Professional Documents

Culture Documents

Lecture - 3 - Loads

Lecture - 3 - Loads

Uploaded by

mohamedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture - 3 - Loads

Lecture - 3 - Loads

Uploaded by

mohamedCopyright:

Available Formats

Structural Design (II) Spring 2010 Building Engineering Program

LECTURE (3): LOADS AND ALLOWABLE STRESSES

3.1 Loads on Steel Buildings

Loads are taken from the Egyptian code for calculating the loads and forces in buildings. The

loads are divided into two main cases:

A) Case I (Primary loads): primary loads are the loads more probable to act together, which

include: dead loads, live loads, dynamic effect of live load and centrifugal forces …etc.

B) Case II (Primary and Secondary loads): Secondary loads are the loads less probable to

act with the primary loads, which may include: wind loads, earthquake loads, braking forces,

temperature effect, erection forces, shrinkage and creep of concrete and differential settlement

of supports.

The loads can be primary or secondary according to the designed element. For example, wind

loads are secondary for the design of main beams and columns and primary for the design of

wind bracing members. In the following sections, some of these loads are summarized.

3.1.1 Dead Load (For a steel factory building)

Dead loads are taken as the loads of the covering material in addition to the own weight of steel

structure itself.

a) The weights of covering material (wc), in the structural analysis can be taken as:

Single Layer Steel Sheets 5kg/m2 to 8 kg/m2

Double Layered Steel Sheets with Isolation 10kg/m2 to 15 kg/m2

b) Own weight of steel structures (w steel) [Trusses, purlins, bracings, ...etc.], can be assumed:

w steel = (20-35) kg/m2 depending on the span of the truss

3.1.2 Live Load

The minimum live loads are taken according the Egyptian code of practice. In case of inclined

roofs, live loads are considered according the angle of roof slope “α” according to the curves

presented in Figure (3.1) for accessible and inaccessible roofs. The value of the live load can

be calculated using equations 3-1 and 3-2 instead of the curve.

L.L. = (60 – 66.67x tanα) ≥ 20 kg/m2 (for Inaccessible roofs) (3.1)

L.L. = (200 – 300x tanα) ≥ 20 kg/m2 (for Accessible roofs) (3.2)

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 1

Structural Design (II) Spring 2010 Building Engineering Program

Accessible Roof

250

L.L. kg/m2

200

150 Inaccessible Roof

100

50

20 kg/m2

0

Tan α

0 0.2 0.4 0.6 0.8 1

Fig. (3.1) Live Loads on

Inclined Roofs

For Truss roofs, the joint dead and live loads can be calculated as follows:

a

Dead Load: PD.L. = wc * * S + w steel * (a * S)

cos α

Live Load: PL.L. = L.L.* (a * S)

PL.L. PL.L. PL.L. PL.L. PL.L.

PL.L. PL.L. PL.L. PL.L.

PL.L./2 PL.L. PL.L. PL.L./2

PD.L. PD.L. PD.L. PD.L. PD.L.

PD.L. PD.L. PD.L. PD.L.

PD.L./2 PD.L. PD.L. PD.L./2

h H

Span L

a

S

S

Main

S

Trusses

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 2

Structural Design (II) Spring 2010 Building Engineering Program

3.1.3 Wind Load

Wind loads are the forces that affect the building in direction perpendicular to the surfaces of

the buildings and structures. This force is considered positive if it is in surface direction

(pressure) and negative if it is outside the surface, away from the surface direction (suction).

The external pressure or suction of wind force affecting the building surfaces is calculated

using the following equation:

Pe = C e .k .q (3.3)

Ce

Where; +0.80

Pe is the external design static wind pressure

affecting the external unit area, +0.60

Wind

Ce is the coefficient of wind effect (pressure +0.40

Pressure

or suction) and it depends on the building

geometric shape as shown in figure (3.2) for +0.20

wind pressure side only.

Tan α

k is a coefficient changes with the change of 0.20 0.40 0.60 0.80

building height and taken according to table -0.20

(3.1), Wind

q is the basic wind pressure and it depends on -0.40 Suction

the location of the building and is taken

-0.60

according to table (3.2) for areas inside Egypt.

-0.80

Fig. (2.2) Coefficient of Wind effect on roof surfaces

Table (3.1) Values of Coefficient “k” facing wind load (Pressure side)

Height “m” Coefficient “k”

0 to 10 1.0

10 to 20 1.10

20 to 30 1.30

30 to 50 1.50

50 to 80 1.70

80 to 120 1.90

120 to 160 2.10

More than 160 2.30

Table (3.2) Basic wind Pressure at different Locations in Egypt

Location q “Kg/m2”

Marsa Matrouh, El-Dabaa, Ras-Sedr 90

Alexandria, El-Saloum,Abu Sower, Hurghada and all coastal 80

areas

Cairo, Asyot, Belbis 70

Fayoum, Menya, Aswan, Modereyat El-Tahrir 60

Tanta, Mansoura, Damanhour 50

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 3

Structural Design (II) Spring 2010 Building Engineering Program

Coefficient of wind effect (Ce) for various roof surfaces according to Egyptian Loads

Code at pressure and suction sides:

Fig. (3.3) Coefficient of Wind Effect on Rectangular Frames

Fig. (3.4) Coefficient of Wind Effect on Pitched Roof Frames

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 4

Structural Design (II) Spring 2010 Building Engineering Program

Fig. (3.5) Coefficient of Wind Effect on Inclined Roof Frames

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 5

Structural Design (II) Spring 2010 Building Engineering Program

For Truss roofs, the wind loads affecting the truss can be calculated as follows:

Case of Wind left:

Wind loads affect perpendicularly on the surfaces and there are usually two sides: pressure side

and suction side.

Pressure Side Suction Side

Wind Left Surface 2 Surface 3

1:Z

h

α

H

a Surface 4

Surface 1

Span L

1. Pressure Side:

For surface (1): α=90o tan α=∞ ⇒ Ce = +0.8

Uniform wind load on column: Wp1 = (+0.8*k*q)*S = Kg./m

For surface (2): From tan α ⇒ get Ce

[Usually Z:1 = 20:1 or 10:1 or 5:1 ⇒ tan α < 0.4 ⇒ Ce =-0.8 (suction)]

a

The joint load: P2= (Ce *k*q)*( *S)

cos α

2. Suction Side: Ce = -0.5 (constant)

For surface (3):

a

P3 = (-0.5*k*q)*( *S)

cos α

For surface (4):

Uniform wind load on column: WS4 = (-0.5*k*q)*S= Kg./m

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 6

Structural Design (II) Spring 2010 Building Engineering Program

Wind Left

P2 P2 P2 P2/2 P3/2 P3 P3 P3

P2/2 P2 P2 P3 P3 P3/2

Wp1= t/m Ws4= t/m

a

Span L

Then, the forces in the truss members due to dead, live and wind loads can be calculated using

any computer program such as STAAD or SAP2000, or manually using stress diagram or

method of sections.

Note:

Steel sections are generally designed according to Case (I) [using primary loads]. If the

sections are designed using Case (II) [using primary and secondary loads], the allowable

stresses increase by 20% according to Egyptian Code of Practice. The critical design case (I or

II) can be determined as follows:

Force(CaseII ) − Force(CaseI )

If ≤ 0.20 Design case is (I)

Force(CaseI )

Force(CaseII ) − Force(CaseI )

If > 0.20 Design case is (II)

Force(CaseI )

Case II

Case I Design

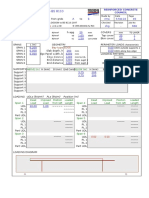

Members D.L. L.L. W.L.L. W.L.R. D+L+W

D+L Case

or D+W

L1

Lower L2

Chord L3

M

U1

Upper U2

Chord U3

M

V1

Verticals V2

M

D1

Diagonals D2

M

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 7

Structural Design (II) Spring 2010 Building Engineering Program

Example:

The shown figure represents the main system of a building made of steel trusses. The covering

material used is single layer steel sheets. Spacing between trusses is S = 6.0 m. Calculate the

dead load, live load and wind load acting on the truss. Calculate also the maximum forces in

the marked member due to dead and live load only.

slope 1 : 20

1.2 m

2 1.6 m

1

6.0 m

Concrete Columns

L = 10 x 1.6 = 16.0 m

Solution:

1) Dead Load: Assume weight of single layer sheets Wc =6 kg/m2

Assume weight of steel structures W steel = 20 kg/m2

PD.L = 6*(1.6/cosα*6) + 20*(1.6*6) = 249.7 kg = 0.25 t

2) Live Load: Case of Inaccessible roofs L.L. =60-66.66*1/20 =56.67 kg/m2

PL.L. = 56.67*(1.6*6) = 545 kg = 0.55 t

PT.L. = 0.25 + 0.55 t = 0.80 t

b a

0.80 t 0.80 t 0.80 t 0.80 t 0.80 t 0.80 t 0.80 t

0.40 t 0.80 t 0.80 t 0.40 t

c

2

1

4.0 t b a 4.0 t

L = 10 x 1.6 = 16.0 m

Dead and Live Loads

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 8

Structural Design (II) Spring 2010 Building Engineering Program

Force in member (1):

From section (a-a), Σ Mc, left = zero:

(4-0.40)*6.4-0.8*(1.6+3.2+4.8)-F1* 1.52 = zero

⇒ F1 = 10.11 t (Tension)

Force in member (2):

From section (b-b), Σ Y left = zero:

(4-0.40)-F2* Sin 41o = zero

⇒ F2 = 6.0 t (Tension)

3) Wind Load:

For surface (1): α=90o tan α=∞ ⇒ Ce = +0.8

P1 = (+0.8*1.0*0.07)*(6.0*1.2/2) = 0.202 t

For surface (2): Z:1 = 20:1 tan α = -0.05 < 0.4 ⇒ Ce = -0.8 (suction)]

P2= (-0.8*1.0*0.07)*(1.6/cos3.18 * 6.0) = - 0.54 t

For surface (3):

P3 = (-0.5*1.0*0.07)*(1.6/cos3.18 * 6.0) = - 0.34 t

For surface (4):

P4= (-0.5*1.0*0.07)*(6.0*1.2/2) = 0.13 t

0.54 0.54 0.54 .27 .17 0.34 0.34 0.34

0.27 0.54 0.34 0.17

0.202 0.13

0.202 0.13

L = 10 x 1.6 = 16.0 m

Wind Loads (ton)

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 9

Structural Design (II) Spring 2010 Building Engineering Program

3.2 Allowable Stresses For Steel Structures According To Egyptian Code 2001:

All elements of the steel building shall, in the first instance, be so designed that in no

case the stresses due to case I (primary stresses) exceed the allowable stresses specified in the

Egyptian Code of Practice 2001. The design should then be checked for case II (primary and

secondary stresses), and the stresses shall in no case exceed the aforesaid allowable stresses by

more than 20%.

Classification of Cross-Section

In the Egyptian code of practice (ECP), the sections are classified according to local buckling

of component plate elements (Depending on the maximum width-thickness ratios) into three

section classes; compact sections, non-compact sections and slender sections as follows:

C f = Fy

Class 1: Compact Sections ( fcr > Fy ) tf

Compact sections are the sections that can achieve plastic (-)

moment capacity without the occurrence of local buckling dw

tw

of any of its component plate elements subjected to

compressive stress. (+)

bf Fy

Compact Section

C f = Fy

Class 2: Non-Compact Sections ( fcr > Fy ) tf

(-)

Non-compact sections are the sections that can achieve the

yield moment capacity without the occurrence of local tw

dw

buckling of any of its component plate elements subjected to

compressive stress.

(+)

bf Fy

Non-Compact Section

Class 3: Slender Sections ( fcr < Fy )

C f act < F y

Slender sections are the sections in which local buckling

of component plate elements subjected to compressive (-)

stress takes place before failure takes place. When any of t

the compression component elements of a cross-section H dw

is classified as class 3, the whole section shall be

designed as class 3 cross-section.

t (+)

Where: B

Fy = Yield stress of the material.

fcr = The critical buckling stress at which the local Slender Section

buckling of any of the compression component

elements of the cross-section takes place.

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 10

Structural Design (II) Spring 2010 Building Engineering Program

The limiting plate width-to-thickness ratio for class 1 and class 2 are given in the following

tables:

Table (3.3a) Maximum Width to Thickness Ratios for Stiffened Compression Elements

dw dw dw dw dw h

tw tw tw tw tw

dw=h-3t , (t=t f=t w )

13

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 11

Structural Design (II) Spring 2010 Building Engineering Program

Table (3.3b) Maximum Width to Thickness Ratios for Stiffened Compression Elements

2

Fy in t/cm

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 12

Structural Design (II) Spring 2010 Building Engineering Program

Table (3.3c) Maximum Width to Thickness Ratios for Un-stiffened Compression Elements

Stress distribution

in element

Stress distribution

in element

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 13

Structural Design (II) Spring 2010 Building Engineering Program

Table (3.3d) Maximum Width to Thickness Ratios for Compression Elements

Refer also to

(Table 2.1c)

"Outstand flanges"

1. Compact

2. Non-Compact

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 14

Structural Design (II) Spring 2010 Building Engineering Program

For compact and non-compact sections, the full area of the section shall be used, while

for slender sections, the effective area shall be used. Slender sections which do not meet the

non-compact section requirements shall be designed using the same allowable stresses used for

non-compact sections except that the section properties used in the design shall be based on the

effective widths (be) of compression elements as specified in Table 2.3 for stiffened elements

and Table 2.4 for un-stiffened elements in the ECP.

Allowable stresses for steel structural shall be determined according to the grade of steel used as

shown in tables (3.3a) and (3.3b):

Table (3.3a) Allowable Stresses in Standard Grade Structural Steel (Thickness t ≤ 40 mm)

Compression and Buckling Fc Bending Bending

(t/cm2) (1) for for Non- Shear in

Grade Tension Compact Compact Web

Cause of

of Ft=0.58Fy sections sections

stresses λ=(KL/r) <100 λ=(KL/r)≥100 qall=.35Fy

Steel (t/cm2) Fb=0.64Fy Fb=0.58Fy

(t/cm2) (2) (t/cm2) (3) (t/cm2) (4)

I-Primary St. 37 1.40 1.40-0.000065*λ2 7500/λ2 1.54 1.40 0.84

Stresses

Dead load

Live Load St. 44 1.60 1.60-0.000085*λ2 7500/λ2 1.76 1.60 0.98

Dynamic Effect

Centrifugal

Force St. 52 2.10 2.10-0.000135*λ2 7500/λ2 2.30 2.10 1.25

II- Primary and

Additional All values are 20 % higher than for item I

Stresses(5)

(1) For axially loaded symmetric sections.

(2) For compact sections satisfying the requirements of Clause 2.6.5.1.

(3) For compact sections not satisfying the requirements of Clause 2.6.5.1 or non-compact sections

satisfying the requirements of Clause 2.6.5.5.

(4) For sections satisfying the buckling requirements of Clause 2.6.3.1.

(5) Dead Load, Live Load, Dynamic Effect, Centrifugal Force, (Wind Pressure or Earthquake Loads),

Braking Force, Lateral Shocks, Temperature Effect, Frictional Resistance of Bearings, Settlement

of Supports and Shrinkage and Creep of Concrete.

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 15

Structural Design (II) Spring 2010 Building Engineering Program

Table (3.3b) Allowable Stresses in Standard Grade Structural Steel (100 mm ≥ Thickness t > 40 mm)

Compression and Buckling Fc Bending Bending

(t/cm2) (1) for for Non- Shear in

Grade Tension Compact Compact Web

Cause of

of Ft=0.58Fy sections sections

stresses qall=.35Fy

Steel (t/cm2) λ=(Kl/r) <100 λ=(Kl/r)≥100 Fb=0.64Fy Fb=0.58Fy

(t/cm2) (2) (t/cm2) (3) (t/cm2) (4)

I-Primary St. 37 1.30 1.30-0.000055*λ2 7500/λ2 1.38 1.30 0.75

Stresses

Dead load

Live Load St. 44 1.50 1.50-0.000075*λ2 7500/λ2 1.63 1.50 0.89

Dynamic Effect

Centrifugal

Force St. 52 2.00 2.0-0.000125*λ2 7500/λ2 2.14 2.0 1.17

II- Primary and

Additional All values are 20 % higher than for item I

Stresses(5)

(1) For axially loaded symmetric sections.

(2) For compact sections satisfying the requirements of Clause 2.6.5.1.

(3) For compact sections not satisfying the requirements of Clause 2.6.5.1 or non-compact sections

satisfying the requirements of Clause 2.6.5.5.

(4) For sections satisfying the buckling requirements of Clause 2.6.3.1.

(5) Dead Load, Live Load, Dynamic Effect, Centrifugal Force, (Wind Pressure or Earthquake Loads),

Braking Force, Lateral Shocks, Temperature Effect, Frictional Resistance of Bearings, Settlement

of Supports and Shrinkage and Creep of Concrete.

Dr. Ahmed Hassan yousef Loads and Allowable Stresses 16

You might also like

- Deflection Limits - EurocodeDocument1 pageDeflection Limits - EurocodeielleNo ratings yet

- Dead Loads and Live Loads2Document31 pagesDead Loads and Live Loads2Lasantha DadallageNo ratings yet

- Assessment of The NigolDocument8 pagesAssessment of The NigolVictor JimenezNo ratings yet

- Reliability 4 LoadsDocument177 pagesReliability 4 LoadsNhon NguyenNo ratings yet

- Australian Steel StrengthDocument5 pagesAustralian Steel StrengthDonald HamiltonNo ratings yet

- 5 1,5,9,14,16,22,27,29Document13 pages5 1,5,9,14,16,22,27,29john parker0% (1)

- Eur Ocode Design Factor S and Limits: Horizontal DeflectionsDocument1 pageEur Ocode Design Factor S and Limits: Horizontal DeflectionsJay PadamaNo ratings yet

- Part 6 Analysis and Design of Purlins W PDFDocument17 pagesPart 6 Analysis and Design of Purlins W PDFCalvin TehNo ratings yet

- PurlinsDocument15 pagesPurlinsmohamed tarekNo ratings yet

- Loads On Industrial BuildingsDocument29 pagesLoads On Industrial Buildingsmcg_3m100% (1)

- Pressures: Developed ArcsDocument4 pagesPressures: Developed ArcsMagnoNo ratings yet

- Chapter 1 RC II Columns Design NotesDocument17 pagesChapter 1 RC II Columns Design NotesRakibNo ratings yet

- Lec.2 - Design of Tension Members .Document38 pagesLec.2 - Design of Tension Members .alpegambarliNo ratings yet

- A Framework For Understanding Energy Pile Behaviour: 2.1 GeneralDocument8 pagesA Framework For Understanding Energy Pile Behaviour: 2.1 GeneralransransNo ratings yet

- Report 20220726Document555 pagesReport 20220726Ken KoemhongNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument389 pagesRCC31R Rigorous One-Way SlabsCioabla BogdanNo ratings yet

- Chaper Two - Strain, Hook'S Law, Axial Load Problems: L L L L LDocument11 pagesChaper Two - Strain, Hook'S Law, Axial Load Problems: L L L L Lريام الموسويNo ratings yet

- PE Review Structure LoadsDocument4 pagesPE Review Structure LoadsXhoneyra IraNo ratings yet

- Chapter 6 Design of Combined FootingsDocument13 pagesChapter 6 Design of Combined Footingsalufuq companyNo ratings yet

- Dynamic of Billboard Thin PlateDocument6 pagesDynamic of Billboard Thin PlateJoseph Cloyd LamberteNo ratings yet

- RCC33 Flat Slabs (A & D)Document12 pagesRCC33 Flat Slabs (A & D)Kem RaiNo ratings yet

- 2.3 Live-LoadsDocument7 pages2.3 Live-LoadsnickNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument148 pagesRCC31R Rigorous One-Way SlabsMohammad Twaha JaumbocusNo ratings yet

- Residential Building With Eccentric Footing: Structural Design ReportDocument43 pagesResidential Building With Eccentric Footing: Structural Design ReportRajib MaharjanNo ratings yet

- Calculation Abo AlfadilDocument40 pagesCalculation Abo AlfadiltahaelnourNo ratings yet

- Steel HRBDocument88 pagesSteel HRBFatma ElbanaNo ratings yet

- Parking Shed: Latest Edition of The FollowingDocument78 pagesParking Shed: Latest Edition of The Followingmjnasar khan jamalNo ratings yet

- 2 Estimating PDFDocument9 pages2 Estimating PDFJayNo ratings yet

- Ass1 GQDocument2 pagesAss1 GQFlora LinNo ratings yet

- ETM RC - 1 Chapter - Two (LSDforFlexure)Document41 pagesETM RC - 1 Chapter - Two (LSDforFlexure)Fekadu DebelaNo ratings yet

- Structural AnalysisDocument12 pagesStructural Analysisme-elorm100% (2)

- CHAPTER 2 .Colunm DesignDocument17 pagesCHAPTER 2 .Colunm DesignDechas Mohammed100% (1)

- Buckling Strength of Thin Cylindrical Shells UnderDocument9 pagesBuckling Strength of Thin Cylindrical Shells UnderByron0% (1)

- 2010 Supplement To The 2006 MetalDocument73 pages2010 Supplement To The 2006 MetalMudassir AliNo ratings yet

- sw7675 c003 PDFDocument16 pagessw7675 c003 PDFMeslem MazighNo ratings yet

- 17-09-2015 Midterm + MemoDocument13 pages17-09-2015 Midterm + MemoMakaveliNo ratings yet

- Sheet 4 - 4 PupDocument1 pageSheet 4 - 4 Pupe220b332cfNo ratings yet

- rc-1 2015-16 Chapter Two 141215Document36 pagesrc-1 2015-16 Chapter Two 141215ABAMELANo ratings yet

- Chinese Country Report 2012 - Revision of Wind Loading Code and Wind Tunnel Test GuidelinesDocument9 pagesChinese Country Report 2012 - Revision of Wind Loading Code and Wind Tunnel Test GuidelinesSanthosh Kumar BaswaNo ratings yet

- Field Lines On An Arbitrary TEM Transmission Line.: M S M o 2Document2 pagesField Lines On An Arbitrary TEM Transmission Line.: M S M o 2Cihan KayaNo ratings yet

- Arduino TutorialDocument2 pagesArduino TutorialxxxNo ratings yet

- Deflection of BeamDocument9 pagesDeflection of BeamKirk S PhotongNo ratings yet

- 05 LoadsDocument4 pages05 LoadsniginpNo ratings yet

- Chapter 1 2019Document41 pagesChapter 1 2019Noel BernalesNo ratings yet

- Spreadsheets To BS 8110: L (M) H (MM) BW (MM) HF (MM) Type BF (MM)Document1 pageSpreadsheets To BS 8110: L (M) H (MM) BW (MM) HF (MM) Type BF (MM)Erastus Kagwe Tyson JnrNo ratings yet

- Design of Monopile Foundations For Offshore Wind eDocument11 pagesDesign of Monopile Foundations For Offshore Wind eThanh Đạt NguyễnNo ratings yet

- Beamdesign 2024Document107 pagesBeamdesign 2024Muhammad Afiq Bin KamalNo ratings yet

- Bolton - 1999 - A Non-Linear Elasticperfectly Plastic Analysis For Plane Strain Undrained Expansion TestsDocument9 pagesBolton - 1999 - A Non-Linear Elasticperfectly Plastic Analysis For Plane Strain Undrained Expansion TestsHUGINo ratings yet

- RCC33 Flat Slabs (A & D)Document13 pagesRCC33 Flat Slabs (A & D)Mohammad Twaha JaumbocusNo ratings yet

- Volume 2 - Hollow Sections Second Edition 4Document1 pageVolume 2 - Hollow Sections Second Edition 4Anonymous 0x2pwMCWgjNo ratings yet

- Moment FormulasDocument18 pagesMoment FormulasVhorn Tiu0% (1)

- Live Loads in Industrial WarehousesDocument10 pagesLive Loads in Industrial WarehousesScribdTranslationsNo ratings yet

- Structural Design Proposal For The Le Boulevard Sky Light Doha QatarDocument8 pagesStructural Design Proposal For The Le Boulevard Sky Light Doha QatarMuraliNo ratings yet

- Part 6 Analysis and Design of PurlinsDocument18 pagesPart 6 Analysis and Design of PurlinsPaul P.No ratings yet

- Portal FrameDocument38 pagesPortal Framemohamed tarekNo ratings yet

- Research Paper Study On Comparative Analysis of The TDocument14 pagesResearch Paper Study On Comparative Analysis of The Tlilharerakesh12No ratings yet

- Loads For Designing FoundationDocument38 pagesLoads For Designing Foundationmuzaffar86ahmedNo ratings yet

- Gable and BracingDocument19 pagesGable and Bracingabdallashehata024No ratings yet

- Pipe StackingDocument3 pagesPipe Stackingnyak kinahNo ratings yet

- Euro Code-Shear (Concrete)Document74 pagesEuro Code-Shear (Concrete)mohamedNo ratings yet

- Seismic IsolationDocument37 pagesSeismic IsolationmohamedNo ratings yet

- Lecture 12 Built-Up ColumnsDocument10 pagesLecture 12 Built-Up ColumnsmohamedNo ratings yet

- Lecture 10 Crane GirderDocument22 pagesLecture 10 Crane GirdermohamedNo ratings yet

- Air Distribution N Outlet SelectionsDocument43 pagesAir Distribution N Outlet SelectionsatiqulaNo ratings yet

- Cooling Tower TDPDocument34 pagesCooling Tower TDPjayan perkasaNo ratings yet

- Thermodynamics: MTX 220 DefinitionsDocument8 pagesThermodynamics: MTX 220 Definitionspoly WannaNo ratings yet

- VCRS, Vars, Air Refrigiration, SteamjetDocument18 pagesVCRS, Vars, Air Refrigiration, Steamjetdawit abebualNo ratings yet

- SyllabusDocument1 pageSyllabusSaurav SenguptaNo ratings yet

- "Refrigeration Using LPG": Prof. Bhupendra PandeyDocument16 pages"Refrigeration Using LPG": Prof. Bhupendra PandeyAditya Mishra100% (1)

- Virial Equation CoefficientsDocument1 pageVirial Equation CoefficientsJozy McClay50% (2)

- Department of Education: Republic of The PhilippinesDocument7 pagesDepartment of Education: Republic of The PhilippinesNick MabalotNo ratings yet

- Ultrasonic Testing Ut Q Bank A-11: and Reflected at An InterfaceDocument11 pagesUltrasonic Testing Ut Q Bank A-11: and Reflected at An Interfacekingston100% (2)

- Retaining Wall Design: Ver W4.0.04 - 12 Feb 2021 Title: Cantilever Wall Example Input DataDocument7 pagesRetaining Wall Design: Ver W4.0.04 - 12 Feb 2021 Title: Cantilever Wall Example Input Datarodain najjarNo ratings yet

- Fire Safety of Prestressed Hollowcore FloorDocument14 pagesFire Safety of Prestressed Hollowcore Floornenad lazicNo ratings yet

- SOM Part 2Document71 pagesSOM Part 2Lee chanNo ratings yet

- ME 372 (Chapter-3) - Heat Conduction in Cylinder and Sphere, Heat GenerationDocument43 pagesME 372 (Chapter-3) - Heat Conduction in Cylinder and Sphere, Heat Generationالياس يونس مرغلانيNo ratings yet

- Mallick Gupta Notes PDFDocument85 pagesMallick Gupta Notes PDFa dutta0% (2)

- Buckling Behavior of Cold-Formed Zed-Purlins Partially Restrained by Steel SheetingDocument12 pagesBuckling Behavior of Cold-Formed Zed-Purlins Partially Restrained by Steel SheetingamokeNo ratings yet

- Trickle Bed ReactorDocument23 pagesTrickle Bed ReactorgautamahujaNo ratings yet

- Flow - Pressure Chart (US and Metric)Document4 pagesFlow - Pressure Chart (US and Metric)Sylvester SullivanNo ratings yet

- Effectively Remove DropletsDocument1 pageEffectively Remove Dropletsfawmer61No ratings yet

- Eco-Friendly For Anyone, Anywhere.: HydropowerDocument15 pagesEco-Friendly For Anyone, Anywhere.: HydropowerRodri GonzalezNo ratings yet

- Bending Stress & Shear StressDocument94 pagesBending Stress & Shear StressManoj CmNo ratings yet

- Chapter 2: Compressible Flow: But Use R 287Document5 pagesChapter 2: Compressible Flow: But Use R 287MikeMichaelNo ratings yet

- Sy22 Apr08 10Document13 pagesSy22 Apr08 10AdithyaNo ratings yet

- Examples Steady Conduction in Slabs, Cylinders and Spheres Critical Thickness of InsulationDocument22 pagesExamples Steady Conduction in Slabs, Cylinders and Spheres Critical Thickness of InsulationgazileNo ratings yet

- APL - LEA135.E0.ED1 - 20180723 - Approved PDFDocument6 pagesAPL - LEA135.E0.ED1 - 20180723 - Approved PDFSalmanShaikhNo ratings yet

- Ch6-Mechanical PropertiesDocument39 pagesCh6-Mechanical PropertiesSaif AlbaddawiNo ratings yet

- General Properties of MaterialsDocument24 pagesGeneral Properties of Materials1900651No ratings yet

- Ag5 2002Document134 pagesAg5 2002rasheedillikkalNo ratings yet

- Forced Convection CompleteDocument9 pagesForced Convection Completeismail100% (1)

- Act 5 RadiationExperiments Grp1Document10 pagesAct 5 RadiationExperiments Grp1Junn Edgar LibotNo ratings yet