Professional Documents

Culture Documents

To: Holders of Avtechtyee Component Maintenance Manual (CMM) 33-20-08, Revision 11, June 3, 2019. Revision 12: January 22, 2020 Highlights

To: Holders of Avtechtyee Component Maintenance Manual (CMM) 33-20-08, Revision 11, June 3, 2019. Revision 12: January 22, 2020 Highlights

Uploaded by

Thanh VoCopyright:

Available Formats

You might also like

- Musical Acoustics PDFDocument26 pagesMusical Acoustics PDFGino Mendoza0% (1)

- Professional Practice Session 1Document23 pagesProfessional Practice Session 1Dina HawashNo ratings yet

- Jolly Grammar Programme P1-6Document8 pagesJolly Grammar Programme P1-6Mandy Whorlow100% (3)

- User Guide V 1.4: February 2019Document56 pagesUser Guide V 1.4: February 2019Thanh VoNo ratings yet

- JEA Rules and Regulations For Electric ServiceDocument168 pagesJEA Rules and Regulations For Electric ServiceJonathan FerueloNo ratings yet

- Primary Clarifiers PDFDocument163 pagesPrimary Clarifiers PDFHNo ratings yet

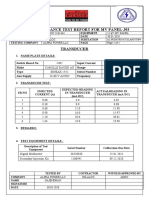

- Site Acceptance Test Report For MV Panel-J03Document1 pageSite Acceptance Test Report For MV Panel-J03Gajendran SriramNo ratings yet

- 3c841 Bumi Unit 1Document725 pages3c841 Bumi Unit 1Jacob Mbang100% (1)

- All About SAP - How To Use F110 in Sap - Step by StepDocument3 pagesAll About SAP - How To Use F110 in Sap - Step by StepAnanthakumar ANo ratings yet

- Be1-50 51MDocument74 pagesBe1-50 51Mgepewin2009No ratings yet

- Aec Q101-004Document7 pagesAec Q101-004mathurashwaniNo ratings yet

- 869 - IEC - 61000-4-6 Conducted RF ImmunityDocument7 pages869 - IEC - 61000-4-6 Conducted RF Immunityandrez880103No ratings yet

- Installation and Operation Manual of Air Conditioning UnitDocument31 pagesInstallation and Operation Manual of Air Conditioning Unitசர்வமும் சிவமயம்No ratings yet

- MIL STD 461F PresentationDocument11 pagesMIL STD 461F Presentationkamran75No ratings yet

- B300 Manual Binder Complete (01487-000 June2008)Document48 pagesB300 Manual Binder Complete (01487-000 June2008)bassemNo ratings yet

- Basler BE1-87B ManualDocument76 pagesBasler BE1-87B ManualstuartsjgNo ratings yet

- MQ SP e 6018Document8 pagesMQ SP e 6018jaseel kNo ratings yet

- Online TS 3.02.04 I5Document31 pagesOnline TS 3.02.04 I5akmezimNo ratings yet

- H4A71110 Vol-1 AllDocument134 pagesH4A71110 Vol-1 AllDwijaputra Templorer100% (1)

- Motor Control Center: Transportadora de Gas Del PeruDocument9 pagesMotor Control Center: Transportadora de Gas Del PeruDavid CamposNo ratings yet

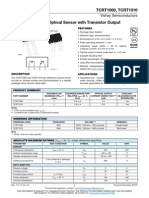

- TCRT 1000Document10 pagesTCRT 1000Boppudi Sasi BinduNo ratings yet

- Modificacion Arnes Sensor Temp Motores Eh4000ac2Document12 pagesModificacion Arnes Sensor Temp Motores Eh4000ac2willy torresNo ratings yet

- GE Proteus XR-A X-Ray - User Manual-20Document1 pageGE Proteus XR-A X-Ray - User Manual-20Elvira RodNo ratings yet

- Enviro MAN 21 00 08rev17Document85 pagesEnviro MAN 21 00 08rev17mguilbeaultNo ratings yet

- Megohmmeter: User Instruction Manual Barfield M/N 2471FDocument27 pagesMegohmmeter: User Instruction Manual Barfield M/N 2471FDavid Santiago GiraldoNo ratings yet

- Publication TransmittalDocument11 pagesPublication TransmittalturboshaftNo ratings yet

- Isat 100 Opd Soi - R02 010Document33 pagesIsat 100 Opd Soi - R02 010874895No ratings yet

- 7200040907-Jwwf-Ee-073-01 Earthing and Lightning System Tech Spec and Data SheetDocument12 pages7200040907-Jwwf-Ee-073-01 Earthing and Lightning System Tech Spec and Data SheetAnwesh Kumar MaddikuntaNo ratings yet

- 111 - CT-NCT Spec-Dec, 2012Document27 pages111 - CT-NCT Spec-Dec, 2012SURJIT SINGHNo ratings yet

- Enterprise Elec 1 MW 2017 Test Report OETDocument33 pagesEnterprise Elec 1 MW 2017 Test Report OETJim OConnorNo ratings yet

- CH93 Clock ManualDocument32 pagesCH93 Clock ManualAnonymous JKGHHgcSMNo ratings yet

- Installation, Operation and Maintenance Manual For at Series Air Conditioning UnitsDocument32 pagesInstallation, Operation and Maintenance Manual For at Series Air Conditioning UnitsEchebiri CollinsNo ratings yet

- CB Test CertificateDocument3 pagesCB Test Certificatemarino palmaresNo ratings yet

- 8series Type Test Report Safety Insulation Resistance Test EN/IEC60255-5: 2000Document7 pages8series Type Test Report Safety Insulation Resistance Test EN/IEC60255-5: 2000andrez880103No ratings yet

- CN 0160 & CN 0161 Concrete Compression MachineDocument54 pagesCN 0160 & CN 0161 Concrete Compression Machinek5sksngkdsNo ratings yet

- Addressable Fire Alarm System Quote Soch Phoenix Mall of AsiaDocument1 pageAddressable Fire Alarm System Quote Soch Phoenix Mall of AsiaKhuzemaBarodawalaNo ratings yet

- Orden de Ingeniería AD 2012-24-08Document68 pagesOrden de Ingeniería AD 2012-24-08Jóse Cedano100% (1)

- HSRAmdtDocument50 pagesHSRAmdtAkash ShindeNo ratings yet

- Naval Headquarters Directorate of Electrical EngineeringDocument50 pagesNaval Headquarters Directorate of Electrical EngineeringAjin ShaNo ratings yet

- DownloadDocument94 pagesDownloadDario Pazmiño CuevaNo ratings yet

- Nokia AZHL DSDocument48 pagesNokia AZHL DSIrfan AzizNo ratings yet

- M&e Quotation - SSK - Thingangyun - 10062020 PDFDocument10 pagesM&e Quotation - SSK - Thingangyun - 10062020 PDFPan Pwint HlaingNo ratings yet

- Freelander - Fuel Pressure Sensor Repair Harness (LTB00052) Technical Service BulletinDocument3 pagesFreelander - Fuel Pressure Sensor Repair Harness (LTB00052) Technical Service BulletinfelborbaNo ratings yet

- Function Test RelayDocument123 pagesFunction Test RelayesutjiadiNo ratings yet

- Sub 011 Submittal Package - 16158 Variable Frequency Drives-1Document460 pagesSub 011 Submittal Package - 16158 Variable Frequency Drives-1Thangarajan NagarajanNo ratings yet

- Addendum No. 3Document84 pagesAddendum No. 3Anik4uNo ratings yet

- DAC1 24 05 Rev 1Document3 pagesDAC1 24 05 Rev 1vanNo ratings yet

- QS1QS1A LATAM CertifacationDocument13 pagesQS1QS1A LATAM Certifacationsteven6diaz-2No ratings yet

- CT Spec Revision 2015Document29 pagesCT Spec Revision 2015Gurmeet SinghNo ratings yet

- 8 Series Type Test Report EMI Power Frequency Immunity Test IEC60255-22-7: 2003Document11 pages8 Series Type Test Report EMI Power Frequency Immunity Test IEC60255-22-7: 2003andrez880103No ratings yet

- TP0000056 (C) Oil ModuleDocument106 pagesTP0000056 (C) Oil ModuleCarlosNo ratings yet

- Ms 27488Document9 pagesMs 27488echobravo1No ratings yet

- AA08024 Fit Large DC To AC ConvertorDocument4 pagesAA08024 Fit Large DC To AC ConvertorHECTORNo ratings yet

- Quectel Antenna YE0007AA Datasheet V3 1-2001030Document20 pagesQuectel Antenna YE0007AA Datasheet V3 1-2001030Ivan MišetićNo ratings yet

- Karnataka Power Transmission Corporation Limited: Bid Enquiry No. Kptcl/Cee/T&P/220Kv/Mittemari/Ptk/ Tlss-701Document397 pagesKarnataka Power Transmission Corporation Limited: Bid Enquiry No. Kptcl/Cee/T&P/220Kv/Mittemari/Ptk/ Tlss-701harishNo ratings yet

- Crown Ce1000 Ce2000 Ce SeriesDocument581 pagesCrown Ce1000 Ce2000 Ce SeriesalexNo ratings yet

- VSD ManualDocument127 pagesVSD Manualvisakhgs0% (1)

- Service BulletinDocument9 pagesService BulletinjussmeeeNo ratings yet

- SamplecertDocument2 pagesSamplecertAsongwe HansNo ratings yet

- Service Bulletin: This Revision Adds More Information Concerning Visual Recognition For Devices AffectedDocument11 pagesService Bulletin: This Revision Adds More Information Concerning Visual Recognition For Devices AffectedjussmeeeNo ratings yet

- t3314 1 El SPC 001 Ra1 Low Voltage MccsDocument19 pagest3314 1 El SPC 001 Ra1 Low Voltage MccsPablo Barrios CNo ratings yet

- EMC Technical File: 1.1. Object: Digital Proximity SystemDocument7 pagesEMC Technical File: 1.1. Object: Digital Proximity SystemВладимир СкорняковNo ratings yet

- Operation and Maintenance Manual For The 7200 Antenna Control SystemDocument250 pagesOperation and Maintenance Manual For The 7200 Antenna Control SystemIrancell TellNo ratings yet

- Ti SPC Psi Protct 5071 06-2014Document26 pagesTi SPC Psi Protct 5071 06-2014Kajal SarkarNo ratings yet

- Technical Data: PNP High Power Silicon TransistorDocument3 pagesTechnical Data: PNP High Power Silicon TransistorThanh VoNo ratings yet

- Ups 2020 2025Document140 pagesUps 2020 2025Thanh VoNo ratings yet

- ReceiptDocument1 pageReceiptThanh VoNo ratings yet

- MessageDocument2 pagesMessageThanh VoNo ratings yet

- 07-35-05 New, Replacement and Modification PartsDocument25 pages07-35-05 New, Replacement and Modification PartsThanh VoNo ratings yet

- Ad3215-31 Airbus Battery UnserviceableDocument1 pageAd3215-31 Airbus Battery UnserviceableThanh VoNo ratings yet

- Activity 6.3 PDFDocument1 pageActivity 6.3 PDFThanh VoNo ratings yet

- ENISA Secure Software Engineering InitiativesDocument96 pagesENISA Secure Software Engineering InitiativesstrokenfilledNo ratings yet

- Installation, Operation and Maintenance Manual: Rotoclone LVNDocument23 pagesInstallation, Operation and Maintenance Manual: Rotoclone LVNbertan dağıstanlıNo ratings yet

- Roger Dale Stafford, Sr. v. Ron Ward, Warden, Oklahoma State Penitentiary at McAlester Oklahoma Drew Edmondson, Attorney General of Oklahoma, 59 F.3d 1025, 10th Cir. (1995)Document6 pagesRoger Dale Stafford, Sr. v. Ron Ward, Warden, Oklahoma State Penitentiary at McAlester Oklahoma Drew Edmondson, Attorney General of Oklahoma, 59 F.3d 1025, 10th Cir. (1995)Scribd Government DocsNo ratings yet

- Prop Design PacketDocument8 pagesProp Design Packetapi-236024657No ratings yet

- 5 He-Man Vs Skeletor Their Final BattleDocument9 pages5 He-Man Vs Skeletor Their Final BattleRodrigo Sorokin100% (2)

- SocratesDocument10 pagesSocratesarvin paruliNo ratings yet

- How To Cook Pork AdoboDocument3 pagesHow To Cook Pork AdoboJennyRoseVelascoNo ratings yet

- Mitc For DisbursementDocument7 pagesMitc For DisbursementMukesh MishraNo ratings yet

- The Secret Book of JamesDocument17 pagesThe Secret Book of JameslaniNo ratings yet

- Module 3 Segmentation Targeting Positioning FINAL PDFDocument13 pagesModule 3 Segmentation Targeting Positioning FINAL PDFLusiana Lie100% (1)

- Event - Vsphere 7.0 DayDocument71 pagesEvent - Vsphere 7.0 Dayrico devizaNo ratings yet

- Autocad Layout Tutorial - EhowDocument3 pagesAutocad Layout Tutorial - EhowdidlakiranNo ratings yet

- The Role of Green InfrastractureDocument18 pagesThe Role of Green InfrastractureYonaminos Taye WassieNo ratings yet

- A Biblical Philosophy of MinistryDocument11 pagesA Biblical Philosophy of MinistryDavid Salazar100% (4)

- Birinci Pozisyon Notalar Ve IsimleriDocument3 pagesBirinci Pozisyon Notalar Ve IsimleriEmre KözNo ratings yet

- Term Paper (Dev - Econ-2)Document14 pagesTerm Paper (Dev - Econ-2)acharya.arpan08No ratings yet

- The Politics of Plural SocietiesDocument14 pagesThe Politics of Plural SocietiesAngel StephensNo ratings yet

- Leo HistoryDocument14 pagesLeo HistoryJeamil Esthiff Terán ToledoNo ratings yet

- List Peserta Swab Antigen - 5 Juni 2021Document11 pagesList Peserta Swab Antigen - 5 Juni 2021minhyun hwangNo ratings yet

- Edo Mite GenealogiesDocument23 pagesEdo Mite GenealogiesPeace Matasavaii LeifiNo ratings yet

- Engr Qazi Arsalan Hamid AliDocument4 pagesEngr Qazi Arsalan Hamid AliEnpak ArsalanNo ratings yet

- New Hardcore 3 Month Workout PlanDocument3 pagesNew Hardcore 3 Month Workout PlanCarmen Gonzalez LopezNo ratings yet

- Republic of Rhetoric by Abhinav ChandrachudDocument356 pagesRepublic of Rhetoric by Abhinav ChandrachudVinayak Gupta100% (1)

- Dual-Band Wearable Rectenna For Low-Power RF Energy HarvestingDocument10 pagesDual-Band Wearable Rectenna For Low-Power RF Energy HarvestingbabuNo ratings yet

- Bilingualism Problems in NigeriaDocument9 pagesBilingualism Problems in NigeriaBasil OvuNo ratings yet

- Company Feasibility StudyDocument21 pagesCompany Feasibility StudyDesiree Raot RaotNo ratings yet

To: Holders of Avtechtyee Component Maintenance Manual (CMM) 33-20-08, Revision 11, June 3, 2019. Revision 12: January 22, 2020 Highlights

To: Holders of Avtechtyee Component Maintenance Manual (CMM) 33-20-08, Revision 11, June 3, 2019. Revision 12: January 22, 2020 Highlights

Uploaded by

Thanh VoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

To: Holders of Avtechtyee Component Maintenance Manual (CMM) 33-20-08, Revision 11, June 3, 2019. Revision 12: January 22, 2020 Highlights

To: Holders of Avtechtyee Component Maintenance Manual (CMM) 33-20-08, Revision 11, June 3, 2019. Revision 12: January 22, 2020 Highlights

Uploaded by

Thanh VoCopyright:

Available Formats

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

TO: Holders of AvtechTyee Component Maintenance Manual (CMM) 33-20-08,

Revision 11, June 3, 2019.

REVISION 12: January 22, 2020

HIGHLIGHTS

This Revision 12 includes revised testing and calibration procedures and expanded procedures

for cleaning, inspection and check, and repair.

NOTE: The pagination in this revision does not match previous revisions. Please replace

previous versions of CMM 33-20-08 with this Revision 12.

Please direct questions or concerns to AvtechTyee Customer Support at (1) 425.249.4636, or

support@avtechtyee.com

AvtechTyee, Inc.

6500 Merrill Creek Pkwy, Everett, WA 98203

Tel: 425.290.3100 | Fax: 425.513.6474

CAGE: 30242

Section Page Description

Title Page TP-1 Added Revision 12 information.

Record of Revisions RR-1 Added Revision 12 information.

List of Effective Pages LEP-1-4 Added Revision 12 changes.

Testing and Fault Isolation 1001 5.A. Added required test equipment.

1002 5.B. Added dielectric test procedure. Added required

equipment and procedure for insulation resistance test.

1003 Added 7.A. Required equipment for functional test using

TR8170-1-1. Table 1001: Added specifications for true

RMS meter and average sensing meter. 7.B. Added test

setup steps for clarification.

1004 7.C. Added FO17 lamps. 7.C.(4). Added reference to

new Figure 1003.

1005 7.C.(5). Added reference to new Figure 1004. 7.D. was

Test Procedure - 9W Lamp.

1007 Added new Figure 1003. Filament Voltage Test Setup.

1008 Added new Figure 1004. Open Circuit Voltage Test

Setup.

1017 Added new Figure 1006. Added selectable resistor

values to table 1004.

1018 11. A.(3). Added “ range of 630 - 660 Vrms.”

Revision 12: Jan 22/20

33-20-08 HL-1

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

Section Page Description

1020 Added 11.B. Calibration procedure without the ballast

tester.

1021 Added new Figure 1008. Calibration Setup - Option 2.

Cleaning 4001 Table 4001. Added source information for Tex Wipes

and Windex. Added pipe cleaners and 3M Adhesive

Remover. 4.A.(2) CAUTION was NOTE.

Inspection and Check 5001-5003 Updated all content to add specific inspection details and

clearer criteria for acceptable, rejectable, and defect

conditions.

Repair 6002 Table 6002: Added vendor and CAGE info on marked

rows.

6003 Table 6003: Added black touch-up paint.

6004 Added 7. Ballast Exterior Finish Repair.

Special Tools and 9002-9003 Added equipment/consumables to reflect changes in

Equipment CLEANING and INSPECTION AND CHECK.

Illustrated Parts List 10017 Added items 3-533, 3-534, 3A-493, 3A-494.

10018-10019 Added new vendor info to reflect changes in CLEANING

and INSPECTION AND CHECK.

10034 Added items 533, 534, selectable resistors.

10042 Added items 493, 494, selectable resistors.

Revision 12: Jan 22/20

33-20-08 HL-2

8184-9000

CAGE CODE: 30242

6500 Merrill Creek Parkway

Everett, Washington USA 98203

Tel: 425.290.3100

Fax: 425.513.6474

COMPONENT MAINTENANCE MANUAL

WITH

ILLUSTRATED PARTS LIST

Electronic Ballast

AvtechTyee Part Number Boeing Part Number

8184-1 S283U008-16

Revision 12, January 22, 2020

PROPRIETARY RIGHTS NOTICE

THIS DATA IS PROPRIETARY TO AVTECHTYEE INC. DISCLOSURE, REPRODUCTION, OR USE OF THIS DATA FOR ANY PURPOSE IS

NOT AUTHORIZED WITHOUT WRITTEN PERMISSION FROM AVTECHTYEE.

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This document may contain technical data whose export, transfer and/or disclosure is restricted by United States law. Dissemination to non-U.S.

persons, whether in the United States or abroad may require an export license or other authorization.

Export Control Classification Number (ECCN) for the 8184-1 Electronic Ballast is 7A994.

Export Control Classification Number (ECCN) for this CMM 33-20-08 (IPN 8184-9000) is 7E994.

Initial Release: Apr 04/96

Revision 12: Jan 22/20 33-20-08 TP-1

8184-9000

CAGE CODE: 30242

THIS PAGE INTENTIONALLY BLANK

Revision 12: Jan 22/20

33-20-08 TP-2

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

RECORD OF REVISIONS

This Record of Revisions documents the revision of the Component Maintenance Manual as released by

AvtechTyee, Inc. Retain this record in front of the manual. Upon receipt of a revision, insert the revised

pages into the manual. Add a signature/initials and date that the new pages were added the manual.

Rev. Issue Date Date Inserted By

000 Apr 04/96

001 Sep 10/98

002 Oct 05/00

003 Apr 06/01

004 Sep 30/03

005 Nov 20/03

006 Apr 02/09

007 Oct 08/09

008 Jun 10/11

009 Aug 16/12

010 Apr 30/19

011 Jun 03/19

012 Jan 22/20

Revision 12: Jan 22/20

33-20-08 RR-1

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

THIS PAGE INTENTIONALLY BLANK

Revision 12: Jan 22/20

33-20-08 RR-2

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

RECORD OF TEMPORARY REVISIONS

Temporary Revisions are documents produced by AvtechTyee, Inc. that is time-limited data to be used

until it is incorporated, superseded, or withdrawn.

Rev. Issue Date Date Inserted/By Date Removed/By Date Incorporated

Revision 8: Jun 10/11

33-20-08 RTR-1

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

THIS PAGE INTENTIONALLY BLANK

Revision 8: Jun 10/11

33-20-08 RTR-2

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

SERVICE BULLETIN LIST

Service Bulletins are documents produced by AvtechTyee engineering, authorizing a customer or

authorized repair facility to perform modification work on AvtechTyee products.

SB Number Issued Title/Description

8184-33-901 Rev 0 Aug 23/00 Incorporation of this service bulletin reduces internal heat

generation and extends the life of the ballast. This is accomplished

by installing R320 on power PCB 8184-30 PCB ([3-630]), replacing

C307 ([3-360A]). Inductor L301 ([3-440]) is resoldered with silver

solder, transformer T402 ([4- 90]) is tested and the thermal pad

([1-50A]) inside the cover is replaced.

8184-33-903 Jun 11/15 This modification replaces the obsolete buck controller hybrid

SCD313-49-4 (U300) with SCD313-49-5 on the power PCB

(8184-30). Applies to the 8184-1 Mod A Electronic Ballast units

manufactured before June 16, 2015. Incorporating this modification

changes the mod status from Mod A to Mod B.

8184-33-904 Mar 08/16 This modification replaces buck control hybrid SCD313-49-5 (U300

on the power PCB) with SCD313-49-6 to improve reliability when

the input voltage is near the lower limit. Incorporating this

modification changes the mod status from Mod B to Mod C.

Revision 10: Apr 30/19

33-20-08 SB-1

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

THIS PAGE INTENTIONALLY BLANK

Revision 10: Apr 30/19

33-20-08 SB-2

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

LIST OF EFFECTIVE PAGES

Section Page Date

Title Page TP-1 Jan 22/20

TP-2 Jan 22/20

Record of Revisions RR-1 Jan 22/20

RR-2 Jan 22/20

Record of Temporary Revisions RTR-1 Jun 10/11

RTR-2 Jun 10/11

Service Bulletin List SB-1 Apr 30/19

SB-2 Apr 30/19

List of Effective Pages LEP-1 Jan 22/20

LEP-2 Jan 22/20

LEP-3 Jan 22/20

LEP-4 Jan 22/20

Table of Contents TOC-1 Jan 22/20

TOC-2 Jan 22/20

TOC-3 Jan 22/20

TOC-4 Jan 22/20

TOC-5 Jan 22/20

TOC-6 Jan 22/20

TOC-7 Jan 22/20

TOC-8 Jan 22/20

Introduction Intro-1 Apr 30/19

Intro-2 Apr 30/19

Intro-3 Apr 30/19

Intro-4 Apr 30/19

Intro-5 Apr 30/19

Intro-6 Apr 30/19

Intro-7 Apr 30/19

Intro-8 Apr 30/19

Description and Operation 1 Apr 30/19

2 Apr 30/19

3 Apr 30/19

4 Apr 30/19

5 Jun 10/11

6 Jun 10/11

7 Jun 10/11

8 Apr 30/19

9 Jun 10/11

10 Jun 10/11

11 Jun 10/11

Revision 12: Jan 22/20

33-20-08 LEP-1

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

Section Page Date

Description and Operation (Continued) 12 Jun 10/11

Testing and Fault Isolation 1001 Jan 22/20

1002 Jan 22/20

1003 Jan 22/20

1004 Jan 22/20

1005 Jan 22/20

1006 Apr 30/19

1007 Jan 22/20

1008 Jan 22/20

1009 Apr 30/19

1010 Apr 30/19

1011 Apr 30/19

1012 Apr 30/19

1013 Apr 30/19

1014 Apr 30/19

1015 Apr 30/19

1016 Apr 30/19

1017 Jan 22/20

1018 Jan 22/20

1019 Jan 22/20

1020 Jan 22/20

1021 Jan 22/20

1022 Apr 30/19

1023 Apr 30/19

1024 Apr 30/19

Schematics and Wiring Diagrams 2001 Apr 30/19

2002 Apr 30/19

2003 Jun 10/11

2004 Apr 30/19

2005 Apr 30/19

2006 Apr 30/19

2007 Apr 30/19

2008 Apr 30/19

2009 Apr 30/19

2010 Apr 30/19

2011 Apr 30/19

2012 Apr 30/19

Disassembly 3001 Jun 10/11

3002 Apr 30/19

3003 Apr 30/19

3004 Apr 30/19

Revision 12: Jan 22/20

33-20-08 LEP-2

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

Section Page Date

Cleaning 4001 Apr 30/19

4002 Jan 22/20

4003 Apr 30/19

4004 Apr 30/19

Inspection and Check 5001 Jan 22/20

5002 Jan 22/20

5003 Jan 22/20

5004 Jan 22/20

Repair 6001 Jun 03/19

6002 Jan 22/20

6003 Jan 22/20

6004 Jan 22/20

6005 Jun 03/19

6006 Jun 03/19

6007 Jun 03/19

6008 Jun 03/19

6009 Jun 03/19

6010 Jun 03/19

Assembly 7001 Apr 30/19

7002 Apr 30/19

7003 Apr 30/19

7004 Apr 30/19

Fits and Clearances 8001 Apr 30/19

8002 Apr 30/19

Special Tools, Fixtures, and Equipment 9001 Apr 30/19

9002 Jan 22/20

9003 Jan 22/20

9004 Apr 30/19

9005 Apr 30/19

9006 Apr 30/19

Illustrated Parts Lists 10001 Jun 03/19

10002 Jun 03/19

10003 Jun 03/19

10004 Jun 03/19

10005 Jun 03/19

10006 Jun 03/19

10007 Jun 03/19

10008 Jun 03/19

10009 Jun 03/19

10010 Jun 03/19

10011 Jun 03/19

Revision 12: Jan 22/20

33-20-08 LEP-3

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

Section Page Date

Illustrated Parts Lists (Continued) 10012 Jun 03/19

10013 Jun 03/19

10014 Jun 03/19

10015 Jun 03/19

10016 Jun 03/19

10017 Jan 22/20

10018 Jan 22/20

10019 Jan 22/20

10020 Apr 30/19

10021 Apr 30/19

10022 Apr 30/19

10023 Apr 30/19

10024 Apr 30/19

10025 Apr 30/19

10026 Apr 30/19

10027 Apr 30/19

10028 Apr 30/19

10029 Apr 30/19

10030 Apr 30/19

10031 Apr 30/19

10032 Apr 30/19

10033 Apr 30/19

10034 Jan 22/20

10035 Apr 30/19

10036 Apr 30/19

10037 Apr 30/19

10038 Apr 30/19

10039 Apr 30/19

10040 Apr 30/19

10041 Apr 30/19

10042 Jan 22/20

10043 Apr 30/19

10044 Apr 30/19

10045 Apr 30/19

10046 Apr 30/19

10047 Apr 30/19

10048 Apr 30/19

Storage and Transportation 15001 Apr 30/19

15002 Apr 30/19

Revision 12: Jan 22/20

33-20-08 LEP-4

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

TABLE OF CONTENTS

INTRODUCTION

1. Overview ............................................................................................................................... Intro-1

A. Scope ....................................................................................................................... Intro-1

B. Manual Conventions ................................................................................................. Intro-1

C. Manual Sections ....................................................................................................... Intro-2

D. Units and Measures.................................................................................................. Intro-3

E. Product Support Services ......................................................................................... Intro-3

F. Comments or Corrections ........................................................................................ Intro-3

2. Electrostatic Discharge (ESD) Sensitive Devices................................................................. Intro-3

3. Shop Verification ................................................................................................................... Intro-4

4. Abbreviations and Acronyms ................................................................................................ Intro-4

DESCRIPTION AND OPERATION

1. Introduction ................................................................................................................................... 1

2. Modification History ...................................................................................................................... 1

3. Mechanical Description ................................................................................................................. 2

4. Operation ...................................................................................................................................... 5

A. Remote (Operator) On/Off Switch .................................................................................... 5

B. Remote (Operator) Bright/Dim Switch .............................................................................. 5

5. Electrical Description .................................................................................................................... 5

A. Input Section..................................................................................................................... 5

B. Boost Control .................................................................................................................... 6

C. Current Sense/Level Shifter ............................................................................................. 6

D. Buck Control ..................................................................................................................... 6

E. Bridge Hybrid .................................................................................................................... 6

F. Filament Transformer ....................................................................................................... 7

G. ON/OFF and BRIGHT/DIM Circuit ................................................................................... 7

H. Output Short Circuit Protection......................................................................................... 8

6. Integrated Circuits ......................................................................................................................... 8

A. Buck Control Hybrid U300 ................................................................................................ 8

B. Bridge Hybrid U401 (SCD313-30-1)................................................................................. 9

C. On/Off, Bright/Dim Control Hybrid U402 (SCD313-41-1) ............................................... 10

D. Boost Control Hybrid U301 (SCD313-49-3) ................................................................... 11

TESTING AND FAULT ISOLATION

1. Introduction ............................................................................................................................. 1001

2. Test Conditions ....................................................................................................................... 1001

3. UUT Verification ...................................................................................................................... 1001

4. Continuity Test ........................................................................................................................ 1001

Revision 12: Jan 22/20

33-20-08 TOC-1

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

5. Dielectric Test ......................................................................................................................... 1001

A. Equipment Required For This Test ............................................................................ 1001

B. Test Procedure ........................................................................................................... 1002

6. Insulation Resistance Test...................................................................................................... 1002

A. Equipment Required For This Test ............................................................................ 1002

B. Test Procedure ........................................................................................................... 1002

7. Functional Testing - Option 1: Using AvtechTyee Ballast Tester TR8170-1-1 ....................... 1003

A. Equipment Required for Option 1 Functional Testing ................................................ 1003

B. Test Setup .................................................................................................................. 1003

C. Current Test with Two FO40 Lamps or Two FO17 Lamps as the Lamp Load .......... 1004

D. Current test with One FO90 Lamp as the Lamp Load ............................................... 1005

E. Low Voltage On/Off Test (104 Vac Line Input) .......................................................... 1009

F. High Voltage ON/OFF Test (122 Vac Line Input)....................................................... 1010

8. Functional Testing - Option 2: Without AvtechTyee Ballast Tester TR8170-1-1 .................... 1011

A. Required Equipment for Option 2 Function Testing ................................................... 1011

B. Test Setup .................................................................................................................. 1013

C. Current Test with Two FO40 Lamps or Two FO17 Lamps as the Lamp Load .......... 1013

D. Current Test with One FO9 Lamp as the Lamp Load ................................................ 1014

E. Low Voltage ON/OFF Test ......................................................................................... 1014

F. High Voltage ON/OFF Test ........................................................................................ 1015

9. Unit Level Fault Isolation ........................................................................................................ 1016

10. End of Testing and Fault Isolation .......................................................................................... 1017

11. Calibration ............................................................................................................................... 1017

A. Calibration Procedure - Option 1: Using AvtechTyee Tester TR8170-1-1 ................. 1017

B. Calibration - Option 2: Without AvtechTyee Tester TR8170-1-1 ............................... 1020

12. PCB Component Layouts ....................................................................................................... 1021

SCHEMATICS AND WIRING DIAGRAMS

Introduction ....................................................................................................................................... 2001

Figure 2001. 8184-1 Electronic Ballast Block Diagram .................................................................... 2003

Figure 2002. IO PCB Assembly 8184-40, 8184-40-1 ....................................................................... 2005

Figure 2003. Power PCB Assembly 8184-30, 8184-30-1, 8184-30-2 .............................................. 2007

Figure 2004. U300 Buck Hybrid Controller ....................................................................................... 2009

DISASSEMBLY

1. Introduction ............................................................................................................................. 3001

2. Required Equipment ............................................................................................................... 3001

3. Disassembly Procedure .......................................................................................................... 3002

A. Remove the Baseplate ............................................................................................... 3002

B. Remove the Cover...................................................................................................... 3002

C. Disassemble the Electronic Ballast Subassembly ..................................................... 3002

Revision 12: Jan 22/20

33-20-08 TOC-2

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

CLEANING

1. Introduction ............................................................................................................................ 4001

2. Safety Precautions ................................................................................................................. 4001

3. Cleaning Tools and Materials ................................................................................................ 4002

4. Cleaning Procedures ............................................................................................................. 4002

A. Cleaning Printed Circuit Boards (PCBs) and Magnetic Devices

(Transformers/Inductors) ............................................................................................ 4002

B. Cleaning Tarnished Gold Contacts or Fingers ........................................................... 4003

C. Cleaning Metal and Plastic Parts ............................................................................... 4003

INSPECTION AND CHECK

1. Introduction ............................................................................................................................. 5001

2. Necessary Tools and Equipment ............................................................................................ 5001

3. Inspection Procedure .............................................................................................................. 5001

A. Criteria for Passing / Failing Inspection ...................................................................... 5001

B. Visual Inspection - Exterior ......................................................................................... 5002

C. Visual Inspection - Interior .......................................................................................... 5003

REPAIR

1. Introduction ............................................................................................................................. 6001

2. Recommended Tools and Equipment .................................................................................... 6001

3. Standard Torque Requirements for Stainless Steel Fasteners .............................................. 6001

A. Standard Screws and Nuts ......................................................................................... 6001

B. Locking Screws and Nuts ........................................................................................... 6001

4. Recommended Repair Materials ............................................................................................ 6002

5. PCB Repair Procedures ......................................................................................................... 6003

6. Repairing Metal Parts ............................................................................................................. 6003

7. Ballast Exterior Finish Repair ................................................................................................. 6004

8. Repair Notes for Power PCBs 8184-30, 8184-30-1, and 8184-30-2 ...................................... 6004

9. Repair Notes for IO PCBs 8184-40 and 8184-40-1 ................................................................ 6007

ASSEMBLY

1. Introduction ............................................................................................................................. 7001

2. Recommended Tools and Equipment .................................................................................... 7001

3. Required Materials .................................................................................................................. 7001

4. Standard Torque Requirements for Stainless Steel Fasteners .............................................. 7002

A. Standard Screws and Nuts ............................................................................................. 7002

B. Locking Screws and Nuts................................................................................................ 7002

5. Assembly Procedures ............................................................................................................. 7002

A. Assemble the Subassembly ....................................................................................... 7003

B. Top Assembly ............................................................................................................. 7003

Revision 12: Jan 22/20

33-20-08 TOC-3

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

FITS AND CLEARANCE

1. Introduction ............................................................................................................................. 8001

2. Standard Torque Requirements for Stainless Steel Fasteners .............................................. 8001

A. Standard Screws and Nuts ......................................................................................... 8001

B. Locking Screws and Nuts ........................................................................................... 8001

3. Critical Fits .............................................................................................................................. 8001

SPECIAL TOOLS, FIXTURES, AND EQUIPMENT

1. Introduction ............................................................................................................................. 9001

2. Recommended Tools .............................................................................................................. 9001

3. Required Test Equipment ....................................................................................................... 9001

4. Selectable Resistors ............................................................................................................... 9002

5. Cleaning Tools and Materials ................................................................................................. 9002

6. Inspection and Check Tools and Equipment .......................................................................... 9002

7. Repair and Assembly Materials .............................................................................................. 9003

8. Storage and Shipping Materials.............................................................................................. 9003

9. AvtechTyee Testers and Cables............................................................................................. 9004

ILLUSTRATED PARTS LIST

1. Introduction ........................................................................................................................... 10001

2. Equipment Designator Index ................................................................................................ 10001

3. Alpha-Numerical Part Number Index .................................................................................... 10001

4. Optional Vendor Index .......................................................................................................... 10001

5. Vendor Code List .................................................................................................................. 10001

6. Illustrated Parts List .............................................................................................................. 10001

A. Figure and Item Number Column ............................................................................. 10001

B. Part Number Column ................................................................................................ 10001

C. Airline Part Number Column ..................................................................................... 10002

D. Nomenclature Column .............................................................................................. 10002

E. Effectivity Column ..................................................................................................... 10004

F. Units Per Assembly Column ..................................................................................... 10004

7. Illustrations ............................................................................................................................ 10005

8. How To Order Parts .............................................................................................................. 10005

9. Equipment Designator Index ................................................................................................ 10005

10. Alpha-Numeric Part Number Index ....................................................................................... 10009

11. Optional Vendor Index .......................................................................................................... 10015

12. Vendor Code List .................................................................................................................. 10018

IPL Figure 1. 8184-1 Electronic Ballast Assembly ......................................................................... 10020

IPL Figure 2. 8184-21-3 Electronic Ballast Subassembly .............................................................. 10023

IPL Figure 3. 8184-30 Power PCB Assembly ................................................................................ 10026

Revision 12: Jan 22/20

33-20-08 TOC-4

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

IPL Figure 3A. 8184-30-1 and 818430-2 Power PCB Assemblies ................................................. 10036

IPL Figure 4. 8184-40 and 8184-40-1 IO PCB Assembly .............................................................. 10043

STORAGE AND TRANSPORTATION

1. Introduction ........................................................................................................................... 15001

2. Storage Conditions ............................................................................................................... 15001

3. Storage Materials .................................................................................................................. 15001

4. Storage Procedure ................................................................................................................ 15002

5. Transportation/Shipping Procedure ...................................................................................... 15002

Revision 12: Jan 22/20

33-20-08 TOC-5

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

LIST OF FIGURES

Figure Intro- 1. Electronic Ballast 8184-1..............................................................................................Intro-5

Figure Intro- 2. Electronic Ballast 8184-1 Major Subassemblies ..........................................................Intro-6

Figure Intro- 3. Guide to Using the Manual ...........................................................................................Intro-7

Figure 1.8184-1 System Level Block Diagram.............................................................................................. 3

Figure 2. 8184-1 Outline Dimensions ........................................................................................................... 4

Figure 3. U401 Hybrid Bridge Circuit ............................................................................................................ 9

Figure 4. U402 - On/Off, Bright/Dim Control Hybrid ................................................................................... 10

Figure 5. Boost Control Hybrid U301 .......................................................................................................... 11

Figure 1001. Dielectric / Insulation Resistance Test Setup .................................................................... 1002

Figure 1002. Functional Test Setup Using TR8170-1-1 ......................................................................... 1006

Figure 1003. Filament Voltage Test Setup ............................................................................................. 1007

Figure 1004. Open Circuit Voltage Test Setup ....................................................................................... 1008

Figure 1005. Functional Test Setup - Option 2 ....................................................................................... 1012

Figure 1006. Selectable Resistors R303, R304 (Power PCB)................................................................ 1017

Figure 1007. Calibration Setup - Option 1 .............................................................................................. 1019

Figure 1008. Calibration Setup - Option 2 .............................................................................................. 1021

Figure 1009. Power PCB 8184-30, Pre SB 8184-33-901 ....................................................................... 1022

Figure 1010. IO PCB 8184-40 and 8184-40-1 ........................................................................................ 1024

Figure 2001. 8184-1 Electronic Ballast Block Diagram .......................................................................... 2003

Figure 2002. IO PCB Assembly 8184-40, 8184-40-1 ............................................................................. 2005

Figure 2003. Power PCB Assembly 8184-30, 8184-30-1, 8184-30-2 .................................................... 2007

Figure 2004. U300 Buck Controller Hybrid ............................................................................................. 2009

Figure 3001. Electronic Ballast Disassembly .......................................................................................... 3003

Figure 6001. Power PCB 8184-30, 8184-30-1, 8184-30-2 Repair Notes ............................................... 6005

Figure 6002. IO PCB 8184-40 and 8184-40-1 Repair Notes .................................................................. 6008

Figure 7001. Thermal Pad [1-60] Replacement ...................................................................................... 7003

Figure 7002. Electronic Ballast Assembly............................................................................................... 7004

Figure 9001. AvtechTyee Ballast Tester P/N 8170-1-1 .......................................................................... 9004

Figure 9002. AvtechTyee Ballast Tester P/N 8170-1-1 Schematic ........................................................ 9005

Figure 9003. AvtechTyee Test Cables TC8170-1-9 and TC8170-1-40 .................................................. 9006

IPL Figure 1. 8184-1 Electronic Ballast Assembly ................................................................................ 10020

IPL Figure 2. 8184-21-3 Electronic Ballast Subassembly ..................................................................... 10023

IPL Figure 3. 8184-30 Power PCB Assembly ....................................................................................... 10026

IPL Figure 3A. 8184-30-1 and 8184-30-2 Power PCB Assemblies ...................................................... 10036

IPL Figure 4. 8184-40 and 8184-40-1 IO PCB Assembly ..................................................................... 10043

Revision 12: Jan 22/20

33-20-08 TOC-6

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

LIST OF TABLES

Table 1. 8184-1 Mod Level Configuration Changes ..................................................................................... 2

Table 2. Equipment Specifications ................................................................................................................ 2

Table 3. U300 Buck Controller Hybrid Modification History .......................................................................... 8

Table 1001. Equipment Required for Functional Testing Option 1 ......................................................... 1003

Table 1002. Equipment Required for Functional Testing Option 2 ......................................................... 1011

Table 1003. Fault Isolation Guide ........................................................................................................... 1016

Table 1004. Selectable Value Resistors ................................................................................................. 1017

Table 4001. Cleaning Tools and Materials ............................................................................................. 4002

Table 5001. Tools and Equipment Necessary for Inspection and Check ............................................... 5001

Table 6001. Standard Torque Requirements for Stainless Steel Fasteners .......................................... 6002

Table 6002. Recommended Repair Materials - Cleaning ....................................................................... 6002

Table 6003. Repair Materials .................................................................................................................. 6003

Table 7001. Standard Torque Requirements for Stainless Steel Fasteners .......................................... 7002

Table 8001. Standard Torque Requirements for Stainless Steel Fasteners .......................................... 8001

Table 9001. Required Test Equipment ................................................................................................... 9001

Table 9002. Selectable Value Metal Film Resistors for Calibration ........................................................ 9002

Table 9003. Cleaning Materials .............................................................................................................. 9002

Table 9004. Inspection and Check Tools and Equipment ...................................................................... 9002

Table 9005. Repair and Assembly Materials .......................................................................................... 9003

Table 9006. Storage and Shipping Materials .......................................................................................... 9003

Table 15001. Storage and Shipping Materials. ..................................................................................... 15001

Revision 12: Jan 22/20

33-20-08 TOC-7

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

THIS PAGE INTENTIONALLY BLANK

Revision 12: Jan 22/20

33-20-08 TOC-8

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

INTRODUCTION

1. Overview

A. Scope

This manual provides procedures for maintenance, testing, fault isolation, repair, and

replacement of components that comprise the AvtechTyee Electronic Ballast 8184-1.

This Electronic Ballast is manufactured by AvtechTyee, Inc., Everett, Washington, 98203

USA.

This document is prepared, issued, and revised by AvtechTyee, Inc. (AvtechTyee) for the

exclusive use of its customers and is intended for use in provisioning, repair, and

maintenance of the aircraft components described herein.

The content of this document is proprietary to AvtechTyee and its customers and is

subject to change. The use of any part of this document by any other person or persons

for any other purpose without written consent of AvtechTyee is expressly prohibited. In

addition, AvtechTyee expressly disclaims any and all responsibility arising from or in any

way related to any unauthorized use of this manual.

B. Manual Conventions

Users of this manual should be aware of the following information:

1) The format of this manual follows the guidelines of the Air Transport Association

specification (ATA iSpec 2200) for Component Maintenance Manuals and the

Boeing Technical Data Guide D6-54487.

2) Throughout this manual:

WARNING! An operating procedure, technique, etc., that may result in personal injury if

not carefully followed. A warning notice precedes the procedure to which it

applies.

CAUTION: An operating procedure, technique, etc., that may result in damage to

equipment if not carefully followed. The caution precedes the procedure to

which it applies.

NOTE: A note highlights additional information related to a procedure, instruction,

technique, etc.. Information contained in notes may also be safety related.

A note follows the information to which it applies.

Revision 10: Apr 30/19

33-20-08 Intro-1

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

C. Manual Sections

This manual includes the following sections:

(1) HIGHLIGHTS - Describes changes in the current revision

(2) FRONT MATTER - Includes Title Page, List of Effective Pages, Record of

Revisions, Record of Temporary Revisions, Service Bulletin List, Table of

Contents and Introduction.

(3) DESCRIPTION AND OPERATION (page block 1) describes the function,

primary components, operation, and technical properties of the assemblies

covered in this manual.

(4) TESTING AND FAULT ISOLATION (page block 1001) contains bench test,

fault isolation, and calibration procedures.

(5) SCHEMATICS AND WIRING DIAGRAMS (page block 2001).

(6) DISASSEMBLY (page block 3001) contains procedures to disassemble ACP

components for inspection, testing, repair and/or part replacement.

(7) CLEANING (page block 4001) contains procedures to clean ACP components.

(8) INSPECTION AND CHECK (page block 5001) contains procedures to check

parts for excessive wear, corrosion, and other damage.

(9) REPAIR (page block 6001) contains procedures to refinish and rework parts to

serviceable condition.

(10) ASSEMBLY (page block 7001) contains procedures to reassemble ACP

components.

(11) FITS AND CLEARANCES (page block 8001) provides information on torque

values for standard and locking fasteners and in-service wear limits.

(12) SPECIAL TOOLS, FIXTURES, AND EQUIPMENT (page block 9001) contains

a table of recommended special tools, fixtures, and test equipment.

(13) ILLUSTRATED PARTS LIST (IPL) (page block 10001) contains the information

needed to order replacement parts. A list of vendors, numerical index, and

exploded view illustrations are provided to help locate and identify parts.

(14) SPECIAL PROCEDURES (page block 11001) N/A to this manual.

(15) REMOVAL (page block 12001) N/A to this manual..

(16) INSTALLATION (page block 13001) N/A to this manual.

(17) SERVICING (page block 14001) N/A to this manual.

(18) STORAGE AND TRANSPORTATION (page block 15001) provides instructions

for packaging the ACP prior to storage and/or transportation.

Revision 10: Apr 30/19

33-20-08 Intro-2

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

D. Units and Measures

Unless stated otherwise:

All weights and measurements in this manual are in English units, with metric

equivalents in parenthesis.

Abbreviations and symbols for weights and measures follow the conventions of

the National Institute for Standards and Technology (NIST) Guide for the Use of

the International System of Units (SI).

Abbreviations for electrical units are per the Institute of Electrical and Electronics

Engineers (IEEE) Style Manual.

E. Product Support Services

Complete assemblies, replacement parts, and spares are available from AvtechTyee.

AvtechTyee Inc.

6500 Merrill Creek Parkway

Everett, WA 98203-5860

Tel: 425.290.3100

Fax: 425.513.6474

After hours/AOG: 425.290.3100

http://www.avtechtyee.com

CAGE Code: 30242

F. Comments or Corrections

Every effort has been made to give complete and accurate information in this CMM and

to present the information in a clear and concise manner.

If an error or discrepancy is found, or a better procedure for accomplishing a task given in

this CMM is available, please communicate this information to AvtechTyee Customer

Support. The information supplied will be evaluated and the appropriate action taken.

2. Electrostatic Discharge (ESD) Sensitive Devices

CAUTION: ACP components contain electrostatic sensitive devices (ESD) that can be

damaged by electrostatic discharge. Use appropriate ESD precautions and

procedures whenever you see one of these or any other ESD precaution

symbols.

Revision 10: Apr 30/19

33-20-08 Intro-3

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

3. Shop Verification

The following tests and procedures were performed in the AvtechTyee engineering and repair

station by authorized engineers and FAA-authorized repair technicians.

Engineering Technical Review

8184-1 May 27/92

8184-1 Mod A Sep 26/95

8184-1 Mod B Apr 09/15

8184-1 Mod C Nov 05/15

Testing and Fault Isolation Apr15/19

Disassembly Apr15/19

Assembly Apr15/19

4. Abbreviations and Acronyms

The following abbreviations and acronyms are used in this manual:

Abbreviation Definition

A/amp Ampere

ADJ Adjust

ALT/NORM Alternate/Normal

AR As Required

ASSY Assembly

ATA Air Transport Association

AWG American Wire Gage

CAGE Commercial and Government Entity

cm Centimeter

CMM Component Maintenance Manual

DMM Digital Multimeter

ECCN Export Control Classification Number

EMI Electromagnetic Interference

ESD Electrostatic Discharge

ESDS Electrostatic Discharge Sensitive

GND Ground

Hz Hertz

IEEE Institute of Electrical and Electronics Engineers

in. Inch

IPL Illustrated Parts List

kg Kilogram

lb Pound

LED Light Emitting Diode

ms Millisecond

mA Milliampere

MHz Megahertz

N/A Not Applicable (Does not apply)

NHA Next Higher Assembly

OVI Optional Vendor Index

PCB Printed Circuit Board Assembly

P/N Part Number

Revision 10: Apr 30/19

33-20-08 Intro-4

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

Abbreviation Definition

psi Pounds per Square Inch

PTT Push to Test/Push to Talk

PWM Pulse Width Modulator

RF Reference

RMS Root Mean Square

RTCA Radio Technical Communications for Aeronautics

RTN Return

UUT Unit Under Test

Vac Volts Alternating Current

Vdc Volts Direct Current

Figure Intro- 1. Electronic Ballast 8184-1

Revision 10: Apr 30/19

33-20-08 Intro-5

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

Figure Intro- 2. Electronic Ballast 8184-1 Major Subassemblies

Revision 10: Apr 30/19

33-20-08 Intro-6

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

Figure Intro- 3. Guide to Using the Manual

Revision 10: Apr 30/19

33-20-08 Intro-7

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

THIS PAGE INTENTIONALLY BLANK

Revision 10: Apr 30/19

33-20-08 Intro-8

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

DESCRIPTION AND OPERATION

1. Introduction

The AvtechTyee 8184-1 Electronic Ballast is a repairable, dimmable, solid state ballast designed

for use in the Boeing 747-400 cabin. It has a 115 V, 400 Hz input for use with one or two

fluorescent T8 Octron rapid start fluorescent lamps rated at 265 mA nominal lamp current.

Because of its feedback-regulated current, the 8184-1 can drive many combinations of different

length Octron lamps ranging from a single 9 watt lamp to dual 40 watt lamps. A five-to-one step

dimming function is activated by connecting the BRIGHT/DIM control line to the control line

return. Average lamp current in bright mode (265mA) and in dim mode (50mA). Starting voltage is

controlled by means of a feedback path to the BOOST controller IC. A slow start circuit allows the

filaments to be energized for approximately 500 ms before the lamp starts. Filament voltage is

derived from an off-line 400 Hz transformer.

The BOOST controller IC is configured as a power factor correcting stage. This stage keeps the

power factor high and the harmonic distortion low. Constant lamp current is maintained by

sensing and feeding it back to the BUCK controller IC. Power conversion is accomplished at 100

kHz while maintaining the output lamp voltage and current at 400Hz. This allows the use of

relatively small magnetic components to handle the power. The 400Hz lamp output allows for low

EMI generation. The 8184-1 includes a power factor correcting stage at the front end that makes

the ballast look resistive to the line.

The 8184-1 has the capability of shutting off all outputs, while input power is applied, by

connecting the ON/OFF control line to the control line return.

The 8184-1 is designed to withstand considerable abuse without sustaining damage. It can

withstand: Shorted filaments, shorted lamps, and over-temperature.

Figure 1 shows a system-level block diagram of the 8184-1 Electronic Ballast.

2. Modification History

Refer to Table 1 for a summary of 8184-1 modification history.

8184-1 Electronic Ballast was introduced in April, 1995.

8184-1 Mod A was released in September, 1995 per internal change paper. Mod A

addresses a customer request to increase the height of the IO PCB standoff by 0.030 in

(0.076 cm).

8184-1 Mod B, was released in June, 2015 per service bulletin 8184-33-903. Mod B

replaces buck controller hybrid U300, P/N SCD313-49-4 with SCD313-49-5 due to

obsolescence. The IC mounting clip was also revised from 8184-22 to 8184-22-1.

8184-1 Mod C was released in March, 2016 per service bulletin 8184-33-904. Mod C

replaces buck controller hybrid U300, P/N SCD313-49-5 with SCD313-49-6 to improve

DIM mode reliability.

Revision 10: Apr 30/19

33-20-08 Page 1

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

Table 1. 8184-1 Mod Level Configuration Changes

Mod Status MOD A MOD B MOD C

NO MOD

Component S/Ns 100001 and up (SB 8184-33-903) (SB 8184-33-904)

Cover 8184-24 [1-40] 8184-24-1 [1-40A] 8184-24-3 [1-40B] 8184-24-4 [1-40C]

Thermal Pad SCD310-16-1 [1-50] SCD310-16-3 SCD310-16-3 SCD310-16-3 [1-50A]

[1-50A] [1-50A]

Hybrid 8184-22 [1-60] 8184-22 [1-60] 8184-22-1 [1-60A] 8184-22-1 [1-60A]

Mounting Clip

Subassembly 8184-21 [1-70] 8184-21-1 [1-70A] 8184-21-2 [1-70B] 8184-21-3 [1-70C]

Label 7778-1-51 [1-75] 7778-1-51 [1-75] 7778-1-51 [1-75] 000246 [1-75A]

Power PCB 8184-30 [2-10] 8184-30 [2-10] 8184-30-1 [2-10A] 8184-30-2 [2-10B]

IO PCB 8184-40 [2-20] 8184-40-1 [2-20A] 8184-40-1 [2-20A] 8184-40-1 [2-20A]

U300 SCD313-49-1 [3-40] SCD313-49-4 SCD313-49-5 SCD313-49-6

[3-40A] [3A-40] [3A-40A]

IO PCB 8181-25 [4-310] 8184-25 [4-310A] 8184-25 [4-310A] 8184-25 [4-310A]

Standoff

3. Mechanical Description

The 8184-1 Electronic Ballast is housed in a two-piece aluminum chassis that consists of a cover

and base plate. The cover has silkscreened artwork that provides unit identification, mod level,

serial number, date of manufacture, J1 connector pinout, and schematic diagram illustrating

connections to fluorescent lamps. There are no external controls, indicators, service, or

adjustment controls. The ballast connects to aircraft power through the J1 connector on the

IO PCB.

8184-1 Ballast outline dimensions are show in Figure 2. Specifications are listed in Table 2.

Table 2. Equipment Specifications

Feature Specification

Length 7.00 in. (17.78 cm)

Height 1.50 inches (3.8 mm)

Width 2.00 inches (5.1 mm)

Lamp Type T8 Octron fluorescent lamps

Maximum Load 80 watts

Weight 0.73 lb (0.3 kg)

Normal Operating Temperature 20 to 130 °F (-7 to 55 °C)

Maximum Operating Temperature -40 to 158 °F (-40 to 70 °C)

Revision 10: Apr 30/19

33-20-08 Page 2

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

A AND F IS OFF

A OPEN F IS ON

D AND F IS DIM

D OPEN TO F IS BRIGHT

Figure 1. 8184-1 System Level Block Diagram

Revision 10: Apr 30/19

33-20-08 Page 3

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

Figure 2. 8184-1 Outline Dimensions

Revision 10: Apr 30/19

33-20-08 Page 4

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

4. Operation

This 8184-1 Electronic Ballast operates from 115-Vac, 400-Hz aircraft power. The ballast supplies

power to any combination of Octron, T8, rapid-start fluorescent lamps from a single, 9-Watt to

dual, 40-Watt loads. It provides control lines for ON/OFF and BRIGHT/DIM modes. Electronic

feedback controls the ballast. It does not require an impedance in series with the lamp.

A. Remote (Operator) On/Off Switch

The Ballast is switched on / off from a remote location. An open condition between

connector terminals J1-A and J1-F will cause the lamp(s) to come on. A closed condition

between connector terminals J1-A and J1-F will cause the lamp(s) to go off.

B. Remote (Operator) Bright/Dim Switch

Bright or dim operation of the lamp(s) is switched from a remote location. An open

condition between connector terminals J1-D and J1-F puts the lamp(s) in bright mode. A

closed condition between connector terminals J1-D and J1-F puts the lamp(s) in dim

mode..

5. Electrical Description

This circuit description describes the operation of the Ballast from bus input to lamp output.

Schematic diagrams of the Ballast PCBs are shown in the SCHEMATICS AND WIRING

DIAGRAMS section.

A. Input Section

The input section starts at the input terminals J1-E and J1-G and includes the following

components: F401, L401, L402, L403, C401, C402, C409, C417, C418, C450, CR411,

CR412, CR413, CR414, R411, R412 and R450.

(1) Common Mode Filter

The common mode filter decreases common mode signals. Inductor L403

cancels the common mode signals in the input power. This gives a very low

impedance to the input power source and a high impedance to any common

mode signals. Damping resistors R411 and R412 decrease the reactance of filter

capacitors C406 and C407 and prevent ringing.

(2) Differential-mode Filter

Inductors L401 and L402, capacitors C409 and C450 and resistor R450 make a

fourth order filter that decreases differential-mode signals. Capacitor C450 and

resistor R450 decrease the effective capacitance of the center leg of the filter and

maintain the 400 Hz voltage division necessary for transformer T401 and the

control circuit.

(3) Electromagnetic Interference (EMI) Filtering

Inductors L401, L402, and L403, and capacitors C401, C402, C409 filter EMI

from the 115 Vac, 400 Hz aircraft bus power. A diode bridge (CR411, CR412,

CR413, and CR414) rectifies the power. Then, the power goes to the boost

control circuit.

Revision 8: Jun 10/11

33-20-08 Page 5

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

B. Boost Control

The boost control circuit is part of a thick-film hybrid (U301). This hybrid (along with

inductor L301, transistor Q301, diode D302 and capacitor C302) make a boost circuit.

The boost circuit is a current mode circuit that operates through voltage feedback. This

circuit boosts the rectified line voltage to 640 Vdc. The 640 Vdc output goes to the current

sense/level shifter circuit.

NOTE: Do not try to replace any faulty components on the hybrid.

C. Current Sense/Level Shifter

Operational amplifier U302 and transistors Q303 and Q305 make up the current

sense/level shifter circuit. This circuit senses the lamp current and shifts the signal down

to the reference level of the Buck Control hybrid U300.

D. Buck Control

The buck control circuit is part of a thick film hybrid (U300). This hybrid (along with

inductors L302 and L303, diode D305, and transistor Q302) makes a current-feedback,

current-mode buck circuit. The Buck Control circuit decreases the 640 Vdc to the voltage

needed to start and keep an arc in the selected lamp set. The current feedback keeps the

lamp current at a constant 255 mA in bright mode and 50 mA in dim mode.

On hybrid U300, a delayed start circuit delays the high voltage on the lamps until the

filaments are warm (approximately 500 mS).

The Pulse Width Modulator (PWM) Dimming circuit is also part of the hybrid U300. This

circuit decreases the duty cycle of the lamp current during dim mode. This makes an

average dim mode current that is approximately 20% of the bright mode current.

E. Bridge Hybrid

The bridge hybrid (U401) takes the 640

Vdc output from the buck control circuit and converts it to a symmetrical, 400 Hz square

wave to drive the lamps.

NOTE: Treat this hybrid as a single component. Do not try to replace any faulty

components on the hybrid.

The bridge hybrid input is converted to a square wave as each side of the lamp load is

alternately connected between the high voltage rail and circuit ground.

First, transistors Q101 and Q104 are set on, and then reversed biased off as transistors

Q102 and Q103 are set on. The base drive for Q101 and Q103 comes from independent

windings of transformer T402. The base drive for Q102 and Q104 comes from a common

winding because their emitters are connected to circuit ground. Resistors R103, R104

and R405 give proper bias for the transistors. Resistors R111 and R112 give a return

path to ground for stored base current. (Refer to the Figure 2002, sheets 1 and 2 in the

SCHEMATICS section).

Capacitors C126, C127, C128 and C129 decrease the bridge switching frequency, which

reduces radiated emissions.

Revision 8: Jun 10/11

33-20-08 Page 6

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

F. Filament Transformer

The filament transformer (T402) supplies filament voltage for the lamps, bridge drive for

bridge hybrid U401, and power for hybrids U300 and U301. The base drive windings of

T402 supply approximately 5.0 Vrms at 40 mA base current.

(1) Filament Shorting Protection

Transformer T402 is protected from shorted lamp filaments by a thermal limiter in

series with the primary winding of T402. The primary winding opens at 150 °C

and closes at 100 °C. A shorted filament causes the lamp(s) to come on and go

off until the lamp is replaced. The normal resistance of the lamp filament at

operating temperature is 11 ohms.

(2) Housekeeping Power

Transformer T402, diode bridge CR405, and capacitor C419 are the power

source for the PWM IC (U3). The voltage is approximately 12.5 Vdc measured

between U3, pins 9 or 13 and 1 or 14.

G. ON/OFF and BRIGHT/DIM Circuit

Input Hybrid U402, capacitors C409, C417, C418, diodes CR405, CR416, CR417,

transistors Q405, Q406, resistor R410 and transformer T401 make up the ON/OFF and

BRIGHT/DIM circuit. The circuit is totally isolated from circuit ground and provides its own

isolated power. External switches control the ON/OFF and BRIGHT/DIM circuit. Either

the ON/OFF pin (J1-A) or the BRIGHT/DIM pin (J1-D) is connected to the CONTROL

LINE RETURN pin (J1-F).

This circuit has two functions. One is to select the OFF operation (remove both high

voltage and filament voltage from the lamp(s)) by connecting terminals J1-A and J1-F

together. The other is to select the dim operation by connecting terminals J1-D and J1-F

together.

(1) AC Switch

Transformer T401 drives an AC switch that includes diodes CR416, CR417 and

transistors Q405 and Q406. This AC switch is connected in series with the

primary windings of transformer T402.

Primary voltage for T401 comes from a capacitive voltage divider C409, C417

and C418. The T401 primary voltage is 8.2 Vrms when the line voltage is 115

Vrms. The voltage divider shifts the phase of the T401 primary current relative to

the T402 primary current. Resistor R410 limits current through the primary

windings of T401.

(2) Off Control

All outputs are disabled when terminals J1-A and J1-F are connected. This

places a short between T401 pins 5 and 6 and removes the drive to SCRs Q405

and Q406 through the primary windings of T401. This puts an open (high

resistance) circuit in series with the primary windings of T402, making the

lamp(s) go off.

Revision 8: Jun 10/11

33-20-08 Page 7

8184-9000

COMPONENT MAINTENANCE MANUAL

ELECTRONIC BALLAST 8184-1

(3) Dim Control

Ballast Dim mode is actuated when terminals J1-D and J1-F are connected. This

causes current to flow through the LED part of IC U201 on the input Hybrid. The

light from the LED turns on the phototransistor portion of U201. The

phototransistor turns on transistor Q4 in IC U300, the control hybrid. This causes

PWM IC U1 to regulate at a lower current.

H. Output Short Circuit Protection

If any one of the six lamp output terminals (J1-B, J1-C, J1-J, J1-K, J1-L or J1-M) is

accidently shorted to either 115 Vac input or AC return, the Ballast will not be damaged.

Depending on which terminals are shorted, the lamp(s) will either go off immediately or

will come on and go off at a rate of approximately a 10 Hz. In all cases, the input current

and lamp current decrease.

6. Integrated Circuits

A. Buck Control Hybrid U300

Refer to Figure 2004 in the SCHEMATICS section.

The buck control circuit is incorporated into a thick film hybrid (U300). This hybrid (along

with inductors L302 and L303, diode D305, and transistor Q302) makes a current-

feedback, current-mode buck circuit. The buck circuit decreases the 640 Vdc to the

voltage necessary to start and maintain an arc in the selected lamp set. The current

feedback keeps the lamp current at a constant 255 mA in bright mode and 50 mA in dim

mode. Transistor Q1 and capacitor C5 make up a delayed start circuit. This circuit delays

the high voltage on the lamps until the filaments are warm (approximately 500 ms).

The PWM dimming circuit decreases the duty cycle of the lamp current during dim mode.

The average dim mode current is approximately 20% of the bright mode current.

Modification history for U300, P/N SCD313-49-X is shown below in

Table 3. U300 Buck Controller Hybrid Modification History

Part Number Used On

SCD313-49-1 8184-1, 8184-1 Mod A

SCD313-49-4 8184-1, 8184-1 Mod A