SRK100% (1)

- Acid Base MCQ PDFDocument6 pagesAcid Base MCQ PDFAsghar100% (1)

- Quakebond J300Sr: The Infrastructure InnovatorsDocument2 pagesQuakebond J300Sr: The Infrastructure Innovatorskhoirul ramadhanNo ratings yet

- QuakeBond-220TC-PDS-0120 (Renforcement Des Hea Avec de La Resine)Document2 pagesQuakeBond-220TC-PDS-0120 (Renforcement Des Hea Avec de La Resine)Amel RNo ratings yet

- RCT-ConGrout EP GPDocument2 pagesRCT-ConGrout EP GPfahadNo ratings yet

- Ikote CM 50X TDS (02-April-2024) V1.3Document2 pagesIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNo ratings yet

- iKOTE CM 40X (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- DR Fixit Coal Tar EpoxyDocument3 pagesDR Fixit Coal Tar EpoxyPritha DasNo ratings yet

- Epoject 304I: General DescriptionDocument2 pagesEpoject 304I: General Descriptionnoblas melNo ratings yet

- Cmci Cmci: High Performance Epoxy Grout SystemDocument2 pagesCmci Cmci: High Performance Epoxy Grout Systempravi3434No ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Sikafloor Proseal 90Document5 pagesSikafloor Proseal 90rakib ahsanNo ratings yet

- X-Roc Epoxybond: Epoxy Resin Bonding AgentDocument2 pagesX-Roc Epoxybond: Epoxy Resin Bonding AgentAmr RagabNo ratings yet

- Resutile Topcoat SD System Guide SWDocument4 pagesResutile Topcoat SD System Guide SWServandoNo ratings yet

- Plastic Steel 5 Minute PuttyDocument3 pagesPlastic Steel 5 Minute PuttyDivyanshu GuptaNo ratings yet

- NG NP Sikatop Seal 107Document3 pagesNG NP Sikatop Seal 107NourhoudaNo ratings yet

- Sika Repair Grout 223Document2 pagesSika Repair Grout 223Bill MurrayNo ratings yet

- PS 14 Anchor Bolt TolerancesDocument4 pagesPS 14 Anchor Bolt TolerancesjebrijaNo ratings yet

- Technical Data Sheet: DescriptionDocument4 pagesTechnical Data Sheet: Descriptionerode els erodeNo ratings yet

- Cmci Cmci: High Flow Epoxy Grout SystemDocument2 pagesCmci Cmci: High Flow Epoxy Grout Systempravi3434No ratings yet

- Epoxy Coating Solvent Free TDSDocument3 pagesEpoxy Coating Solvent Free TDSMohamed MagdiNo ratings yet

- FLEXICOAT PU (I) LatestDocument3 pagesFLEXICOAT PU (I) Latestmathewsujith31No ratings yet

- Sikadur-42 HF PDS PDFDocument4 pagesSikadur-42 HF PDS PDFMiljan MilanovicNo ratings yet

- Epoxy Coating Basf-Masterprotect-100 Sewer StructureDocument3 pagesEpoxy Coating Basf-Masterprotect-100 Sewer StructuresatheeshvmNo ratings yet

- CEMTECR88Document2 pagesCEMTECR88infoNo ratings yet

- Masterflow 622: Heavy Duty Epoxy Resin Chocking GroutDocument2 pagesMasterflow 622: Heavy Duty Epoxy Resin Chocking GroutAndri AjaNo ratings yet

- Conbextra HFDocument4 pagesConbextra HFm.elsanee.cubicNo ratings yet

- Epoxy Sealer SP810Document2 pagesEpoxy Sealer SP810melvinkorahNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- IKOTE CM 31 TDS (11-Oct-2023)Document2 pagesIKOTE CM 31 TDS (11-Oct-2023)nguyen hoang AnhNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- Conbextra EP75: High Strength, Epoxy Resin GroutDocument4 pagesConbextra EP75: High Strength, Epoxy Resin GroutHamkarNo ratings yet

- Mea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaDocument2 pagesMea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaMuhammad hussainNo ratings yet

- Florgard SL: Self Levelling Epoxy Based FlooringDocument3 pagesFlorgard SL: Self Levelling Epoxy Based FlooringRavi KantNo ratings yet

- Sikafloor - 89: 2-Part Water Based Epoxy CoatingDocument4 pagesSikafloor - 89: 2-Part Water Based Epoxy CoatingEaswar KumarNo ratings yet

- 001 PDS Sikafloor-261 SystemDocument10 pages001 PDS Sikafloor-261 SystemdebojyotihatiNo ratings yet

- New 1550HTDocument2 pagesNew 1550HTSantiago MonteroNo ratings yet

- Sikafloor-ColourSeal W 0307Document4 pagesSikafloor-ColourSeal W 0307Chris AdaminovicNo ratings yet

- High Performance Industrial Coal Tar Epoxy: Description and Uses Product ApplicationDocument4 pagesHigh Performance Industrial Coal Tar Epoxy: Description and Uses Product ApplicationChandresh M SachdevNo ratings yet

- Datasheet File Conbextra - HFDocument4 pagesDatasheet File Conbextra - HFandikaNo ratings yet

- Tds-Cpd-Sikalastic 601 BC-usDocument5 pagesTds-Cpd-Sikalastic 601 BC-usgamini pereraNo ratings yet

- Conbextra EP75Document2 pagesConbextra EP75m.basim.technitalNo ratings yet

- DC 1000Document2 pagesDC 1000bassemreda72No ratings yet

- Specification GlassFiberDocument6 pagesSpecification GlassFiberMukesh MaharjanNo ratings yet

- TDS Conbextra EP10 India6Document3 pagesTDS Conbextra EP10 India6jasonNo ratings yet

- Carbozinc Data SheetDocument2 pagesCarbozinc Data SheetIra Purnama SariNo ratings yet

- Conbextra HFDocument4 pagesConbextra HFm.basim.technitalNo ratings yet

- SECTION 09980 Thin Film Polymer Floor Sealer Part 1 - General 1.01Document2 pagesSECTION 09980 Thin Film Polymer Floor Sealer Part 1 - General 1.01Eng CivilNo ratings yet

- SikaTop® Armatec®-110 EpoCem® - PDS - GCC - (10-2016) - 2 - 1Document3 pagesSikaTop® Armatec®-110 EpoCem® - PDS - GCC - (10-2016) - 2 - 1kamran abbasiNo ratings yet

- Fosroc Guncrete E: High Strength, Low Shrinkage, High Build Dry-Spray Applied Repair Mortar Uses Application InstructionsDocument3 pagesFosroc Guncrete E: High Strength, Low Shrinkage, High Build Dry-Spray Applied Repair Mortar Uses Application InstructionsJohnNo ratings yet

- Conbextra HFDocument4 pagesConbextra HFThrtThrthNo ratings yet

- Devcon Plastic Steel Putty (A) - TDSDocument3 pagesDevcon Plastic Steel Putty (A) - TDSsibi_s_raj100% (2)

- Shaliseal Ps GG: DescriptionDocument3 pagesShaliseal Ps GG: DescriptionVikas Singh ChandelNo ratings yet

- 00 Flowcrete Uk Technical Data Isocrete K Screed Bagged July 2021Document2 pages00 Flowcrete Uk Technical Data Isocrete K Screed Bagged July 2021straktwizNo ratings yet

- Plastic Steel Putty (A) : Technical Data SheetDocument3 pagesPlastic Steel Putty (A) : Technical Data SheetsanjayNo ratings yet

- Arkifloor EHGDocument2 pagesArkifloor EHGChristinaNo ratings yet

- Jotafloor: Traffic Deck SystemDocument12 pagesJotafloor: Traffic Deck SystemUnited Construction Est. TechnicalNo ratings yet

- Sikafloor 21 Purcem LP - Pds enDocument6 pagesSikafloor 21 Purcem LP - Pds enWahidCesarRNo ratings yet

- Pro Mastic Ste 87Document4 pagesPro Mastic Ste 87ahmedyahea181No ratings yet

- Sikadur®-42 IN: Product Data SheetDocument4 pagesSikadur®-42 IN: Product Data SheetJackson OmindiNo ratings yet

- Piping Welding General Specification Consortium) Rev-3Document48 pagesPiping Welding General Specification Consortium) Rev-3rvsreddy1972No ratings yet

- Energy Balance and Thermo PresentationDocument83 pagesEnergy Balance and Thermo Presentationca2n27No ratings yet

- UntitledDocument1 pageUntitledgamada begnaNo ratings yet

- Materials Chemistry A: Journal ofDocument9 pagesMaterials Chemistry A: Journal ofnimzaiNo ratings yet

- Ijftr 38 (2) 207-214Document8 pagesIjftr 38 (2) 207-214Suyashi PurwarNo ratings yet

- Welding TipsDocument5 pagesWelding TipsOliverNo ratings yet

- USP 1207 Guidance HerneticidadDocument44 pagesUSP 1207 Guidance HerneticidadEusebio Rodriguez BarraganNo ratings yet

- 242 Wikarta Kuliah IV Keseimbangan Benda TegarDocument21 pages242 Wikarta Kuliah IV Keseimbangan Benda TegarsuidanoverniNo ratings yet

- Centrigual Compressors Course - Very Good PDFDocument91 pagesCentrigual Compressors Course - Very Good PDFVILLANUEVA_DANIEL2064100% (1)

- 2102 Shell Alvania RL PDFDocument1 page2102 Shell Alvania RL PDFthawatchai11222512No ratings yet

- Treatment of Chlorophenols From Wastewaters by Advanced Oxidation ProcessesDocument34 pagesTreatment of Chlorophenols From Wastewaters by Advanced Oxidation Processesvijay kumarNo ratings yet

- AC - MonthlyDocument1 pageAC - MonthlyManibalanNo ratings yet

- Heat Recovery Unit With Built-In Heat Pump System From 900 To 4.000 M /HDocument3 pagesHeat Recovery Unit With Built-In Heat Pump System From 900 To 4.000 M /HAnonymous ZPTCAz9No ratings yet

- Aits 1920 FT V JeemDocument20 pagesAits 1920 FT V JeemManali MishraNo ratings yet

- Automatic Clinical Chemistry Analyzer: Technical SpecificationDocument2 pagesAutomatic Clinical Chemistry Analyzer: Technical SpecificationDharmesh PatelNo ratings yet

- Cryogenic SystemsDocument9 pagesCryogenic SystemsGanesh ThoratNo ratings yet

- Chemical Engineering Science: Yanchang Wang, Fazhi Zhang, Sailong Xu, Lan Yang, Dianqing Li, David G. Evans, Xue DuanDocument7 pagesChemical Engineering Science: Yanchang Wang, Fazhi Zhang, Sailong Xu, Lan Yang, Dianqing Li, David G. Evans, Xue DuankarpanaiNo ratings yet

- Energy Conversion and Management: G. D'Andrea, M. Gandiglio, A. Lanzini, M. SantarelliDocument14 pagesEnergy Conversion and Management: G. D'Andrea, M. Gandiglio, A. Lanzini, M. SantarelliMasis 'Ara' ShahbaziansNo ratings yet

- Tribological Behaviour of Alumina As A Lubricant AdditiveDocument14 pagesTribological Behaviour of Alumina As A Lubricant AdditiveSaipranitha ReddyNo ratings yet

- Bronkhorst Folder El FlowDocument4 pagesBronkhorst Folder El FlowPankaj GargNo ratings yet

- SAC 101 Fundamentals of Soil ScienceDocument5 pagesSAC 101 Fundamentals of Soil Sciencerajap02100% (3)

- ElectrolysisDocument20 pagesElectrolysisGowriram RamNo ratings yet

- Joncryl 1687: PropertiesDocument2 pagesJoncryl 1687: PropertiesHiba NaserNo ratings yet

- Storage Tank Design: Email:moemen - Hussein@alexu - Edu.egDocument58 pagesStorage Tank Design: Email:moemen - Hussein@alexu - Edu.egahmadhatakeNo ratings yet

- Homeostasis AnswersDocument9 pagesHomeostasis AnswersNur AmalinaNo ratings yet

- Corrosion RatesDocument25 pagesCorrosion RatesPanji Aji WibowoNo ratings yet

- 2000... Moujlin, Process IntensificationDocument13 pages2000... Moujlin, Process IntensificationMarilyn Stefanie SevillaNo ratings yet