Professional Documents

Culture Documents

Voice Electro PP 8

Voice Electro PP 8

Uploaded by

Ahmed Dieb0 ratings0% found this document useful (0 votes)

1 views8 pageselectro

Original Title

voice electro pp 8

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentelectro

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views8 pagesVoice Electro PP 8

Voice Electro PP 8

Uploaded by

Ahmed Diebelectro

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 8

Industrial Applications

DR/ OLFAT FADALY

Electrochemical Processes (Industrial Application)

1. Electro-winning of metals.

2. Electro-refinning of metals.

3. Electroplating of metals.

4. Electrolytic production of chemicals.

5. Electro-machining.

6. Production of metal powder.

7. Electroforming and Electrotyping.

8. Aluminum production.

9. Water treatment by electrocoagulation.

10.Water treatment by electrooxidation.

1-Electro-winning of metals:

The process of electrolytic recovery of metals from their ores by

electrolysis.

The process consists of 3 steps:

1. Leaching: the ore is dissolved in a suitable acid.

2. Purification; of the leach liquor by one of the following:

a. Fractional crystallization (SA is much more than SB)

b. Fractional precipitation

c. Solvent extraction

d. Displacement: Zn + Cu++ ---------- Zn++ +Cu (ppt.)

3. The pure electrolyte is electrolyzed by an electrolytic cell to obtain the metal.

The spent acid is circulated to increase leaching.

In electrowinning of metals an insoluble anode is used such

as ( Lead or Carbon or Platinum) Electrodes reactions:

Cathode :

M+ + e ------------------------ M

2H+ + 2e -------------------- H2

(Insoluble Anode) :

4OH- ------------------------------ O2 + 2H2O + 4 e

1-Metals below H2 in e.m.s. deposit with 100% C.E. efficiency ( e.g.

Cu, Ag).

2- Metals above H2 in e.m.s. series deposit with C.E. less than

100% C.E. efficiency due to simultaneous evolution of H2 with

metal.

3- Metals on the top of e.m.s. (e.g. Al, Mg) cannot be deposited

from aqueous solution, but electrolysis from molten bath e.g. Al, is

produced by electrolysis of Cryolite Na3AlF6 at about 1000 0C

2-Electro-refining of Metals:

Anode: consist of the crude metal (impure).

Cathode: of the pure metal is used.

Conditions:

adjusted to deposit the metal at the cathode.

e.g. Crude Cu obtained by thermal reduction contain Two types of impurities:

a- Impurities which are more noble than Cu (e.g. Ag, Au, Se, Te)

b- Impurities which are less noble than Cu (e.g. Zn, Pb, Fe,Ni)

If the anode potential is on the value required to dissolve Cu then:

a. Less noble impurities (above Cu) will dissolve and,

b. More noble impurities (below Cu) will precipitate.

And cathode on the value required to deposit Cu:

The Anode:

Cu --------------------------- Cu++ + 2e

ediss. = eo – [ (RT/ZF) ln(Cu++)]

The Cathode:

Cu++ + 2e ------------------------- Cu

edepos. = eo + [ (RT/ZF) ln (Cu++)]

Ecell(theo) = ecathode + eanode = 0

BUT Notice That:

Ecell(act) = Etheo + 𝜂 e + 𝜂 a + IR

Therefore,

Eact = 𝜂 c + 𝜂 a + IR

From the above equation, the voltage required to operate the

electrorefining cells is small because

Etheo = 0

You might also like

- STOAT Unit Process DescriptionsDocument322 pagesSTOAT Unit Process Descriptionsjjiménez_142046No ratings yet

- Xii em 2022 - 23Document89 pagesXii em 2022 - 23Karan MishraNo ratings yet

- Chemistry General Principles and Processes of Isolation of Elements Q&A 5marksDocument6 pagesChemistry General Principles and Processes of Isolation of Elements Q&A 5marksPramit RanjanNo ratings yet

- ELECTROLYSIS Notes SeparateDocument12 pagesELECTROLYSIS Notes Separatetareakatlo54No ratings yet

- 12 TH V-I ModifiedDocument151 pages12 TH V-I ModifiedAkash VigneshwarNo ratings yet

- METALLURGY NotesDocument7 pagesMETALLURGY NotesRiddhi KhandelwalNo ratings yet

- 10 Unit 3 PrintDocument10 pages10 Unit 3 PrintClaresse NavarroNo ratings yet

- Study Material 6: Concentration of OresDocument15 pagesStudy Material 6: Concentration of OresitishaNo ratings yet

- Isolation and Purification of Metals Easy NotesDocument4 pagesIsolation and Purification of Metals Easy NotesYogesh PatilNo ratings yet

- General PrincipalDocument6 pagesGeneral PrincipalthinkiitNo ratings yet

- Ballad May Alyssa G. MetalsDocument18 pagesBallad May Alyssa G. MetalsMay Alyssa BalladNo ratings yet

- Chapter 13, 14 - Metals PDFDocument9 pagesChapter 13, 14 - Metals PDFAarush SharmaNo ratings yet

- Metalextraction 160519154730 PDFDocument12 pagesMetalextraction 160519154730 PDFnor ainNo ratings yet

- Notes Chapter 3 Class 10 (Metallurgy)Document2 pagesNotes Chapter 3 Class 10 (Metallurgy)Yashmit SanwariaNo ratings yet

- Lesson 1Document21 pagesLesson 1Durairaj RagupathikumarNo ratings yet

- Electrolysis NotesDocument11 pagesElectrolysis NotesMichaela PowellNo ratings yet

- Chem G - 10 Reading Material - IIDocument5 pagesChem G - 10 Reading Material - IIYishakNo ratings yet

- Ores and MetallurgyDocument9 pagesOres and MetallurgyKarthikayan BalajiNo ratings yet

- Module 4 PCEA003Document11 pagesModule 4 PCEA003lightningdarkmemoryNo ratings yet

- General Principles ProcessesDocument19 pagesGeneral Principles ProcessesAnand MurugananthamNo ratings yet

- Metallurgy 2024Document13 pagesMetallurgy 2024pokeninjazxNo ratings yet

- Metals and PolymersDocument37 pagesMetals and PolymerscharlotteconsigoNo ratings yet

- Philsslides Ig IonsandelectrolysisDocument13 pagesPhilsslides Ig Ionsandelectrolysisapi-181176018No ratings yet

- Electrochemical Cell.Document9 pagesElectrochemical Cell.Maku MichaelNo ratings yet

- Chemistry - Notes Icse 10Document25 pagesChemistry - Notes Icse 10Suneet MohanNo ratings yet

- Metals and Non-MetalsDocument23 pagesMetals and Non-MetalsAnonymous ufMAGXcskMNo ratings yet

- Chemistry Corrected Material Unit 12-17Document55 pagesChemistry Corrected Material Unit 12-17Pandu RockingNo ratings yet

- Che Vol1Document139 pagesChe Vol1abiramanNo ratings yet

- Gen Chem - Finals ReviewerDocument9 pagesGen Chem - Finals ReviewerMariel Dela Cruz TeanilaNo ratings yet

- Gen Chem - Finals ReviewerDocument7 pagesGen Chem - Finals ReviewerMariel Dela Cruz TeanilaNo ratings yet

- Chemistry Application of Electrolysis PDFDocument3 pagesChemistry Application of Electrolysis PDFMohammad RussellNo ratings yet

- 7 LensesDocument7 pages7 Lenseskrushnakadam0029No ratings yet

- Copper Electrode PositionDocument4 pagesCopper Electrode Positioncharles-oscar-requiez-4181No ratings yet

- Chemistry Both VolumeDocument293 pagesChemistry Both VolumeHa- -riNo ratings yet

- ElectrochemistryDocument16 pagesElectrochemistryitsshaunboteNo ratings yet

- Project Report On Fused Salt Solution ElectrolysisDocument9 pagesProject Report On Fused Salt Solution Electrolysisvaibhav12345678No ratings yet

- Edited Namma Kalvi 12th Chemistry Unit 1267 Study Material em 215233Document53 pagesEdited Namma Kalvi 12th Chemistry Unit 1267 Study Material em 215233Aakaash C.K.No ratings yet

- Cikgu S.Murali: Chemistry 4 25Document7 pagesCikgu S.Murali: Chemistry 4 25muraliMuNo ratings yet

- Edited Namma Kalvi 12th Chemistry Unit 1267 Study Material em 215233 PDFDocument53 pagesEdited Namma Kalvi 12th Chemistry Unit 1267 Study Material em 215233 PDFAakaash C.K.No ratings yet

- Introduction To Metal ExtractionDocument15 pagesIntroduction To Metal ExtractionschlemielzNo ratings yet

- Parts of A Galvanic CellDocument11 pagesParts of A Galvanic CellHelene Jewel LaxaNo ratings yet

- General Principles and Process of Isolation of Elements-1st DraftDocument43 pagesGeneral Principles and Process of Isolation of Elements-1st DraftKunalWadhawanNo ratings yet

- Metallurgy NotesDocument4 pagesMetallurgy Notesrajeevrai692No ratings yet

- Sat PalDocument4 pagesSat PalAmit Rashmi MishraNo ratings yet

- LXL - Gr12PhysicalSciences - 27 - Redox Reactions - 02sep2014Document5 pagesLXL - Gr12PhysicalSciences - 27 - Redox Reactions - 02sep2014HNo ratings yet

- Electrochemistry - F4Document5 pagesElectrochemistry - F4felixNo ratings yet

- D-& F Block ElementsDocument46 pagesD-& F Block ElementsdetectionisimpressionNo ratings yet

- Electrolysis ChemistryDocument5 pagesElectrolysis ChemistryjamesisaiahlallaNo ratings yet

- General Principles of Isolation of Metals A SHORT NOTEDocument19 pagesGeneral Principles of Isolation of Metals A SHORT NOTEBalaji Selvaraj100% (1)

- Chemistry 6Document7 pagesChemistry 6sinhasuryansh2801No ratings yet

- CHAPTER 6 ElctrochemistryDocument8 pagesCHAPTER 6 ElctrochemistryMohd Nazri Mat JaridNo ratings yet

- Ores & MetallurgyDocument35 pagesOres & MetallurgyCarlosNo ratings yet

- Metallurgy: Metals Physical PropertiesDocument10 pagesMetallurgy: Metals Physical PropertiespbNo ratings yet

- Occurrence of MetalsDocument24 pagesOccurrence of MetalsPamo CaytanoNo ratings yet

- CH 6Document11 pagesCH 6Tr Mazhar PunjabiNo ratings yet

- Chemistry Form 4 Chapter 6Document9 pagesChemistry Form 4 Chapter 6Steven Wong50% (2)

- Handouts FilledDocument31 pagesHandouts FilledMeherwaan SayyedNo ratings yet

- Extractive Metallurgy 2: Metallurgical Reaction ProcessesFrom EverandExtractive Metallurgy 2: Metallurgical Reaction ProcessesRating: 5 out of 5 stars5/5 (1)

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsNo ratings yet

- Magnetic Refrigeration Seminar ReportDocument49 pagesMagnetic Refrigeration Seminar ReportAman agrawal94% (17)

- 037 048djeghaderDocument13 pages037 048djeghaderBorisNo ratings yet

- Bottom Hole PressureDocument12 pagesBottom Hole PressurebrayangtNo ratings yet

- Review Synthesis Properties and Practical ApplicationDocument23 pagesReview Synthesis Properties and Practical ApplicationRasha El-GhazawyNo ratings yet

- Service Manual For Cold RoomsDocument14 pagesService Manual For Cold RoomsDavid NoreñaNo ratings yet

- Engineering Encyclopedia: Saudi Aramco Desktop StandardsDocument12 pagesEngineering Encyclopedia: Saudi Aramco Desktop StandardsFA Ay100% (1)

- Supercritical Fluid Extraction From Vegetable MaterialsDocument78 pagesSupercritical Fluid Extraction From Vegetable MaterialsJonatas LopesNo ratings yet

- Dip PDFDocument27 pagesDip PDFolenin64No ratings yet

- Fatigue Test ProcedureDocument30 pagesFatigue Test ProcedureAsprilla Mangombe100% (1)

- 036 - Guard SFDocument3 pages036 - Guard SFhemajsurya0% (1)

- Equation K-1, K-3 Calculation SpreadsheetDocument4 pagesEquation K-1, K-3 Calculation SpreadsheetjowarNo ratings yet

- An Overview On The Influence of Various Factors On The Properties of Geopolymer Concrete Derived From Industrial By-ProductsDocument26 pagesAn Overview On The Influence of Various Factors On The Properties of Geopolymer Concrete Derived From Industrial By-ProductsTaci AlvesNo ratings yet

- LFC23760 Lgeus) Ecn02 MFL62526026Document42 pagesLFC23760 Lgeus) Ecn02 MFL62526026APmanualshop zNo ratings yet

- Water Repellency - Spray TestDocument3 pagesWater Repellency - Spray TestRetno AnggrainiNo ratings yet

- 18F46-DOMI of Compressors Blowers Level 2Document2 pages18F46-DOMI of Compressors Blowers Level 2ehabwardaNo ratings yet

- Boiler Inspection Report TemplateDocument7 pagesBoiler Inspection Report TemplateDanu KautsarNo ratings yet

- A New Hybrid Thermal Comfort Guideline For The Netherlands (ISSO 74: 2014)Document12 pagesA New Hybrid Thermal Comfort Guideline For The Netherlands (ISSO 74: 2014)ramy86No ratings yet

- Structural Calculation/Stress Analysis: SiplanDocument4 pagesStructural Calculation/Stress Analysis: SiplanMEPMANNo ratings yet

- Calculo de Drenaje Con GeotextilesDocument22 pagesCalculo de Drenaje Con GeotextilesAlba DecimaNo ratings yet

- Experiment (13) : Flow ChannelDocument10 pagesExperiment (13) : Flow ChannelSaikumar GadaleNo ratings yet

- Thermister TrainingDocument6 pagesThermister TrainingkazishahNo ratings yet

- 10 1111@cote 12391Document9 pages10 1111@cote 12391departamento FinancieroNo ratings yet

- The Diffusion of Ammonia and Hydrogen Chloride - Technician NotesDocument2 pagesThe Diffusion of Ammonia and Hydrogen Chloride - Technician NotesFranca OkechukwuNo ratings yet

- Liquid Soap MakingDocument14 pagesLiquid Soap MakingAldjo Sjaaf86% (7)

- Fun With Water Potential WorksheetDocument1 pageFun With Water Potential Worksheetaastha dograNo ratings yet

- Piping Course هام جداDocument206 pagesPiping Course هام جداMohamed Ibrahim100% (1)

- SUPREME Graphene Oxide: Single Layer NanosheetsDocument3 pagesSUPREME Graphene Oxide: Single Layer Nanosheetsonin saspaNo ratings yet

- CornusDocument8 pagesCornusBeni BenjaminNo ratings yet

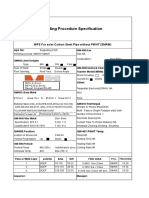

- Welding Procedure Specification: WPS For Exist Carbon Steel Pipe Without PWHT (SMAW)Document1 pageWelding Procedure Specification: WPS For Exist Carbon Steel Pipe Without PWHT (SMAW)Lipika Gayen100% (1)