Professional Documents

Culture Documents

Dyn - DBS-MC-SD

Dyn - DBS-MC-SD

Uploaded by

Docu CenterCopyright:

Available Formats

You might also like

- How Many Toilets Do You Need - BS 6465 Sanitary InstallationsDocument10 pagesHow Many Toilets Do You Need - BS 6465 Sanitary InstallationsRHaikal Ming Zhi LeeNo ratings yet

- Family Nursing Care PlanDocument2 pagesFamily Nursing Care PlanJoeven Hilario83% (6)

- National Health ProgrammesDocument12 pagesNational Health ProgrammesRAJU100% (2)

- Food Safety at A GlanceDocument5 pagesFood Safety at A GlanceAliceNo ratings yet

- Reference LevelDocument1 pageReference Level123epcNo ratings yet

- Jalan Outlet Menuju Rumah KatupDocument7 pagesJalan Outlet Menuju Rumah Katupchandra adriawanNo ratings yet

- 10 603110 0000100201 Mah Civ SHD 000032 - 01Document1 page10 603110 0000100201 Mah Civ SHD 000032 - 01ibrahemomr9993No ratings yet

- Basement - With Cameras-BasementDocument1 pageBasement - With Cameras-BasementpknawazNo ratings yet

- Project #9Document11 pagesProject #9indyecraftsNo ratings yet

- Ground Floor Access Control PlanDocument1 pageGround Floor Access Control PlanRajesh RajendranNo ratings yet

- HD Actualizado Mod.22Document1 pageHD Actualizado Mod.22Luís G. MorenoNo ratings yet

- HW Nic Allam DD Ge 003Document1 pageHW Nic Allam DD Ge 003ehab.m.saad88No ratings yet

- Plano Upeu GeneralDocument1 pagePlano Upeu GeneralAllisson Arone ValenciaNo ratings yet

- Emaar Plot A017 Icon Bay Residential Tower On DCH Island DistrictDocument1 pageEmaar Plot A017 Icon Bay Residential Tower On DCH Island DistrictZeeZ HNo ratings yet

- Emaar Plot A017 Icon Bay Residential Tower On DCH Island DistrictDocument1 pageEmaar Plot A017 Icon Bay Residential Tower On DCH Island DistrictZeeZ HNo ratings yet

- Pumb & Water Tank Construction Area Fence-Drawing - CommentedDocument3 pagesPumb & Water Tank Construction Area Fence-Drawing - CommentedVinodNo ratings yet

- GWT Siram Taman - 02Document4 pagesGWT Siram Taman - 02sanusiNo ratings yet

- Qfab Yard Layout - Rev A3 - 31may22 - Nfs JKT-NFXP Topside and Subsea StrucDocument45 pagesQfab Yard Layout - Rev A3 - 31may22 - Nfs JKT-NFXP Topside and Subsea StrucSajin Chacko NinanNo ratings yet

- River View South-FinalDocument1 pageRiver View South-FinalAryan MalikNo ratings yet

- A10.FF.01 - Ceiling Layout REV MI-Layout1Document1 pageA10.FF.01 - Ceiling Layout REV MI-Layout1muqtar4uNo ratings yet

- Hartland: LegendDocument1 pageHartland: LegendrajatNo ratings yet

- SHC G.PH. 2 B 03 3dr.F BW SD 005 Layout1Document1 pageSHC G.PH. 2 B 03 3dr.F BW SD 005 Layout1rajatNo ratings yet

- Government Berths: Limit of Work IP1 IP4Document1 pageGovernment Berths: Limit of Work IP1 IP4Sid BlankNo ratings yet

- Av. 450 Años-Model5 PDFDocument1 pageAv. 450 Años-Model5 PDFPablo Helio Mieles PoloNo ratings yet

- 10 603110 0000100201 Mah Civ SHD 000030 - 01Document1 page10 603110 0000100201 Mah Civ SHD 000030 - 01ibrahemomr9993No ratings yet

- 1-PLANTA Y PERFIL-Layout1-Planta Perfil - A1Document1 page1-PLANTA Y PERFIL-Layout1-Planta Perfil - A1Alfredo Villanueva ParedesNo ratings yet

- Campo de Futebol: Escola EstadualDocument1 pageCampo de Futebol: Escola EstadualDimas JuniorNo ratings yet

- Pnateamiento General Desague PluvialDocument1 pagePnateamiento General Desague PluvialJJesusNo ratings yet

- CJ-JZ-KAIS - FDT-002 Distribution Layout Diagram (DLD)Document1 pageCJ-JZ-KAIS - FDT-002 Distribution Layout Diagram (DLD)Agayel darNo ratings yet

- Memorias de CalculoDocument85 pagesMemorias de CalculoSmith GutierrezNo ratings yet

- As-Built Drawing - Sports CityDocument2 pagesAs-Built Drawing - Sports Cityzubair khanNo ratings yet

- Project #1Document15 pagesProject #1indyecraftsNo ratings yet

- Tower-2 (3BHK) ELECTRICAL LAYOUT C2 PDFDocument1 pageTower-2 (3BHK) ELECTRICAL LAYOUT C2 PDFakhilNo ratings yet

- Mat Bang Giao Thong-A0Document1 pageMat Bang Giao Thong-A0Nguyễn Tiến ĐạtNo ratings yet

- Parking 8.5x11 0 PDFDocument1 pageParking 8.5x11 0 PDFuser5839No ratings yet

- Prelude in G-MinorDocument3 pagesPrelude in G-Minordarklord285No ratings yet

- Áreas y DistanciasDocument9 pagesÁreas y DistanciasKarlixPanNo ratings yet

- CR Ingenieros: Limite de ProyectoDocument4 pagesCR Ingenieros: Limite de ProyectoJorge GutierrezNo ratings yet

- Sector 2 - PMDocument1 pageSector 2 - PMalexlandivarvelaNo ratings yet

- Declivitati: Elemente de Profil Cote Proiect Cote Teren PichetiDocument1 pageDeclivitati: Elemente de Profil Cote Proiect Cote Teren PichetiElena RomanNo ratings yet

- FLS .Mall Eltahlia 26-08-2023-MezzDocument1 pageFLS .Mall Eltahlia 26-08-2023-Mezzengrabbas75No ratings yet

- Proposed LayoutDocument5 pagesProposed LayoutAbdul RafeyNo ratings yet

- Terrenourba ModelDocument1 pageTerrenourba ModelLiz C TicsihuaNo ratings yet

- Universidad Peruana Union: Facultad de Ingenieria Y ArquitecturaDocument1 pageUniversidad Peruana Union: Facultad de Ingenieria Y ArquitecturaFernando Luis Llerena TorrejónNo ratings yet

- 10 02 16 Temporary Transformer Location LayoutDocument1 page10 02 16 Temporary Transformer Location Layoutmudassir mNo ratings yet

- BLDG B MergedDocument3 pagesBLDG B Mergedgunjan.mallpNo ratings yet

- Campus MapDocument1 pageCampus MapZaid DeanNo ratings yet

- Nguyen Van Ban - 04 - So Do Mach Dieu Khien Dong Co (2AZ-FE)Document2 pagesNguyen Van Ban - 04 - So Do Mach Dieu Khien Dong Co (2AZ-FE)1264Nguyễn Hữu ThắngNo ratings yet

- Aldeinha Lotes 250-ModeloDocument1 pageAldeinha Lotes 250-ModelotelminhopaimNo ratings yet

- 2017-18 Lambton County Road MapDocument2 pages2017-18 Lambton County Road MapTourismSarniaNo ratings yet

- Edinburgh MapDocument1 pageEdinburgh MapPrabhakar JhaNo ratings yet

- 0987rebdDocument1 page0987rebdToni BioksicNo ratings yet

- Comparison Design - As-Built 3Document1 pageComparison Design - As-Built 3abm2irzathNo ratings yet

- полная схемаDocument2 pagesполная схемаZhan AinabekovNo ratings yet

- Trail Pit Section Sheet - 01ADocument1 pageTrail Pit Section Sheet - 01ASamar AliNo ratings yet

- S19091 Sal Bawi Sob FD e Ele 01 B1 00 0100 01Document1 pageS19091 Sal Bawi Sob FD e Ele 01 B1 00 0100 01Ibrahim AlqunoonNo ratings yet

- Auld Lang SyneDocument1 pageAuld Lang SynesppainistanNo ratings yet

- Sanitaria y Pluvial 1Document1 pageSanitaria y Pluvial 1christophergiovannivaldespacheNo ratings yet

- Zoning Districts Map 50 x50Document1 pageZoning Districts Map 50 x50Jorge MartinezNo ratings yet

- Cópia de PROJETO URBANÍSTICO - RESIDENCIAL NOVA BENEVIDES I 2-3 01082023Document1 pageCópia de PROJETO URBANÍSTICO - RESIDENCIAL NOVA BENEVIDES I 2-3 01082023ReinaldoNo ratings yet

- LENANTAMIENTO - GENERAL - InterventoriaDocument1 pageLENANTAMIENTO - GENERAL - Interventoriatopografia gilma jimenezNo ratings yet

- Leyenda: Universidad Nacional Del Altiplano-PunoDocument1 pageLeyenda: Universidad Nacional Del Altiplano-Punojhon kevinNo ratings yet

- Dist 06Document1 pageDist 06Jesús Enrique Cruz LorenzanaNo ratings yet

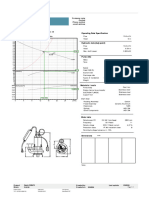

- DataSheet DD9 10 enDocument1 pageDataSheet DD9 10 enDocu CenterNo ratings yet

- Pumpset 10.25 LsDocument3 pagesPumpset 10.25 LsDocu CenterNo ratings yet

- SUPERNATANTDocument1 pageSUPERNATANTDocu CenterNo ratings yet

- Seko - 2022 Pompes & Accessoires - EngDocument128 pagesSeko - 2022 Pompes & Accessoires - EngDocu CenterNo ratings yet

- Hibon NX Serisi Blover Katalogu - IngilizceDocument8 pagesHibon NX Serisi Blover Katalogu - IngilizceDocu CenterNo ratings yet

- Aquaflex Filter Press Manuals in EnglishDocument28 pagesAquaflex Filter Press Manuals in EnglishDocu CenterNo ratings yet

- T Ta Tac Eng UlDocument44 pagesT Ta Tac Eng UlDocu CenterNo ratings yet

- CEMP Appendix F VAR BAM ZZ ZZ MS C 0004 Surface Water Stormwater DewateringDocument14 pagesCEMP Appendix F VAR BAM ZZ ZZ MS C 0004 Surface Water Stormwater DewateringDocu CenterNo ratings yet

- Operating Data: Pressure Drop IncludedDocument1 pageOperating Data: Pressure Drop IncludedDocu CenterNo ratings yet

- Nva-Cm-20121502 Tekpa Iso 10002Document1 pageNva-Cm-20121502 Tekpa Iso 10002Docu CenterNo ratings yet

- NVA-EC-22020801 TEKPA CE UYGUNLUK BELGESİ Pnömatik Ve Elektrik AktüatörlerDocument1 pageNVA-EC-22020801 TEKPA CE UYGUNLUK BELGESİ Pnömatik Ve Elektrik AktüatörlerDocu CenterNo ratings yet

- Annual Report 2017Document24 pagesAnnual Report 2017John Glenn SpaceNo ratings yet

- WPL Lamella Separator Technical DatasheetDocument1 pageWPL Lamella Separator Technical Datasheettallef001No ratings yet

- Narrative Report of InsetDocument20 pagesNarrative Report of Insetjessa mie lacarNo ratings yet

- Sanitary EnggDocument8 pagesSanitary EnggAdNo ratings yet

- Com Kitchen Plumbing Indirect Waste Fact Sheet 2205Document3 pagesCom Kitchen Plumbing Indirect Waste Fact Sheet 2205parelkidNo ratings yet

- Ownership Frequency Percentage Owned Rent-Free Shared TotalDocument20 pagesOwnership Frequency Percentage Owned Rent-Free Shared TotalTintin TagupaNo ratings yet

- Pastor Fred Mwesigye ManifestoDocument24 pagesPastor Fred Mwesigye ManifestoAfrican Centre for Media ExcellenceNo ratings yet

- Disposing of A Sanitary FadDocument5 pagesDisposing of A Sanitary FadMomil FatimaNo ratings yet

- The Changing Status of Women in India-The Challenges Ahead: DR Suvarna Sen Ishita MukherjeeDocument21 pagesThe Changing Status of Women in India-The Challenges Ahead: DR Suvarna Sen Ishita MukherjeeShyamsunder SinghNo ratings yet

- Design Handbook of Plumbing INDIANDocument198 pagesDesign Handbook of Plumbing INDIANsameera priyashanthaNo ratings yet

- Temporary Labor Camp Facilities GuideDocument9 pagesTemporary Labor Camp Facilities Guiderasputin0780803494No ratings yet

- WINS Checklist Sample Ctto: DePedQuezonDocument2 pagesWINS Checklist Sample Ctto: DePedQuezonsammy ferrer baysa100% (1)

- Sas 15Document5 pagesSas 15Kristinelou Marie ReynaNo ratings yet

- FNCPDocument30 pagesFNCPAJ S Nvrro100% (1)

- Water, Sanitation, Socioeconomic Status and Prevalence of Waterborne Diseases A Cross-Sectional Study at Makwanpur District, NepalDocument61 pagesWater, Sanitation, Socioeconomic Status and Prevalence of Waterborne Diseases A Cross-Sectional Study at Makwanpur District, NepalMichael SamwelNo ratings yet

- St. Paul University Philippines: School of Nursing and Allied Health Sciences College of NursingDocument4 pagesSt. Paul University Philippines: School of Nursing and Allied Health Sciences College of NursingChristian UmosoNo ratings yet

- WASH in Schools in AngolaDocument52 pagesWASH in Schools in AngolaHelder MbidiNo ratings yet

- Nigerian Standard For Drinking Water QualityDocument28 pagesNigerian Standard For Drinking Water QualityIsa Usman100% (1)

- Program Manual 23-03-2015 FINAL PDFDocument455 pagesProgram Manual 23-03-2015 FINAL PDFbhagyashriNo ratings yet

- The Phil Water Situation Report 2006Document71 pagesThe Phil Water Situation Report 2006Amir RasNo ratings yet

- Standards For WASH in Schools in Bangladesh - LatestDocument52 pagesStandards For WASH in Schools in Bangladesh - LatestushasaimaNo ratings yet

- Women and Water Management A Case Study From The Rural Communities in The Vietnamese Mekong Delta - PublishedDocument44 pagesWomen and Water Management A Case Study From The Rural Communities in The Vietnamese Mekong Delta - PublishedThai Nguyen VanNo ratings yet

- Cholera and The Origins of The American Sanitary Order in The PhilippinesDocument3 pagesCholera and The Origins of The American Sanitary Order in The PhilippinesAizen IchigoNo ratings yet

- Lecture 7. Migration and UrbanizationDocument43 pagesLecture 7. Migration and UrbanizationBiruk MengstieNo ratings yet

- Washbook TrainingDocument54 pagesWashbook TrainingMark BwanakayaNo ratings yet

- Your Crossword Puzzle 1 PDFDocument1 pageYour Crossword Puzzle 1 PDFRose Celine DiazNo ratings yet

Dyn - DBS-MC-SD

Dyn - DBS-MC-SD

Uploaded by

Docu CenterOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dyn - DBS-MC-SD

Dyn - DBS-MC-SD

Uploaded by

Docu CenterCopyright:

Available Formats

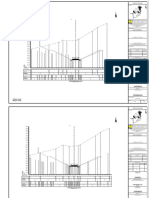

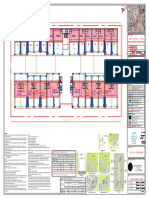

Key plan

EXIST

ING

W W PT

12

18

21

18

20

01

6.00

(+6.3

12

12

5)

7.50

11

02

16

6.00

11

13

12

12

22

03

11

6.00

10

09

19

14

04

05

17

15

07

GEN

ROOM

06

07

06

07

06

Outlet of Waste Sludge

07

Outlet of Effluent Outlet of Effluent 15,00

06

12

07

08

DN300 AISI316 DN100 AISI316 SCH 10S DN300 AISI316

06

07

08

15.0013

06

08

12

08

Bioblock Main Air Supply

08

Bioblock Air Supply DN200 AISI304 SCH 10S

08

Blower

23

-0,95

15,00

Equalization Tank

Air Supply Blower

6,20

Notes

+7.00

Wastewater

Feeding Tank GENERAL NOTES

(AISI304)

Monorail for Bioblock

Feeding Pumps Lift

Stainless steel pipes immersed in sewage shall be AISI 316 acc. to

+7,00 Wastewater

Flowmeter

ASTM778, ANSI B36.19 and wall thickness Sched. 10s.

DN150

Stainless steel pipes external to sewage shall be AISI 304 acc. to

Wastewater Discharge Pipe

DN150 AISI316 SCH10S ASTM778, ANSI B36.19 and wall thickness Sched. 10s.

Equalization Tank Air Supply

DETAIL - G DN100 AISI304 SCH 10S All stainless steel Flanges are acc. to DIN 2576

11,50

AIR LIFT No2

(AISI 304)

( 1 : 25 ) All pipe connections on the drawing are indicative. Please refer to

AIR LIFT No1

(AISI 304)

relevant drawings.

Wastewater Feeding Pipe

uPVC 200 PN10

Collection Circular Channel uPVC piping shall be solvent weld on site.

Bioblock Main Air Supply of Clarified Wastewater

(perforated at the bottom) DN200 AISI304 SCH 10S

G 315 HDPE PE100 PN10 For supports of piping please refer to the relevant drawings.

Wastewater Feeding Pipe

uPVC 200 PN10 DN100 AISI304 SCH10S

(perforated at the bottom)) All supports of piping and structures external to sewage shall be

hot dip galvanized.

0,95

Waste Sludge Outlet Wastewater Discharge Pipe

DN100 AISI316 SCH 10S DN150 AISI316 SCH10S +7.00

All supports of piping and structures immersed in sewage shall be

+6.40 AISI304.

+4.15 Equalization Tank

DN125 AISI304

Air Supply

SCH 10S

1,00

Air Supply for Inclined Wall DN200 AISI304 DN65 AISI304 SCH10S

Opening Cleaning SCH 10S

A

DN50 AISI316 SCH 10S

Lifting guide rails for F

24,00

24,00

0,50

0.00 0.00 Bioblock Feeding Pumps

2,50 +0,10 +0,10 DN65 AISI316 SCH10S Wastewater Overflow

+4.15 Pipe DN300

A Equalization Tank Air Supply

uPVC 32 PN16 DETAIL - F +3.80 Sheet Metal Partition

(perforated at the bottom) uPVC 63 ( 1 : 25 ) for Deaeration Zone

Supports for Sheet Metal Partition

PN16 AISI304

of Deaeration Zone AISI304

Wastewater Discharge Pipe

DN150 AISI316 SCH10S

28,50

Air Supply for Inclined Wall

Opening Cleaning

DN50 AISI316 SCH 10S

Equalization Tank

Air Supply

DN65 AISI316 SCH10S

Legend

Collection Circular Channel Collection Circular Channel

of Clarified Wastewater AIR LIFT No1 of Clarified Wastewater Fine Bubble

315 HDPE PE100 PN10 (AISI 304) 315 HDPE PE100 PN10 Disc Diffusers

uPVC 32

uPVC 90 PN16

PN16

0,50

uPVC 110 0.00 E

PN16

uPVC Tee

110 PN16 DYN GN MEC 006----

0,50

11,50

Equalization Tank

D Air Supply

SECTION A-A

uPVC 75 PN16

0,50

0,425 0,425

Air Supply for Inclined Wall Air Supply for Inclined Wall

Opening Cleaning uPVC 90 Equalization Tank

Opening Cleaning Air Supply

uPVC 63 PN16 PN16

uPVC 63 PN16 uPVC 75 PN16

(perforated at the bottom)) (perforated at the bottom) 0,85 0,85

Fine Bubble Equalization Tank

Disc Diffusers Air Supply

0,70

uPVC 63 PN16

0.00

0,10

DETAIL- D

( 1 : 25 )

+7,00 +0,10 +0,10

Connection Flange to Adjacent

Bioblock Air Supply Network DETAIL- E

( 1 : 25 )

DN100 AISI304

SCH 10S

0,15

REV. DATE REMARKS

C

0,70

2,70 3,70 2,30

1,50

0,60

1,70

DN200 AISI304

SCH 10S 1,20 DN80 AISI304 -0,85

1,75

SCH 10S uPVC 63 uPVC 63 uPVC 75

DN150 AISI304 Wastewater 0,825

SCH 10S PN16 PN16 PN16

Feeding Tank B

(AISI 304)

-0,95

3,00

DN65 AISI304

4,00

0,50 1,00 0,50 SCH 10S

Equalization Tank Air Supply

uPVC 32 PN16 1,00 0,70 0,30

(perforated at the bottom) 0.00 0.00 +4,15

0.00 uPVC 32

0,60 0,50 PN16

1,00

Equalization Tank

0,60

0,50

+7,00 Air Supply Blowers C:\Users\tifas\Documents\26.png

Bioblock Air Supply

0,50

Blowers

Wastewater Overflow Bell-mouth for

Bioblock Wastewater Wastewater Inlet

Wastewater Inlet Pipe DN300 Fine Bubble Bioblock Wastewater Wastewater

Wastewater Feeding Pipe Feeding Pumps Pipe DN300

Pipe DN300 Disc Diffusers Feeding Pumps Overflow Pipe

0,35 uPVC 200 PN10

Wastewater Overflow

Waste Sludge Outlet (perforated at the bottom)

SECTION AT +0.50 Fine Bubble

SECTION AT +6.00

DN100 AISI316 SCH 10S

Pipe DN300 Equalization Tank Air Supply A Disc Diffusers

uPVC 32 PN16

TOP VIEW (perforated at the bottom)

0,15 0,70 0,15 Wastewater Feeding Pipe

uPVC 200 PN10 Support for Fine Bubble

(perforated at the bottom) Disc Diffusers - AISI316

Equalization Tank

0,65

Air Supply

uPVC 63 PN16

1,05 0,85 0,85 0,35

0,50

0,20

1,30

uPVC 90

0,35

PN16

0,25

0,60

Air Supply for Inclined Wall

Opening Cleaning

DN50 AISI304 SCH 10S

Bioblock Air Supply Dropleg

BioblockDN125

Main Air Supply

AISI304 SCH 10S

Equalization Tank Air Supply

uPVC 32 PN16 CONTRACTOR

DN200 AISI304 SCH 10S (perforated at the bottom)

DETAIL- B EMAK

( 1 : 25 ) DETAIL- C

DETAIL- A ( 1 : 25 )

( 1 : 25 ) Zero Level = +(5.46)

Client Consultant: TALAAT IMAM

CONSULTING ENGINEERS

11 Sphinx Square - Mohandesin, Giza, Egypt, 12411

Tel: 202 33461888 Fax:202 33036364

DESIGNR

IN ASSOCIATION WITH :

&

DWG.TITLE

PROJ.NAME MAIN DISCIPLINE SHEET TYPE SHEET NO TOTAL SHEETS NO

OF

DYN PR MEC 1 2

DATE SHEET SIZE SCALE REV SERIAL TO TOTAL DRAWINGS NO.

13.10.2020 A1 1 / 100 FINAL 006 089

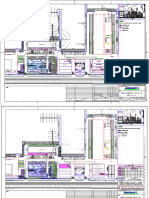

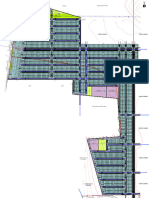

B Key plan

EXIST

J J

ING

W W PT

12

H H

18

21

18

20

01

6.00

(+6.3

Bioblock Air Supply Wastewater

Equalization Tank

12

12

5)

Blowers Feeding Tank Bioblock Main Air Supply Air Supply Pipe 7.50

11

(AISI 304)

02

DN200 AISI304 SCH 10S Air Supply for Inclined Wall DN100 AISI304 SCH 10S

16

Wastewater

6.00

DN200 AISI304 Bioblock Main Air Supply Opening Cleaning Equalization Tank G G

11

AIR LIFT No1

13

12

SCH 10S DN200 AISI304 SCH10S DN65 AISI304 SCH 10S Feeding Tank

12

Air Supply Blowers

22

03

(AISI 304) Bioblock Air Supply Dropleg (AISI304)

Flow Control

11

DN125 AISI316 SCH 10S AIR LIFT No2 6.00

10

Flow Control

09

19

(AISI 304) Gates AISI304

14

04

Gates AISI304

05

17

H

15

07

GEN

ROOM

06

DN200 AISI316 Condensate Discharge

07

DN65 AISI316

06

+7,00 +7,00 DN25 AISI316 +7,00

07

SCH 10S Flow Control SCH 10S

06

07

SCH 10S F F

0,95

Gates AISI304

06

C

12

07

08

06

+6.50

07

08

Monorail for Bioblock Air Supply Dropleg

06

3 +6.40 +6.40 +6.40 +6.40 +6.40 E E

08

12

Pump Lift DN125 AISI316 SCH 10S

08

+6.00 +7,00

08

0,60 DN100 AISI304

08

Wastewater SCH 10S

23

Flowmeter DN150 uPVC 200 Waste Sludge +5.40

0,20

PN10 +5.30 Discharge Pipe +5.30 Condensate Discharge

DN100 AISI316 SCH 10S DN25 AISI316

SCH 10S Equalization Tank

Equalization Tank Air Supply Air Supply

DN100 AISI304 SCH 10S +6.40

DN65 AISI 304 SCH 10S

Air Vent Pipe

Waste Sludge Outlet D D TOP VIEW

+4,15 DN100 AISI316 +4,15

Notes

uPVC 110 PN10

+3.80 +3.80

GENERAL NOTES

Guide-rails for 3

Pump Lift

Air Lift Suction Pipe

Waste Sludge

Discharge Pipe

DN65 AISI 316 SCH 10S C B Stainless steel pipes immersed in sewage shall be AISI 316 acc. to

Wastewater Discharge Pipe DN80 AISI316 SCH 10S DN100 AISI316 SCH 10S TOP VIEW

DN150 AISI 316 SCH 10S DETAIL- H ASTM778, ANSI B36.19 and wall thickness Sched. 10s.

DN65 AISI 316 +1.80 ( 1 : 25 ) 0,50

SCH 10S +1.80

DN125 AISI316

SCH 10S +1.80 Stainless steel pipes external to sewage shall be AISI 304 acc. to

J

Bioblock Air Supply Dropleg

uPVC 75 DN125 AISI316 SCH 10S

ASTM778, ANSI B36.19 and wall thickness Sched. 10s.

PN16 Equalization Tank Air Supply

1,00

uPVC 32 PN16 All stainless steel Flanges are acc. to DIN 2576

(perforated at the bottom)

Fine Bubble +0,10

All pipe connections on the drawing are indicative. Please refer to

0.00 0.00

Disk Diffusers

+0.60 relevant drawings.

1,00

uPVC piping shall be solvent weld on site.

0,70

-0,95 -0.85 -0,95 -0,95 -0,95

0,30

0,70

For supports of piping please refer to the relevant drawings.

0,40

Wastewater Feeding Pipe

0,30

uPVC 200 PN10 0.00

SECTION B-B (perforated at the bottom)

uPVC 90 Wastewater Feeding Pipe

All supports of piping and structures external to sewage shall be

Equalization Tank Air Supply PN16 uPVC 200 PN10 Bioblock Wastewater

Wastewater Inlet DETAIL- J

Pipe DN300

Bioblock Wastewater

Feeding Pumps DN100 AISI 304 SCH 10S (perforated at the bottom 65mm/3m) Feeding Pumps Overflow Pipe

DN300

hot dip galvanized.

Bioblock Main Air Supply ( 1 : 25 ) SECTION C-C

2,18

Equalization Tank Air Supply DN200 AISI304 SCH 10S All supports of piping and structures immersed in sewage shall be

DN65 AISI 304 SCH 10S

1,20

DN200 AISI304

1,75 2,30 3,70 2,70 AISI304.

+4,15

SCH 10S Connection Flange to Adjacent

Bioblock Air Supply Network

Bioblock Air Supply

DN100 AISI304

Manifold DN200 AISI304 SCH 10S

Equalization Tank SCH 10S

DN200 AISI304

SCH 10S Wastewater

DETAIL SECTION 3 - 3 Air Supply Blowers

Feeding Tank ( 1 : 50 ) AIR LIFT No1

2 2

2,10

2,10

(AISI304) (AISI304)

Bioblock Air Supply

1,06

Blowers

+7,00

0,36

+7,00 +7,00

0,26

Wastewater +6.40 +6.40 +6.40 +6.40

Flowmeter DN150 Equalization Tank Air Supply

Wastewater DN65 AISI 304 DN100 AISI 304 SCH 10S

Discharge Pipe Air Supply for Inclined Wall

SCH 10S Collection Circular Channel Collection Circular Channel Opening Cleaning

DN150 AISI316 SCH 10S of Clarified Wastewater 15.0000 of Clarified Wastewater DN50 AISI316 SCH 10S

315 HDPE PE100 PN10 315 HDPE PE100 PN10

+4,15 DN32 AISI 316

+3.80 +3.80

Air Lift Suction Pipe

DN80 AISI316 SCH 10S

SCH 10S

Legend

DN65 AISI 316

SCH 10S Equalization Tank Air Supply DN125 AISI316

DN65 AISI 316 SCH 10S SCH 10S

uPVC 140

PN16

O

uPVC 200 uPVC 110 DYN GN HY 007----

PN10 PN16

uPVC 75 uPVC 75

PN16 PN16

0,40

uPVC 63 N

PN16 +0,10

M +0,10

0.00 0.00 0.00 0.00

uPVC 90 0,85 0,85 0,35

PN16

-0,95

Air Supply for Inclined Wall

Bioblock Air Supply Manifold Opening Cleaning & Air Lift Pumps +7.00 SECTION F-F Waste Sludge

Air Supply for Air Lift No2 SECTION E-E 0,35

DN200 AISI304 SCH 10S DN65 AISI304 SCH 10S Discharge Pipe

DN32 AISI304 SCH 10S

Air Supply for Inclined Wall DN100 AISI316 SCH 10S

0,15 0,70 0,15

+6.63 Opening Cleaning Needle Valve DN25 DETAIL- O

Bioblock Air Supply Dropleg DN50 AISI316 SCH 10S for air supply ( 1 : 25 )

1 1 SECTION D-D DN125 AISI316 SCH 10S

+6.40

flow regulation

+6.285

Air Vent Pipe +6.20 uPVC 75 PN16 Motorized

uPVC 110 PN10 Ball Valve DN25

0,95

Bioblock Air Supply Dropleg 0,3

DN125 AISI316 SCH 10S Equalization Tank Air Supply 0,31 5

0,50 0,50

0,30 uPVC 32 PN16 Air Supply By-pass

+7.00 0,30 0,10 Collection Circular Channel

+7,00 (perforated at the bottom) 2 Ball Valve DN25

0,70

of Clarified Wastewater

0,15

Wastewater Feeding Pipe 0,1

1,30

0,35

315 HDPE PE100 PN10 Air Supply for Inclined Wall Opening Cleaning +7.00

Sheet Metal Partition +0,10 uPVC 200 PN10

Air Supply for Inclined Wall for Deaeration Zone 0.00 (perforated at the bottom) uPVC 63 PN16

Air Supply for Inclined Wall (perforated at the bottom)

0,65

Opening Cleaning AISI304 - 2mm

Opening Cleaning

DN50 AISI316 SCH 10S

DN50 AISI316 SCH 10S REV. DATE REMARKS

AIR LIFT No1

0,15

0,70 (AISI304)

0,75

Air Supply for Air Lift No1 +4.70 Supports for Sheet Metal Partition

DN32 AISI304 SCH 10S of Deaeration Zone AISI304 DETAIL - M

K

DN65 AISI304 DETAIL- L ( 1 : 25 )

DETAIL SECTION 1-1

SCH 10S DETAIL- N

DETAIL- K ( 1 : 25 ) DETAIL SECTION 2-2

( 1 : 25 )

L ( 1 : 25 )

( 1 : 25 ) +7,00 +7,00 +7,00 ( 1 : 25 )

+6.40 +6.40 +6.40 +6.40 +6.40 +6.40

C:\Users\tifas\Documents\26.png

Condensate Discharge Condensate Discharge

DN25 AISI316 DN25 AISI316

SCH 10S SCH 10S

Air Vent Pipe

uPVC 110 PN10

+1.80

+1.54

+0.60

+0,10 +0,10

0,50

0.00 0.00 0.00

1,00

-0,95

0,50

SECTION G-G SECTION H-H

SECTION J-J Zero Level = +(5.46)

CONTRACTOR

EMAK

Client Consultant: TALAAT IMAM

CONSULTING ENGINEERS

11 Sphinx Square - Mohandesin, Giza, Egypt, 12411

Tel: 202 33461888 Fax:202 33036364

DESIGNR

IN ASSOCIATION WITH :

&

DWG.TITLE

PROJ.NAME MAIN DISCIPLINE SHEET TYPE SHEET NO TOTAL SHEETS NO

OF

DYN PR HY 2 2

DATE SHEET SIZE SCALE REV SERIAL TO TOTAL DRAWINGS NO.

13/10/2020 A1 1 / 100 FINAL 007 089

You might also like

- How Many Toilets Do You Need - BS 6465 Sanitary InstallationsDocument10 pagesHow Many Toilets Do You Need - BS 6465 Sanitary InstallationsRHaikal Ming Zhi LeeNo ratings yet

- Family Nursing Care PlanDocument2 pagesFamily Nursing Care PlanJoeven Hilario83% (6)

- National Health ProgrammesDocument12 pagesNational Health ProgrammesRAJU100% (2)

- Food Safety at A GlanceDocument5 pagesFood Safety at A GlanceAliceNo ratings yet

- Reference LevelDocument1 pageReference Level123epcNo ratings yet

- Jalan Outlet Menuju Rumah KatupDocument7 pagesJalan Outlet Menuju Rumah Katupchandra adriawanNo ratings yet

- 10 603110 0000100201 Mah Civ SHD 000032 - 01Document1 page10 603110 0000100201 Mah Civ SHD 000032 - 01ibrahemomr9993No ratings yet

- Basement - With Cameras-BasementDocument1 pageBasement - With Cameras-BasementpknawazNo ratings yet

- Project #9Document11 pagesProject #9indyecraftsNo ratings yet

- Ground Floor Access Control PlanDocument1 pageGround Floor Access Control PlanRajesh RajendranNo ratings yet

- HD Actualizado Mod.22Document1 pageHD Actualizado Mod.22Luís G. MorenoNo ratings yet

- HW Nic Allam DD Ge 003Document1 pageHW Nic Allam DD Ge 003ehab.m.saad88No ratings yet

- Plano Upeu GeneralDocument1 pagePlano Upeu GeneralAllisson Arone ValenciaNo ratings yet

- Emaar Plot A017 Icon Bay Residential Tower On DCH Island DistrictDocument1 pageEmaar Plot A017 Icon Bay Residential Tower On DCH Island DistrictZeeZ HNo ratings yet

- Emaar Plot A017 Icon Bay Residential Tower On DCH Island DistrictDocument1 pageEmaar Plot A017 Icon Bay Residential Tower On DCH Island DistrictZeeZ HNo ratings yet

- Pumb & Water Tank Construction Area Fence-Drawing - CommentedDocument3 pagesPumb & Water Tank Construction Area Fence-Drawing - CommentedVinodNo ratings yet

- GWT Siram Taman - 02Document4 pagesGWT Siram Taman - 02sanusiNo ratings yet

- Qfab Yard Layout - Rev A3 - 31may22 - Nfs JKT-NFXP Topside and Subsea StrucDocument45 pagesQfab Yard Layout - Rev A3 - 31may22 - Nfs JKT-NFXP Topside and Subsea StrucSajin Chacko NinanNo ratings yet

- River View South-FinalDocument1 pageRiver View South-FinalAryan MalikNo ratings yet

- A10.FF.01 - Ceiling Layout REV MI-Layout1Document1 pageA10.FF.01 - Ceiling Layout REV MI-Layout1muqtar4uNo ratings yet

- Hartland: LegendDocument1 pageHartland: LegendrajatNo ratings yet

- SHC G.PH. 2 B 03 3dr.F BW SD 005 Layout1Document1 pageSHC G.PH. 2 B 03 3dr.F BW SD 005 Layout1rajatNo ratings yet

- Government Berths: Limit of Work IP1 IP4Document1 pageGovernment Berths: Limit of Work IP1 IP4Sid BlankNo ratings yet

- Av. 450 Años-Model5 PDFDocument1 pageAv. 450 Años-Model5 PDFPablo Helio Mieles PoloNo ratings yet

- 10 603110 0000100201 Mah Civ SHD 000030 - 01Document1 page10 603110 0000100201 Mah Civ SHD 000030 - 01ibrahemomr9993No ratings yet

- 1-PLANTA Y PERFIL-Layout1-Planta Perfil - A1Document1 page1-PLANTA Y PERFIL-Layout1-Planta Perfil - A1Alfredo Villanueva ParedesNo ratings yet

- Campo de Futebol: Escola EstadualDocument1 pageCampo de Futebol: Escola EstadualDimas JuniorNo ratings yet

- Pnateamiento General Desague PluvialDocument1 pagePnateamiento General Desague PluvialJJesusNo ratings yet

- CJ-JZ-KAIS - FDT-002 Distribution Layout Diagram (DLD)Document1 pageCJ-JZ-KAIS - FDT-002 Distribution Layout Diagram (DLD)Agayel darNo ratings yet

- Memorias de CalculoDocument85 pagesMemorias de CalculoSmith GutierrezNo ratings yet

- As-Built Drawing - Sports CityDocument2 pagesAs-Built Drawing - Sports Cityzubair khanNo ratings yet

- Project #1Document15 pagesProject #1indyecraftsNo ratings yet

- Tower-2 (3BHK) ELECTRICAL LAYOUT C2 PDFDocument1 pageTower-2 (3BHK) ELECTRICAL LAYOUT C2 PDFakhilNo ratings yet

- Mat Bang Giao Thong-A0Document1 pageMat Bang Giao Thong-A0Nguyễn Tiến ĐạtNo ratings yet

- Parking 8.5x11 0 PDFDocument1 pageParking 8.5x11 0 PDFuser5839No ratings yet

- Prelude in G-MinorDocument3 pagesPrelude in G-Minordarklord285No ratings yet

- Áreas y DistanciasDocument9 pagesÁreas y DistanciasKarlixPanNo ratings yet

- CR Ingenieros: Limite de ProyectoDocument4 pagesCR Ingenieros: Limite de ProyectoJorge GutierrezNo ratings yet

- Sector 2 - PMDocument1 pageSector 2 - PMalexlandivarvelaNo ratings yet

- Declivitati: Elemente de Profil Cote Proiect Cote Teren PichetiDocument1 pageDeclivitati: Elemente de Profil Cote Proiect Cote Teren PichetiElena RomanNo ratings yet

- FLS .Mall Eltahlia 26-08-2023-MezzDocument1 pageFLS .Mall Eltahlia 26-08-2023-Mezzengrabbas75No ratings yet

- Proposed LayoutDocument5 pagesProposed LayoutAbdul RafeyNo ratings yet

- Terrenourba ModelDocument1 pageTerrenourba ModelLiz C TicsihuaNo ratings yet

- Universidad Peruana Union: Facultad de Ingenieria Y ArquitecturaDocument1 pageUniversidad Peruana Union: Facultad de Ingenieria Y ArquitecturaFernando Luis Llerena TorrejónNo ratings yet

- 10 02 16 Temporary Transformer Location LayoutDocument1 page10 02 16 Temporary Transformer Location Layoutmudassir mNo ratings yet

- BLDG B MergedDocument3 pagesBLDG B Mergedgunjan.mallpNo ratings yet

- Campus MapDocument1 pageCampus MapZaid DeanNo ratings yet

- Nguyen Van Ban - 04 - So Do Mach Dieu Khien Dong Co (2AZ-FE)Document2 pagesNguyen Van Ban - 04 - So Do Mach Dieu Khien Dong Co (2AZ-FE)1264Nguyễn Hữu ThắngNo ratings yet

- Aldeinha Lotes 250-ModeloDocument1 pageAldeinha Lotes 250-ModelotelminhopaimNo ratings yet

- 2017-18 Lambton County Road MapDocument2 pages2017-18 Lambton County Road MapTourismSarniaNo ratings yet

- Edinburgh MapDocument1 pageEdinburgh MapPrabhakar JhaNo ratings yet

- 0987rebdDocument1 page0987rebdToni BioksicNo ratings yet

- Comparison Design - As-Built 3Document1 pageComparison Design - As-Built 3abm2irzathNo ratings yet

- полная схемаDocument2 pagesполная схемаZhan AinabekovNo ratings yet

- Trail Pit Section Sheet - 01ADocument1 pageTrail Pit Section Sheet - 01ASamar AliNo ratings yet

- S19091 Sal Bawi Sob FD e Ele 01 B1 00 0100 01Document1 pageS19091 Sal Bawi Sob FD e Ele 01 B1 00 0100 01Ibrahim AlqunoonNo ratings yet

- Auld Lang SyneDocument1 pageAuld Lang SynesppainistanNo ratings yet

- Sanitaria y Pluvial 1Document1 pageSanitaria y Pluvial 1christophergiovannivaldespacheNo ratings yet

- Zoning Districts Map 50 x50Document1 pageZoning Districts Map 50 x50Jorge MartinezNo ratings yet

- Cópia de PROJETO URBANÍSTICO - RESIDENCIAL NOVA BENEVIDES I 2-3 01082023Document1 pageCópia de PROJETO URBANÍSTICO - RESIDENCIAL NOVA BENEVIDES I 2-3 01082023ReinaldoNo ratings yet

- LENANTAMIENTO - GENERAL - InterventoriaDocument1 pageLENANTAMIENTO - GENERAL - Interventoriatopografia gilma jimenezNo ratings yet

- Leyenda: Universidad Nacional Del Altiplano-PunoDocument1 pageLeyenda: Universidad Nacional Del Altiplano-Punojhon kevinNo ratings yet

- Dist 06Document1 pageDist 06Jesús Enrique Cruz LorenzanaNo ratings yet

- DataSheet DD9 10 enDocument1 pageDataSheet DD9 10 enDocu CenterNo ratings yet

- Pumpset 10.25 LsDocument3 pagesPumpset 10.25 LsDocu CenterNo ratings yet

- SUPERNATANTDocument1 pageSUPERNATANTDocu CenterNo ratings yet

- Seko - 2022 Pompes & Accessoires - EngDocument128 pagesSeko - 2022 Pompes & Accessoires - EngDocu CenterNo ratings yet

- Hibon NX Serisi Blover Katalogu - IngilizceDocument8 pagesHibon NX Serisi Blover Katalogu - IngilizceDocu CenterNo ratings yet

- Aquaflex Filter Press Manuals in EnglishDocument28 pagesAquaflex Filter Press Manuals in EnglishDocu CenterNo ratings yet

- T Ta Tac Eng UlDocument44 pagesT Ta Tac Eng UlDocu CenterNo ratings yet

- CEMP Appendix F VAR BAM ZZ ZZ MS C 0004 Surface Water Stormwater DewateringDocument14 pagesCEMP Appendix F VAR BAM ZZ ZZ MS C 0004 Surface Water Stormwater DewateringDocu CenterNo ratings yet

- Operating Data: Pressure Drop IncludedDocument1 pageOperating Data: Pressure Drop IncludedDocu CenterNo ratings yet

- Nva-Cm-20121502 Tekpa Iso 10002Document1 pageNva-Cm-20121502 Tekpa Iso 10002Docu CenterNo ratings yet

- NVA-EC-22020801 TEKPA CE UYGUNLUK BELGESİ Pnömatik Ve Elektrik AktüatörlerDocument1 pageNVA-EC-22020801 TEKPA CE UYGUNLUK BELGESİ Pnömatik Ve Elektrik AktüatörlerDocu CenterNo ratings yet

- Annual Report 2017Document24 pagesAnnual Report 2017John Glenn SpaceNo ratings yet

- WPL Lamella Separator Technical DatasheetDocument1 pageWPL Lamella Separator Technical Datasheettallef001No ratings yet

- Narrative Report of InsetDocument20 pagesNarrative Report of Insetjessa mie lacarNo ratings yet

- Sanitary EnggDocument8 pagesSanitary EnggAdNo ratings yet

- Com Kitchen Plumbing Indirect Waste Fact Sheet 2205Document3 pagesCom Kitchen Plumbing Indirect Waste Fact Sheet 2205parelkidNo ratings yet

- Ownership Frequency Percentage Owned Rent-Free Shared TotalDocument20 pagesOwnership Frequency Percentage Owned Rent-Free Shared TotalTintin TagupaNo ratings yet

- Pastor Fred Mwesigye ManifestoDocument24 pagesPastor Fred Mwesigye ManifestoAfrican Centre for Media ExcellenceNo ratings yet

- Disposing of A Sanitary FadDocument5 pagesDisposing of A Sanitary FadMomil FatimaNo ratings yet

- The Changing Status of Women in India-The Challenges Ahead: DR Suvarna Sen Ishita MukherjeeDocument21 pagesThe Changing Status of Women in India-The Challenges Ahead: DR Suvarna Sen Ishita MukherjeeShyamsunder SinghNo ratings yet

- Design Handbook of Plumbing INDIANDocument198 pagesDesign Handbook of Plumbing INDIANsameera priyashanthaNo ratings yet

- Temporary Labor Camp Facilities GuideDocument9 pagesTemporary Labor Camp Facilities Guiderasputin0780803494No ratings yet

- WINS Checklist Sample Ctto: DePedQuezonDocument2 pagesWINS Checklist Sample Ctto: DePedQuezonsammy ferrer baysa100% (1)

- Sas 15Document5 pagesSas 15Kristinelou Marie ReynaNo ratings yet

- FNCPDocument30 pagesFNCPAJ S Nvrro100% (1)

- Water, Sanitation, Socioeconomic Status and Prevalence of Waterborne Diseases A Cross-Sectional Study at Makwanpur District, NepalDocument61 pagesWater, Sanitation, Socioeconomic Status and Prevalence of Waterborne Diseases A Cross-Sectional Study at Makwanpur District, NepalMichael SamwelNo ratings yet

- St. Paul University Philippines: School of Nursing and Allied Health Sciences College of NursingDocument4 pagesSt. Paul University Philippines: School of Nursing and Allied Health Sciences College of NursingChristian UmosoNo ratings yet

- WASH in Schools in AngolaDocument52 pagesWASH in Schools in AngolaHelder MbidiNo ratings yet

- Nigerian Standard For Drinking Water QualityDocument28 pagesNigerian Standard For Drinking Water QualityIsa Usman100% (1)

- Program Manual 23-03-2015 FINAL PDFDocument455 pagesProgram Manual 23-03-2015 FINAL PDFbhagyashriNo ratings yet

- The Phil Water Situation Report 2006Document71 pagesThe Phil Water Situation Report 2006Amir RasNo ratings yet

- Standards For WASH in Schools in Bangladesh - LatestDocument52 pagesStandards For WASH in Schools in Bangladesh - LatestushasaimaNo ratings yet

- Women and Water Management A Case Study From The Rural Communities in The Vietnamese Mekong Delta - PublishedDocument44 pagesWomen and Water Management A Case Study From The Rural Communities in The Vietnamese Mekong Delta - PublishedThai Nguyen VanNo ratings yet

- Cholera and The Origins of The American Sanitary Order in The PhilippinesDocument3 pagesCholera and The Origins of The American Sanitary Order in The PhilippinesAizen IchigoNo ratings yet

- Lecture 7. Migration and UrbanizationDocument43 pagesLecture 7. Migration and UrbanizationBiruk MengstieNo ratings yet

- Washbook TrainingDocument54 pagesWashbook TrainingMark BwanakayaNo ratings yet

- Your Crossword Puzzle 1 PDFDocument1 pageYour Crossword Puzzle 1 PDFRose Celine DiazNo ratings yet