Professional Documents

Culture Documents

RMD1609-001 FDR Smart FGXR-S Operation Manual Rev.15-36-169

RMD1609-001 FDR Smart FGXR-S Operation Manual Rev.15-36-169

Uploaded by

christisking8888888Copyright:

Available Formats

You might also like

- Instant Download Ebook PDF Advanced Health Assessment Clinical Diagnosis in Primary Care 6th Edition PDF ScribdDocument41 pagesInstant Download Ebook PDF Advanced Health Assessment Clinical Diagnosis in Primary Care 6th Edition PDF Scribdroger.maldonado98598% (53)

- Dja2500 - 4000 Service Manual PDFDocument38 pagesDja2500 - 4000 Service Manual PDFVedmitra Sharma74% (19)

- Waukesha L7044GSI PLANOS ESM2Document443 pagesWaukesha L7044GSI PLANOS ESM2Juan Hernández Gil100% (3)

- Dja2500 - 4000 Service Manual PDFDocument38 pagesDja2500 - 4000 Service Manual PDFVedmitra Sharma100% (3)

- Emf 839 ManualDocument28 pagesEmf 839 ManualCarlos CrisostomoNo ratings yet

- Smartpocket™ Optical Power Meters: Key FeaturesDocument4 pagesSmartpocket™ Optical Power Meters: Key FeaturesZezo MarchettiNo ratings yet

- Del DRV Indico 100 Operator's ManualDocument64 pagesDel DRV Indico 100 Operator's ManualBusari Oyinlola BimpeNo ratings yet

- FCC ID: K66FT-2800M Operating ManualDocument42 pagesFCC ID: K66FT-2800M Operating ManualLisnik W. F. BerrielNo ratings yet

- The English Manual of FUTV4443A 4in1 Mux-Scrambling QAMDocument42 pagesThe English Manual of FUTV4443A 4in1 Mux-Scrambling QAMbalthazorrNo ratings yet

- USRP-2900: SpecificationsDocument6 pagesUSRP-2900: SpecificationssubuhpramonoNo ratings yet

- Analizador Divaiser e 8600bDocument2 pagesAnalizador Divaiser e 8600bFernando Aquino BerriosNo ratings yet

- WF 300 User Manual 20.10.20Document12 pagesWF 300 User Manual 20.10.20Nabeel TahirNo ratings yet

- DSEA106 MKII Installation InstructionsDocument2 pagesDSEA106 MKII Installation Instructionssami akermiNo ratings yet

- Quality Performance Reputation 2 - Year Limited Warranty: Multi-Frequency Digital Line TracerDocument8 pagesQuality Performance Reputation 2 - Year Limited Warranty: Multi-Frequency Digital Line Tracerlogistica 902No ratings yet

- User Manual - Band RepeaterDocument11 pagesUser Manual - Band RepeaterVictor BejaranoNo ratings yet

- LELO - TOR 3 - Online Manual - ENGDocument20 pagesLELO - TOR 3 - Online Manual - ENGebercueNo ratings yet

- Orca ManualDocument93 pagesOrca ManualanamackicNo ratings yet

- RF-382A Series: Tactical Radio ProductsDocument2 pagesRF-382A Series: Tactical Radio Productsfalcom2No ratings yet

- IC-9700 Serv MANUAL PDFDocument93 pagesIC-9700 Serv MANUAL PDFZibi WolfNo ratings yet

- 6G Spectrum - Analyzer Device User ManualDocument23 pages6G Spectrum - Analyzer Device User ManualddgChrgrNo ratings yet

- GFG 8219a Doc 1Document20 pagesGFG 8219a Doc 1alexjx65No ratings yet

- Function GeneratorDocument37 pagesFunction GeneratorRoberto Angel Lora MartinezNo ratings yet

- VHF Transceiver: S-14708XZ-C1 Sep. 2010Document29 pagesVHF Transceiver: S-14708XZ-C1 Sep. 2010Kien NguyenNo ratings yet

- Service Manual: Uhf/Vhf FM Transceiver PX-777/328/338Document15 pagesService Manual: Uhf/Vhf FM Transceiver PX-777/328/338fure fdaqNo ratings yet

- 34 Xy 03 57Document8 pages34 Xy 03 57Manzoor-ul- HassanNo ratings yet

- Entrust Data SheetDocument2 pagesEntrust Data SheetJorge Iván Bustamante LoperaNo ratings yet

- 27C8744 (Rev. 1) Printed in U.S.A.: 2008 Shure IncorporatedDocument6 pages27C8744 (Rev. 1) Printed in U.S.A.: 2008 Shure IncorporatedAbdalhakeem Al turkyNo ratings yet

- AT-100Pro Automatic Antenna Tuner: LDG ElectronicsDocument22 pagesAT-100Pro Automatic Antenna Tuner: LDG ElectronicsAndriyNo ratings yet

- Cable Fault LocationDocument16 pagesCable Fault LocationPaulo CardosoNo ratings yet

- Ic-M34 Service ManualDocument30 pagesIc-M34 Service Manualандрей назаровNo ratings yet

- DVR 2400 Digital Voltage Regulator: New Features True Rms Voltage Sensing - Single or Three PhaseDocument2 pagesDVR 2400 Digital Voltage Regulator: New Features True Rms Voltage Sensing - Single or Three Phasezakie0690No ratings yet

- VHF Marine Transceiver: Downloaded From Manuals Search EngineDocument7 pagesVHF Marine Transceiver: Downloaded From Manuals Search EngineKo AzaniNo ratings yet

- TW8800) 05.14.12 - ReaderDocument16 pagesTW8800) 05.14.12 - ReaderJavier iimareNo ratings yet

- Vertex Evx 5300 5400 Owners ManualDocument44 pagesVertex Evx 5300 5400 Owners Manual1spoot33No ratings yet

- The RC Link and ASK Environment: RF Based Wireless Remote Control SystemDocument9 pagesThe RC Link and ASK Environment: RF Based Wireless Remote Control SystemKhang VanNo ratings yet

- DPR300 Data SheetDocument2 pagesDPR300 Data Sheetdhayalan rNo ratings yet

- IGABEDA Covid19 S MRI4234Document2 pagesIGABEDA Covid19 S MRI4234Conrad WaluddeNo ratings yet

- Haefely Tdr-1150 SpecDocument2 pagesHaefely Tdr-1150 SpecZain ArhamNo ratings yet

- Q Amp PDFDocument60 pagesQ Amp PDFJosué TobíasNo ratings yet

- Active Monopole Antennas Operation ManualualDocument15 pagesActive Monopole Antennas Operation Manualualmid_cycloneNo ratings yet

- Icm803 Manual ServicioDocument83 pagesIcm803 Manual ServicioHèctor AlarcònNo ratings yet

- EMF-819 Electromagnetic PollutionDocument2 pagesEMF-819 Electromagnetic PollutionLenin SucaNo ratings yet

- Full C-Band 10W BUC: Model No. NJT5763 SeriesDocument21 pagesFull C-Band 10W BUC: Model No. NJT5763 SeriesSpeed ConnectNo ratings yet

- Presentation On EMF: U. K. Srivastava DDG (Radio) Telecom Engineering Centre New DelhiDocument38 pagesPresentation On EMF: U. K. Srivastava DDG (Radio) Telecom Engineering Centre New DelhiAshutosh PandeyNo ratings yet

- PA4600 & PA6000 User Manual - Rev GDocument53 pagesPA4600 & PA6000 User Manual - Rev GjatzireNo ratings yet

- 59718608rva OpMan822-HRDocument10 pages59718608rva OpMan822-HRCalidad CocoNo ratings yet

- Harman Kardon Avr7000Document163 pagesHarman Kardon Avr7000videosonNo ratings yet

- CUBDocument12 pagesCUBelizabethNo ratings yet

- MX920 Base Station/Repeater SpecDocument4 pagesMX920 Base Station/Repeater Specstato69No ratings yet

- EMI Measurements, Test Receiver vs. Spectrum AnalyzerDocument7 pagesEMI Measurements, Test Receiver vs. Spectrum AnalyzerYusafxai YxaiNo ratings yet

- Sharp 21GFx10LDocument49 pagesSharp 21GFx10LRobert F Mendoza GilNo ratings yet

- Manual IC F4013 PDFDocument32 pagesManual IC F4013 PDFFabián Peña AlvearNo ratings yet

- Cable Route TracerDocument4 pagesCable Route TracerPrashanth RajuNo ratings yet

- Canopy BU ManualDocument53 pagesCanopy BU ManualGustavo PargadeNo ratings yet

- X-Ray - 300 - Ma SpecificationDocument4 pagesX-Ray - 300 - Ma SpecificationMurali KrishnaNo ratings yet

- Lutron DW-6092 PDFDocument61 pagesLutron DW-6092 PDFedyyurisNo ratings yet

- Harman Kardon Service Manual For AVR 430 and AVR 630 ReceiversDocument126 pagesHarman Kardon Service Manual For AVR 430 and AVR 630 ReceiversDavid Derting100% (1)

- 74 300ma X Ray MachineDocument2 pages74 300ma X Ray MachineAwadhNo ratings yet

- Build Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterFrom EverandBuild Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterRating: 5 out of 5 stars5/5 (4)

- 216B, 226, 232B, 236, 242, 246, 248, 252, 262, and 268 Skid Steer Loaders and 247, 257, 267, 277, and 287 Multi Terrain Loader Sist. Elect.Document4 pages216B, 226, 232B, 236, 242, 246, 248, 252, 262, and 268 Skid Steer Loaders and 247, 257, 267, 277, and 287 Multi Terrain Loader Sist. Elect.Pablo PorrasNo ratings yet

- Endocrine System Notes - NCERT BasedDocument8 pagesEndocrine System Notes - NCERT Basedpallab mukherjeeNo ratings yet

- STAAR Tutor Job Description - Highly Qualified 3-05-2012Document2 pagesSTAAR Tutor Job Description - Highly Qualified 3-05-2012ResponsiveEdNo ratings yet

- HL1620... 2320E 110041003 Owners Manual04324 PDFDocument30 pagesHL1620... 2320E 110041003 Owners Manual04324 PDFmarkos kontomitrosNo ratings yet

- Oxley Ve Barcza, 2013Document12 pagesOxley Ve Barcza, 2013laguna028No ratings yet

- 1000 Kva 400v c32 Low BSFC PrimeDocument6 pages1000 Kva 400v c32 Low BSFC PrimeelipholebNo ratings yet

- Lathyrism Baghalpur IND Buchanan 1810-1811 Par MilesDocument7 pagesLathyrism Baghalpur IND Buchanan 1810-1811 Par MilesennescribeNo ratings yet

- Adaptation ModelDocument2 pagesAdaptation ModelDenise Allyson MoldezNo ratings yet

- Disaster Management and Social WorkDocument2 pagesDisaster Management and Social WorkSiddarth Gurung100% (1)

- National Population PolicyDocument28 pagesNational Population PolicyPinki BarmanNo ratings yet

- Nido Single Mast Mobile Awp: MODEL: ND-AWP-M (I) SeriesDocument3 pagesNido Single Mast Mobile Awp: MODEL: ND-AWP-M (I) SeriesMukarramuddinNo ratings yet

- Especificaciones Nutritivas - Hyline RosDocument16 pagesEspecificaciones Nutritivas - Hyline RosPatriciaNo ratings yet

- Protein SupplementDocument93 pagesProtein Supplementdesaitejas100% (1)

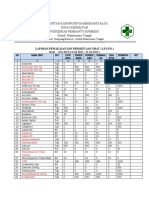

- Permintaan Pustu Burmeso Agustus 2023Document3 pagesPermintaan Pustu Burmeso Agustus 2023Black Bullet13No ratings yet

- Drilling Cuttings Re InjectionDocument12 pagesDrilling Cuttings Re InjectionTrini_thugNo ratings yet

- Hse Monthly Report Ke-2Document8 pagesHse Monthly Report Ke-2perdinalNo ratings yet

- cnl-509 Social and Cultural DiversityDocument9 pagescnl-509 Social and Cultural Diversityapi-742559605No ratings yet

- 108 Echographe Sle 901 CD PDFDocument1 page108 Echographe Sle 901 CD PDFMathurin Edmond WolaeNo ratings yet

- Mrs. Romine's Classroom Contract 2014-2015: ExpectationsDocument2 pagesMrs. Romine's Classroom Contract 2014-2015: ExpectationsMeggen Cooper RomineNo ratings yet

- DIY Seed Vault Save Seed For 10 YearsDocument3 pagesDIY Seed Vault Save Seed For 10 Yearskhsds22098No ratings yet

- 1 s2.0 036012859390003W Main PDFDocument82 pages1 s2.0 036012859390003W Main PDFAnonymous pv63gnBMAZNo ratings yet

- MBA Unemployment ReportDocument19 pagesMBA Unemployment ReportShiva NandNo ratings yet

- SoR - 2019-20 (1) Andhra PradeshDocument526 pagesSoR - 2019-20 (1) Andhra Pradeshsudhakar170588% (8)

- 1 BAC Resolution Declaring SCRB and Recommending Approval Brgy 4Document2 pages1 BAC Resolution Declaring SCRB and Recommending Approval Brgy 4Carthenlen Caratao FloresNo ratings yet

- Lab Equipments List DetailsDocument5 pagesLab Equipments List DetailsAyan DuttaNo ratings yet

- Legal MEdicineDocument29 pagesLegal MEdicineMuktar CabangcalaNo ratings yet

RMD1609-001 FDR Smart FGXR-S Operation Manual Rev.15-36-169

RMD1609-001 FDR Smart FGXR-S Operation Manual Rev.15-36-169

Uploaded by

christisking8888888Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RMD1609-001 FDR Smart FGXR-S Operation Manual Rev.15-36-169

RMD1609-001 FDR Smart FGXR-S Operation Manual Rev.15-36-169

Uploaded by

christisking8888888Copyright:

Available Formats

1.

Introduction

1.3 GENERATOR DUTY CYCLE LIMIT

THE FOLLOWING SECTION CONTAINS IMPORTANT INFORMATION. PLEASE

READ AND UNDERSTAND THIS MATERIAL BEFORE CONTINUING.

Internal X-ray generator components will heat up during normal use of the generator. This is similar to X-ray

tube heating during normal generator operation. The amount of heat produced is proportional to the product of

kV, mA, and time.

Modern X-ray generators are designed to operate with the majority of X-ray tubes over their rated power ranges.

They are designed for operating duty cycles consistent with practical patient examination routines that

allow for reasonable cooling intervals between X-ray exposures. Insufficient cooling time between

exposures may lead to excessive heat build - up in the generator, which may cause serious generator damage.

THIS X-RAY GENERATOR HAS TEMPERATURE MONITORING OF POWER-

STACK TO PROTECT THE EXCESSIVE HEAT BUILD-UP.

IF THE GENERATOR DETECTS THE OVER-HEAT OF POWER-STACK, AN

ERROR CODE “E04” OR “E05” WILL BE DISPLAYED. EXPOSURE WILL BE

INHIBITED WHEN THIS MESSAGE IS DISPLAYED, AND IT SHOULD BE

UNDERSTOOD THAT CONTINUING TO MAKE EXPOSURES MIGHT CAUSE

GENERATOR DAMAGE DUE TO OVERHEATING. THE GNENRATOR

SHOULD BE ALLOWED TO COOL SUFFICIENTLY SUCH THAT THIS

MESSAGE IS NO LONGER DISPLAYED.

Page 36 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

1.4 DAILY X-RAY TUBE WARM-UP PROCEDURE

THE FOLLOWING PROCEDURE PRODUCES X-RAYS.

OBSERVE ALL SAFETY PRECAUTIONS TO PROTECT PERSONNEL.

Use this procedure when the generator has not been used for several days. This procedure provides for

exposures at medium power before the tube is used at maximum mA or kV values. This will reduce the

possibility of damaging the anode and high voltage components. No test setup is required.

For maximum stability and reliability, use the following techniques at start up:

Select the following:

Large focal spot.

80 kV.

Normal 50/60 Hz anode rotation.

For a 300 kHU to a 400 kHU tube, use approximately 80 mAs per exposure.

For a 200 kHU to 300 kHU tube, use approximately 64 mAs per exposure.

For a below 200 kHU tube, use approximately 50 mAs per exposure.

Depending on the X-ray tube power rating, select either 100 mA or 200 mA.

Make three to five exposures (depending on tube loading) at 30 second intervals.

Operation Manual RMD1609-001, Rev.15 Page 37

1. Introduction

1.5 APPLICATION SPECIFICATION

1.5.1 INTENDED MEDICAL INDICATION

The FDR SMART FGXR-S, Diagnostic X-ray System is indicated for use in generating radiographic images

of human anatomy. The Diagnostic X-ray System is primarily used in a hospital for diagnosis of diseases in

skeletal, respiratory and urinary systems. Such as the skull, spinal column, chest, abdomen, extremities, and

other body parts.

1.5.2 INTENDED PATIENT POPULATION

a) Intended patient population

b) Age: Available all people, but is not intended to use for dedicated pediatric application

c) Weight: not relevant

d) Height: not relevant

e) Nationality: multiple

f) Patient state: PATIENT is not USER

Page 38 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

1.5.3 INTENDED USER PROFILE

a) Operator

Considerations Requirement description

• Qualified person (He/she must have license for radiologist or

Minimum have to meet local regulation)

Education

• Educated person by manufacturer

Maximum • N/A

• Qualified person (He/she must have license for radiologist or

Minimum

Knowledge have to meet local regulation)

Maximum • N/A

Language Minimum • Local language

understanding Maximum • Understanding of manual that is writing in English

• He/she must have license for radiologist or have to meet local

regulation

Minimum

Experience • He/she have to be educated by manufacturer or local

distributor

Maximum • N/A

Permissible

• N/A

impairments

a) Service engineer

Considerations Requirement description

• Qualified person by manufacturer or local distributer

Minimum regarding installation, maintenance and service.

Education

• Educated person by manufacturer

Maximum • N/A

• Qualified person (He/she must have knowledge of electrical

Minimum

Knowledge engineering and/or radiology procedure)

Maximum • N/A

Language Minimum • Local language

understanding Maximum • English

• He/she have to be educated by manufacturer or local

Minimum

Experience distributor

Maximum • N/A

Permissible

• N/A

impairments

Operation Manual RMD1609-001, Rev.15 Page 39

1. Introduction

1.6 SPECIFICATIONS

X-ray Generators

FDR Smart FDR Smart FDR Smart FDR Smart FDR Smart

System Model

FGXR-32S FGXR-40S FGXR-52S FGXR-68S FGXR-82S

Generator

GXR-32 GXR-40 GXR-52 GXR-68 GXR-82

Model

Power Rating 32kW 40kW 52kW 68kW 82kW

220-230V~, 400V3~, 480V3~ 400V3~, 480V3~

Line Power

±10% (Frequency: 50/60Hz)

40~125kV,

1kV step

40~125kV, (Option :

kV Range 40~150kV, 1kV step

1kV step 40~150kV for 3

phase line

power)

mA Range 10 to 400mA 10 to 500mA 10 to 640mA 10 to 800mA 10 to 1,000mA

Timer Range 0.001 to 10 sec, 38 steps

AEC Shortest

Irradiation 1ms

Time

mAs Range 0.1 to 500mAs (Optional up to 1000mAs)

640mA@81kV 800mA@85kV 1,000mA@82kV

Max. 400mA@80kV 500mA@80kV

500mA@104kV 640mA@106kV 800mA@102kV

320mA@100kV 400mA@100kV

Power Output 400mA@130kV 500mA@136kV 640mA@128kV

250mA@125kV 320mA@125kV

320mA@150kV 400mA@150kV 500mA@150kV

Low Speed

Low Speed

(Option:

Rotor Supply (Option: LSS Brake, Dual Speed

LSS Brake,

Dual Speed for 3Ф)

Dual Speed)

Technique

4 point display(kV, mA, Time, mAs)

Selection

Image

2 Bucky + 1 Non-Bucky

Receptors

230VAC, 1A, 230W

External System Power

Auxiliary 110VAC, 1A, 110W

Power Supply Magnetic Lock Power 28VDC, 5A, 140W

Collimator Lamp Power 24VAC, 6.3A, 150W

X-ray Ripple

30kHz

Frequency

Reproducibility Coefficient of Variation: kV < 0.005, Time < 0.005, mAs < 0.01

Accuracy kV < ±(1%+1kV), mA < ±(3%+1mA), Time < ±(1%+0.5ms), mAs < ±(3%+0.1mAs)

Page 40 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

Linearity Coefficient of Linearity < 0.01 : CL = (X1-X2)/(X1+X2), where X is mR/mAs

Dimension 622 x 652 x 405mm (W x H x D)

Weight 100kg

Patient Table

1) 4-way Floating tabletop table

Model PBT-4

Longitudinal 1,000(±500)mm

Tabletop

Transverse(Lateral) 250(±125)mm

Movement

350mm with N-type Bucky

Bucky Longitudinal

310mm with R, RD, RD2, ND, ND2 type Bucky

Laminate : 1.2mmAl at 100kV

Inherent Filtration

Carbon : 0.5mmAL at 100kV

Max. Patient Weight 300kg (660lbs)

Tabletop

2,200(W) x 818(D) x 45(H) mm

Size 2,000(W) x 818(D) x 45(H) mm

1,800(W) x 818(D) x 45(H) mm

-N, -R Fixed Grid type / Oscillating Grid type

Bucky Type

-RD, -RD2, -ND, -ND2 Removable Grid

Standard tray for CR and Analog cassette

- Tray size: 17”x17” (for 8”x10” to 17”x17” cassette)

-N

- Rotating: Not supported

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-R

- Rotating: Center reference

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD - Rotating: Center reference

- Automatic connection for D-EVO

- Fail safe function (optional)

Tray Type

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD2 - Rotating: Center reference

- Automatic connection for D-EVO2

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND

- Automatic connection for D-EVO

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND2

- Automatic connection for D-EVO2

- Fail safe function (optional)

Grid FD 100cm, 103 lpi, ratio 10:1(Optional 215 lpi ration 10:1)

Lock(Brake) EM Lock, beam sensor on/off

Center indication Buzzer sound and LED

Electrical Rating 100–240Vac, 200VA, 50/60Hz

2,200(W) x 818(D) x 660(H) mm / 150kg(330lbs)

Dimension / Weight Laminate

2,000(W) x 818(D) x 660(H) mm / 147kg(324lbs)

Operation Manual RMD1609-001, Rev.15 Page 41

1. Introduction

1,800(W) x 818(D) x 660(H) mm / 144kg(317lbs)

Carbon 2,200(W) x 818(D) x 660(H) mm / 145kg(320lbs)

* APPLIED PART

Page 42 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

2) Elevating table

Model PBT-6

Longitudinal 1,000(±500)mm

Tabletop

Transverse(Lateral) 250(±125)mm

Travel 285(565~850)mm,

Movement Speed 17mm/sec

Vertical

Motorized movement by Foot Switch

Operating

DC-motor (Linear Actuator)

350mm with N-type Bucky

Bucky Longitudinal

310mm with R, RD, RD2, ND, ND2 type Bucky

Laminate : 1.2mmAl at 100kV

Inherent Filtration

Carbon : 0.5mmAL at 100kV

Tabletop

Max. Patient Weight 300kg(660lbs)

Size 2,200(W) x 878(D) x 45(H) mm

-N, -R Fixed Grid type / Oscillating Grid type

Bucky Type

-RD, -RD2

Removable Grid

-ND, -ND2

Standard tray for CR and Analog cassette

- Tray size: 17”x17” (for 8”x10” to 17”x17” cassette)

-N

- Rotating: Not supported

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-R

- Rotating: Center reference

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD

- Rotating: Center reference

- Automatic connection for D-EVO

- Fail safe function (optional)

Tray Type

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD2 - Rotating: Center reference

- Automatic connection for D-EVO2

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND

- Automatic connection for D-EVO

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND2

- Automatic connection for D-EVO2

- Fail safe function (optional)

Grid FD 100cm, 103 lpi, ratio 10:1(Optional 215 lpi ration 10:1)

Lock(Brake) EM Lock, Foot Switch on/off

Center indication Transverse center, height center

Operation Manual RMD1609-001, Rev.15 Page 43

1. Introduction

Side Cover 2-story telescopic Cover

Option Motorized table Bucky tracking (Premium version)

Electrical Rating 100–240Vac, 400VA, 50/60Hz

2200(W) x 878(D) x 850(H) mm / 260kg(573lbs)

Laminate 2000(W) x 878(D) x 850(H) mm / 257kg(567lbs)

Dimension / Weight 1800(W) x 878(D) x 850(H) mm / 253kg(558lbs)

Carbon 2200(W) x 878(D) x 850(H) mm / 254kg(573lbs)

* APPLIED PART

3) Mobile table

Model PDT-1

Max. Patient Weight Max. 200kg (441lbs)

Dimension / Weight 2004(W) x 650(D) X 712(H)mm / 62kg (137lb)

Page 44 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

Vertical Wall Stand(Manual)

Model WBS(Manual)

1,070mm (300~1,370mm from floor to Bucky center)

1,220mm (300~1,520mm from floor to Bucky center)

Vertical Cassette stroke

1,390mm (300~1,690mm from floor to Bucky center)

1,640mm (300~1,940mm from floor to Bucky center)

-N, -R Fixed Grid type / Oscillating Grid type

Bucky Type -RD, -RD2

Removable Grid

-ND, -ND2

Standard tray for CR and Analog cassette

- Tray size: 17”x17” (for 8”x10” to 17”x17” cassette)

-N

- Rotating: Not supported

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-R

- Rotating: Center reference

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD

- Rotating: Center reference

- Automatic connection for D-EVO

- Fail safe function (optional)

Tray Type

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD2 - Rotating: Center reference

- Automatic connection for D-EVO2

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND

- Automatic connection for D-EVO

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND2

- Automatic connection for D-EVO2

- Fail safe function (optional)

Grid FD 150cm, 103 lpi, ratio 10:1(Optional 215 lpi ration 10:1)

Inherent Filtration 0.5mmAl at 100kV

Lock(Brake) EM Lock, Switch on/off

Balance Counter Weight

Electrical Rating 24VDC, 1A

1,599(H) x 659(W) x 445(D) mm / 110kg(242lbs)

1,749(H) x 659W) x 445(D) mm / 113kg(249lbs)

Dimension / Weight

1,919(H) x 659(W) x 445(D) mm / 116kg(255lbs)

2,169(H) x 659(W) x 445(D) mm / 120kg(264lbs)

* APPLIED PART

Operation Manual RMD1609-001, Rev.15 Page 45

1. Introduction

Vertical Wall Stand(Motorized)

Model WBS(Vertical Motorized)

970mm(300mm~1,270mm from floor to focus)

1,120mm(300mm~1,420mm from floor to focus)

Vertical Cassette stroke

1,290mm(300mm~1,590mm from floor to focus)

1,540mm(300mm~1,840mm from floor to focus)

-N, -R Fixed Grid type / Oscillating Grid type

Bucky Type

-RD, -RD2

Removable Grid

-ND, -ND2

Standard tray for CR and Analog cassette

- Tray size: 17”x17” (for 8”x10” to 17”x17” cassette)

-N

- Rotating: Not supported

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-R

- Rotating: Center reference

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD

- Rotating: Center reference

- Automatic connection for D-EVO

- Fail safe function (optional)

Tray Type

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD2 - Rotating: Center reference

- Automatic connection for D-EVO2

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND

- Automatic connection for D-EVO

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND2

- Automatic connection for D-EVO2

- Fail safe function (optional)

Grid FD 150cm, 103 lpi, ratio 10:1(Optional 215 lpi ration 10:1)

Inherent Filtration 0.5mmAl at 100kV

Lock(Brake) EM Lock, Switch on/off

Balance Counter Weight

Electrical Rating 100-240VAC, 160VA, 50/60Hz

1,614(H) x 738(W) x 544(D) mm / 126kg(277lbs)

1,764(H) x 738(W) x 544(D) mm / 130kg(286lbs)

Dimension / Weight

1,934(H) x 738(W) x 544(D) mm / 132kg(291lbs)

2,184(H) x 738(W) x 544(D) mm / 135kg(297lbs)

* APPLIED PART

Page 46 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

Manual Tilting Wall Stand

Model WBS-TM

Vertical 1,492mm (286~1,778mm from floor to Bucky center)

Stroke

Tilted 90˚ 1,500mm (658~2,158mm from floor to Bucky surface)

-N, -R Fixed Grid type / Oscillating Grid type

Bucky Type

-RD, -RD2, -ND, -ND2 Removable Grid

Standard tray for CR and Analog cassette

- Tray size: 17”x17” (for 8”x10” to 17”x17”

-N cassette)

- Rotating: Not supported

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-R

- Rotating: Center reference

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD

- Rotating: Center reference

- Automatic connection for D-EVO

Tray Type - Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD2 - Rotating: Center reference

- Automatic connection for D-EVO2

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND

- Automatic connection for D-EVO

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND2

- Automatic connection for D-EVO2

- Fail safe function (optional)

Grid FD 150cm, 103 lpi, ratio 10:1(Optional 215 lpi ration 10:1)

Tilting Angle -30 ~ 90˚

Withstanding load 20kgf

(at tilting angle 90°) at the point 150mm from the side.

Inherent Filtration 0.5mmAl at 100kV

Lock(Brake) EM Lock, Switch on/off by foot switch(Vertical movement, Tilting)

Vertical Balance Counter Weight

Tilting Balance Spring

Electrical Rating 24VDC, 2.5A

Dimension Max. 2,169(H) x 728(W) x 732(D) mm

Weight 187kg(412lbs)

* APPLIED PART

Operation Manual RMD1609-001, Rev.15 Page 47

1. Introduction

Automatic Tilting Wall Stand

1) WBS-TA Motor type

Model WBS-TA(Motor type)

Vertical Vertical 1,526mm (326~1,852mm from floor to Bucky center)

Stroke

Tilted 90˚ Vertical 1,526mm (440~1,966mm from floor to Bucky center)

Vertical Movement Manual and Motorized

-N, -R Fixed Grid type / Oscillating Grid type

Bucky Type

-RD, -RD2, -ND, -ND2 Removable Grid

Standard tray for CR and Analog cassette

- Tray size: 17”x17” (for 8”x10” to 17”x17” cassette)

-N

- Rotating: Not supported

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-R

- Rotating: Center reference

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD

- Rotating: Center reference

- Automatic connection for D-EVO

- Fail safe function (optional)

Tray Type

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD2 - Rotating: Center reference

- Automatic connection for D-EVO2

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND

- Automatic connection for D-EVO

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND2

- Automatic connection for D-EVO2

- Fail safe function (optional)

Grid FD 150cm, 103 lpi, ratio 10:1(Optional 215 lpi ration 10:1)

Tilting Angle -30 ~ 90˚

Tilting Movement Motorized

Inherent Filtration 0.5mmAl at 100kV

Lock(Brake) EM Lock, Switch on/off

Balance Counter Weight

Electrical Rating 100~240VAC, 200VA, 50/60Hz

Dimension Max. 2,179(H) x 743(W) x 949(D) mm

Weight 195kg(430lbs)

* APPLIED PART

Page 48 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

2) WBS-TA Actuator type

Model WBS-TA(Actuator type)

Vertical Vertical 1,526mm (283~1,809mm from floor to Bucky center)

Stroke

Tilted 90˚ Vertical 1,526mm (450~1,976mm from floor to Bucky center)

Vertical Movement Manual and Motorized

-N, -R Fixed Grid type / Oscillating Grid type

Bucky Type

-RD, -RD2, -ND, -ND2 Removable Grid

Standard tray for CR and Analog cassette

- Tray size: 17”x17” (for 8”x10” to 17”x17” cassette)

-N

- Rotating: Not supported

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-R

- Rotating: Center reference

- Fail safe function (optional)

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD

- Rotating: Center reference

- Automatic connection for D-EVO

- Fail safe function (optional)

Tray Type

Rotating tray for DR cassette

- Tray size: 14”x17”(only for 14”x17” cassette)

-RD2 - Rotating: Center reference

- Automatic connection for D-EVO2

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND

- Automatic connection for D-EVO

- Fail safe function (optional)

Non-rotating tray for DR cassette

- Tray size: 17”x17”(only for 17”x17” cassette)

-ND2

- Automatic connection for D-EVO2

- Fail safe function (optional)

Grid FD 150cm, 103 lpi, ratio 10:1(Optional 215 lpi ration 10:1)

Tilting Angle -20 ~ 90˚

Tilting Movement Motorized

Inherent Filtration 0.5mmAl at 100kV

Lock(Brake) EM Lock, Switch on/off

Balance Counter Weight

Electrical Rating 100~240VAC, 200VA, 50/60Hz

Dimension Max. 2,184(H) x 734(W) x 893(D) mm

Weight 191kg(421lbs)

* APPLIED PART

Operation Manual RMD1609-001, Rev.15 Page 49

1. Introduction

Tube stand

1) Floor Mounted

Model TS-FM6(Manual)

Tube Rotation Angle ±135°

2,200mm

Longitudinal

(Optional 3,000mm and 3,700mm)

Tube stroke

Lateral 220mm

Vertical 1,580mm (440~2,020mm from floor to focus)

Lock(Brake) EM Lock, Switch on/off

Balance Counter Weight

Column Rotation 90° step

Electrical Rating 24VDC, 3A

2,317(H) x 1,373(D) mm x 3,006(W)

Dimension

when transverse direction is fully extended

Weight 240kg(529lbs)

Model TS-FM6 (Motorized)

Tube Rotation Angle ±135°

2,100mm

Longitudinal

(Optional 2,900mm and 3,600mm)

Tube stroke

Lateral 250mm

Vertical 1,526mm (420~1,946mm from floor to focus)

Manual and Motorized

Vertical Movement Optional vertical synchronization with WBS-TA and PBT-6 for motorized

stand

Lock(Brake) EM Lock, Switch on/off

Balance Counter Weight

Column Rotation EM lock, Switch on/off

Tube OP 7 inch Touch screen LCD

Electrical Rating 100 ~240VAC, 160VA, 50/60Hz

2,317(H) x 1,445(D) mm x 3,006(W) mm

Dimension

when transverse direction is fully extended

Weight 262kg(578lbs)

Page 50 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

Model TS-FC2(Manual)

Tube Rotation Angle ±135°

Longitudinal N/A

Lateral N/A

Tube stroke 1,243mm(294mm~1,537mm from floor to focus)

Vertical 1,413mm(294mm~1,707mm from floor to focus)

1,663mm(294mm~1,957mm from floor to focus)

Vertical Movement Manual

Lock(Brake) EM Lock, Switch on/off

Balance Counter Weight

Electrical Rating 24VDC, 3A

1,749(H) x 659(W) x 790(D) mm / 165kg(363lbs)

Dimension/Weight 1,919(H) x 659(W) x 790(D) mm / 168kg(370lbs)

2,169(H) x 659(W) x 790(D) mm / 171kg(376lbs)

Model TS-FC2(Motorized)

Tube Direction Right-angle or Straight

Tube Rotation N/A

Longitudinal N/A

Lateral N/A

Tube stroke 1) 1,080mm(324mm~1,404mm from floor to focus)

2) 1,230mm(324mm~1,554mm from floor to focus)

Vertical

3) 1,400mm(324mm~1,724mm from floor to focus)

4) 1,650mm(324mm~1,974mm from floor to focus)

Vertical Movement Motorized, Vertical synchronization with wall stand

Lock(Brake) EM Lock, Switch on/off

Balance Counter Weight

Electrical Rating 100–240VAC, 160VA, 50/60Hz

1) Right-angle type: 1,614(H) x 659 (W) x 770(D) mm / 162kg(357lbs)

Straight type: 1,614(H) x 659 (W) x 859(D) mm / 162kg(357lbs)

2) Right-angle type: 1,764(H) x 659 (W) x 770(D) mm / 165kg(363lbs)

Straight type: 1,764(H) x 659 (W) x 859(D) mm / 165kg(363lbs)

Dimension

3) Right-angle type: 1,934(H) x 659(W) x 770(D) mm / 155kg(341lbs)

Straight type: 1,934(H) x 659(W) x 859(D) mm / 155kg(341lbs)

4) Right-angle type: 2,184(H) x 659(W) x 770(D) mm / 160kg(352lbs)

Straight type: 2,184(H) x 659(W) x 859(D) mm / 160kg(352lbs)

Operation Manual RMD1609-001, Rev.15 Page 51

1. Introduction

2) Floor-Ceiling Mounted

Model TS-FC6

Tube Rotation Angle ±135°

Longitudinal 2,500mm

Tube stroke Lateral 220mm

Vertical 1,580mm (430~2,010mm from floor to focus)

Lock(Brake) EM Lock, Switch on/off

Balance Counter Weight

Column Rotation 90° step

Electrical Rating 24VDC, 3A

2,465(H) x 1,373(D) mm x 3,600(W)

Dimension

when transverse direction is fully extended

Weight 180kg(397lbs)

3) Ceiling suspended

Model TS-CSA-M

Horizontal axis ±180° (LCD display)

Tube Rotation Angle

Vertical axis ±180° (mechanical detents at every 90°)

Longitudinal 3,280mm(with 4m rail), 4,280mm(with 5m rail)

Tube stroke

Lateral 2,200mm(with 3m rail), 3,200mm(with 4m rail)

(Transverse x Longitudinal)

Vertical 1,600mm

Lock(Brake) EM Lock, Switch on/off

Balance Spring

Vertical Movement Manual

Tube Rotation Manual

Option Auto Collimation, Mechanical detent

SID Indication 7inch Touch Screen LCD with control buttons

Electrical Rating 100–240VAC, 200VA, 50/60Hz

2,830(H) x 3,000(D) mm x 4,000(W) mm

Dimension

when vertical direction is fully extended with 1,600mm stroke and 3x4m rails

Main body: 160kg(353lbs) except tube and collimator,

Weight

Rails: 115kg(254lbs, 3x4m rails)

Page 52 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

Model TS-CSA_A

Horizontal axis ±180° (LCD display)

Tube Rotation Angle

Vertical axis ±180° (mechanical detents at every 90°)

Longitudinal 3,280mm(with 4m rail), 4,280mm(with 5m rail)

Tube stroke

Lateral 2,200mm(with 3m rail), 3,200mm(with 4m rail)

(Transverse x Longitudinal)

Vertical 1,600mm

Lock(Brake) EM Lock, Switch on/off

Balance Spring

Vertical Movement Motorized(Motorized supports vertical sync with table and wall stand)

Tube Rotation Manual

Option Auto Collimation, Mechanical detent

SID Indication 7inch Touch Screen LCD with control buttons

Electrical Rating 100–240VAC, 200VA, 50/60Hz

2,830(H) x 3,000(D) mm x 4,000(W) mm

Dimension

when vertical direction is fully extended with 1,600mm stroke and 3x4m rails

Main body: 170kg(375lbs) except tube and collimator,

Weight

Rails: 115kg(254lbs, 3x4m rails)

Model TS-CSA_A(Stitching)

Horizontal axis ±180° (LCD display)

Tube Rotation Angle

Vertical axis ±180° (mechanical detents at every 90°)

Longitudinal 3,280mm(with 4m rail), 4,280mm(with 5m rail)

Tube stroke

Lateral 2,200mm(with 3m rail), 3,200mm(with 4m rail)

(Transverse x Longitudinal)

Vertical 1,600mm

Lock(Brake) EM Lock, Switch on/off

Balance Spring

Vertical Movement Motorized (Motorized supports vertical sync with table and wall stand)

Motorized

Tube Rotation

(Motorized supports the source tilting type image stitching operation)

Option Auto Collimation, Mechanical detent

SID Indication 7inch Touch Screen LCD with control buttons

Electrical Rating 100–240VAC, 200VA, 50/60Hz

2,830(H) x 3,000(D) mm x 4,000(W) mm

Dimension

when vertical direction is fully extended with 1,600mm stroke and 3x4m rails

Main body: 170kg(375lbs) except tube and collimator,

Weight

Rails: 115kg(254lbs, 3x4m rails)

Operation Manual RMD1609-001, Rev.15 Page 53

1. Introduction

X-ray Tube

Tube Model E7239X DXT-8M E7242X DXT-11M

Manufacturer CANON DRGEM CANON DRGEM

Focal Spot Size 1.0/2.0mm 1.0/2.0mm 0.6/1.5mm 0.6/1.5mm

Rating(0.1s) 22.5/47kW@60Hz 22.5/47kW@60Hz 18/50kW@60Hz 18/50kW@60Hz

Max. Anode HU 140kHU(100kJ) 140kHU(100kJ) 200kHU(142kJ) 200kHU(142kJ)

Target Angle 16° 16° 14° 14°

Max. kV 125kV 125Kv 125kV 125kV

Weight 16kg(35.3lbs) 16kg(35.3lbs) 16kg(35.3lbs) 16kg(35.3lbs)

Inherent Filtration 0.9mmAl/75kV 1.0mmAl/75kV 0.9mmAl/75kV 1.0mmAl/75kV

Half Value Layer More than 2.9mmAl eq. at 80kVp

Leakage Less than 100mR/hr

Radiation

Tube Model E7843X DXT-10M E7876X

Manufacturer CANON DRGEM CANON

Focal Spot Size 0.6/1.2mm 0.6/1.2mm 0.6/1.2mm

Rating(0.1s) 22/50kW@60Hz 17/48kW@60Hz 22/54kW@60Hz

Max. Anode HU 150kHU(111kJ) 150kHU(111kJ) 230kHU(163kJ)

Target Angle 12° 12° 12°

Max. kV 150kV 125kV 150kV

Weight 16kg(35.3lbs) 16kg(35.3lbs) 16kg(55.1lbs)

Inherent Filtration 1.3mmAl/75kV 1.0mmAl/75kV 1.3mmAl/75kV

Half Value Layer More than 2.9mmAl eq. at 80kVp

Leakage Radiation Less than 100mR/hr

Page 54 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

Tube Model E7884X DXT-12M E7252X

Manufacturer CANON DRGEM CANON

Focal Spot Size 0.6/1.2mm 0.6/1.2mm 0.6/1.2mm

Rating(0.1s) 22/54kW@60Hz 22/54kW@60Hz 27/75kW

Max. Anode HU 300kHU(210kJ) 300kHU(210kJ) 300kHU(210kJ)

Target Angle 12° 12° 12°

Max. kV 150kV 150kV 150kV

Weight 16kg(35.3lbs) 16kg(35.3lbs) 18kg(39.7lbs)

Inherent Filtration 0.9mmAl/75kV 1.0mmAl/75kV 0.9mmAl/75kV

Half Value Layer More than 2.9mmAl eq. at 80kVp

Leakage Radiation Less than 100mR/hr

Tube Model DXT-14U DXT-15U * RAD-92

Manufacturer DRGEM DRGEM VAREX

Focal Spot Size 0.6/1.2mm 0.6/1.2mm 0.6/1.2mm

Rating(0.1s) 27/75kW 32/77kW 40/100kW

Max. Anode HU 300kHU(210kJ) 300kHU(210kJ) 600kHU(444kJ)

Target Angle 12° 12° 12°

Max. kV 150kV 150kV 150kV

Weight 18kg(39.7lbs) 16.4kg(36.2lbs) 18.9kg(41.7lbs)

Inherent Filtration 1.0mmAl/75kV 0.7mmAl/75kV 0.7mmAl/75kV

Additional Filtration - 0.5mmAl

Half Value Layer More than 2.9mmAl eq. at 80kVp

Leakage Radiation Less than 100mR/hr

Operation Manual RMD1609-001, Rev.15 Page 55

1. Introduction

Tube Model E7255FX E7254FX E7869X

Manufacturer CANON CANON CANON

Focal Spot Size 0.6/1.2mm 0.6/1.2mm 0.6/1.2mm

Rating(0.1s) 40/102kW 40/102kW 40/100kW

Max. Anode HU 300kHU(210kJ) 400kHU(285kJ) 600kHU(444kJ)

Target Angle 12° 12° 12°

Max. kV 150kV 150kV 150kV

Weight 20kg(44.1lbs) 25kg(55.1lbs) 24kg(52.9lbs)

Inherent Filtration 0.8mmAl/75kV 0.8mmAl/75kV 1.1mmAl/75kV

Additional Filtration 0.5mmAl -

Half Value Layer More than 2.9mmAl eq. at 80kVp

Leakage Radiation Less than 100mR/hr

* Total filtration including X-ray tube assembly and collimator will be matched by appropriate additional filters to

within the range from 2.9 to 3.3mmAl. eq.

If the target angle of the applied tube is 12°, the field size (43cm X 43cm) cannot be

realized by SID 100cm when combined with a collimator. To use the field size (43cm X

43cm), please use SID 105cm or 110cm.

Page 56 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

Collimator

Model R108 R302A, R302MLP/A, R302MFMLP/A

Manufacturer RALCO RALCO

Control Manual with 30sec. lamp timer

Field Shape Rectangular

Max. Field Size More than 43x43cm(17x17inch) at 100cm SID

Leakage Radiation Less than 100mR/hr

Max. kVp shield 150kV (Optional 125kV) 150kV

Inherent Filtration 2.0mmAl eq. 2.0mmAl eq.

Over 160LUX at 100cm SID (Typ. Over 160LUX at 100cm SID (Typ.

Luminosity

250LUX) 200LUX)

HLX64638 100W 24V

Light source Single LED

/ OSRAM

Auto collimation for R302 MLP/A and R

Tape measure, Line laser

Standard 302 MFMLP/A

rotating flange

Auto filter selection for R 302 MFMLP/A

Tape measure, line laser, rotating flange,

Option -

LED Type

Electrical Rating 20–30Vac, 30VA, 50/60Hz 24Vac, 6.3A, 50/60Hz

223(W) x 246(D) x 140(H) mm / 195.5(W) x 237(D) x 206.5(H) mm /

Dimension / Weight

6.6kg(14.6lb) 9.4kg(20.7lb)

Operation Manual RMD1609-001, Rev.15 Page 57

1. Introduction

Model DXC-RML/DXC-RMH

Manufacturer DRGEM

Control Manual with 30sec. lamp timer

Field Shape Rectangular

Max. Field Size More than 43x43cm(17x17inch) at 100cm SID

Leakage Radiation Less than 40 mR/h

Max. kVp shield 150kV

Inherent Filtration Min. 2.0mmAl eq.

Luminosity Over 160LUX at 1cm SID

Light source LED and Halogen

Standard Rotating flange with fixing knob

Line laser+shutter, Measure tape

Near port moving shutters,

Additional filter

Option

Mounting flange mechanical detent

Accessory guides spring

DAP rail

Halogen type - 24 V DC/AC - 50~60Hz 160VA

Electrical Rating

LED type - 12~45V DC 35VA / 20~30VAC 35VA - 50~60Hz

Dimension / Weight 196(W) x 250(D) x 171(H) mm / 7.1kg(15.6lb)

AEC Ion Chamber (Option)

Model Amplimat 5-Field

Manufacturer Philips

Field 5 Fields(Using 3 Fields)

X-ray Energy Range 40~150kV

Exposure time Range 1ms to 6s

Inherent Filtration 0.8 mm Al eq.

Weight 1.8kg (4lb)

Page 58 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

Stitching specifications

- Maximum of 4 exposures with 1 push (shot SW.)

FGXR automatically calculates required exposure number in accordance with the long-view

range setting.

- Maximum length of stitch exposure: 160cm image size given 3cm overlap between images (Note: object

length depends on the magnification factor)

- Stitching can be used with 14x17inch detector and 17x17inch detector.

- Not only portrait but also landscape can be used for 14x17inch size detector.

- Can be used only with wall stand(WBS-TA) exposure

- Can be used only with ‘premium system’, ‘stitching’ and ‘PC console’ (One console) options

- Exposure size and conditions can be received from DR system

- Stitching stand is mandatory.

- FGXR for stitching is the special purpose system for stitching that axis of ceiling tube head is rotated by

only motor.

- Required time for stitching (from shot start to shot end): 17.5 seconds for 3 exposure count

DAP Meter (Option)

DAP Resolution 0.01 μGym²

Interface RS485

Active area 115 x 115mm / 146 x 146mm

Display integrated or separate display (single or dual line)

Dimension 158 x 134.5 x 17mm / 180 x 156 x 17mm

Options

- AEC

Upgrade AEC 3-field ion chamber for table & stand

- DAP

Upgrade DAP kit, Stand-alone Display type

Upgrade DAP kit, for DR system

- Cassette center tracking

Upgrade table cassette tracking for TS-FM6

- Dual Speed Starter (DSS)

Up-grade DSS for the dual speed rotating tube under the 3 phase(32/40/52KW)

- LSS Brake for Low speed rotor supply

- Console stand

- PC X-Ray console option

Operation Manual RMD1609-001, Rev.15 Page 59

1. Introduction

- Lateral cassette holder for the table

- Cassette holder for WBS/WBS-TM/WBS-TA

- Hand holder for WBS/WBS-TM/WBS-TA

- Overhead handgrip for WBS

- Short Overhead handgrip for WBS

- Overhead handgrip for WBS-TM

- Short Overhead handgrip for WBS-TM

- Overhead handgrip for WBS-TA

- Short Overhead handgrip for WBS-TA

- 3.8m floor rail of TS-FM6 (recommend for WBS-TM or WBS-TA)

- 4.5m floor rail of TS-FM6 (recommend for WBS-TM or WBS-TA)

- 3x5m(transverse x longitudinal) rails for TS-CSA

- 4x4m(transverse x longitudinal) rails for TS-CSA

- 4x5m(transverse x longitudinal) rails for TS-CSA

- Cable chain for TS-FM6 with 3.0m rails

- Cable chain for TS-FM6 with 3.8m rails

- Cable chain for TS-FM6 with 4.5m rails

- Cable chain for TS-CSA with 3x4m rails

- Cable chain for TS-CSA with 3x5m rails

- Cable chain for TS-CSA with 4x4m rails

- Cable chain for TS-CSA with 4x5m rails

- Handgrip for the table

- Patient compression belt for the table

- Fail- safe switch

- Stitching Stand

- Remote controller for WBS-TA

- LED light upgrade from Hallogen lamp for R302MFMLP/A

- Built-in laser of R302 Series collimators

- Rotating flange of R302 Series collimators

- Extend HV cable length from 8m to 10m for TS_FM6/TS_CSA

- Extend HV cable length from 8m to 15m for TS_FM6/TS_CSA

- Extend HV cable length from 8m to 18m for TS_CSA

- Extend HV cable length from 8m to 20m for TS_CSA

- Extend HV cable length from 8m to 25m for TS_CSA

- Extend HV cable length from 10m to 15m for TS_FM6/TS_CSA

- Extend HV cable length from 10m to 18m for TS_CSA

- Extend HV cable length from 10m to 20m for TS_CSA

- Extend HV cable length from 10m to 25m for TS_CSA

Page 60 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

- Extend HV cable length from 15m to 18m for TS_CSA

- Extend HV cable length from 15m to 20m for TS_CSA

- Extend HV cable length from 15m to 25m for TS_CSA

- Extend HV cable length from 18m to 20m for TS_CSA

- Extend HV cable length from 18m to 25m for TS_CSA

- Extend HV cable length from 20m to 25m for TS_CSA

- XConF software without PC

- Ceiling rail for TS-FM6 with 3.0m rails

- Ceiling rail for TS-FM6 with 3.8m rails

- Ceiling rail for TS-FM6 with 4.5m rails

- Right side drawer tray for WBS/WBS-TM/WBS-TA

- Mechanical detent for TS-CSA

OPERATING

Ambient temperature range 10 °C to 40 °C (50 °F to 104 °F)

Relative humidity range 30% to 75%, non-condensing

Atmospheric pressure range 700 hPa to 1060 hPa

Altitude Limit This product is rated to operate at an altitude ≤3000m

TRANSPORT AND STORAGE

Ambient temperature range -10 °C to 70 °C (14 °F to 158 °F)..

Relative humidity range 10% to 90%, non-condensing.

Atmospheric pressure range 500 hPa to 1060 hPa

Operation Manual RMD1609-001, Rev.15 Page 61

1. Introduction

1.7 APPLICABLE STANDARDS

The main components of FDR Smart FGXR-S System comply with the regulatory requirements and design

standards in this section as follows:

- Type of protection against electric shock: Class I equipment.

- Degree of protection against electric shock: Not classified.

- Degree of protection against harmful ingress of water: Ordinary equipment.

- Mode of operation: Continuous operation with intermittent loading (standby-exposure).

- Equipment not suitable for use in presence of flammable mixtures.

1) SAFETY

■ EN60601-1:2006/A1:2013

Medical electrical equipment -- Part 1: General requirements for basic safety and essential performance

IEC60601-1:2005/A1:2012

■ EN60601-1-3:2008/A11:2016

Medical electrical equipment -- Part 1-3: General requirements for basic safety and essential performance -

Collateral Standard: Radiation protection in diagnostic X-ray equipment

IEC60601-1-3:2008/A1:2013

■ EN60601-1-6:2010/A1:2015

Medical electrical equipment -- Part 1-6: General requirements for basic safety and essential performance -

Collateral standard: Usability

IEC60601-1-6:2010/A1:2013

■ EN60601-2-28:2010

Medical electrical equipment -- Part 2-28: Particular requirements for the basic safety and essential

performance of X-ray tube assemblies for medical diagnosis

IEC60601-2-28:2010

■ EN60601-2-54:2009/A1:2015

Medical electrical equipment -- Part 2-54: Particular requirements for the basic safety and essential

performance of X-ray equipment for radiography and radioscopy

IEC60601-2-54:2009/A1:2015

Page 62 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

2) EMC

■ EN60601-1-2:2015

Medical electrical equipment - Part 1-2: General requirements for safety - Collateral standard: Electromagnetic

compatibility - Requirements and tests

■ EN55011:2009/A1:2010

■ CISPR11:2014

■ EN61000-3-2:2006

■ EN61000-3-3:2013

■ EN61000-4-2:2009

■ EN61000-4-3:2006/A1:2008/A2:2010

■ EN61000-4-4:2012

■ EN61000-4-5:2006

■ EN61000-4-6:2014

■ EN61000-4-8:2010

■ EN61000-4-11:2004

Electromagnetic Compatibility (EMC)

The FDR Smart FGXR-S complies with the requirements of IEC 60601-1-2:2014 regarding electromagnetic

compatibility. Surrounding equipment shall follow the standard IEC 60601-1-2:2014.

Mobile telephones or other radiating equipment can interfere with the function of

the FDR Smart FGXR-S and can therefore cause safety hazards.

Operation Manual RMD1609-001, Rev.15 Page 63

1. Introduction

Guidance and manufacturer´s declaration - electromagnetic emissions

The FDR Smart FGXR-S is intended for use in the electromagnetic environment specified below. The

customer or the user of the FDR Smart FGXR-S should assure that it is used in such an environment

Emissions test Compliance Electromagnetic environment - guidance

The FDR Smart FGXR-S uses RF energy only for its internal

RF emissions

Group 1 function. Therefore, its RF emissions are very low and are not

CISPR 11

likely to cause any interference in nearby electronic equipment.

RF emissions

Class A

CISPR 11

The FDR Smart FGXR-S is suitable for use in all establishments,

Harmonic other than domestic and those directly connected to the public

emissions Not applicable

low-voltage power supply network that supplies buildings used

for domestic purpose. For information purpose the system

Voltage

complies with IEC61000-3-11 and is suitable for connection to

fluctuations/ Flicker

Not applicable public mains network if the impedance is 0,32 Ohm or lower

emissions IEC

61000-3-3

Page 64 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

Guidance and manufacturer´s declaration - electromagnetic immunity

The FDR Smart FGXR-S is intended for use in the electromagnetic environment specified below. The

customer or the user of the FDR Smart FGXR-S should assure that it is used in such an environment.

Immunity test IEC 60601 Compliance level Electromagnetic environment -

test level

guidance

Electrostatic ± 2 kV, ± 4 kV, ± 6 kV, ± 2 kV, ± 4 kV, ± 6 kV, Floors should be wood, concrete or

discharge (ESD) ± 8 kV contact ± 8 kV contact ceramic tile. If floors are covered with

IEC 61000-4-2 ± 2 kV, ± 4 kV, ± 8 kV, ± 2 kV, ± 4 kV, ± 8 kV, synthetic material, the relative humidity

± 15 kV air ± 15 kV air should be at least 30%.

Electrical fast ± 2 kV for power ± 2 kV for power Mains power quality should be that of a

transient/burst supply lines supply lines typical commercial or hospital

IEC 61000-4-4 ± 1 kV for input/ n/a. for input/output environment.

output lines lines

Surge ± 0.5 kV , ± 1 kV ± 0.5 kV , ± 1 kV Mains power quality should be that of a

IEC 61000-4-5 Line to Earth Line to Earth typical commercial or hospital

± 0.5 kV, ± 1 kV, ± 0.5 kV, ± 1 kV, environment.

± 2 kV Line to ± 2 kV Line to

Line Line

Voltage dips, short <5 % UT <5 % UT Mains power quality should be that of a

(>95 % dip in UT) for (>95 % dip in UT) for

interruptions and typical commercial or hospital

0,5 cycle at 0, 45, 90, 0,5 cycle at 0, 45, 90,

voltage variations on environment. If the user of the DR- XD

135, 180, 225, 270, 135, 180, 225, 270,

power supply input 315 deg. 315 deg. 200 requires continued operation during

lines. <5 % UT <5 % UT power mains interruptions, it is

(>95 % dip in UT) for (>95 % dip in UT) for

IEC 61000-4-11 recommended that the FDR Smart

1 cycle at 0 deg. 1 cycle at 0 deg.

FGXR-S be powered from an

30 % UT 30 % UT

(70 % dip in UT) for (70 % dip in UT) for uninterruptible power supply or battery.

25/30 cycles at 0 deg. 25/30 cycles at 0 deg.

<5 % UT <5 % UT

(>95 % dip in UT) for (>95 % dip in UT) for

250(50Hz)/300(60Hz) 250(50Hz)/300(60Hz)

cycles at 0 deg. cycles at 0 deg.

NOTE: UT is the A.C. mains voltage prior to application of the test level.

Operation Manual RMD1609-001, Rev.15 Page 65

1. Introduction

Guidance and manufacturer´s declaration - electromagnetic immunity

The FDR Smart FGXR-S is intended for use in the electromagnetic environment specified below.

The customer or the user of the FDR Smart FGXR-S should assure that it is used in such an environment.

Immunity test IEC 60601 Compliance Electromagnetic environment – guidance

test level level

Power frequency 30 A/m 30 A/m Power frequency magnetic fields should be at levels

(50/60 Hz) characteristic of a typical location in a typical

magnetic field commercial or hospital environment.

IEC 61000-4-8

Portable and mobile RF communications equipment

should be used no closer to any part of the FDR Smart

FGXR-S, including cables, than the recommended

separation distance calculated from the equation

applicable to the frequency of the transmitter.

Recommended separation distance

Conducted RF 3 Vrms 3 Vrms 𝑑𝑑 = 1, 2 �𝑝𝑝

IEC 61000-4-6 150 kHz to 80 MHz 150 kHz to 80

MHz

𝑑𝑑 = 1, 2 �𝑝𝑝 80 MHz to 800 MHz

Radiated RF 3 V/m 3 V/m

IEC 61000-4-3 80 MHz to 2,5 GHz 80 MHz to 2,5 𝑑𝑑 = 2, 3 �𝑝𝑝 800 MHz to 2,5 GHz

GHz

where p is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site survey, a

should be range. b

Interference may occur in the vicinity of equipment

marked with the following symbol:

Page 66 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

NOTE 1: At 80 Mhz and 800 MHz, the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation i affected by absorption

and reflection from structures, objects and people.

a Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land

mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically

with accuracy. To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site

survey should be considered. If the measured field strength in the location in which the FDR Smart FGX-S is

used exceeds the applicable RF compliance level above, the FDR Smart FGX-S should be observed to verify

normal operation. If abnormal performance is observed, additional measures may be necessary, such as

reorienting or relocating the FDR Smart FGX-S.

b Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 10 V/m.

Recommended separation distances between portable and mobile RF communications equipment

and FDR Smart FGXR-S

The FDR Smart FGXR-S is intended for use in an electromagnetic environment in which radiated RF

disturbances are controlled. The customer or the user of the FDR Smart FGXR-S can help prevent

electromagnetic interference by maintaining a minimum distance between portable and mobile RF

communications equipment (transmitters) and the FDR Smart FGXR-S as recommended below, according to

the maximum output power of the communications equipment.

Rated maximum output Separation distance according to frequency of transmitter

power of transmitter 150 kHz to 80 MHz 80 MHz to 800 MHz 800 MHz to 2,5 GHz

W 𝑑𝑑 = 1, 17 �𝑝𝑝 𝑑𝑑 = 0, 35 �𝑝𝑝 𝑑𝑑 = 0, 7 �𝑝𝑝

0,01 0,12 0,04 0,07

0,1 0,37 0,11 0,22

1 1,17 0,35 0,7

10 3,69 1,11 2,21

100 11,67 3,5 7

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in

meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where p is the

maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption

and reflection from structures, objects and people.

Operation Manual RMD1609-001, Rev.15 Page 67

1. Introduction

3) CLINICAL EVALUATION

■ MEDDEV 2.7/1 Rev.4

EVALUATION OF CLINICAL DATA:

A GUIDE FOR MANUFACTURERS AND NOTIFIED BODIES

4) OTHERS

■ EN ISO 15223-1:2021

Medical devices - Symbols to be used with medical device labels, labelling and information to be supplied -

Part 1: General requirements

ISO 15223-1:2021

■ IEC TR60878:2015

Graphical Symbols for electrical equipment in medical practice

■ IEC60417-1:2002DB

Graphical Symbols for use on equipment-part1 : overview and application

■ EN ISO14971:2012

Medical devices - Application of risk management to medical devices

ISO 14971:2012

■ EN ISO13485:2016

Medical devices - Quality management systems - Requirements for regulatory purposes

ISO13485:2016

■ Regulation (EU) 2017/745

Medical Devices Regulation

■ EN1041:2008/A1:2013

Information supplied by the manufacturer with medical devices

■ EN62304:2006

Medical device software — Software lifecycle processes

IEC62304:2006

■ EN62366:2008

Medical devices - Application of usability engineering to medical devices

IEC62366:2007

Page 68 RMD1609-001, Rev.15 Operation Manual

1. Introduction FDR Smart FGXR-S

1.8 CUSTOMER SUPPORT

Address any questions regarding FDR SMART FGXR-S to:

FUJIFILM Hong Kong Limited

Unit No.08-11, 19th Floor, CDW Building, 388 Castle Peak Road, Tsuen Wan, N.T. Hong Kong

Fujifilm India Private Limited,

Unitech Cyber Park, Unit No.801-807, 8th Floor, Tower C, Sector 39, Gurugram, Haryana - 122001,

India

FUJIFILM Malaysia Sdn. Bhd.

22, Jalan Jurunilai U1/20, Seksyen U1, Hicom Glenmarie Industrial Park, 40150 Shah Alam, Selangor,

Malaysia

Fujifilm Philippines Inc.

25th Floor, SM Aura Tower, 26th St. Corner McKinley Parkway, Taguig City

FUJIFILM Thailand Ltd.

S.P. Building, 8th Floor, 388 Phaholyothin Road, Bangkok 10400, Thailand

FUJIFILM VIETNAM Co., Ltd.

30thFloor, Saigon Trade Center, 37 Ton Duc Thang street, Ben Nghe Ward, District 1, Ho Chi Minh

City, Vietnam

FUJIFILM Australia Pty Ltd

54 Waterloo Road Macquarie Park, NSW 2113 Australia

FUJIFILM Europe GmbH

Heesenstrasse 31, 40549 Dusseldorf, Germany

FUJIFILM Europe B.V.

Oudenstaart 1, 5047 TK Tilburg, The Netherlands

Authorized Representative: Obelis s.a

Bd.Général Wahis 53,1030 Brussels, Belgium

Tel) +32.2.732.59.54, Fax) +32.2.732.60.03

Operation Manual RMD1609-001, Rev.15 Page 69

1. Introduction

(This page intentionally left blank)

Page 70 RMD1609-001, Rev.15 Operation Manual

2. Console Controls FDR Smart FGXR-S

2. CONSOLE CONTROLS

OPERATOR CONTROL (Membrane Console: XCMC-R1)

1. Power ON and OFF buttons

2. Image receptor (Bucky) selection button and indicators

3. Film/Screen selection button and indicators (On/Off optional AEC function)

4. AEC field selection button and indicators (active only with AEC option)

5. RESET, APR, ms/mAs selection button

6. State Indicators (small focal spot, large focal spot, stand-by, warning, error)

7. Functional buttons concerned about graphic LCD display include APR controls

8. PREP and X-RAY EXPOSURE indicators

9. MENU, SET, ESC buttons

10. PREP and X-RAY EXPOSE buttons

11. Radiography control buttons (kV, mA, exposure time/mAs)

12. Graphic LCD display

Operation Manual RMD1609-001, Rev.15 Page 71

2. Console Controls

Basic LCD display with manual x-ray exposure condition

LCD display with manual x-ray exposure condition and AEC option selected

Page 72 RMD1609-001, Rev.15 Operation Manual

2. Console Controls FDR Smart FGXR-S

OPERATOR CONTROL (XconF with XCSD-R1)

(XCSD-R1 : PC Interface Module)

(XconF : X-ray control software)

1. Power ON and OFF buttons

2. PREP and X-RAY EXPOSE buttons

3. Image receptor (Bucky) selection button and indicators

4. Film/Screen selection button and indicators (On/Off optional AEC function)

5. AEC field selection button and indicators (active only with AEC option)

6. State Indicators (small focal spot, large focal spot, stand-by, warning, error)

7. PREP and X-RAY EXPOSURE indicators

8. RESET button

9. DR enable button

10. Radiography control buttons (kV, mA, exposure time)

11. Status message display area

12. Collimation size display area (This area is displayed only for systems with auto collimator.)

13. Filer selection area (This area is displayed only for systems with auto collimator.)

14. Stitch button (This button is displayed only for systems with auto stitch function.)

Refer to XCONAPP Settings section of the service manual for a list of supported

system types.

Operation Manual RMD1609-001, Rev.15 Page 73

2. Console Controls

2.1 POWER ON/OFF CONTROLS, STAND-BY INDICATOR / DISPLAY

Press ON to switch the X-ray generator on. The console will light up

and a brief self - check will be performed.

All front panel LEDs and indicators, including the X-ray exposure indicator, should

light shortly. This is an LED self-test and does NOT indicate the presence of X-

RAYS.

Immediately after light blinks, stand-by indicator will light on.

Press OFF to switch the generator off.

(PC Interface Module)

After stand-by indicator lights on, LCD displays logo, model name and firmware version of control console and

HT controller.

The speaker should beep and LCD displays exposure condition at the end of the preparation and power charge.

Press the or button to continue if any error messages are presented.

Page 74 RMD1609-001, Rev.15 Operation Manual

2. Console Controls FDR Smart FGXR-S

2.2 PREP, X-RAY EXPOSURE CONTROLS AND INDICATOR / DISPLAY

Press and hold the PREP button to spin the rotor.

LCD status window displays ‘x-ray preparation’ message.

The prep indicator will light on and the LCD status window will

display 'X-ray exposure ready' message when the system is ready to

make an exposure.

While pressing the prep button, press and hold the EXPOSE button

to make an X-ray exposure.

The X-ray exposure indicator will light on and the LCD status

window will display 'X-ray exposure' message when X-ray exposure is

being made.

Pressing the EXPOSE button only will cycle the generator through prep

and then exposure.

After the exposure, LCD status window displays ‘X-ray exposed’ message

for 1 second.

The exposure hand-switch has an alternate function of PREP/EXPOSE

buttons. The dead-man type exposure hand-switch is located at side of

the control console. To use the switch, release from the switch holder

and press the buttons following operating sequences as above.

Operation Manual RMD1609-001, Rev.15 Page 75

2. Console Controls

As for PC interface module, X-ray exposure can be done by PREP and EXP switches as well as the hand

switch.

Page 76 RMD1609-001, Rev.15 Operation Manual

2. Console Controls FDR Smart FGXR-S

2.3 RADIOGRAPHY CONTROLS AND DISPLAY

2.3.1 MS/MAS SELECT BUTTON

The ms/mAs button allows you to work in either exposure time (ms) mode or

mAs mode. Pressing this button will toggle between ms and mAs mode.

Xcon_F displays ms with mAs together so this button does not exist.

2.3.2 MS/MAS READOUT, AEC - ON INDICATOR / POST-MAS DISPLAY

The significance of the ms/mAs readout varies depending on mode selected:

• In AEC mode, the AEC backup time and calculated Post mAs is displayed after x-ray exposure. The

maximum AEC backup ms and mAs is installer programmable. The generator will then set the backup

ms so as to not exceed the preset ms and mAs limits.

• Displays when AEC is selected.

• Displays Post mAs after an AEC exposure.

• In mA/ms mode, the calculated exposure mAs will be displayed (based on the mA and ms selected).

• In mAs mode, the calculated exposure ms will be displayed (based on the mAs selected).

Operation Manual RMD1609-001, Rev.15 Page 77

2. Console Controls

2.3.3 KV UP/DOWN BUTTONS AND DISPLAY

To increase kV, press

To decrease kV, press

Displays demanded kVp of the exposure.

(XconF)

2.3.4 MA UP/DOWN BUTTONS AND DISPLAY

To increase mA, press

To decrease mA, press

(XconF)

Page 78 RMD1609-001, Rev.15 Operation Manual

2. Console Controls FDR Smart FGXR-S

2.3.5 DENSITY / MS / MAS UP/DOWN BUTTONS AND DISPLAY

To increase density, ms, or mAs, press

To decrease density, ms, or mAs, press

• Displays mAs when mAs is selected.

• Displays ms or sec when mA/ms is selected.

• Displays Density when AEC is selected.

The density range is -8 to +8.

This varies the optical density by changing the dose.

(XconF)

The rate of scrolling for the kV, mA, and ms display increases if the buttons are

held down for more than 1 second.

The scroll rate changes after one second.

Specially, kV scroll rate increases to turbo speed 3 seconds after buttons are

pressed.

To return to the slowest scroll rate, release the button and start again.

Operation Manual RMD1609-001, Rev.15 Page 79

2. Console Controls

2.3.6 FILM/SCREEN SELECT BUTTON AND INDICATORS (FOR AEC ONLY)

Pressing FILM/SCREEN button allows operator to use AEC function

and to select desired film/screen combination.

Selected button lights up LED and previous AEC field combination

used before is selected automatically.

If the AEC feature is saved to be used with APR function, the

selection of APR will automatically select stored Film/Screen and

AEC field combination.

Pressing the button with lighted LED will turn off AEC feature.

• for film/screen I. (Slow, Low Sensitivity)

• for film/screen II. (Middle, Medium Sensitivity)

• for film/screen III. (Fast, High Sensitivity)

This function works only for the system equipped with AEC option.

Page 80 RMD1609-001, Rev.15 Operation Manual

2. Console Controls FDR Smart FGXR-S

2.3.7 AEC FIELD SELECT BUTTONS AND INDICATORS (FOR AEC ONLY)

When AEC function is selected by pressing FILM/SCREEN button,

AEC Field can be selected by pressing the specific field positions.

Once selected, the FIELD button LED will be lit.

To cancel the selected field, press the specific button once.

Combination of AEC field is determined by the attached sensor.

The number of fields selectable by the operator is determined by the

installation/service engineer.

For 1-field case, only the center-field button is selectable.

This function works only for the system equipped with AEC option.

2.3.8 FOCAL SPOT SIZE INDICATORS

Focal spot size indicator shows currently selected x-ray tube focal spot

size.

• for small focus.

• for large focus.

GXR series generators support auto focal spot selection feature which is

controlled by a reference mA value accessible only to installation/service

engineer.

The selected focus indicator will blink to indicate that X-ray exposure is

unavailable for the following two cases:

• When focal spot size has changed, generator requires filament preheat

time for selected focus. Filament preheat time is about 4 seconds.

• When X-ray exposure exceeds 100mAs, the generator requires a cooling

time for the IGBT in proportion to mA step and mAs.

Operation Manual RMD1609-001, Rev.15 Page 81

2. Console Controls

2.3.9 ANODE HEAT INDICATOR (%HU) READOUT

Indicates the tube anode heat unit for the selected X-ray tube in percentage.

An anode HU warning message will be displayed at programmed safety level;

typically 75 % of the tube anode H.U. rating.

An anode HU Error message (E18) will be displayed at programmed safety level;

typically 90 % of the maximum tube anode H.U. rating and exposures will be

inhibited.

In reality, tube anode heat unit depends on tube housing and ambient temperature

so it may be different from the one calculated by the x-ray generator.

Therefore, for the safety reason, the maximum tube anode HU rating is set as

90% of maximum HU possible.

When ‘HU Warning Level’ message or Anode HU Error message (E18) appears,

tube has to be cooled down before taking next x-ray exposure.

2.3.10 DATE AND TIME READOUT

The current date and time is displayed in LCD of membrane console.

This date and time information is used for the system diagnostic information.

Page 82 RMD1609-001, Rev.15 Operation Manual

2. Console Controls FDR Smart FGXR-S

2.3.11 STATE INDICATORS

(Membrane Console)

(XconF)

2.3.12 OPERATOR MESSAGE DISPLAY AREA

This area shows generator status, warning, and error messages.

(XconF)

Up to three (3) recent Error Messages are displayed.

Status messages indicate various states of the generator. No action is required.

STATUS MESSAGE DESCRIPTION

Displayed after initialization and indicates generator is

Normal

normal.

X-ray Preparation… Displayed when in active prep state

X-ray Exposure Ready Displayed when generator is ready to expose

X-ray Exposure Displayed when x-ray exposure is being made.

X-ray Exposed Displayed after x-ray exposure for 1 second.

Operation Manual RMD1609-001, Rev.15 Page 83

2. Console Controls

2.3.13 FILTER SELECTION

BUTTON DESCRIPTION

Selects no filter.

Selects 1.0 mm Aluminum.

Selects 0.1 mm Copper.

Selects 0.2 mm Copper.

2.3.14 WARNING MESSAGE DISPLAY

Warning message is issued to warn the operator of generation of troubles which is not critical for the

system operation except ‘HU Warning Level’.

Therefore, it is not necessary to press button when Warning message appears.

When the Warning message is issued, warning indicator turns on for 1 second before the

message disappears.

Refer to Section Warning Messages of Service Manual about descriptions for Warning messages.

2.3.15 ERROR MESSAGE DISPLAY

The GXR console will display error messages during abnormal operation of the generator.

When error occurs, error indicator is turns on with buzzer sound.

Messages may be cleared by pressing the button.

If the error message is not cleared after the following corrective actions are taken, contact a service

representative.

In order to stop the buzzer sound while the error is not cleared, move to APR selection menu or main

menu in which x-ray exposure is not allowed.

Refer to the section Error Messages of the Service Manual for descriptions of the error messages

Page 84 RMD1609-001, Rev.15 Operation Manual

2. Console Controls FDR Smart FGXR-S

2.4 IMAGE RECEPTOR (BUCKY) BUTTONS AND INDICATORS

2.4.1 NON-BUCKY IMAGE RECEPTOR

Press this button to select the Non-Bucky image receptor.

The adjacent indicator will light.

2.4.2 BUCKY1 IMAGE RECEPTOR

Press this button to select the Bucky 1 image receptor.

The adjacent indicator will light.

Usually, this button is used for table Bucky.

2.4.3 BUCKY2 IMAGE RECEPTOR

Press this button to select Bucky 2 image receptor.

The adjacent indicator will light.

Usually, this button is used for wall Bucky.

Image Receptors are depicted as the console is shipped from the factory. The

receptors may have been reprogrammed during installation. As a result, the

receptors may contain installer - applied icons that differ from those shown in this

manual.

For membrane console, the long pressing of the selected Bucky button over 4

seconds will switch the interface between DR and CR.

If CR is needed, this function is needed. If the generator is powered on or Bucky

is changed, DR will be activated automatically.

Operation Manual RMD1609-001, Rev.15 Page 85

2. Console Controls

2.4.4 EXTERNAL DEVICES FOR EACH IMAGE RECEPTOR

For GXR series generators, DR may be connected to the image receptors.

The following status message indicates that the external device for the selected Bucky is Digital Radiography.

This status is possible only when the generator has DR option.

(Membrane Console)

(XconF)

Page 86 RMD1609-001, Rev.15 Operation Manual

3. Operator’s Utility FDR Smart FGXR-S

3. OPERATOR’S UTILITY

3.1 ENTERING INTO OPERATOR’S UTILITY

This section is for membrane console (Model: XCMC-R1).