Professional Documents

Culture Documents

2 - Referecne Documentsettling Basin (Civil Engineering Works of Small High-Head Hydropower Plants (SHP) )

2 - Referecne Documentsettling Basin (Civil Engineering Works of Small High-Head Hydropower Plants (SHP) )

Uploaded by

Muhammad Mohsin0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

2_referecne documentSettling Basin (civil engineering works of small high-head hydropower plants(SHP))

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views1 page2 - Referecne Documentsettling Basin (Civil Engineering Works of Small High-Head Hydropower Plants (SHP) )

2 - Referecne Documentsettling Basin (Civil Engineering Works of Small High-Head Hydropower Plants (SHP) )

Uploaded by

Muhammad MohsinCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

4.

2 Settling basin (sand trap)

The settling basin is located downstream of the intake and permits to separate the sand from the

incoming water and to prevent them from settling in the headrace conduit or being carried

through the turbine, which causes abrasion and a decrease of the turbine’s life and efficiency.

The longitudinal settling basin consists of one or two chambers of sufficient length with sloping

bottoms to allow the sediment particles to settle down. Before entering the main basin, water will

pass through a transition part with stilling rack system for creating a uniform flow distribution. In

the high mountains the desander basins have to be protected in certain cases against

avalanches and stonefalls. They can be built into caverns or covered with concrete plates. In

lower regions, the desanders do not have to be covered.

For the purpose of this study, two well known types of settling basins, the Bieri and Büchi

flushing systems have been selected.

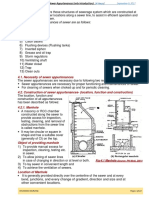

4.2.1 Bieri flushing system

In Bieri type the sediments which settle in the basin are flushed vertically through the opening

into the channel and back to the river [1] (Figure 4.10). The flushing water volume is therefore

minimized and energy production is ensured even during the flushing procedure. For about 50

years, more than 80 Bieri flushing systems have been in operation around the world [19].

Canal Racks Settling basin Weir

a) b)

Servomotor Flushing unit Bieri Flushing channel Flushing gate

Figure 4.10: Layout of Bieri sediment trap: a) Longitudinal section; b) cross section [1]

4.2.1.1 Basin unit

The water flows through the basin in the longitudinal direction, and the overflow structure at the

end of the basin maintains an adequate water level, and regular flow through the basin. The sand

flushing unit is installed at the bottom of the V-shaped desander basin (Figure 4.11). An inlet gate

is necessary for drainage of the desander for inspections and maintenance work and is fully

opened during operation. The sand flushing gate also serves as an emergency closing gate in

the event of any of the flushing units becoming blocked in the open position.

b)

a)

Figure 4.11: a) Longitudinal view of a Bieri system; b) Different components of Bieri flushing system [19]

-17-

You might also like

- A Study On Squatter Settlements of Kathmandu Using GIS, Aerial Photography, Remote Sensing and Household SurveyDocument8 pagesA Study On Squatter Settlements of Kathmandu Using GIS, Aerial Photography, Remote Sensing and Household SurveyMamata SubediNo ratings yet

- Water Conveyance Structures: 5.1 Intakes and Head Race 5.1.1 Water Intake, Inlet StructuresDocument20 pagesWater Conveyance Structures: 5.1 Intakes and Head Race 5.1.1 Water Intake, Inlet Structuresክበር ተመስጌንNo ratings yet

- Chapter 4 Diversion Head WorksDocument30 pagesChapter 4 Diversion Head Worksloserboi10180% (15)

- Chapter 4 PART 1Document30 pagesChapter 4 PART 1Fetene Nigussie100% (1)

- Chapter 5 - Irrigation SystemDocument18 pagesChapter 5 - Irrigation SystemAnonymous kJPqPhiYAWNo ratings yet

- River Diversion HeadworksDocument31 pagesRiver Diversion HeadworksRahulNo ratings yet

- IrrigationDocument12 pagesIrrigationPaul John NazarenoNo ratings yet

- Chap 4-3-4 Spillways-Energy Dissipators RR ST VersDocument12 pagesChap 4-3-4 Spillways-Energy Dissipators RR ST VersCivil EngineeringNo ratings yet

- CENG 6606 HSII - 2 Diversion Head WorksDocument29 pagesCENG 6606 HSII - 2 Diversion Head WorksKenenisa BultiNo ratings yet

- Unit 4Document38 pagesUnit 4RidhamNo ratings yet

- Unit-4 Sewer Appurtenances - Only Introduction (4 Hours) R2Document13 pagesUnit-4 Sewer Appurtenances - Only Introduction (4 Hours) R2Girman RanaNo ratings yet

- SPILL WAYSmodDocument22 pagesSPILL WAYSmodhailishNo ratings yet

- Hydraulic Structures PresentationDocument22 pagesHydraulic Structures PresentationRajabu Hatibu67% (3)

- Intakes PDFDocument12 pagesIntakes PDFaggrey noah100% (1)

- Part 2H - Settling BasinDocument23 pagesPart 2H - Settling Basinnirajlamichhane100% (3)

- Welmel Feeder Canal Escape at 24+420 - Edited SeidDocument6 pagesWelmel Feeder Canal Escape at 24+420 - Edited SeidABAMELANo ratings yet

- Guidelines SelectiopenchannelmeterDocument11 pagesGuidelines SelectiopenchannelmeterShawn HopperNo ratings yet

- CE Circular No. 119Document3 pagesCE Circular No. 119Md. Shiraz JinnathNo ratings yet

- CanalsDocument19 pagesCanalsFemeena P-vNo ratings yet

- CounterweightDocument25 pagesCounterweightLami BojaNo ratings yet

- Spill WaysDocument14 pagesSpill WayshailishNo ratings yet

- Sewer Appurtenances 4 G2Document22 pagesSewer Appurtenances 4 G2Sital ParajuliNo ratings yet

- Initial FillingDocument5 pagesInitial FillingSujeet JhaNo ratings yet

- Unit 6 Sewer Appurtenances and Materials: StructureDocument24 pagesUnit 6 Sewer Appurtenances and Materials: StructureSANTHAGURU TNo ratings yet

- Chapter 5 Diversion Head WorksDocument58 pagesChapter 5 Diversion Head Worksbpiuyt123No ratings yet

- Section C - Dikes & DiversionsDocument20 pagesSection C - Dikes & DiversionsmeseretNo ratings yet

- Criteria DesandingDocument13 pagesCriteria Desandinglebrix100% (1)

- Causes of Failures of Earth DamDocument12 pagesCauses of Failures of Earth DamdevendarNo ratings yet

- Wre ct2Document5 pagesWre ct2aditya.patil21212121No ratings yet

- CENG 6606 HSII - 4 Cross DrainageDocument19 pagesCENG 6606 HSII - 4 Cross DrainageKenenisa BultiNo ratings yet

- Calculation and Specification of Ballast System: Design Iv Machinery System Department of Marine EngineeringDocument19 pagesCalculation and Specification of Ballast System: Design Iv Machinery System Department of Marine Engineeringhilal permanaNo ratings yet

- Type of WellsDocument10 pagesType of WellsAddrien Daniel100% (1)

- Level Crossing in RailsDocument6 pagesLevel Crossing in RailsezequilNo ratings yet

- Diversion Head Work: Prof. M.B Chougule DKTE' YCP IchalkaranjiDocument63 pagesDiversion Head Work: Prof. M.B Chougule DKTE' YCP Ichalkaranjishamsu100% (1)

- CH 44 - Subsoil DrainageDocument8 pagesCH 44 - Subsoil DrainageLit Phen TuNo ratings yet

- Book Water Supply and Sewerage DR Sajjad 211 241Document31 pagesBook Water Supply and Sewerage DR Sajjad 211 241Atif NawazNo ratings yet

- Erforating Fracking and Stimulation: 4.1 Completion Fluid FlowDocument7 pagesErforating Fracking and Stimulation: 4.1 Completion Fluid Flowkingsley peprahNo ratings yet

- Chapter 61447729098970692523Document87 pagesChapter 61447729098970692523Sandesh KhadkaNo ratings yet

- Irrigation Structures Modulical DesignDocument26 pagesIrrigation Structures Modulical DesignIssa DrdrNo ratings yet

- Chapter 2 SpillwayDocument83 pagesChapter 2 SpillwayKaseye AmareNo ratings yet

- Lecture 20 - Spillways 03.04.2021Document5 pagesLecture 20 - Spillways 03.04.2021Morio MosoroNo ratings yet

- Is 9429Document21 pagesIs 9429Sourav HaitNo ratings yet

- Chapter Four Pumping Tests of WellsDocument6 pagesChapter Four Pumping Tests of WellsMistireselassieNo ratings yet

- Perhitungan Bilga Berdasarkan Rules BVDocument40 pagesPerhitungan Bilga Berdasarkan Rules BVPutu Widhi Aprilia100% (1)

- Lecturenote - 489027965chapter 3 SpillwayDocument26 pagesLecturenote - 489027965chapter 3 SpillwayJemera TeshomeNo ratings yet

- Chapter Four Ogee SpillwayDocument21 pagesChapter Four Ogee SpillwayhabtamuNo ratings yet

- Hydraulics: 6.1. Headworks For River Water OfftakeDocument50 pagesHydraulics: 6.1. Headworks For River Water OfftakesuonsovannakaNo ratings yet

- GW 6-Tube Well Construction, Comparison of Tube Well Irrigation With Canal IrrigationDocument16 pagesGW 6-Tube Well Construction, Comparison of Tube Well Irrigation With Canal Irrigationwajid malikNo ratings yet

- Water Resource Engineering Slides by Prof Ujjwal Saha of IIESTSDocument23 pagesWater Resource Engineering Slides by Prof Ujjwal Saha of IIESTSRudra KushalNo ratings yet

- Hydraulic Structures II 4602Document69 pagesHydraulic Structures II 4602Tsegaw FikaduNo ratings yet

- Flow Over NotchDocument15 pagesFlow Over NotchMan Made Man100% (14)

- Chapter FourDocument54 pagesChapter FourtemuyemerryNo ratings yet

- Glossaryoftermsrelatingto River Valleyprojects: Indian StandardDocument26 pagesGlossaryoftermsrelatingto River Valleyprojects: Indian StandardkumarNo ratings yet

- CH 3 Diversion WorkDocument51 pagesCH 3 Diversion WorkAbuye HD100% (1)

- Report D4Document7 pagesReport D4hilal permanaNo ratings yet

- Chapter 9 Primary SedimentationDocument21 pagesChapter 9 Primary SedimentationAce Thunder100% (1)

- Environmental Engineering (Unit-2)Document9 pagesEnvironmental Engineering (Unit-2)Brahmaji KommojuNo ratings yet

- Groundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterFrom EverandGroundwater Technology Handbook: A Field Guide to Extraction and Usage of GroundwaterRating: 5 out of 5 stars5/5 (1)

- Case Studies in Fluid Mechanics with Sensitivities to Governing VariablesFrom EverandCase Studies in Fluid Mechanics with Sensitivities to Governing VariablesNo ratings yet

- Seabed Prehistory: Investigating the Palaeogeography and Early Middle Palaeolithic Archaeology in the Southern North SeaFrom EverandSeabed Prehistory: Investigating the Palaeogeography and Early Middle Palaeolithic Archaeology in the Southern North SeaNo ratings yet

- KRO2-WQ00-M-8038 - Installation, Operating, Maintenance, Commissioning Instructions and Assembling Drawings Rev.0Document126 pagesKRO2-WQ00-M-8038 - Installation, Operating, Maintenance, Commissioning Instructions and Assembling Drawings Rev.0ABAID ULLAHNo ratings yet

- 1 SMDocument11 pages1 SMhabeebalabi91No ratings yet

- Usaid Manager Non Revenue Water Handbook For Africa enDocument123 pagesUsaid Manager Non Revenue Water Handbook For Africa enRedemir MagnayeNo ratings yet

- Microplastic Pollution, A Threat To Marine Ecosystem and Human Health: A Short ReviewDocument21 pagesMicroplastic Pollution, A Threat To Marine Ecosystem and Human Health: A Short ReviewALFINA DAMAYANTINo ratings yet

- Ventós: 1. Identification of The Substance/Mixture and The Company/UndertakingDocument5 pagesVentós: 1. Identification of The Substance/Mixture and The Company/UndertakingOctavian CoifanNo ratings yet

- MSDS Lithium Grease EP2Document4 pagesMSDS Lithium Grease EP2Septian AdityaNo ratings yet

- Plastic Pollution Solutions 46366 Article OnlyDocument3 pagesPlastic Pollution Solutions 46366 Article OnlyLaura FlorezNo ratings yet

- Artificial ReefsDocument30 pagesArtificial ReefsEthan LukNo ratings yet

- Independence Day Special SupplementDocument1 pageIndependence Day Special SupplementMuna KhanNo ratings yet

- Tle Week 3 QuizDocument3 pagesTle Week 3 QuizCharito G Albarracin PanerioNo ratings yet

- Dr. Liji K T No. f2247 MRP 15 16 Klca021 Ugc SwroDocument85 pagesDr. Liji K T No. f2247 MRP 15 16 Klca021 Ugc SwroDhruvjeet SinghNo ratings yet

- C 2Document32 pagesC 2vijaykumarlambaNo ratings yet

- 03 National Research Priorities On Aquatic ResourcesDocument51 pages03 National Research Priorities On Aquatic ResourcesresearchslcarpNo ratings yet

- Final Pro22Document130 pagesFinal Pro22Otoma OrkaidoNo ratings yet

- Holocene Geology of The Central South Louisiana Coastal ZoneDocument92 pagesHolocene Geology of The Central South Louisiana Coastal ZoneetchplainNo ratings yet

- Safety Data Sheet Cydal + Alcohol FreeDocument5 pagesSafety Data Sheet Cydal + Alcohol FreeBawah BumiNo ratings yet

- CsUnit5 Standard Test With AnswersDocument4 pagesCsUnit5 Standard Test With AnswersSpeak EnglishNo ratings yet

- Environment Kindly Coalbed Methane Drilling Fluids: Lou Xuanqing, Zheng Lihui, Fu Yuwei, Wang SiwenDocument4 pagesEnvironment Kindly Coalbed Methane Drilling Fluids: Lou Xuanqing, Zheng Lihui, Fu Yuwei, Wang SiwenerpublicationNo ratings yet

- PSNGP FinalPermit2022Document61 pagesPSNGP FinalPermit2022Laurie PierceNo ratings yet

- Subjective Question SettlementDocument6 pagesSubjective Question SettlementAden SitaraNo ratings yet

- Annex 7 - Contractor S Obligations According To Environmental and Social Code of Practice (ESCOP)Document10 pagesAnnex 7 - Contractor S Obligations According To Environmental and Social Code of Practice (ESCOP)Engr Shahin HawladerNo ratings yet

- Question Answers (Weather and Seasons)Document2 pagesQuestion Answers (Weather and Seasons)Parmita SarkarNo ratings yet

- Instructions For Use: Washing MachineDocument32 pagesInstructions For Use: Washing Machinemona_mi8202No ratings yet

- 3.1 Design BriefDocument5 pages3.1 Design BriefRaj KamalNo ratings yet

- Oil Record Book Part I ExamplesDocument6 pagesOil Record Book Part I ExamplesRosario SisniegasNo ratings yet

- C Eers: For A Good LifeDocument13 pagesC Eers: For A Good LifeAbhishek100% (1)

- Hydrostatic Test Procedure and Lay-Up ProceduresDocument13 pagesHydrostatic Test Procedure and Lay-Up ProceduresMohamedNo ratings yet

- EEA 26 2016 Rivers and Lakes - THAL16025ENNDocument56 pagesEEA 26 2016 Rivers and Lakes - THAL16025ENNMajugoNo ratings yet

- Inventory (GIP)Document16 pagesInventory (GIP)Juan CarlosNo ratings yet