Professional Documents

Culture Documents

CI-WI-002 - Blasting & Painting - R1.1

CI-WI-002 - Blasting & Painting - R1.1

Uploaded by

Joe DsouzaCopyright:

Available Formats

You might also like

- Painting Procedure Chugoku PaintDocument129 pagesPainting Procedure Chugoku PaintKarthik SNo ratings yet

- Linde Forklift Series 1172 Asl10l10bl12l12i Error List en 1407 Service ManualsDocument22 pagesLinde Forklift Series 1172 Asl10l10bl12l12i Error List en 1407 Service Manualslaurenmays140683dpo100% (134)

- YOUNG, Marnin - Realism in The Age of Impressionism Painting and The Politics of TimeDocument270 pagesYOUNG, Marnin - Realism in The Age of Impressionism Painting and The Politics of TimeAnonymous 9ep4UXzRxx100% (4)

- Mix Design DLC-DelDocument9 pagesMix Design DLC-DelSanjay Constructions100% (1)

- SOP 03 SP Painting Procedure PDFDocument5 pagesSOP 03 SP Painting Procedure PDFBalaji Guru100% (2)

- History-Italian Futurism, Art Nouveau Movement &Document23 pagesHistory-Italian Futurism, Art Nouveau Movement &Ayesha roosminNo ratings yet

- ISO 12944 5 C5 Paint System WilkoDocument5 pagesISO 12944 5 C5 Paint System Wilkojayakumar100% (3)

- Road Marking Paint SB AcrylicDocument4 pagesRoad Marking Paint SB AcrylicAngga PratamaNo ratings yet

- Jotafloor EP SL Uni - Abrasion & Impact ResistDocument6 pagesJotafloor EP SL Uni - Abrasion & Impact Resistangelito bernalNo ratings yet

- TDS Jotafloor EP SL UniDocument6 pagesTDS Jotafloor EP SL UniGemilang KubNo ratings yet

- Issue/Rev Details of Changes Date: Name Designation Signature Date LevelDocument6 pagesIssue/Rev Details of Changes Date: Name Designation Signature Date LevelAbhey DograNo ratings yet

- Surface Treatment ProcedureDocument5 pagesSurface Treatment Proceduredeepan85No ratings yet

- Tbqm-Zamil-406-Coat-014Document3 pagesTbqm-Zamil-406-Coat-014Muhammad RizwanNo ratings yet

- JC Ceiling PaintDocument2 pagesJC Ceiling PaintGrace tpplNo ratings yet

- Quality Plan 1325-27 Rev 02 - Blasting PaintingDocument10 pagesQuality Plan 1325-27 Rev 02 - Blasting Paintingsuriya100% (1)

- Cost EconomicsDocument14 pagesCost Economicsamitvaze316No ratings yet

- Painting Procedure: Doc. No.: PLP-PAINT-P001Document9 pagesPainting Procedure: Doc. No.: PLP-PAINT-P001คุณพ่อน้อง บิ๊กบอสNo ratings yet

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua Sua100% (1)

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua SuaNo ratings yet

- B015-79-41-CG-01 Rev 0 - F-19 Specs by EILDocument6 pagesB015-79-41-CG-01 Rev 0 - F-19 Specs by EILSagarBabuNo ratings yet

- REPORT On Improvement in Quality of Paint Used On FIAT Bogies FinalDocument24 pagesREPORT On Improvement in Quality of Paint Used On FIAT Bogies FinalPammy JainNo ratings yet

- BSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartDocument9 pagesBSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartHồng Trung DươngNo ratings yet

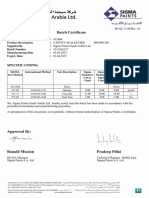

- Batch Certificate::::::: SpecificationsDocument1 pageBatch Certificate::::::: SpecificationsMohammed Omer AliNo ratings yet

- Engineering Material Specification: Date Action RevisionsDocument3 pagesEngineering Material Specification: Date Action RevisionsALEX MURPHY100% (1)

- Painting Procedure For CondenceDocument26 pagesPainting Procedure For CondenceNamta GeorgeNo ratings yet

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- Tbqm-Zamil-37-Coat-002Document4 pagesTbqm-Zamil-37-Coat-002Muhammad RizwanNo ratings yet

- Screenshot 2021-07-09 at 4.15.18 PMDocument46 pagesScreenshot 2021-07-09 at 4.15.18 PMYOGENDRAN RAJANDARANNo ratings yet

- Sand BlastingDocument12 pagesSand Blastingazreengamers09No ratings yet

- Application Guide - Jotafloor EP GlassFlakeDocument8 pagesApplication Guide - Jotafloor EP GlassFlakeKenji TanNo ratings yet

- Silcon 090518Document3 pagesSilcon 090518Abhijeet AnkushNo ratings yet

- Wet Blasting Procedure AIFDocument8 pagesWet Blasting Procedure AIFhash117No ratings yet

- 12 06 12 A&C 33 To RVNL Civil Specs DFTDocument5 pages12 06 12 A&C 33 To RVNL Civil Specs DFTRVNL GoaNo ratings yet

- Mythri Metallizing PVT LTD Bangalore Job Procedure For Surface Preparation by Grit Blasting Cleaning and Application of Primer 1. ScopeDocument3 pagesMythri Metallizing PVT LTD Bangalore Job Procedure For Surface Preparation by Grit Blasting Cleaning and Application of Primer 1. ScopeCorrosion FactoryNo ratings yet

- Cortec, VpCI-371 Application GuideDocument2 pagesCortec, VpCI-371 Application Guidemonserrat PereaNo ratings yet

- 018 Insitu FlooringDocument4 pages018 Insitu FlooringAnonymous 3eHGEDbxNo ratings yet

- Corro-Coat PE Series 50Document4 pagesCorro-Coat PE Series 50Biju_PottayilNo ratings yet

- Process Bulletin: 3000-A - Solid Film Lubricants & Engineered CoatingsDocument5 pagesProcess Bulletin: 3000-A - Solid Film Lubricants & Engineered CoatingsValentinNo ratings yet

- G16S-0202-07 - Two Layer PaintingDocument7 pagesG16S-0202-07 - Two Layer Paintingpuwarin naja100% (1)

- 23T3 SeriesDocument5 pages23T3 SeriesEliana FLTNo ratings yet

- Site Paint Repair Procedure IntumescentDocument4 pagesSite Paint Repair Procedure Intumescentrimshadtp100% (3)

- Ciclo Di Verniciatura: Proprietà TecnicheDocument9 pagesCiclo Di Verniciatura: Proprietà TecnicheMaffone NumerounoNo ratings yet

- TJY STRUC Methos StateDocument16 pagesTJY STRUC Methos StatewdavidchristopherNo ratings yet

- TDS 1493 Solvalitt Midtherm Euk GBDocument5 pagesTDS 1493 Solvalitt Midtherm Euk GBlee loqueNo ratings yet

- Surface Preparation & Paint Procedure (RevB)Document19 pagesSurface Preparation & Paint Procedure (RevB)Mohd Taufiq IsmailNo ratings yet

- Blasting &painting Pocedures MTD SOP 15 01Document1 pageBlasting &painting Pocedures MTD SOP 15 01vinothNo ratings yet

- Gre Pipe Technical Documents PDFDocument64 pagesGre Pipe Technical Documents PDFSunriseNo ratings yet

- PA02 Spec MIT Spot & Soda Blasting (IFC)Document7 pagesPA02 Spec MIT Spot & Soda Blasting (IFC)Mohd YusriNo ratings yet

- Standard Paint Finish: Keeping The World FlowingDocument2 pagesStandard Paint Finish: Keeping The World FlowingEmiliano PazNo ratings yet

- AS10169Document11 pagesAS10169JOECOOL67No ratings yet

- LOBP SHELL 3-9 Maret 2014Document3 pagesLOBP SHELL 3-9 Maret 2014dian prihatmeikoNo ratings yet

- Method Statement For Steel Substrate - Unique Eng - 03.10.2023Document2 pagesMethod Statement For Steel Substrate - Unique Eng - 03.10.2023janakaNo ratings yet

- Powder Coat Performance Spec WSS M70J5 C1Document9 pagesPowder Coat Performance Spec WSS M70J5 C1Michal BílekNo ratings yet

- Painting & Coating Interview QuestionsDocument28 pagesPainting & Coating Interview QuestionsAswin sukumaranNo ratings yet

- Method of StatementDocument10 pagesMethod of StatementNaim ZeghriniNo ratings yet

- Painting Instructions For Domestic Projects: Document No. 70008187Document7 pagesPainting Instructions For Domestic Projects: Document No. 70008187Baskaran BossNo ratings yet

- M&C-PCN-100-2013 DraftDocument31 pagesM&C-PCN-100-2013 DraftManoj KumarNo ratings yet

- TDS 37942 Barrier 80 S Euk GBDocument5 pagesTDS 37942 Barrier 80 S Euk GBHung Mai VanNo ratings yet

- MDTS 262rev 02 04.11.2020Document6 pagesMDTS 262rev 02 04.11.2020Abhey DograNo ratings yet

- Tada, Sricity: Control Conponent India Private LimitedDocument1 pageTada, Sricity: Control Conponent India Private LimitedBhanuvikas CHNo ratings yet

- Painting Procedure (Repainting Flow Indicator)Document6 pagesPainting Procedure (Repainting Flow Indicator)nds setyawanNo ratings yet

- Corro-Coat PE Series 50: Technical Data SheetDocument3 pagesCorro-Coat PE Series 50: Technical Data SheetBiju_PottayilNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- J.C. Leyendecker American PDF DownloadDocument10 pagesJ.C. Leyendecker American PDF DownloadArnab Mondal0% (2)

- Sea of Fog by Caspar David FriedrichDocument11 pagesSea of Fog by Caspar David Friedrichapi-474938119No ratings yet

- 01 - Bill Nye Light and Colour 1 PageDocument1 page01 - Bill Nye Light and Colour 1 PageTracey MusclowNo ratings yet

- Math SBA Sample - 2018Document19 pagesMath SBA Sample - 2018curdellferron2018No ratings yet

- Apex Ultima: Product BenefitsDocument2 pagesApex Ultima: Product BenefitssudhakarrrrrrNo ratings yet

- By: Gwen Jade B. Vinuya 9-FaradayDocument4 pagesBy: Gwen Jade B. Vinuya 9-FaradayPATRICIA ANGELICA VINUYANo ratings yet

- Edited - Q4 - Adm Module - 1 10 Illustration 9 1Document33 pagesEdited - Q4 - Adm Module - 1 10 Illustration 9 1oliver naragNo ratings yet

- Font Pairing Guide FW 2023 UpdateDocument13 pagesFont Pairing Guide FW 2023 Updateandreeacerna04No ratings yet

- News-Article MacasiebDocument1 pageNews-Article MacasiebJohn Rey MacasiebNo ratings yet

- Week 13 - Module 14 Local ArtsDocument4 pagesWeek 13 - Module 14 Local Artstomiwa iluromiNo ratings yet

- Art - An IntroductionDocument32 pagesArt - An IntroductionJuan Dela CruzNo ratings yet

- Nursery Activity Book 1Document36 pagesNursery Activity Book 1Mrs Jyoti GolakiaNo ratings yet

- Quotation For Fabrication Works: Material Purchase, Fabrication Cost 10ft High Cube Shipping ContainerDocument4 pagesQuotation For Fabrication Works: Material Purchase, Fabrication Cost 10ft High Cube Shipping ContaineroiboriowoNo ratings yet

- Gawad Sa Manlilikha NG BayanDocument16 pagesGawad Sa Manlilikha NG BayanMariel BurceNo ratings yet

- Evan Lindquist, Old InkDocument1 pageEvan Lindquist, Old InkMichal SlavNo ratings yet

- Art in Early CivilizationDocument24 pagesArt in Early CivilizationJomari Gavino100% (1)

- Soul Making Appropriation and Improvisation PDFDocument6 pagesSoul Making Appropriation and Improvisation PDFMaria Christyll Gene SolilapNo ratings yet

- Ferrari: Full-Size Wood ToyDocument10 pagesFerrari: Full-Size Wood ToyErv Hill100% (3)

- Fashion Styling: - Rojina Pandit Fashion Designer / Stylist/ Makeup ArtistDocument15 pagesFashion Styling: - Rojina Pandit Fashion Designer / Stylist/ Makeup ArtistRohan MaharjanNo ratings yet

- Unit 1 - Introduction To HumanitiesDocument41 pagesUnit 1 - Introduction To HumanitiesCarl Zornosa100% (1)

- Azerbaijan Ceramics of The Ancient PeriodDocument45 pagesAzerbaijan Ceramics of The Ancient PeriodRisus ChanNo ratings yet

- E9 - Review Unit 1Document5 pagesE9 - Review Unit 1Nguyễn Phương Dung0% (1)

- DRC Application Ombelle 300 Ne 3Rd Street Fort Lauderdale, FL Date Submitted: 04/21/2022Document85 pagesDRC Application Ombelle 300 Ne 3Rd Street Fort Lauderdale, FL Date Submitted: 04/21/2022the next miami100% (1)

- BOQ Proposed Completion of Three Storey Building For Isolation RoomsDocument12 pagesBOQ Proposed Completion of Three Storey Building For Isolation RoomsJake CanlasNo ratings yet

- Joinery and Fitting (Wooden Doors Detail-Flush) : Department of Interior & Furniture Design LsadDocument17 pagesJoinery and Fitting (Wooden Doors Detail-Flush) : Department of Interior & Furniture Design LsadAnmol MehanNo ratings yet

- 21 Century Arts in AsiaDocument45 pages21 Century Arts in AsiaJannel SanielNo ratings yet

- Ramson - Abp Iii Construction: Architects Engineers Builders ContractorsDocument5 pagesRamson - Abp Iii Construction: Architects Engineers Builders ContractorsJunrey SabladNo ratings yet

CI-WI-002 - Blasting & Painting - R1.1

CI-WI-002 - Blasting & Painting - R1.1

Uploaded by

Joe DsouzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CI-WI-002 - Blasting & Painting - R1.1

CI-WI-002 - Blasting & Painting - R1.1

Uploaded by

Joe DsouzaCopyright:

Available Formats

Instruction

<QA-Inspection>

<India/Mumbai>

Work Instruction (WI) for Blasting & Painting

(CCM Equipments)

1.0 After fabrication all temporary cleats and lugs attachments should be removed and area

under them should be ground smooth.

2.0 All the surfaces to be painted should be cleaned with turpentine / GP thinner to remove

oil, grease, dirt, and dust.

3.0 SURFACE PREPARATION :

3.1 Weld spatter shall be removed, and sharp or rough welds rounded and contoured. Sharp

edges shall be rounded or chamfered.

3.2 Surface to be coated shall be free of all grease, oil, loose rust, and loose mill scale. Oil

and grease shall be removed by solvent cleaning method (turpentine / GP thinner) only.

3.3.1 Rust, mill scale, weld spatter, flux, and shall be removed by abrasive blasting with the

cleaned surface conforming to Sa 2.5 quality of Swedish Specification.

3.3.2 The surface profile depth of 50-80 micron shall be achieved by using a medium that

has good angularity of form, sharp cutting edges and is substantially free from “half rounds”.

3.3.3 Abrasive used should be preferably chilled CI grits/Shots with good angularity.

3.3.4 Surface prepared for Primer coating shall be coated within 3 hours on or before any

visible rusting occurs (Atmospheric conditions), whichever is earlier, failing which the surface

should be re-blasted.

Sand / Shot Blasting Testing :

The Sand / shot – blasted surface shall be visually checked for proper cleaning to Near White

Metal quality with Surface Comparator gauge Or Surface Profile gauge.

4.0 PRIMER PAINT :

4.1 The Sand/Shot blasted surface should be coated with Two coat of Zinc Chromate primer

by Airless / Conventional spray gun to give minimum 25-30 micron DFT per Coat as per Point

no. 3.3.4.

4.2 Thinner will be normally added in a proportion as recommended in the product data

sheet / Technical data sheet as attached.

Prepared by: Pradeep Shirke

Document no: CI-WI-002 Page 1 of 3

Formally reviewed by: Prashant Sawant

Version no.: 1.1

Valid as of: 09.10.2019 Released by: Stephen D’Souza Restricted. Copyright © Primetals Technologies. All rights reserved.

Instruction

<QA-Inspection>

<India/Mumbai>

5.0 FINISH PAINT (TOP COAT):

5.1 Two coats of finish paint will be applied over the primer coat by Airless / Conventional

spray gun method to achieve minimum 25-30 micron DFT per Coat.

5.2 Ensure the Primer painted surface to be sanded by 400-600 no. sand paper to prepare

smooth surface before finish / top coat to achieve good finish.

5.3 Thinner will be normally added in a proportion as recommended in the product data

sheet / Technical data sheet as attached.

6.0 APPLICATION:

6.1 Primer and Paint will be applied by Airless Or Conventional spray gun. The air pressure

to the gun will be kept as low as possible to avoid dry spray. The gun will be held at 25 to 30

cms from the surface & a wet coat will be applied with 50% overlap. Do not apply paint when

temperature falls below 10⁰C or rises above 50⁰ C and when relative humidity rises above 90%.

6.2 Ensure the Stripe coating at sharp corners / edges , Welded area shall be carried out

before start of Primer paint as well as for Top coat application.

6.3 All painting (Primer & Top coat) should be carried out by Spray Painting method

only.

7.0 DRYING:

7.1 Primer and Paint each coat of paint shall be allowed to dry as recommended data sheet.

8.0 COATING SYSTEM:

Coating system is as listed below.

TYPE DESCRIPTION CIL Approved Paint Manufacturer

1 Primer – F300 (zinc i) MONOPOL Paints

Chromate) Grey / Yellow

2 Top Coat paint – MONOFER ii) MONOPOL Paints

G341 – QD

3 Thinner (As recommended in iii) MONOPOL Paints

TDS_Painting Specification)

4 Paint Shade / Code Refer CIL Painting Specification(CI-WI-002-01)

Prepared by: Pradeep Shirke

Document no: CI-WI-002 Page 2 of 3

Formally reviewed by: Prashant Sawant

Version no.: 1.1

Valid as of: 09.10.2019 Released by: Stephen D’Souza Restricted. Copyright © Primetals Technologies. All rights reserved.

Instruction

<QA-Inspection>

<India/Mumbai>

OR

TYPE DESCRIPTION CIL Approved Paint Manufacturer

1 Primer – SYNCOAT Epoxy i) ESDEE Paints

(zinc Phosphate) Grey /

Yellow

2 Top Coat paint – SYNCOAT ii) ESDEE Paints

1K

3 Thinner (As recommended in iii) ESDEE Paints

TDS_Painting Specification)

4 Paint Shade / Code Refer CIL Painting Specification(CI-WI-002-01)

9.0 PAINT INSPECTION:

9.1 The primer & paint coats shall be examined visually for proper application & dry film

thickness (DFT) shall be measured with DFT meter & recorded.

TYPE PAINT COATING SPECIFICATION.

1 Primer (One + One Coat) Min. 25-30 micron DFT per Coat.

2 Top Coat (One + One Min. 25-30 micron DFT per Coat.

Coat)

3 Paint Shade / Code RAL – 5019 (CAPRI BLUE) , RAL-1004

(GOLDEN YELLOW), Refer CIL Painting

Specification (CI-WI-002-01)

10.0 After inspection and testing all painted components shall be cleaned to remove stains if

any. If required any touch-up shall be done.

NOTE:

i) Refer CIL Painting specification (CI-WI-002-01) for Paint Shade / Code for CCM Equipment’s.

ii) Ensure the person who is going to perform spray painting operation must be qualified /

Competent.

iii) Ensure the person who is carrying out painting must be wearing appropriate PPE (Personal

Protective Equipment’s), like Safety gloves, safety glass, safety shoes, safety mask…

iv) Ensure the Paint PDS/TDS (Product / Technical data sheet), MSDS (Material safety data sheet)

and SOP (Standard operating procedure ) of the paint manufacturer to be followed strictly.

Prepared by: Pradeep Shirke

Document no: CI-WI-002 Page 3 of 3

Formally reviewed by: Prashant Sawant

Version no.: 1.1

Valid as of: 09.10.2019 Released by: Stephen D’Souza Restricted. Copyright © Primetals Technologies. All rights reserved.

You might also like

- Painting Procedure Chugoku PaintDocument129 pagesPainting Procedure Chugoku PaintKarthik SNo ratings yet

- Linde Forklift Series 1172 Asl10l10bl12l12i Error List en 1407 Service ManualsDocument22 pagesLinde Forklift Series 1172 Asl10l10bl12l12i Error List en 1407 Service Manualslaurenmays140683dpo100% (134)

- YOUNG, Marnin - Realism in The Age of Impressionism Painting and The Politics of TimeDocument270 pagesYOUNG, Marnin - Realism in The Age of Impressionism Painting and The Politics of TimeAnonymous 9ep4UXzRxx100% (4)

- Mix Design DLC-DelDocument9 pagesMix Design DLC-DelSanjay Constructions100% (1)

- SOP 03 SP Painting Procedure PDFDocument5 pagesSOP 03 SP Painting Procedure PDFBalaji Guru100% (2)

- History-Italian Futurism, Art Nouveau Movement &Document23 pagesHistory-Italian Futurism, Art Nouveau Movement &Ayesha roosminNo ratings yet

- ISO 12944 5 C5 Paint System WilkoDocument5 pagesISO 12944 5 C5 Paint System Wilkojayakumar100% (3)

- Road Marking Paint SB AcrylicDocument4 pagesRoad Marking Paint SB AcrylicAngga PratamaNo ratings yet

- Jotafloor EP SL Uni - Abrasion & Impact ResistDocument6 pagesJotafloor EP SL Uni - Abrasion & Impact Resistangelito bernalNo ratings yet

- TDS Jotafloor EP SL UniDocument6 pagesTDS Jotafloor EP SL UniGemilang KubNo ratings yet

- Issue/Rev Details of Changes Date: Name Designation Signature Date LevelDocument6 pagesIssue/Rev Details of Changes Date: Name Designation Signature Date LevelAbhey DograNo ratings yet

- Surface Treatment ProcedureDocument5 pagesSurface Treatment Proceduredeepan85No ratings yet

- Tbqm-Zamil-406-Coat-014Document3 pagesTbqm-Zamil-406-Coat-014Muhammad RizwanNo ratings yet

- JC Ceiling PaintDocument2 pagesJC Ceiling PaintGrace tpplNo ratings yet

- Quality Plan 1325-27 Rev 02 - Blasting PaintingDocument10 pagesQuality Plan 1325-27 Rev 02 - Blasting Paintingsuriya100% (1)

- Cost EconomicsDocument14 pagesCost Economicsamitvaze316No ratings yet

- Painting Procedure: Doc. No.: PLP-PAINT-P001Document9 pagesPainting Procedure: Doc. No.: PLP-PAINT-P001คุณพ่อน้อง บิ๊กบอสNo ratings yet

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua Sua100% (1)

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua SuaNo ratings yet

- B015-79-41-CG-01 Rev 0 - F-19 Specs by EILDocument6 pagesB015-79-41-CG-01 Rev 0 - F-19 Specs by EILSagarBabuNo ratings yet

- REPORT On Improvement in Quality of Paint Used On FIAT Bogies FinalDocument24 pagesREPORT On Improvement in Quality of Paint Used On FIAT Bogies FinalPammy JainNo ratings yet

- BSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartDocument9 pagesBSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartHồng Trung DươngNo ratings yet

- Batch Certificate::::::: SpecificationsDocument1 pageBatch Certificate::::::: SpecificationsMohammed Omer AliNo ratings yet

- Engineering Material Specification: Date Action RevisionsDocument3 pagesEngineering Material Specification: Date Action RevisionsALEX MURPHY100% (1)

- Painting Procedure For CondenceDocument26 pagesPainting Procedure For CondenceNamta GeorgeNo ratings yet

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- Tbqm-Zamil-37-Coat-002Document4 pagesTbqm-Zamil-37-Coat-002Muhammad RizwanNo ratings yet

- Screenshot 2021-07-09 at 4.15.18 PMDocument46 pagesScreenshot 2021-07-09 at 4.15.18 PMYOGENDRAN RAJANDARANNo ratings yet

- Sand BlastingDocument12 pagesSand Blastingazreengamers09No ratings yet

- Application Guide - Jotafloor EP GlassFlakeDocument8 pagesApplication Guide - Jotafloor EP GlassFlakeKenji TanNo ratings yet

- Silcon 090518Document3 pagesSilcon 090518Abhijeet AnkushNo ratings yet

- Wet Blasting Procedure AIFDocument8 pagesWet Blasting Procedure AIFhash117No ratings yet

- 12 06 12 A&C 33 To RVNL Civil Specs DFTDocument5 pages12 06 12 A&C 33 To RVNL Civil Specs DFTRVNL GoaNo ratings yet

- Mythri Metallizing PVT LTD Bangalore Job Procedure For Surface Preparation by Grit Blasting Cleaning and Application of Primer 1. ScopeDocument3 pagesMythri Metallizing PVT LTD Bangalore Job Procedure For Surface Preparation by Grit Blasting Cleaning and Application of Primer 1. ScopeCorrosion FactoryNo ratings yet

- Cortec, VpCI-371 Application GuideDocument2 pagesCortec, VpCI-371 Application Guidemonserrat PereaNo ratings yet

- 018 Insitu FlooringDocument4 pages018 Insitu FlooringAnonymous 3eHGEDbxNo ratings yet

- Corro-Coat PE Series 50Document4 pagesCorro-Coat PE Series 50Biju_PottayilNo ratings yet

- Process Bulletin: 3000-A - Solid Film Lubricants & Engineered CoatingsDocument5 pagesProcess Bulletin: 3000-A - Solid Film Lubricants & Engineered CoatingsValentinNo ratings yet

- G16S-0202-07 - Two Layer PaintingDocument7 pagesG16S-0202-07 - Two Layer Paintingpuwarin naja100% (1)

- 23T3 SeriesDocument5 pages23T3 SeriesEliana FLTNo ratings yet

- Site Paint Repair Procedure IntumescentDocument4 pagesSite Paint Repair Procedure Intumescentrimshadtp100% (3)

- Ciclo Di Verniciatura: Proprietà TecnicheDocument9 pagesCiclo Di Verniciatura: Proprietà TecnicheMaffone NumerounoNo ratings yet

- TJY STRUC Methos StateDocument16 pagesTJY STRUC Methos StatewdavidchristopherNo ratings yet

- TDS 1493 Solvalitt Midtherm Euk GBDocument5 pagesTDS 1493 Solvalitt Midtherm Euk GBlee loqueNo ratings yet

- Surface Preparation & Paint Procedure (RevB)Document19 pagesSurface Preparation & Paint Procedure (RevB)Mohd Taufiq IsmailNo ratings yet

- Blasting &painting Pocedures MTD SOP 15 01Document1 pageBlasting &painting Pocedures MTD SOP 15 01vinothNo ratings yet

- Gre Pipe Technical Documents PDFDocument64 pagesGre Pipe Technical Documents PDFSunriseNo ratings yet

- PA02 Spec MIT Spot & Soda Blasting (IFC)Document7 pagesPA02 Spec MIT Spot & Soda Blasting (IFC)Mohd YusriNo ratings yet

- Standard Paint Finish: Keeping The World FlowingDocument2 pagesStandard Paint Finish: Keeping The World FlowingEmiliano PazNo ratings yet

- AS10169Document11 pagesAS10169JOECOOL67No ratings yet

- LOBP SHELL 3-9 Maret 2014Document3 pagesLOBP SHELL 3-9 Maret 2014dian prihatmeikoNo ratings yet

- Method Statement For Steel Substrate - Unique Eng - 03.10.2023Document2 pagesMethod Statement For Steel Substrate - Unique Eng - 03.10.2023janakaNo ratings yet

- Powder Coat Performance Spec WSS M70J5 C1Document9 pagesPowder Coat Performance Spec WSS M70J5 C1Michal BílekNo ratings yet

- Painting & Coating Interview QuestionsDocument28 pagesPainting & Coating Interview QuestionsAswin sukumaranNo ratings yet

- Method of StatementDocument10 pagesMethod of StatementNaim ZeghriniNo ratings yet

- Painting Instructions For Domestic Projects: Document No. 70008187Document7 pagesPainting Instructions For Domestic Projects: Document No. 70008187Baskaran BossNo ratings yet

- M&C-PCN-100-2013 DraftDocument31 pagesM&C-PCN-100-2013 DraftManoj KumarNo ratings yet

- TDS 37942 Barrier 80 S Euk GBDocument5 pagesTDS 37942 Barrier 80 S Euk GBHung Mai VanNo ratings yet

- MDTS 262rev 02 04.11.2020Document6 pagesMDTS 262rev 02 04.11.2020Abhey DograNo ratings yet

- Tada, Sricity: Control Conponent India Private LimitedDocument1 pageTada, Sricity: Control Conponent India Private LimitedBhanuvikas CHNo ratings yet

- Painting Procedure (Repainting Flow Indicator)Document6 pagesPainting Procedure (Repainting Flow Indicator)nds setyawanNo ratings yet

- Corro-Coat PE Series 50: Technical Data SheetDocument3 pagesCorro-Coat PE Series 50: Technical Data SheetBiju_PottayilNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- J.C. Leyendecker American PDF DownloadDocument10 pagesJ.C. Leyendecker American PDF DownloadArnab Mondal0% (2)

- Sea of Fog by Caspar David FriedrichDocument11 pagesSea of Fog by Caspar David Friedrichapi-474938119No ratings yet

- 01 - Bill Nye Light and Colour 1 PageDocument1 page01 - Bill Nye Light and Colour 1 PageTracey MusclowNo ratings yet

- Math SBA Sample - 2018Document19 pagesMath SBA Sample - 2018curdellferron2018No ratings yet

- Apex Ultima: Product BenefitsDocument2 pagesApex Ultima: Product BenefitssudhakarrrrrrNo ratings yet

- By: Gwen Jade B. Vinuya 9-FaradayDocument4 pagesBy: Gwen Jade B. Vinuya 9-FaradayPATRICIA ANGELICA VINUYANo ratings yet

- Edited - Q4 - Adm Module - 1 10 Illustration 9 1Document33 pagesEdited - Q4 - Adm Module - 1 10 Illustration 9 1oliver naragNo ratings yet

- Font Pairing Guide FW 2023 UpdateDocument13 pagesFont Pairing Guide FW 2023 Updateandreeacerna04No ratings yet

- News-Article MacasiebDocument1 pageNews-Article MacasiebJohn Rey MacasiebNo ratings yet

- Week 13 - Module 14 Local ArtsDocument4 pagesWeek 13 - Module 14 Local Artstomiwa iluromiNo ratings yet

- Art - An IntroductionDocument32 pagesArt - An IntroductionJuan Dela CruzNo ratings yet

- Nursery Activity Book 1Document36 pagesNursery Activity Book 1Mrs Jyoti GolakiaNo ratings yet

- Quotation For Fabrication Works: Material Purchase, Fabrication Cost 10ft High Cube Shipping ContainerDocument4 pagesQuotation For Fabrication Works: Material Purchase, Fabrication Cost 10ft High Cube Shipping ContaineroiboriowoNo ratings yet

- Gawad Sa Manlilikha NG BayanDocument16 pagesGawad Sa Manlilikha NG BayanMariel BurceNo ratings yet

- Evan Lindquist, Old InkDocument1 pageEvan Lindquist, Old InkMichal SlavNo ratings yet

- Art in Early CivilizationDocument24 pagesArt in Early CivilizationJomari Gavino100% (1)

- Soul Making Appropriation and Improvisation PDFDocument6 pagesSoul Making Appropriation and Improvisation PDFMaria Christyll Gene SolilapNo ratings yet

- Ferrari: Full-Size Wood ToyDocument10 pagesFerrari: Full-Size Wood ToyErv Hill100% (3)

- Fashion Styling: - Rojina Pandit Fashion Designer / Stylist/ Makeup ArtistDocument15 pagesFashion Styling: - Rojina Pandit Fashion Designer / Stylist/ Makeup ArtistRohan MaharjanNo ratings yet

- Unit 1 - Introduction To HumanitiesDocument41 pagesUnit 1 - Introduction To HumanitiesCarl Zornosa100% (1)

- Azerbaijan Ceramics of The Ancient PeriodDocument45 pagesAzerbaijan Ceramics of The Ancient PeriodRisus ChanNo ratings yet

- E9 - Review Unit 1Document5 pagesE9 - Review Unit 1Nguyễn Phương Dung0% (1)

- DRC Application Ombelle 300 Ne 3Rd Street Fort Lauderdale, FL Date Submitted: 04/21/2022Document85 pagesDRC Application Ombelle 300 Ne 3Rd Street Fort Lauderdale, FL Date Submitted: 04/21/2022the next miami100% (1)

- BOQ Proposed Completion of Three Storey Building For Isolation RoomsDocument12 pagesBOQ Proposed Completion of Three Storey Building For Isolation RoomsJake CanlasNo ratings yet

- Joinery and Fitting (Wooden Doors Detail-Flush) : Department of Interior & Furniture Design LsadDocument17 pagesJoinery and Fitting (Wooden Doors Detail-Flush) : Department of Interior & Furniture Design LsadAnmol MehanNo ratings yet

- 21 Century Arts in AsiaDocument45 pages21 Century Arts in AsiaJannel SanielNo ratings yet

- Ramson - Abp Iii Construction: Architects Engineers Builders ContractorsDocument5 pagesRamson - Abp Iii Construction: Architects Engineers Builders ContractorsJunrey SabladNo ratings yet