Professional Documents

Culture Documents

767-05-20-02 B767 PRE FLIGHT CHECK TFL, Iss 05 050815

767-05-20-02 B767 PRE FLIGHT CHECK TFL, Iss 05 050815

Uploaded by

samyghallab0 ratings0% found this document useful (0 votes)

2 views3 pagesOriginal Title

767-05-20-02 B767 PRE FLIGHT CHECK TFL, iss 05 050815

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views3 pages767-05-20-02 B767 PRE FLIGHT CHECK TFL, Iss 05 050815

767-05-20-02 B767 PRE FLIGHT CHECK TFL, Iss 05 050815

Uploaded by

samyghallabCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

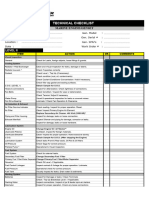

B767 PRE FLIGHT CHECK (GE Powered A/C)

NOTE: For ETOPS flights this check must be accomplished by ETOPS authorised person

Aircraft Operator: Arke Registration

AMP: BAL/BOE/6/TFL Date

Station

Form Revision Date: 05 August 2015

th Performed IAW AMM Revision:

NOTE:

Both the Post Flight and Pre Flight Sections must be accomplished before the aircraft may be dispatched.

Check is to be completed within 2-4 hours of ETOPS departure unless a higher level check has been completed.

The ‘Post Flight’ section tasks must be repeated prior to flight if the time interval between carrying out the ‘Post Flight’ and ‘Pre

Flight’ sections is more than 12 hrs; the only exception being that the task to ‘check engine oil quantity and service as required’,

need not be repeated (as this task is to be carried out within 30 minutes from engine shutdown).

POST FLIGHT SECTION MECH/ INSP

1. Check Radome for damage and security.

Radome

2. Check conductor straps are secured.

1. Check Nose Wheel Bay and Nose Landing Gear for obvious leaks and security.

2. Check Nose Gear Wheel and tyres for condition Ref AMM 32-45-04.

Nose Wheel

3. Check Nose Landing Gear shock strut extension appears normal.

Bay Check

4. Check if nose wheel spin brakes are in place.

5. Check landing light lenses are clean and not damaged.

1. Check surfaces and structures are not damaged.

2. Check static ports, TAT & pitot probes and angle of attack sensors for condition,

also fuselage in area around pitot probes and static ports (RVSM).

3. Check drain masts and drains for fluid leakages.

4. Check navigation/communication antennas for condition.

Fwd Fuselage 5. Visually inspect the ram air inlet/exhaust doors to ensure there are no

Check obstructions.

6. Check positive pressure relief valves have not opened (Red area of valve not on

display).

7. Visually inspect crew oxygen discharge indicator disc for presence.

8. Visually inspect if the negative pressure relief door is closed.

9. Check light lenses are clean and not damaged.

1. General visual inspection of the right engine cowling, inlet cowl, spinner and visible

fan blades for obvious damage.

2. General visual inspection of access panels and doors for condition and security.

3. General visual inspection for open latches and signs of fluid leakage Ref AMM

71-71-00.

Right 4. General Visual inspection of the right engine thrust reverser, exhaust area, strut

Engine Check and visible turbine blades for obvious damage and evidence of metal/oil

accumulation.

5. Check sensors and probes for condition.

6. Check Thrust Reversers are stowed.

7. Check right IDG oil level. Ref AMM 12-13-03

8. Check right IDG Scavenge Filter Differential Pressure Indicator.

1. Check RH wing surface and winglet for obvious damage and fluid leakage and

presence of static dischargers.

2. Make sure the Surge Tank Fuel Press indicator is flush and the vent scoop is not

obstructed.

Right Wing

3. Check visible portion of RH wing flight control surfaces for obvious damage and

Check

fluid leakage.

4. Make sure all wing- and center tank fuel measuring sticks are flush and secured.

5. Check light lenses are clean and not damaged.

6. Check the Fuel Jettison nozzle for condition.

1. Check right Main Wheel Bay and Main Landing Gear as far as visible for obvious

leaks and condition.

Right Main

2. Check right landing gear wheels, tyres Ref AMM 32-45-04 and brakes for wear and

Gear Check

condition Ref AMM 32-41-08.

3. Check right MLG shock strut extension appears normal.

FORM No: 767-05-20-02/TFL - Issue 05 - Page 1 of 3

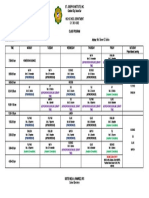

B767 PRE FLIGHT CHECK (GE Powered A/C)

NOTE: For ETOPS flights this check must be accomplished by ETOPS authorised person

1. Check surfaces and structures are not damaged.

2. Check navigation/communication antennas for condition.

3. Check the Ram Air Turbine door for security.

Aft 4. Check vertical fin and rudder, horizontal stabilizers and elevators for obvious

Fuselage and damage, evidence of fluid leakage, and presence of static dischargers.

Empennage 5. Check drain masts and drains for fluid leakage.

Check 6. Visually inspect the cabin pressure outflow valve to ensure there are no

obstructions.

7. Check APU Exhaust outlet to ensure there are no obstructions.

8. Visually inspect the tailskid assembly for signs of tail strike.

1. Check LH wing surface and winglet for obvious damage and fluid leakage and

presence of static dischargers.

2. Make sure the Surge Tank Fuel Press indicator is flush and the vent scoop is not

obstructed.

Left Wing Check 3. Check visible portion of LH wing flight control surfaces for obvious damage and

fluid leakage.

4. Make sure all wing- and center tank fuel measuring sticks are flush and secured.

5. Check light lenses are clean and not damaged.

6. Check the Fuel Jettison nozzle for condition.

1. General visual inspection of the left engine cowling, inlet cowl, spinner and visible

fan blades for obvious damage.

2. General visual inspection of access panels and doors for condition and security.

3. General visual inspection for open latches and signs of fluid leakage Ref AMM

71-71-00.

Left Engine

4. General Visual inspection of the left engine thrust reverser, exhaust area, strut and

Check

visible turbine blades for obvious damage and evidence of metal/oil accumulation.

5. Check sensors and probes for condition.

6. Check Thrust Reversers are stowed.

7. Check left IDG oil level. Ref AMM 12-13-03.

8. Check left IDG Scavenge Filter Differential Pressure Indicator.

1. Check left Main Wheel Bay and Main Landing Gear as far as visible for obvious

leaks and condition.

Left Main Gear

2. Check left landing gear wheels, tyres Ref AMM 32-45-04 and brakes for wear and

Check

condition Ref AMM 32-41-08.

3. Check Left MLG shock strut extension appears normal.

VOLCANIC ASH

If obvious signs of ash contamination, or flight through suspected volcanic ash

Special environment or flight crew report in ATL:

Ensure that a Technical Occurrence Report is raised and carryout the Volcanic Ash

Inspection Supplement of ENG 767-05-20-02/TFL.

Check crew seats (including adjusters and seat lock) and harness for operation,

condition and security. Ensure life jackets in stowage and panels secure.

ETOPS QUALIFICATION REQUIRED

BETWEEN 5 AND 30 MINUTES FROM ENGINE SHUTDOWN

Check the Left and Right Engine oil quantity by EICAS and service for intended flight

(MPD 79-309-01). Assess previous sector reports for excessive oil up-lift, consult

Maintrol for an oil consumption report if concerned.

Record in the ATL the amount of oil up lifted.

Calculate oil consumption as per AMM TASK 71-00-00/201 and take corrective

actions as required.

NOTE: If no oil uplift report 0

Flight Deck Check the left, right and centre hydraulic system quantities using flight deck

indications Ref AMM 29-33-00. Record in the ATL the amount of fluid uplifted.

NOTE: If no fluid uplift report 0

Verify EICAS STATUS level messages or higher are resolved. If not, confirm approved

dispatch paperwork is applied.

Check APU and engine fire extinguisher bottle discharge pressure warning lights are

extinguished.

Check flight deck windscreens and windows for cleanliness and serviceability.

Check crew oxygen pressure on EICAS, ensure above 1000 psi. Raise ADD if pressure

is below 1000 psi.

1. Check crew seats (including adjusters and seat lock) and harness for operation,

condition and security. Ensure life jackets in stowage and panels secure.

FORM No: 767-05-20-02/TFL - Issue 05 - Page 2 of 3

B767 PRE FLIGHT CHECK (GE Powered A/C)

NOTE: For ETOPS flights this check must be accomplished by ETOPS authorised person

2. Check cockpit windscreens and windows for cleanliness and serviceability.

3. ETOPS Check Engine oil quantity (within 30 minutes from engine shutdown) by

EICAS and service for intended flight (MPD 79-309-01). Assess previous sector

reports for excessive oil up-lift, consult Maintrol for an oil consumption report if

concerned - Record uplift on Sector Page. Ref. AMM 12-13-01.

1. Perform a general visual inspection of the passenger cabin.

2. Check lavatories:

a. All receptacles shall be inserted to ascertain that all entry flaps or doors

Cabin still operate, fit, seal and latch correctly, ashtrays are fitted, 'No Smoking'

placards installed and receptacle stowage compartment is clean with all

debris removed.

b. Any defects revealed by inspection of (a.) are corrected.

PRE FLIGHT SECTION MECH / INSP

Check complete aircraft externally:

1. Check for obvious damage, defects and leakage.

2. Check panels for security.

3. Check landing gear and flight control locks/pins removed.

4. Check pitot static covers and blanks removed.

5. Ensure Ice, frost or snow removed as required paying particular attention to

External

airfoils, control surfaces and hinges.

6. Visually inspect crew oxygen discharge indicator disc for presence.

7. Check that fuelling station door is closed.

8. After toilet and water servicing, check cavities and water tank drain outlets for

signs of leakage and correct fitment of blanking caps.

9. Check tyres after towing Ref AMM 32-45-04.

Review aircraft logbook for reported discrepancies and oil consumption from

previous flights.

Check circuit breakers – appropriate circuit breakers closed and correctly TAGGED if

deactivated.

Flight Deck Ensure wing and tail hydraulic shut-off valves are selected on.

Check the left, right and centre hydraulic system quantities using flight deck

indications Ref AMM 29-33-00.

Record in the ATL the amount of fluid uplifted.

NOTE: If no fluid uplift report 0

ETOPS Check ‘APU Oil Qty’ EICAS status message is NOT displayed.

If engine oil uplift has been performed:

Ensure left and right oil filler cap are fitted correct and secure.

Check if all landing gear pins are removed.

Check if all engine, pitot tube and static port covers are removed.

Re-Inspect Check if all access doors and service panels are closed and locked.

Verify EICAS STATUS level messages and higher are resolved. If not, confirm

approved dispatch paperwork is applied.

Check ADD's for any items that may affect the intended flight.

Verify if 48 hrs check is still valid.

ITEM Maintenance task List MECH/INSP

FINAL ACTIONS

Certify ETOPS PFC in the Aircraft Technical Log. At Check carried out fill in: PFC +

ETOPS (ETOPS only if it is required)

………………………………………….END………………………………………….

FORM No: 767-05-20-02/TFL - Issue 05 - Page 3 of 3

You might also like

- Technical Report Checklist - MARINE ENGINESDocument2 pagesTechnical Report Checklist - MARINE ENGINESsary qasimNo ratings yet

- VMC Preventive Master Check ListDocument33 pagesVMC Preventive Master Check Listmugunthaa6686% (14)

- Emirates Daily CHK B777 Rev.99 (Qaf0336) PDFDocument12 pagesEmirates Daily CHK B777 Rev.99 (Qaf0336) PDFabu72100% (1)

- Moduspec ChecklistDocument64 pagesModuspec Checklistbehnam197100% (9)

- A319/A320/A321 Transit CheckDocument2 pagesA319/A320/A321 Transit CheckHiram ThomasNo ratings yet

- A320-200 WEEKLY CHECK (Daily) : Airworthiness ManagementDocument7 pagesA320-200 WEEKLY CHECK (Daily) : Airworthiness ManagementOmair Aziz Rabbani100% (3)

- A320 Family Line Maintenance Task Card - Weekly Check: CockpitDocument4 pagesA320 Family Line Maintenance Task Card - Weekly Check: CockpitSuman BajracharyaNo ratings yet

- Truck and Trailer Report DocumentDocument1 pageTruck and Trailer Report DocumentZeckNo ratings yet

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsFrom EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsRating: 5 out of 5 stars5/5 (1)

- Is A 80th Percent Design Point Logical?Document7 pagesIs A 80th Percent Design Point Logical?Thiago JatobáNo ratings yet

- 767-05-20-02 B767 PRE FLIGHT CHECK Iss 22Document2 pages767-05-20-02 B767 PRE FLIGHT CHECK Iss 22samyghallabNo ratings yet

- 737-05-20-02-JT - PRE FLIGHT Iss 01 Rev 02Document2 pages737-05-20-02-JT - PRE FLIGHT Iss 01 Rev 02samyghallabNo ratings yet

- Mooney M20 100 Hour Annual 2007Document2 pagesMooney M20 100 Hour Annual 2007flyokie100% (1)

- Weekly Check A320Document7 pagesWeekly Check A320TDHNo ratings yet

- Weekly Check A320 PDFDocument7 pagesWeekly Check A320 PDFTDHNo ratings yet

- Effective From 17.07.19 PFI Boeing 737NG & MAX Issue 5, Rev-8Document3 pagesEffective From 17.07.19 PFI Boeing 737NG & MAX Issue 5, Rev-8Naresh Kumar PrajapatNo ratings yet

- 767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07Document3 pages767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07samyghallabNo ratings yet

- 737-05-20-02-NG - PRE FLIGHT Iss 13Document2 pages737-05-20-02-NG - PRE FLIGHT Iss 13samyghallabNo ratings yet

- Transit CheckDocument2 pagesTransit Checka.teamwork2016No ratings yet

- Transit Card A320 A321 NEO Transit Task Card Issue 23 - Rev 1 - 21-Mar-2023Document4 pagesTransit Card A320 A321 NEO Transit Task Card Issue 23 - Rev 1 - 21-Mar-2023Debasis Roy100% (1)

- Etops Pre-Departure Service CheckDocument2 pagesEtops Pre-Departure Service CheckHerix Ferrer100% (1)

- Guia 695Document16 pagesGuia 695Elikaty Servicios AereosNo ratings yet

- P2006T Tua Quick Checkli̇stDocument19 pagesP2006T Tua Quick Checkli̇staskinfirataskinNo ratings yet

- Updated ChklistDocument29 pagesUpdated ChklistKushal MankaniNo ratings yet

- Guias de Inspeccion Cheyenne IIDocument23 pagesGuias de Inspeccion Cheyenne IIesedgar100% (1)

- 2AB Daily Check A319Document8 pages2AB Daily Check A319Umer JavedNo ratings yet

- Transit Pre Flight Task Card AirbusDocument8 pagesTransit Pre Flight Task Card AirbusAbhijeet ChinchaneNo ratings yet

- CT182T Normal ProceduresDocument19 pagesCT182T Normal Proceduresrhqcrtv88vNo ratings yet

- 1 PRVDocument280 pages1 PRVroberto.mesaNo ratings yet

- 61-ESSAY Questions-M8Document12 pages61-ESSAY Questions-M8Raul DeonarainNo ratings yet

- MotorDocument4 pagesMotorjoaofelippejsaNo ratings yet

- Trip Check A330Document4 pagesTrip Check A330Omair Aziz RabbaniNo ratings yet

- Checklist Pa38Document14 pagesChecklist Pa38LarsNo ratings yet

- Unit Iv Classification of Jet Engine ComponentsDocument81 pagesUnit Iv Classification of Jet Engine Componentsraj6062No ratings yet

- B737-300F Aircraft Daily CheckDocument10 pagesB737-300F Aircraft Daily CheckUmer JavedNo ratings yet

- Engine Essay QuestionDocument7 pagesEngine Essay QuestionFikri MohamadNo ratings yet

- BOEING 737-Resumo Checks ManutençãoDocument4 pagesBOEING 737-Resumo Checks ManutençãoWendler PaivaNo ratings yet

- 05 20 00Document27 pages05 20 00Walter TorenaNo ratings yet

- Weekly Check A320 (ISSUE 01 REV 00 01-JUN-15) PDFDocument10 pagesWeekly Check A320 (ISSUE 01 REV 00 01-JUN-15) PDFSabeeka BatoulNo ratings yet

- Daily Check A320 (Issue 02 Rev 04)Document8 pagesDaily Check A320 (Issue 02 Rev 04)Junaid YounusNo ratings yet

- Inspection Unit PC 200Lc - 8moDocument28 pagesInspection Unit PC 200Lc - 8moBima AditamaNo ratings yet

- Moe P 2L Rev 1Document9 pagesMoe P 2L Rev 1Trailblazer487No ratings yet

- Impac Vehicle Maintenance Sheet - C, D, EDocument6 pagesImpac Vehicle Maintenance Sheet - C, D, EFranklyn MunroeNo ratings yet

- Sample Preventative Maintenance Inspection Sheet: Fixed Route Vehicle InspectionDocument4 pagesSample Preventative Maintenance Inspection Sheet: Fixed Route Vehicle InspectionVin BdsNo ratings yet

- Mooney M20 100hour PDFDocument2 pagesMooney M20 100hour PDFsplyn100% (1)

- PM Inspection SheetDocument4 pagesPM Inspection SheetYogeshNo ratings yet

- Pa 18 InspDocument4 pagesPa 18 InspPeter Thomas100% (1)

- 36-Hours Check SheetDocument15 pages36-Hours Check SheetThax NgeNo ratings yet

- Authority Prepared by Reviewed L1 Reviewed L2 Approved byDocument33 pagesAuthority Prepared by Reviewed L1 Reviewed L2 Approved byASHXQ39WNo ratings yet

- Annual&100 Check ListDocument13 pagesAnnual&100 Check ListTarek ElghazzalyNo ratings yet

- Chapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1Document75 pagesChapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1carmen solanoNo ratings yet

- A320-214 Transit Check Sheet Pictorial Issue-07 Dated Jul 19,2021Document4 pagesA320-214 Transit Check Sheet Pictorial Issue-07 Dated Jul 19,2021nobertadilNo ratings yet

- Routine and Non ROUTine Hau HandoutsDocument2 pagesRoutine and Non ROUTine Hau HandoutsIan BautistaNo ratings yet

- Periodic Service Maintenance CheckpointDocument2 pagesPeriodic Service Maintenance Checkpointresumemurahmy11No ratings yet

- Lesson Hydraulic Control Oil TroubleshootingDocument6 pagesLesson Hydraulic Control Oil Troubleshootingmister pogi100% (1)

- RR250 - C30 OmmDocument16 pagesRR250 - C30 OmmturboshaftNo ratings yet

- Preventive Maintenance Check ListDocument23 pagesPreventive Maintenance Check Listindrabhansingh22443No ratings yet

- Internal - 3 Afme Part - A 1. What Are The Types Aircraft Hydraulic FluidDocument6 pagesInternal - 3 Afme Part - A 1. What Are The Types Aircraft Hydraulic FluidNambi RajanNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Druck PTX1400Document4 pagesDruck PTX1400samyghallabNo ratings yet

- Druck Dpi261Document5 pagesDruck Dpi261samyghallabNo ratings yet

- RadiallDocument67 pagesRadiallsamyghallabNo ratings yet

- 767-1501-Part B - Kit ListDocument3 pages767-1501-Part B - Kit ListsamyghallabNo ratings yet

- M85049 38 9W Amphenol 1158036Document12 pagesM85049 38 9W Amphenol 1158036samyghallabNo ratings yet

- BKAD 17augDocument19 pagesBKAD 17augsamyghallabNo ratings yet

- Arinc 600 SeriesDocument48 pagesArinc 600 SeriessamyghallabNo ratings yet

- 767-05-20-08-TFL B767 125 HOUR SERVICE CHECK (FLIGHT HOURS) TFL (Iss 07)Document2 pages767-05-20-08-TFL B767 125 HOUR SERVICE CHECK (FLIGHT HOURS) TFL (Iss 07)samyghallabNo ratings yet

- 757-05-20-07.iss2. POST MAINTENANCE CHECK FORMDocument2 pages757-05-20-07.iss2. POST MAINTENANCE CHECK FORMsamyghallabNo ratings yet

- 737-35-21-04 Iss 4Document2 pages737-35-21-04 Iss 4samyghallabNo ratings yet

- 767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07Document3 pages767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07samyghallabNo ratings yet

- 767-05-20-07 POST MAINTENANCE CHECK FORM - Iss3Document2 pages767-05-20-07 POST MAINTENANCE CHECK FORM - Iss3samyghallabNo ratings yet

- 737-05-20-04-JT - 48 HRS Iss 01 Rev 02Document3 pages737-05-20-04-JT - 48 HRS Iss 01 Rev 02samyghallabNo ratings yet

- 131-9B Discrepancy SheetDocument2 pages131-9B Discrepancy SheetsamyghallabNo ratings yet

- 737-05-20-02-NG - PRE FLIGHT Iss 13Document2 pages737-05-20-02-NG - PRE FLIGHT Iss 13samyghallabNo ratings yet

- Senior RadiographerDocument1 pageSenior Radiographertafi66No ratings yet

- Magmatic Garnet in The TriassicDocument27 pagesMagmatic Garnet in The TriassicCARLOS RODRIGUEZNo ratings yet

- Waxes For PVC ProcessingDocument33 pagesWaxes For PVC ProcessingFrancisco Venegas Zuñiga100% (1)

- MD ShaftDocument18 pagesMD Shaftiftikhar ahmedNo ratings yet

- How To Calculate Paint QtyDocument2 pagesHow To Calculate Paint QtyVijay GaikwadNo ratings yet

- David J. A. Clines The Theme of The Pentateuch Jsot Supplement Series, 10 1997 PDFDocument177 pagesDavid J. A. Clines The Theme of The Pentateuch Jsot Supplement Series, 10 1997 PDFVeteris Testamenti Lector100% (14)

- ACP Employability WorkshopDocument12 pagesACP Employability Workshoplalit saraswatNo ratings yet

- Kisssoft Tut 016 E WormgearDocument16 pagesKisssoft Tut 016 E WormgearIbraheem KhressNo ratings yet

- Exp 6Document12 pagesExp 6Mehul VermaNo ratings yet

- KB00194 - DCOM Settings For The OPC Interface That Cause The Following Errors - Advise Returns Error 8004020 - or PIPCDocument1 pageKB00194 - DCOM Settings For The OPC Interface That Cause The Following Errors - Advise Returns Error 8004020 - or PIPCJunior PassosNo ratings yet

- Delhi Building Bye Law Related To FireDocument68 pagesDelhi Building Bye Law Related To FireTaniya SahaNo ratings yet

- 9 St. Catherine Class ScheduleDocument1 page9 St. Catherine Class ScheduleAleah TungbabanNo ratings yet

- Book Order FormDocument2 pagesBook Order Formbinaya BehuraNo ratings yet

- Himax HX8347Document170 pagesHimax HX8347whistle-blowerNo ratings yet

- 47lw5600 PDFDocument28 pages47lw5600 PDFJose Barroso GuerraNo ratings yet

- TM Meeting Roles HBDDocument4 pagesTM Meeting Roles HBDHB DayaratneNo ratings yet

- Effect Coolant Temp OnDocument7 pagesEffect Coolant Temp OnM Hidayatullah NurNo ratings yet

- Ainscow, Farrell y Tweddle IJIE - 00 Developing Policies For Inclusive EducationDocument19 pagesAinscow, Farrell y Tweddle IJIE - 00 Developing Policies For Inclusive EducationMatías Reviriego RomeroNo ratings yet

- The Importance of Work-Life Balance On Employee Performance Millennial Generation in IndonesiaDocument6 pagesThe Importance of Work-Life Balance On Employee Performance Millennial Generation in IndonesiaChristianWiradendiNo ratings yet

- Z:/windchill/codebase Z:/windchill/codebaseDocument3 pagesZ:/windchill/codebase Z:/windchill/codebaseamalNo ratings yet

- Career Point: Fresher Course For IIT JEE (Main & Advanced) - 2017Document3 pagesCareer Point: Fresher Course For IIT JEE (Main & Advanced) - 2017PrashantNo ratings yet

- Lesson Plan Template - Social EmotionalDocument2 pagesLesson Plan Template - Social Emotionalapi-573540610No ratings yet

- Social and Cultural Issues On GenderDocument25 pagesSocial and Cultural Issues On GenderKipi Waruku BinisutiNo ratings yet

- Nuclear Plant - Tdl-011webDocument133 pagesNuclear Plant - Tdl-011webMayer FernandesNo ratings yet

- Biomaterials and Nanotechnology For Tissue Engineering KrishnanDocument371 pagesBiomaterials and Nanotechnology For Tissue Engineering KrishnanRêmulo FariasNo ratings yet

- Instruction Manual of PLC WS3U-B Series: For The Following Models: WS3U-14MR-K-B WS3U-14MT-K-B WS3U-14MRT-K-BDocument17 pagesInstruction Manual of PLC WS3U-B Series: For The Following Models: WS3U-14MR-K-B WS3U-14MT-K-B WS3U-14MRT-K-BLegendNo ratings yet

- KE Units CompDocument7 pagesKE Units CompKhanNo ratings yet

- Paint Finishing Quality and Defect AnalysisDocument6 pagesPaint Finishing Quality and Defect AnalysisAnurag SrivastavaNo ratings yet

- Effective Communication ActivityDocument4 pagesEffective Communication ActivityLaura Ruiz BallesterosNo ratings yet