Professional Documents

Culture Documents

Sorbitol - 70% Process Flow Chart

Sorbitol - 70% Process Flow Chart

Uploaded by

sachinmittal.nitkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sorbitol - 70% Process Flow Chart

Sorbitol - 70% Process Flow Chart

Uploaded by

sachinmittal.nitkCopyright:

Available Formats

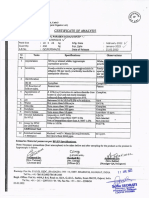

SORBITOL 70% PROCESS FLOW CHART

CRYSTALLIZING & NON CRYSTALLIZING GRADES

Technical Data & Specifications

Description

Appearance of solution Clear, colourless, syrupy liquid, miscible with water.

D-Sorbitol%(m/m) Min.50%

Water Content Between 28% to 31%

Dry Matter Min.69%

Reducing Sugar Max.0.2%

pH 5.00 to 7.00

Sulphated Ash%(m/m) Max.0.1%

Lead Max.0.5ppm

Nickel Max 1ppm

Sulphate Max 100ppm

Chloride Max 50ppm

Arsenic(As) Max 3mg/Kg

Heavy metals Max 10ppm

Sorbitol 70% - Non-Crystalline (Pharmaceutical Grade / IP Grade)

Specific Gravity: 1.296 – 1.298

D Sorbitol: 72 – 92%

Total Sugar: 4 – 9 % (as per client requirement)

% R.S < 0.2%

R.I: 1.455 – 1.456

Sorbitol 70% - Crystalline (Non-Pharmaceutical Grade / NIP Grade)

Specific Gravity: 1.296 - 1.298

D Sorbitol: >92%

Total Sugars: 1.8 – 2.5%

% R.S < 0.2%

R.I: 1.455 – 1.456

GULSHAN POLYOLS LTD Revised: 30/01/2014 SOP NO.: GPL/SOP/PR/7.5/11 1

SORBITOL 70% PROCESS FLOW CHART

CRYSTALLIZING & NON CRYSTALLIZING GRADES

QC Sample

Colour: Off white

STARCH SLURRY TANKS

Caustic Solution to Be: 16.0 - 17.5

bring pH 5.6 to 5.8 Prepare slurry: SO2 Aeration. Ph: 5.0 – 5.8

Parameters: % Protein (Insoluble):

Alpha Amylase (0.5 D.S. 30 - 33%, pH 5.6 to 5.8, Process 0.45 - 0.55%

Kg/ ton of starch) water 70 - 67% % Protein (Soluble): 0.025

- 0.035%

Slurry Tanks: 50m3 (5 % Oil/fat: 0.1 - 0.14 %

mtr) + 16m3 (3 tanks) SO2 ppm: 90 -100

HYDROLYSIS /JET COOKING

Steam Consumption Start with converting starch into saccharides. This

(0.33 Kg/Tone of DS step enables alpha amylase to break starch

Starch) molecules into saccharides/ Dextrin. Slurry is cooked

for 5-8 minutes at Temp. 107 ± 1°C

QC Sample

DEXTRINATION TANK % DE: NIP: 12-14

% DE: IP: 12-14

Here conversion continues.

Starch test: Slightly +ve

Retention Time: 1.5 to 2.0 Hours at 94-99° C

(purple colour with

Parameters:

Starch: –ve, D.E: 12-14% for NIP and 12 – Iodine solution)

14% for IP (pure dextrose: 6-8%) Colour: slight yellow

(visual)

DS: 29 – 32 %

Dex. Tanks: 45m3 (Tank (By Refractometer)

behind coiled tubes

)

ONLINE DOSING:

HCL for pH:4.0 - 4.5 PLATE COOLER (4 PHE)

Gluco Amylase (0.5 Material is cooled to 60± 2°C to further break

Kg/Tone of starch) dextrin chains into dextrose/ monomer.

GULSHAN POLYOLS LTD Revised: 30/01/2014 SOP NO.: GPL/SOP/PR/7.5/11 2

SORBITOL 70% PROCESS FLOW CHART

CRYSTALLIZING & NON CRYSTALLIZING GRADES

CONTROL

POINT QC Sample

SACCHARIFICATION TANK

DS: 29 – 32 %

Conversion into Dextrose requires retention time (By refractometer )

(IP: 20-25 hours; NIP: 30-35 hours) % DE: NIP: 96 – 99 (As

Tanks: Chemical: n (C6H10O5) + n H2O →n (C6H12O6) per lab manual)

NIP: 8 x 100m3 (6 Parameters: IP: 80 – 90

mtr tank) (TEMP: 60± 2°C & PH:- 4.0 – 4.5), D.S. 29-32% Starch test: - ve

IP: 10 x 32m3 (4 % D.E. ≥ 96% for Crystallizing Grade

mtr height) % D.E. 80 - 90% for Non Crystallizing Grade

CONTROL

POINT

PRESSURE LEAF FILTER

Filter Aid Primary filtration takes place to attain REJECT: Suspended

(2.5 kg/ton physical clarity. impurities + Filter Aid

Sorbitol 70%)

Filters:

` NIP: 4 IP: 2

BENTONITE CLEAR SOLUTION TANK

to absorb oil

SUSPENDED IMPURITIES REMOVED

content

CONTROL

Tank: 50m3 (50% level) POINT

2 tanks (IP & NIP)

PRESSURE LEAF FILTER

Filter Aid Secondary filtration takes place to REJECT: Suspended

(1 kg/ton attain physical clarity. impurities + Filter Aid

Sorbitol 70%)

5 PLF: 2 for Dex NIP, 1 for

Dex IP, and 1 for 1 Sorb

CLEAR CRUDE DEXTROSE TANK

Tanks:

NIP D1: 100m3 (6 mtr)

IP D1: 30m3 (4 mtr)

GULSHAN POLYOLS LTD Revised: 30/01/2014 SOP NO.: GPL/SOP/PR/7.5/11 3

SORBITOL 70% PROCESS FLOW CHART

CRYSTALLIZING & NON CRYSTALLIZING GRADES

HCL AND CAUSTIC SODA CRITICAL

LYE ARE USED FOR CONTROL

REGENERATION OF ION POINT

EXCHANGE RESIN DEXTROSE ION - EXCHANGE

CHECK :Ph 4.5 ;

conductivity 30µS Dissolved ionic impurities like chloride, sulphate and

enzymes are remove.

4 sets NIP (9m3 each)

4 sets IP (6m3 each)

Tanks: DEIONISED DEXTROSE SOLUTION

NIP D2: 100m3 (6 mtr)

IP D2: 30m3 (4 mtr)

DEXTROSE EVAPORATOR

Evap Outlet Tanks: Maintain 90ºC to raise concentration to DS: 50 - 55%

NIP D3 A,B: 30m3 x 2 (4

mtr) IP D3: 30m3 x 1 (4

QC Sample

mtr)

% DS: 50 – 55

GFT/ DEXTROSE FEED TANK % DE: NIP: 96 – 99

% DE: IP: 87 – 92

Caustic Parameters: 50 - 55% D.S. pH: NIP: 6.5 – 7.5

Solution Crystalline pH 6.5 to 7.5, Cond 30 µS pH:IP: 7.5 – 8.5

Non-Cryst. & 7.5 to 8.5, Cond 50 µS Cond: 50 us Max.

So2: 11 – 15 ppm Max

Nickle Catalyst (0.5 Kg/ Tone

of Sorbitol 70%) GFT Tanks:

NIP 3,4: 15m3 x 2 (14 mt)

Magnesium Metal Powder

(0.3 Kg/Tone of Sorbitol 70%) IP 1,2: 6m3 x 2 (5 mt)

HYDROGENATION /AUTOCLAVE QC Sample

HYDROGEN

30 – 35 kg/cm2 Dextrose converts into Sorbitol here at

148 ± 2ºC. Conduct Benedicts solution RS: 6.0 -8.0 ml

Pressure

test to 6-7ml to complete reaction. (By benedict solution

green colour)

Steam Pressure n(C6H12O6)+ H2 Ni & Mg→ C6H14O6 % DS: Check & Report

5Kg/cm2

Parameters: RS < 0.2% before cooling, % RS: 0.2 Max.

Steam Temp:160 oC

DS: 50-54% % TS: NIP: 2.0 +/- 0.2

IP: 3.8 - 8%

Autoclaves:

IP 1,2,3,4: m3 x 4 ( mt)

NIP 5,6,7,8: m3 x 4 ( mt)

GULSHAN POLYOLS LTD Revised: 30/01/2014 SOP NO.: GPL/SOP/PR/7.5/11 4

SORBITOL 70% PROCESS FLOW CHART

CRYSTALLIZING & NON CRYSTALLIZING GRADES

CRUDE SORBITOL COLLECTION TANK

Parameters: 48 – 52% D.S.

Tank: CTT 1 & 2

constant level at 1.3

mtr is maintained

SORBITOL PRESSURE LEAF

REJECT: Suspended

FILTER

impurities + Filter Aid

Parameters:

1 each in IP & NIP

CONTROL

POINT

Tank: ST1 A,B

ION EXCHANGE FEED TANK

NIP: 100m3 x 2 (6m3 )

IP: 30m3 x 2 (4m3)

HYDROCLORIC ACID AND

SORBITOL ION EXCHANGE REJECT: Dissolved

COSTIC SODA LYE ARE

USED FOR REGENERATION impurities: Ni, Mg

OF ION EXCHANGE RESIN 4 sets each for NIP + IP.

CRITICAL

CONTROL

POINT

DEIONISED SORBITOL COLLECTION TANK

Conductivity <20µse

Parameters: pH 6.5

Tank: Max. Conductivity: 20ms, DS: 50% max.

NIP: 65m3 Crystalline: pH 6.5; Non Cryst: pH 6.5

IP: 30m3

GULSHAN POLYOLS LTD Revised: 30/01/2014 SOP NO.: GPL/SOP/PR/7.5/11 5

SORBITOL 70% PROCESS FLOW CHART

CRYSTALLIZING & NON CRYSTALLIZING GRADES

TRIPLE EFFECT EVAPORATOR

Sorbitol 70% (D.S. - 70%)

QC Sample

Colour: NIP: A Clean

colourless (Visual)

IP: Upto faintly yellowish

HOMOGENISATION TANK (Visual )

For final adjustment and solution mixing Sp. gr@ 25o C: 1.296 –

for consistency and quality control 1.298

pH: 5.0 – 7.5

Parameters: RS < 0.2% 70 ± 1 % D.S

% RS: 0.2% Max.

Crystalline: Specific Gravity 1.296 – 1.298 % TS: IP: 3.8-8.0%

Non Cryst: Specific Gravity 1.296 – 1.298 NIP: 2.0 +/- 0.2

Heat test: To pass the

pH: 5.0 to 7.5 for Crystalline & Non- test (Asian paint/Burger

Crystalline grades method)

Mixing Tank: Dye test: To pass the test

( HLL/Prime method)

MT 1,2,3,4 NIP: 20m3 x 4

MT 1, 2IP: 20m3 x 2

STORAGE TANK

Tank:

Paint Grade: 65m3 x 2

Drum Filling: 20m3 x 2

Prime: 65m3

Colgate: 200m3 x 2

IP: 200m3 x 2

New tanks: 200m3 x 2

MATERIAL PACKING

Sorbitol 70% is delivered in 2 type of packing:

1. SS TANKERS

2. HM HDPE BARRELS

GULSHAN POLYOLS LTD Revised: 30/01/2014 SOP NO.: GPL/SOP/PR/7.5/11 6

You might also like

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Sakhalin LNG-Train GenDocument54 pagesSakhalin LNG-Train GenRobert WatersNo ratings yet

- ELS Final Module - 5-08082020Document26 pagesELS Final Module - 5-08082020Adonis Besa86% (100)

- Certificate of Analysis Template For ChemicalDocument4 pagesCertificate of Analysis Template For ChemicalMon J. KamadNo ratings yet

- Pet Flakes ADocument1 pagePet Flakes AReal NanotechNo ratings yet

- Coa Sorbitol-70-LiquidDocument2 pagesCoa Sorbitol-70-LiquidAndriyanto HadiNo ratings yet

- RELITE 3AS - Strongly Basic ResinDocument2 pagesRELITE 3AS - Strongly Basic ResinPanca Erlangga SiregarNo ratings yet

- Presents MMB: One Unique Product For Plenty of InnovationsDocument31 pagesPresents MMB: One Unique Product For Plenty of InnovationsSvetlana ChiganovaNo ratings yet

- Ethamem-G1: Turn-Key Distillery Plant Enhancement With High Efficiency and Low Opex Ethamem TechonologyDocument25 pagesEthamem-G1: Turn-Key Distillery Plant Enhancement With High Efficiency and Low Opex Ethamem TechonologyNikhilNo ratings yet

- Sorbitol 70% Non Crystallizing Liquid RM COADocument2 pagesSorbitol 70% Non Crystallizing Liquid RM COAASHOK KUMAR LENKANo ratings yet

- CMS Flushing GuideDocument2 pagesCMS Flushing GuideAmjedNo ratings yet

- CoA Fabricant Parahydroxybenzoate de Méthyle Sodique (Nipagine Sodee) - H0793Document1 pageCoA Fabricant Parahydroxybenzoate de Méthyle Sodique (Nipagine Sodee) - H0793Kh KaNo ratings yet

- 09-En 15062018Document56 pages09-En 15062018louayNo ratings yet

- Spec Calisto501901 EN 072017 20170706162030Document4 pagesSpec Calisto501901 EN 072017 20170706162030foufou79No ratings yet

- TDS For TSC-RZBCDocument1 pageTDS For TSC-RZBCLuis San AgustínNo ratings yet

- CHN628 Series Elemental Determinators: Specification SheetDocument2 pagesCHN628 Series Elemental Determinators: Specification SheetSukontip SuethaoNo ratings yet

- Complete Immersion Phosphating LineDocument8 pagesComplete Immersion Phosphating LineStay AwayNo ratings yet

- Berger VR 3mc CoaDocument86 pagesBerger VR 3mc CoaSHASHA VALINo ratings yet

- Relite CF WaterDocument2 pagesRelite CF WaterPanca E.SNo ratings yet

- Niosh Methanol 2000Document4 pagesNiosh Methanol 2000Endang MilahNo ratings yet

- Timber Touch: Code: C12310007Document6 pagesTimber Touch: Code: C12310007kapil KleenageNo ratings yet

- 13001-34086 Cap SSTDocument1 page13001-34086 Cap SSTSakthi VelNo ratings yet

- Niosh 5522Document6 pagesNiosh 5522JAVIER MARTINEZNo ratings yet

- Pure Water SpecDocument2 pagesPure Water SpecRisma Berliana PanjaitanNo ratings yet

- Do Sender Chem Brochure - Peroxide Series & Sodium Oxalate Series Mar. 30, 2023 - 0 Likes - 7 ViewsDocument25 pagesDo Sender Chem Brochure - Peroxide Series & Sodium Oxalate Series Mar. 30, 2023 - 0 Likes - 7 ViewsNick SunNo ratings yet

- 19 - Bleaching SOPDocument5 pages19 - Bleaching SOPPaper Application TeamNo ratings yet

- Niosh 2554 PDFDocument4 pagesNiosh 2554 PDFMICROLABORATORIO S.A de C.VNo ratings yet

- J 5 Emwk 2 V 0 Hsgxlks 3 AnhDocument2 pagesJ 5 Emwk 2 V 0 Hsgxlks 3 AnhAlin ChehadeNo ratings yet

- Contavan GalDocument3 pagesContavan Galraju_hosssenNo ratings yet

- Coa PDFDocument4 pagesCoa PDFsaidNo ratings yet

- Performance: 10 20 120 PPM N 1 4LDocument1 pagePerformance: 10 20 120 PPM N 1 4LFikri Total Enviro SolusindoNo ratings yet

- High Solid PU Dispersion FormulationDocument3 pagesHigh Solid PU Dispersion FormulationBudhi NuryantoNo ratings yet

- Hydrogen Sulphide: PerformanceDocument1 pageHydrogen Sulphide: Performanceabbas1368No ratings yet

- Niosh 2500 Metil Etil Cetona (Mek)Document4 pagesNiosh 2500 Metil Etil Cetona (Mek)EverChumpisucaAlvarezNo ratings yet

- Corazol Red RFTDocument3 pagesCorazol Red RFTDHRUVNo ratings yet

- Corazol Golden Yellow RFTDocument3 pagesCorazol Golden Yellow RFTDHRUVNo ratings yet

- Luliconazole Specs and STP - From DMF - Nosch LabsDocument22 pagesLuliconazole Specs and STP - From DMF - Nosch Labsshakt londaNo ratings yet

- Kantor: JLN Mangga III Blok C12-13, Daya-Makassar, 90241Document42 pagesKantor: JLN Mangga III Blok C12-13, Daya-Makassar, 90241ddtank sandyNo ratings yet

- Chemtotal Labs Pvt. LTD.: D.Col - XCDDocument1 pageChemtotal Labs Pvt. LTD.: D.Col - XCDDeepak CharanNo ratings yet

- Denimax GCDocument7 pagesDenimax GCKetan GandhiNo ratings yet

- Pulp BleachingDocument68 pagesPulp Bleachingtommy salimNo ratings yet

- Waterless Liquefied Petroleum Gas (LPG) Gel-Hydraulic Fracturing TechnologyDocument27 pagesWaterless Liquefied Petroleum Gas (LPG) Gel-Hydraulic Fracturing TechnologycjNo ratings yet

- Roche 9180 Electrolyte AnalyzerDocument1 pageRoche 9180 Electrolyte AnalyzerEliana Leal100% (1)

- STEEL Accessories Limited: Effluent Treatment Plant Work Instruction & Standard Operating ProcedureDocument6 pagesSTEEL Accessories Limited: Effluent Treatment Plant Work Instruction & Standard Operating ProcedureMubarak PatelNo ratings yet

- Distillery Industry 7Document15 pagesDistillery Industry 7gundreddy greeshmaNo ratings yet

- Corafix Rubine GDBDocument3 pagesCorafix Rubine GDBDHRUVNo ratings yet

- Niosh 1405Document6 pagesNiosh 1405MICROLABORATORIO S.A de C.VNo ratings yet

- Dowex Monosphere 550a (Oh)Document2 pagesDowex Monosphere 550a (Oh)BrianNo ratings yet

- ZINCDocument1 pageZINCZinar sawinZinarNo ratings yet

- Total Acid Number (TAN) (ASTM D664) : Potentiometric Titration Application: Petrochemical OilsDocument5 pagesTotal Acid Number (TAN) (ASTM D664) : Potentiometric Titration Application: Petrochemical OilsI H AnsariNo ratings yet

- COA SorbitolDocument2 pagesCOA SorbitolAli KhanNo ratings yet

- 892243AA6DD96824618E7CDA189B43Document101 pages892243AA6DD96824618E7CDA189B43Ravi SapraNo ratings yet

- DIPROPHYLLINEDocument2 pagesDIPROPHYLLINEmononoketangqihotmail.comNo ratings yet

- Hardness: DR 900 Analytical ProcedureDocument4 pagesHardness: DR 900 Analytical Procedurewulalan wulan100% (1)

- Glucosamine Hydrochloride COADocument1 pageGlucosamine Hydrochloride COAm.shahin8888No ratings yet

- Dyeing Machine SettingsDocument10 pagesDyeing Machine SettingsJazib YaseenNo ratings yet

- 108 Names of Sri LakshmiDocument3 pages108 Names of Sri LakshmiStaygreenNo ratings yet

- Palm Oil - Peroxide ValueDocument2 pagesPalm Oil - Peroxide ValueIhsan Aditya0% (1)

- Performance of Governor Oil - Soumik Majumdar & Sanjay DasDocument21 pagesPerformance of Governor Oil - Soumik Majumdar & Sanjay DasEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Practical Manual of Analytical ChemistryFrom EverandPractical Manual of Analytical ChemistryRating: 4.5 out of 5 stars4.5/5 (3)

- Application of IC-MS and IC-ICP-MS in Environmental ResearchFrom EverandApplication of IC-MS and IC-ICP-MS in Environmental ResearchRajmund MichalskiNo ratings yet

- Jotun - Hardtop XP TDSDocument5 pagesJotun - Hardtop XP TDSDanu RifaiNo ratings yet

- Chap 8 Fatiguepart 1Document32 pagesChap 8 Fatiguepart 1Abu Salman Said100% (1)

- Test and Analysis of Modes I, II and Mixed-Mode I/II Delamination For Carbon/Epoxy Composite LaminatesDocument17 pagesTest and Analysis of Modes I, II and Mixed-Mode I/II Delamination For Carbon/Epoxy Composite LaminatesFarohaji KurniawanNo ratings yet

- Saes Q 006Document28 pagesSaes Q 006Noor Alam JanNo ratings yet

- Politano PosteriorDocument5 pagesPolitano Posteriorjulijana.veipaNo ratings yet

- DPP 25B Goc Resonance 1684507782845Document4 pagesDPP 25B Goc Resonance 1684507782845Aditya Kumar100% (1)

- Friction of CeramicsDocument37 pagesFriction of CeramicsChandrika LakhanpalNo ratings yet

- 1602 01684 PDFDocument61 pages1602 01684 PDFRahul MulayNo ratings yet

- Technical Data SheetDocument15 pagesTechnical Data SheetOlvera Mendoza Carlos AlbertoNo ratings yet

- Gig - Polymer Catalog 2016Document54 pagesGig - Polymer Catalog 2016huy hùng100% (1)

- MD Problems and Solutions Variable StressesDocument9 pagesMD Problems and Solutions Variable StressesManoy BermeoNo ratings yet

- Is 12444Document5 pagesIs 12444Ankit YadavNo ratings yet

- Vendor ListDocument38 pagesVendor Listsandhiparvez859No ratings yet

- V RV Ambient Air Vaporizer Data SheetDocument3 pagesV RV Ambient Air Vaporizer Data SheetGilberto Yoshida100% (1)

- Types of YSS Cold Work Tool Steels: Sld-Magic SLDDocument6 pagesTypes of YSS Cold Work Tool Steels: Sld-Magic SLDtaknevNo ratings yet

- Laboratorium Geologi Optik: Laporan Resmi Praktikum Mineral Optik Acara: Feldspar Dan KuarsaDocument6 pagesLaboratorium Geologi Optik: Laporan Resmi Praktikum Mineral Optik Acara: Feldspar Dan KuarsaAldi Hendra HermawanNo ratings yet

- Field Emission Scanning Electron Micros PDFDocument2 pagesField Emission Scanning Electron Micros PDFJenniferNo ratings yet

- Thesis Final Review KDDocument130 pagesThesis Final Review KDThiruvengadam SNo ratings yet

- ASME General 100 QuestionsDocument54 pagesASME General 100 Questionsatulpatil99100% (2)

- Libro 1Document136 pagesLibro 1Maela C O'SheaNo ratings yet

- Efka PU 4047: Technical InformationDocument2 pagesEfka PU 4047: Technical InformationAniket PatelNo ratings yet

- BASF Glyoxal BrochureDocument8 pagesBASF Glyoxal BrochureMukund KsNo ratings yet

- Safety Data Sheet: AcetoneDocument4 pagesSafety Data Sheet: AcetoneBuwanah SelvaarajNo ratings yet

- 3 Digit SeriesDocument5 pages3 Digit Seriesharshileng3992No ratings yet

- 01 Subjective Test-02 X Science 25122022 QPDocument6 pages01 Subjective Test-02 X Science 25122022 QPViswa DharshanNo ratings yet

- Physical Properties of Sucrose SolutionDocument23 pagesPhysical Properties of Sucrose Solutionbùi tuấn tùngNo ratings yet

- Basics of Sample System DesigningDocument14 pagesBasics of Sample System DesigningJAY PARIKHNo ratings yet

- Gen Chem 2 ExamDocument2 pagesGen Chem 2 ExamChristian Lloyd ReandinoNo ratings yet