Professional Documents

Culture Documents

LL MYDPIS 017 Dropped Down of Pile Reinforcing Cage

LL MYDPIS 017 Dropped Down of Pile Reinforcing Cage

Uploaded by

Mohammed Akbal AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LL MYDPIS 017 Dropped Down of Pile Reinforcing Cage

LL MYDPIS 017 Dropped Down of Pile Reinforcing Cage

Uploaded by

Mohammed Akbal AhmedCopyright:

Available Formats

Lesson Learned Form

Lesson Learned Title: Dropped down of Pile Reinforcements

Division/Section/Unit C&PPID/MYDPIS/MYDPIU LL Number LL-MYDPIS-017/2019

Originator’s Name Dennis R. Alejandro Date Submitted November 25, 2019

e-Mail dennis.alejandro@aramco.com Contact No. 013 352 4063

Background (What/Where/When/How?)

Context:

During the trimming/cutting of concrete bored pile heads at King Salman International Complex for Maritime

Industries and Services Tuxedo Area for Anchor piles and Relieving Piles, it was observed that several piles

were dropped down from the cut-off level. The piles having diameter of 1.80m & 1.20m with length of 38m &

19m respectively, were casted few months ago by contractor (SARCO-HUTA) with the approved piling

procedure and equipment according to the approved execution plan. The affected piles are about 20 numbers

with dropped ranging from 1.2 to 3.5 meters below the reference cut-off level. Violation logbook entries were

issued upon discovery of the dropped piles and demands further issue of technical query for the proposed

corrective action. These results to delay of the succeeding works for the capping beams and relieving platform

slabs since the short piles needs to extend to the cut-off level for the connection of piles reinforcing bars to

the capping beam.

Cost/Schedule/Safety/Quality impact:

The above construction issues resulted to additional work for the contractor and greatly impact the schedule

for the succeeding activities. Additional cost for pile extension/splicing up to the cut off level that involves

equipment, steel and splicing, concrete and delay on the construction schedule.

Reference to applicable SAES, SAEP, SAMSS, GI or other Saudi Aramco process:

Project Specification for concrete in the Maritime Environment-PB4784-0000-MA-SP-0024 rev. 09, ICE

Specification for Pilling and embedded retaining walls 2nd edition 2007 B1.17, B3.4.1, B3.5.2.4, B3.5.5,

B3.5.9

Investigation/Root Causes (Why did this happen? If positive experience, what were the benefits?)

The following are identified factors that caused the above irregularities:

The failure of contractor to assign competent personnel for monitoring drilling process and not

calibrated measuring device during excavation which lead to over drilled and steel cage dropped down.

Poor monitoring during drilling of bore holes and de-sanding operation (cleaning of bore hole) which

leads to deeper bore hole than the required.

Over drilled which may lead for the reinforcing steel cage to settle down to the bottom immediately after

concrete pouring of bored pile while concrete is still flowable.

Drilling equipment depth monitoring is sometimes disturbed and will not give accurate readings.

Early extraction of temporary steel casing which may lead for the reinforcing cage to settle and or drop

down due to presence of surrounding disturbance (vibrating equipment).

Wrong survey information for top elevation of temporary steel casing which is a factor in locating

theoretical levels of reinforcements.

Recommendation (How would you handle this next time to prevent problem or repeat success?)

Preventive Actions

Only Competent personnel shall be assigned for drilling and de-sanding operation to closely monitor

drilled depth to avoid over excavation.

Saudi Aramco: Company General Use

Drilling equipment depth monitoring shall be calibrated more frequently, and if possible to counter check

randomly with alternative means of checking the depth.

Survey elevations shall be provided accurate.

Avoid equipment’s with vibrating output to operate within the working area while on-going concreting.

Positional tolerance of reinforcement shall be properly maintained.

Reinforcing steel cage shall be extended to bottom of bore hole to accommodate excavation overcuts.

Avoid early extraction of temporary steel casing.

Review of Lesson Learned related to Bored Pile works before commencement of the activities to avoid

repeat of mistakes and to anticipate possible similar conditions.

Attachments

B.I. No. 25-00053-0003

King Salman International Complex for Maritime Industries and Services -

Project Title

Maritime Yard Development Program

Location Ras Al Khair

Contractor Consortium of SEPCO and Sinohydro

Project Phase Installation

(Below To be used by the LL Evaluation Team Only)

Evaluated by: (at least two Archelle Garcesa, Thamer Albaqami

Committee Members):

Team Leader: Abdulrahman G. Asmari

Approved for PMOD Yes/No

Approved for ID LL data base Yes/No

Saudi Aramco: Company General Use

You might also like

- Erection Tower Method StatementDocument23 pagesErection Tower Method StatementJatmiko Purwo Saputro100% (2)

- METHOD Statement of BRIDGE (Major STR)Document6 pagesMETHOD Statement of BRIDGE (Major STR)venkateswara rao Pothina100% (2)

- Method Statement For Navigation Aid C02 EditedDocument40 pagesMethod Statement For Navigation Aid C02 EditedOlugbemiga James OlalekanNo ratings yet

- Civil Engineering Objective Questions PDFDocument13 pagesCivil Engineering Objective Questions PDFMCQQUESTIONS.NETNo ratings yet

- MARJAN INCREMENT PROGRAM Installation of Steel Support and Gratings For TR AreaDocument10 pagesMARJAN INCREMENT PROGRAM Installation of Steel Support and Gratings For TR AreaFaraaz MohammedNo ratings yet

- Method Statement For Installation of Steel Supports For Gratings at TR A...Document9 pagesMethod Statement For Installation of Steel Supports For Gratings at TR A...Faraaz MohammedNo ratings yet

- MOS Roof Truss InstallationDocument19 pagesMOS Roof Truss InstallationMohammad Hadoumi Saldan100% (9)

- Method Statement For Ug Piping 6423dp420!00!00200 00 - Rev03Document20 pagesMethod Statement For Ug Piping 6423dp420!00!00200 00 - Rev03mister pogi100% (2)

- Dismantling of Structure MethodologyDocument3 pagesDismantling of Structure MethodologyAkhilesh Dwivedi100% (3)

- LL MYDPIS 019 Stuck Tremie Pipes and Steel Casing at Bored PilesDocument2 pagesLL MYDPIS 019 Stuck Tremie Pipes and Steel Casing at Bored PilesMohammed Akbal AhmedNo ratings yet

- LL MYDPIS 018 Contaminated Concrete  Bored PileDocument2 pagesLL MYDPIS 018 Contaminated Concrete  Bored PileMohammed Akbal AhmedNo ratings yet

- LL MYDPIS 011 Tie Rods For Anchor Piles at MYDP ProjectDocument2 pagesLL MYDPIS 011 Tie Rods For Anchor Piles at MYDP ProjectMohammed Akbal AhmedNo ratings yet

- Northern Builders North South Commuter Railway Extension Project CP-N05Document5 pagesNorthern Builders North South Commuter Railway Extension Project CP-N05Bryan Joshua PandaanNo ratings yet

- Method Statement of Reinforced ConcreteDocument39 pagesMethod Statement of Reinforced Concretelike saddamNo ratings yet

- TH THDocument9 pagesTH THP.MannaNo ratings yet

- Site Specific Steel Erection PlanDocument34 pagesSite Specific Steel Erection PlanRiaz Ali Khan BangashNo ratings yet

- Sac Myp Qa LL 0002Document6 pagesSac Myp Qa LL 0002Mohammed Akbal AhmedNo ratings yet

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- MS-014 - Steel Structuer Erection Work - Lifeline and ScaffoldingDocument27 pagesMS-014 - Steel Structuer Erection Work - Lifeline and ScaffoldingJessie PimentelNo ratings yet

- Toaz - Info 005 Ms Manhole Construction Sew Risk Assessment From Javeed 1 PRDocument12 pagesToaz - Info 005 Ms Manhole Construction Sew Risk Assessment From Javeed 1 PRShah MuzzamilNo ratings yet

- PP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0Document14 pagesPP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0ibrahimNo ratings yet

- Jgpd-Isf-t-sh-sa-1302-04-Ms For Placement of Light Weight Concrete For Roof Deck Areas Rev-04Document87 pagesJgpd-Isf-t-sh-sa-1302-04-Ms For Placement of Light Weight Concrete For Roof Deck Areas Rev-04gulzamanNo ratings yet

- Earth WorkDocument15 pagesEarth WorkArifian NugrohoNo ratings yet

- Engineering Encyclopedia: Underwater NDTDocument9 pagesEngineering Encyclopedia: Underwater NDTabyNo ratings yet

- JP For Structural WorksDocument4 pagesJP For Structural WorksRajeev KumarNo ratings yet

- Work Procedure For Steel Fab & ErectionDocument5 pagesWork Procedure For Steel Fab & ErectionHiren Thakkar100% (1)

- R11 T02B01 Mag MTS Ci 0015Document15 pagesR11 T02B01 Mag MTS Ci 0015Syed AliNo ratings yet

- METHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Document7 pagesMETHOD STATEMENT FOR Cast in Situ Concrete - Rev 0Osama MZ100% (1)

- Inspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationDocument17 pagesInspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationPrakash SIngh Rawal100% (1)

- CSD Response To CRM-ESR No. 4043448466 Dt. Dec 24, 2020 Coating For Stainless Steel at Splash Zone (Recd Jan 06, 2021)Document3 pagesCSD Response To CRM-ESR No. 4043448466 Dt. Dec 24, 2020 Coating For Stainless Steel at Splash Zone (Recd Jan 06, 2021)Muhammad RizwanNo ratings yet

- Op-3-32. Checklist For Supervision of Sheet Pile Installation (Excavation Work)Document3 pagesOp-3-32. Checklist For Supervision of Sheet Pile Installation (Excavation Work)Garry Yan DiazNo ratings yet

- Method Statement: Project No.: Project TitleDocument7 pagesMethod Statement: Project No.: Project TitleMuhammed Shafeek K TNo ratings yet

- Jacking Procedure PDFDocument14 pagesJacking Procedure PDFmanish pathrabeNo ratings yet

- Recommendations For Structural GroutingDocument6 pagesRecommendations For Structural GroutingwahbiaNo ratings yet

- 2.procedure For Fabrication and ErectionDocument13 pages2.procedure For Fabrication and Erectionanon_106345234100% (2)

- Blasting & Coating Procedure For Fabricated Steel StructureDocument8 pagesBlasting & Coating Procedure For Fabricated Steel Structurejasmineamma100% (1)

- 11 MS For RC Retaining WallDocument25 pages11 MS For RC Retaining WallIlyas Khan100% (3)

- Updated SOW REV 07Document11 pagesUpdated SOW REV 07imri ssNo ratings yet

- Engineer'S Stamp: Contractor'S Stamp:: Al Qunfudhah New City Feeder Water Transmission SystemDocument45 pagesEngineer'S Stamp: Contractor'S Stamp:: Al Qunfudhah New City Feeder Water Transmission SystemUmar ShehzadNo ratings yet

- WMS Erection TowerDocument15 pagesWMS Erection TowerbimoNo ratings yet

- Method Statement For Underground Drainage Piping InstallationDocument8 pagesMethod Statement For Underground Drainage Piping InstallationUSAMANo ratings yet

- Saes L 470Document9 pagesSaes L 470Jaseel KanhirathingalNo ratings yet

- Arthit CPP Structural Lessons1Document5 pagesArthit CPP Structural Lessons1api-3827874No ratings yet

- Method Statement For PCC & RCC WorksDocument11 pagesMethod Statement For PCC & RCC WorkspoovazhaganNo ratings yet

- Division 2Document10 pagesDivision 2Luis Gabriel BautistaNo ratings yet

- Method Statement For BACKFILLING WORKSDocument12 pagesMethod Statement For BACKFILLING WORKSYash Sharma50% (2)

- AGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Document49 pagesAGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Dilshad Ahemad100% (2)

- MAS - Plaster Accessories - EXMET R00Document106 pagesMAS - Plaster Accessories - EXMET R00Jason RazatlabNo ratings yet

- MS008 Steel Tank MSDocument9 pagesMS008 Steel Tank MSMhando IgnasNo ratings yet

- Saes Q 004Document24 pagesSaes Q 004tariqueNo ratings yet

- 26071-100-VSC-SSE4-2-00001 - Rev001 - Method Statement For Field Erected Steel StructureDocument19 pages26071-100-VSC-SSE4-2-00001 - Rev001 - Method Statement For Field Erected Steel StructureAL FAHMINo ratings yet

- P2151 304 A 622 - 3Document8 pagesP2151 304 A 622 - 3hungNo ratings yet

- Icf MD Spec 252 Cast Steel Side Buffer ArrgtDocument17 pagesIcf MD Spec 252 Cast Steel Side Buffer ArrgtDipak Kumar ChatterjeeNo ratings yet

- Method Statement: (Continuous Flight Auger)Document15 pagesMethod Statement: (Continuous Flight Auger)sawkariqbal100% (1)

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocument25 pages007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNo ratings yet

- Method Statement For Ceramic WorksDocument16 pagesMethod Statement For Ceramic Worksmohsin.meizaNo ratings yet

- Ga Qu MS Civ 008Document14 pagesGa Qu MS Civ 008henry.anthirayasNo ratings yet

- Method Statement For Pile Chipping and Capping Beam: Vascon Engineers LTDDocument12 pagesMethod Statement For Pile Chipping and Capping Beam: Vascon Engineers LTDshahaji0% (1)

- TR-CA-MS-003 - B Concrete Foundation Work-Sent To HibaDocument14 pagesTR-CA-MS-003 - B Concrete Foundation Work-Sent To Hibasamer8saifNo ratings yet

- Coke Drum ReliabilityDocument12 pagesCoke Drum ReliabilityMahendra RathoreNo ratings yet

- Principles of Mining: Valuation, Organization and AdministrationFrom EverandPrinciples of Mining: Valuation, Organization and AdministrationNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Projects Oil and Gas BrochureDocument20 pagesProjects Oil and Gas BrochureRussel John RamosNo ratings yet

- TFP1420 09 2004 PDFDocument14 pagesTFP1420 09 2004 PDFPhuNguyenHoangNo ratings yet

- DP Barte: DesignsDocument1 pageDP Barte: DesignsJjammppong AcostaNo ratings yet

- Anexa Saltea GabioaneDocument14 pagesAnexa Saltea GabioaneMocanu Alexandru CiprianNo ratings yet

- TC#3 Security Wall - Belad Mabain (BAN) GDocument6 pagesTC#3 Security Wall - Belad Mabain (BAN) GabasoudaNo ratings yet

- MAXIMUM Grade 1 Fibreglass Step Ladder, 4-ft Canadian TireDocument5 pagesMAXIMUM Grade 1 Fibreglass Step Ladder, 4-ft Canadian Tireming_zhu10No ratings yet

- Notice To Stop WorkDocument2 pagesNotice To Stop WorkBurgosFirestationNo ratings yet

- Attach 3 - A-E Design ManualDocument111 pagesAttach 3 - A-E Design ManualΑνδρέας ΘεοδώρουNo ratings yet

- Tunnel ConstructionDocument95 pagesTunnel ConstructionKunal Khubani100% (3)

- Circular EconomyDocument47 pagesCircular Economy董思辰No ratings yet

- International Tropical Architecture Design CompetitionDocument8 pagesInternational Tropical Architecture Design CompetitionPCWAN88GMAILCOMNo ratings yet

- GPT - 1-8 Link-Seal - 08.2021 - WebDocument22 pagesGPT - 1-8 Link-Seal - 08.2021 - WebRAJKUMARNo ratings yet

- MsandDocument4 pagesMsandKote Bhanu PrakashNo ratings yet

- Detroit Lakes Pavilion Seat Plans, March 2023, RDGDocument8 pagesDetroit Lakes Pavilion Seat Plans, March 2023, RDGMichael AchterlingNo ratings yet

- Concret Mix Design (M10 To M100)Document65 pagesConcret Mix Design (M10 To M100)Rajesh Kollipara93% (15)

- SUPERSTRUCTUREDocument3 pagesSUPERSTRUCTURERizqy Putra KartamaNo ratings yet

- Clarification of FW Removal MethodDocument6 pagesClarification of FW Removal MethodPhú Vũ TrươngNo ratings yet

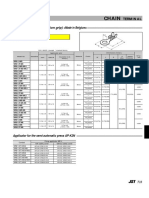

- Chain: SRB Series (With Insulation Grip)Document1 pageChain: SRB Series (With Insulation Grip)shankarNo ratings yet

- Neoloy CS-Highway 6, Israel v2019.2 PDFDocument4 pagesNeoloy CS-Highway 6, Israel v2019.2 PDFsahilNo ratings yet

- Schedule of Rates 2010 Northern Railway PDFDocument248 pagesSchedule of Rates 2010 Northern Railway PDFYong Shen LimNo ratings yet

- 17 Structures - MORTH QueriesDocument3 pages17 Structures - MORTH QueriesAmit PhadatareNo ratings yet

- Application Product Code ' ': Steel, Aluminium and Timber Substructure Tda-S TDB-S TDC-S Steel Substructure TDBL-TDocument9 pagesApplication Product Code ' ': Steel, Aluminium and Timber Substructure Tda-S TDB-S TDC-S Steel Substructure TDBL-Tshare4learnNo ratings yet

- Leakage Test Procedure For Crude Oil Storage Tank: (Arial 12)Document6 pagesLeakage Test Procedure For Crude Oil Storage Tank: (Arial 12)Ahmad MohammadNo ratings yet

- Use of Local Material in Architecture: Mud Architecture: Title:-IntroductionDocument3 pagesUse of Local Material in Architecture: Mud Architecture: Title:-IntroductionTwinkle DudhwalaNo ratings yet

- Cold Mix Technology - BitChemDocument49 pagesCold Mix Technology - BitChemAnirudh SarkarNo ratings yet

- Linear Slot Diffuser-1Document12 pagesLinear Slot Diffuser-1amir.gde.2023No ratings yet

- Compliance SampleDocument5 pagesCompliance SampleAjees AhammedNo ratings yet

- 7-24 Rigging and Lifting Equipment Inspection Procedure (RV)Document8 pages7-24 Rigging and Lifting Equipment Inspection Procedure (RV)Lee JungNo ratings yet