Professional Documents

Culture Documents

Layout Core and Core Barrel

Layout Core and Core Barrel

Uploaded by

hseae1 AE1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Layout Core and Core Barrel

Layout Core and Core Barrel

Uploaded by

hseae1 AE1Copyright:

Available Formats

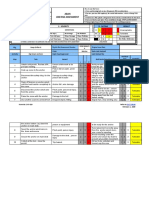

Corpro Ho w to use the form:

JOB RISK ASSESSMENT 1. Crew performing task review ALL generic JRA considerations.

2. Review previous JRA update(s) for useful information, which will help THIS task.

3. Create new JRA update with generic from and ALL considerations for this task.

4. Carry out task per plan. If any conditions change, STOP and RE-ASSESS!

5. Keep 2 copies of JRA update for future reference. Update generic JRA as needed.

Location/Rig: PNG/Twinza - COSL Seeker Crew: Drilling Original Issue Date:

Date Last Revised: 11-Oct-17

Activity: Lay out inner core barrel & core Dept Head Approval: Last Revised By: Ashley Stephens

Residual Acceptable?

Step Task Hazard Risk Reduction Measure Risk Tolerable?

L S R L S R Unacceptable?

Secure operation & clear

Gas at harmful level affects

1 Check last stand for gas at table. 2 3 6 floor if necessary. Re 1 3 3 Tolerable

drillfloor team

assess task

Have Gas detector on the rig floor during the whole

lay out process.

Set slips and dog collar so the connection is at a

3 safe working height,Cover hole around barrel with

tarpaulin.

Open outer barrel head with rig tongs and lay out

4

head. CHECK FOR GAS!!

Form No. OP-018Rev 1 Page 1 of 4

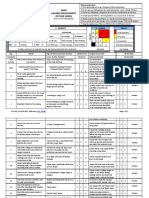

Corpro Ho w to use the form:

JOB RISK ASSESSMENT 1. Crew performing task review ALL generic JRA considerations.

2. Review previous JRA update(s) for useful information, which will help THIS task.

3. Create new JRA update with generic from and ALL considerations for this task.

4. Carry out task per plan. If any conditions change, STOP and RE-ASSESS!

5. Keep 2 copies of JRA update for future reference. Update generic JRA as needed.

Drilling

Install lift sub onto top bearing asembly. Attach

5

Tugger line to inner tube and pick up.

Set clamp, make all service breaks on gyrohead

6 package. Set inner barrel clamp under TSS upset.

Lower onto top of outer barrel. CHECK FOR GAS

The following risk reduction

Remove bearing package and layout Inner barrel measures are required for all

7 tasks:

head on drill floor.

1. Remove air hose from

Common set of hazards for all

elevators

Make up inner barrel lift sub to top TSS tube. Pick up drillfloor work on core barrel (as

8 2. Ensure core is strapped

and remove clamp. for BHA):

securely to transport frame

1. Light loads in the auto elevators

3. Highlight the pinch points

at height

Pick up first inner tube. Set inner barrel clamp below associated with hand tools

2. Core falling out of cradle

upset. Lower onto top of outer barrel. Break 4. Stay alert - always have

3. Fingers caught between tubing

9 connection using pipe wrench/chain tong. Back out a escape route.

clamps & wrenches

few turns. Install shear boot. Back out remainder of 5. Slicker suits, nitrile gloves

4. Caught between area of V-

connection. Insert shear plate. CHECK FOR GAS & barrier cream, shower off

Door, posts and bumper rails

mud & change overalls

5. Dermatitis from skin contact

ASAP

from drilling fluid 2 3 6 1 3 3 Tolerable

Lay out using the crane to tail out while slowly

6. Good communications

6. Uncontrolled lowering of core

10 lowering the TSS core tube with the tugger line. Lift 7. Toolbox talks

barrel to deck

TSS with crane directly to the processing area 8. Well trained & competent

7. Dropped objects from cradle

team

8. Heavy lifting hazard –

9. A) Ensure shear boot

observers on catwalk or pipe deck

Form No. OP-018Rev 1 Page 2 of 4

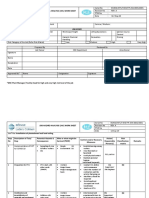

Corpro Ho w to use the form:

JOB RISK ASSESSMENT 1. Crew performing task review ALL generic JRA considerations.

2. Review previous JRA update(s) for useful information, which will help THIS task.

3. Create new JRA update with generic from and ALL considerations for this task.

4. Carry out task per plan. If any conditions change, STOP and RE-ASSESS!

5. Keep 2 copies of JRA update for future reference. Update generic JRA as needed.

9. A) Ensure shear boot

observers on catwalk or pipe deck Drilling

Install lift cap on second inner barrel. Connect clamp secured tight on inner

9. Untrained personnel working on

Tugger line & take weight of inner barrel assembly. barrel.

11 core barrel

Remove inner tube clamp & pick up inner tube to B) Ensure shear plate is in

next connection 20ft. 10. Gas release from core barrel /

correct position

BHA

C) Advise possibility – keep

11.Slips and trips - mud on floor

hands and feet clear.

Repeat steps 6 to 9 until last inner tube has been 12. Over-exertion

12 10. Monitor gas

laid down.

11. Good housekeeping

12. Rotate crews, take

breaks for refreshment.

Pick up outer barrel head, screw in & make up

with chain tongs, mark joint with white chalk.

13 Remove tarpaulin from around hole. Lift core

barrel with blocks, remove dog collar safety

clamp.

Pick up and break apart core barrels in the

15 reverse order to make up or if running back in,

the corehead can be checked.

Break core head with bit breaker in locked

rotary and rig tongs. Cover hole. Set rubber on

14 hole cover. Remove & set back corehead

and bit breaker, clean with pressure gun, make

visual inspection of corehead and bearings.

Form No. OP-018Rev 1 Page 3 of 4

Corpro Ho w to use the form:

JOB RISK ASSESSMENT 1. Crew performing task review ALL generic JRA considerations.

2. Review previous JRA update(s) for useful information, which will help THIS task.

3. Create new JRA update with generic from and ALL considerations for this task.

4. Carry out task per plan. If any conditions change, STOP and RE-ASSESS!

5. Keep 2 copies of JRA update for future reference. Update generic JRA as needed.

Refer to JRA for making up the core barrel for Drilling

16 loading new inner tubes and space-out for next

core run

Form No. OP-018Rev 1 Page 4 of 4

You might also like

- Aviation Medical Examiners Course-2Document1 pageAviation Medical Examiners Course-2Keletso NyathiNo ratings yet

- Principles of Management MCQS With Answers of Stephen PDocument21 pagesPrinciples of Management MCQS With Answers of Stephen Psridharpalleda72% (76)

- Brain Gym Introduction To TheoryDocument29 pagesBrain Gym Introduction To Theoryapi-25074014060% (5)

- Adjust Brake On Draw WorksDocument1 pageAdjust Brake On Draw WorksReda BoualiNo ratings yet

- JSA 115 Slip New Drill-Line On BlocksDocument4 pagesJSA 115 Slip New Drill-Line On BlocksanhlhNo ratings yet

- Makeup Core BarrelDocument5 pagesMakeup Core Barrelhseae1 AE1No ratings yet

- AB8-ELE-75-HMO - Generator Dismantling For 5 Yearly MaintenanaceDocument2 pagesAB8-ELE-75-HMO - Generator Dismantling For 5 Yearly Maintenanacevikrant911No ratings yet

- AB8-ELE-05-HMO - PM On EM GeratorDocument2 pagesAB8-ELE-05-HMO - PM On EM Geratorvikrant911No ratings yet

- Risk Assessment Rig Down AnchorsDocument2 pagesRisk Assessment Rig Down Anchorsdszmlwyn100% (1)

- AB8-ELE-02-HMO - PM On DW Drive & AuxilaryDocument2 pagesAB8-ELE-02-HMO - PM On DW Drive & Auxilaryvikrant911No ratings yet

- AB8-ELE-04-HMO - PM On Mud Pumps Drive & Auxilary MotorsDocument2 pagesAB8-ELE-04-HMO - PM On Mud Pumps Drive & Auxilary Motorsvikrant911No ratings yet

- HIRA Kiln - XLSMDocument14 pagesHIRA Kiln - XLSMshahhussain1031No ratings yet

- KKD-SAMUR-HSEJHA-011 JHA Bar Bending Cutting UPDATE 30.7.2013Document3 pagesKKD-SAMUR-HSEJHA-011 JHA Bar Bending Cutting UPDATE 30.7.2013Fadzli MaddyNo ratings yet

- Sce - Life Saving Equipment, Life Jackets: Tick The Appropriate Box To Indicate Which Areas Require To Be Complied WithDocument4 pagesSce - Life Saving Equipment, Life Jackets: Tick The Appropriate Box To Indicate Which Areas Require To Be Complied Withsafar matakNo ratings yet

- AB8-ELE-54-HMO - Raw Water Pump Pullout For InspectionDocument2 pagesAB8-ELE-54-HMO - Raw Water Pump Pullout For Inspectionvikrant911No ratings yet

- AB8-ELE-73-HMO - Troubleshooting VFDDocument2 pagesAB8-ELE-73-HMO - Troubleshooting VFDvikrant911100% (1)

- Gangway InstallationDocument3 pagesGangway Installationazrul100% (1)

- AB8-ELE 74 - JPO - Shaker Motors Dismantling and Shifting To Main DeckDocument2 pagesAB8-ELE 74 - JPO - Shaker Motors Dismantling and Shifting To Main Deckvikrant911No ratings yet

- SOP 032 - QC Hoist Wire Rope Replacement - V 2.0Document6 pagesSOP 032 - QC Hoist Wire Rope Replacement - V 2.0ncthanhck0% (1)

- Ci Resposta2Document15 pagesCi Resposta2Cesar AugustoNo ratings yet

- Intelligence Preparation of Operational Environment: KP AtmDocument50 pagesIntelligence Preparation of Operational Environment: KP AtmAhmad ZulfadzliNo ratings yet

- Change Out Pipe SpinnerDocument1 pageChange Out Pipe SpinnerReda BoualiNo ratings yet

- 206LMM206LMMCH07Document4 pages206LMM206LMMCH07FABIAN REYES TOVARNo ratings yet

- RIGGING AND INSTALLATION OF 48 Inch REACTOR SPOOL JSA - 18.08.21Document10 pagesRIGGING AND INSTALLATION OF 48 Inch REACTOR SPOOL JSA - 18.08.21Muhammed FawazNo ratings yet

- TomCat Tool2Jun09Document26 pagesTomCat Tool2Jun09Tausif AhmadNo ratings yet

- Test Demonstrated Damage Tolerance of F-22 Wing-Attach LugsDocument27 pagesTest Demonstrated Damage Tolerance of F-22 Wing-Attach LugsyijunjieNo ratings yet

- Job Safety Analysis (Jsa) : Country / Location: MZLN-09 Date Description of Job or Work Activity: Rig: Jsa #Document2 pagesJob Safety Analysis (Jsa) : Country / Location: MZLN-09 Date Description of Job or Work Activity: Rig: Jsa #madjid bobNo ratings yet

- Scaffolds JSA PMTDocument6 pagesScaffolds JSA PMTTeodoro EsquilloNo ratings yet

- Job Safety Analysis (Jsa) JSADocument6 pagesJob Safety Analysis (Jsa) JSATeodoro EsquilloNo ratings yet

- Rafter, Beam, Column Assembly and Erection JsaDocument19 pagesRafter, Beam, Column Assembly and Erection JsavenkatNo ratings yet

- JSA CTU Sand Clean Out BPPDocument8 pagesJSA CTU Sand Clean Out BPPLismi LismiNo ratings yet

- Kill Team 2021 - Hyperspace CollectorsDocument17 pagesKill Team 2021 - Hyperspace CollectorsDrew VolkerNo ratings yet

- CommentsDocument3 pagesCommentsSaleem Khader100% (1)

- JSA For Station PipingDocument4 pagesJSA For Station PipingR Sahadeo ReddyNo ratings yet

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDocument4 pagesJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- Opstandard: Task # Work Element Description Key Points Notes/ DiagramsDocument3 pagesOpstandard: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Maintenance Manual: Raisbeck Engineering Document No 96L-120Document6 pagesMaintenance Manual: Raisbeck Engineering Document No 96L-120HenryNo ratings yet

- TM 173b - Slimline XFR Pulling ToolDocument4 pagesTM 173b - Slimline XFR Pulling ToolvickyNo ratings yet

- CH 04 ExDocument36 pagesCH 04 Exsn2nc22No ratings yet

- Sustain AidDocument2 pagesSustain AidvasanthiNo ratings yet

- Directions For Completing Confined Space Permit Work DescriptionDocument11 pagesDirections For Completing Confined Space Permit Work DescriptionMOHAMEDNo ratings yet

- PipingDocument9 pagesPipingshamierrul shahliNo ratings yet

- SPC TrainingDocument2 pagesSPC TrainingRudi PurnamaNo ratings yet

- As dc08 003 - 1Document5 pagesAs dc08 003 - 1Putra SeptiadyNo ratings yet

- Nipple Up Diverter and RiserDocument2 pagesNipple Up Diverter and RiserHafed HafedNo ratings yet

- Adobe Scan 02 May 2023Document9 pagesAdobe Scan 02 May 2023jdm.drdo20No ratings yet

- SPC SimplifiedDocument2 pagesSPC Simplifiedkuala88No ratings yet

- Design of 75 Pax Solar Catamaran Ferry: Final Project PresentationDocument47 pagesDesign of 75 Pax Solar Catamaran Ferry: Final Project PresentationGaurav TehlanNo ratings yet

- Daqing Petroleum Iraq Branch Job Safety Analysis 工作安全分析: HSE-MS/Doc. No.22Document2 pagesDaqing Petroleum Iraq Branch Job Safety Analysis 工作安全分析: HSE-MS/Doc. No.22khurramNo ratings yet

- PfmeaDocument1 pagePfmeaSridhar DineshNo ratings yet

- R33 - Engine Manual OcrDocument491 pagesR33 - Engine Manual Ocralex.typexNo ratings yet

- Scaffolding ErectionDocument3 pagesScaffolding Erectionm.umarNo ratings yet

- TRA For Fabrication, Cutting, Grinding and WeldingDocument3 pagesTRA For Fabrication, Cutting, Grinding and WeldingSaif Ali100% (1)

- Performance Test InstructorDocument5 pagesPerformance Test InstructorDavid Arenas UribeNo ratings yet

- Blind Back Off Tubing, Drill PipeDocument1 pageBlind Back Off Tubing, Drill PipeReda BoualiNo ratings yet

- Mad Dog HIPO Preliminary Lessons Learned PDFDocument4 pagesMad Dog HIPO Preliminary Lessons Learned PDFbehnazrzNo ratings yet

- Jsa For Tie-In Tp-950Document11 pagesJsa For Tie-In Tp-950rexivyNo ratings yet

- 4.18.1 Mandatory Protocol Checklist For External EmbellishmentDocument1 page4.18.1 Mandatory Protocol Checklist For External EmbellishmentTrang NguyễnNo ratings yet

- Air Winch OperationDocument1 pageAir Winch OperationDQE040 HSSENo ratings yet

- FE-Analysis of An Integrated Plate Connection Between Jacket Structure and Skirt-Pile Sleeve - (3) - MMC Oil & Gas EngineeringDocument3 pagesFE-Analysis of An Integrated Plate Connection Between Jacket Structure and Skirt-Pile Sleeve - (3) - MMC Oil & Gas EngineeringherisiswantogoNo ratings yet

- Crane JHA OKDocument4 pagesCrane JHA OKSyed Ali HassanNo ratings yet

- Control Statements: Part 1: Let's All Move One Place OnDocument40 pagesControl Statements: Part 1: Let's All Move One Place Onvicrattlehead2013No ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingNo ratings yet

- What Is Hypovolemic ShockDocument4 pagesWhat Is Hypovolemic ShockDukittyNo ratings yet

- Procedure 36 5 Participate in A Mock Environmental Exposure EventDocument2 pagesProcedure 36 5 Participate in A Mock Environmental Exposure Eventparji santosaNo ratings yet

- Practice Test For Unit 4 E11Document4 pagesPractice Test For Unit 4 E11k62.2312530024No ratings yet

- Apollo Swimming ChampionshipDocument5 pagesApollo Swimming ChampionshipHein Aung ZinNo ratings yet

- Data Transcriber ResumeDocument7 pagesData Transcriber Resumef5d5wm52100% (2)

- CESC Mod-1 Wk1and2 Bernadette-AspirasDocument32 pagesCESC Mod-1 Wk1and2 Bernadette-AspirasLEAH GRACE NIEGAS100% (3)

- Pre Season We 2.0Document22 pagesPre Season We 2.0Danielle MayoNo ratings yet

- Company ProfileDocument5 pagesCompany ProfileJongabantu NgcuthusheNo ratings yet

- 2010.hye Ee. Development of Banana Peel Jelly and Its Antioxidant and TexturalDocument2 pages2010.hye Ee. Development of Banana Peel Jelly and Its Antioxidant and TexturalAndi NursantiNo ratings yet

- Information For Applicants 20Document7 pagesInformation For Applicants 20riyad j.mNo ratings yet

- Mapeh 7 .CheckingDocument18 pagesMapeh 7 .CheckingElmor SanchezNo ratings yet

- Sai Khelo IndiaDocument7 pagesSai Khelo IndiaPiyush kumarNo ratings yet

- Tibial and Femur FactrueDocument25 pagesTibial and Femur Factruesingireddi1revathiNo ratings yet

- CHN Pnle Board Exam Practice-Part 5Document6 pagesCHN Pnle Board Exam Practice-Part 5jerarddaria.elakNo ratings yet

- Big Data Health Care Using ToolsDocument18 pagesBig Data Health Care Using ToolsGEETHA RANI 218003946No ratings yet

- Hubungan Tingkat Pengetahuan Dan Sikap Masyarakat Dengan Penanganan Awal Gigitan BinatangDocument11 pagesHubungan Tingkat Pengetahuan Dan Sikap Masyarakat Dengan Penanganan Awal Gigitan BinatangRisa FebriantiNo ratings yet

- Ch2 P1 Utilitarianism SVDocument21 pagesCh2 P1 Utilitarianism SVK57 PHAN QUOC THANHNo ratings yet

- Notes On The Cult of Domesticity and WomanhoodDocument7 pagesNotes On The Cult of Domesticity and Womanhood2077 HQNo ratings yet

- Purple Power De-Ruster SDSDocument4 pagesPurple Power De-Ruster SDSAsadNo ratings yet

- Stem Challenge TestDocument1 pageStem Challenge TestR.Srengeeth RAKKESHNo ratings yet

- Newborn Care Case PresDocument11 pagesNewborn Care Case PresCamille GalasNo ratings yet

- 1.1 Roger Walker - Chapter 1 (Lecture 1-Introduction To Clinical Pharmacy)Document12 pages1.1 Roger Walker - Chapter 1 (Lecture 1-Introduction To Clinical Pharmacy)Ateeba Faryal100% (1)

- Larry Scott ArmsDocument7 pagesLarry Scott ArmsCALFNo ratings yet

- Introduction To Geriatric NursingDocument3 pagesIntroduction To Geriatric NursingElle BuhisanNo ratings yet

- A Study On Grivence Management in Improving Employees in A Privete EnterpriseDocument52 pagesA Study On Grivence Management in Improving Employees in A Privete Enterpriseavinash bulusuNo ratings yet

- Critical Incident Reporting Guideline and FormDocument8 pagesCritical Incident Reporting Guideline and FormkinyzoNo ratings yet

- Urban Food Systems and COVID-19: The Role of Cities and Local Governments in Responding To The EmergencyDocument6 pagesUrban Food Systems and COVID-19: The Role of Cities and Local Governments in Responding To The EmergencyJorge SalcedoNo ratings yet