Professional Documents

Culture Documents

Comp Terms

Comp Terms

Uploaded by

andradajc60 ratings0% found this document useful (0 votes)

2 views1 pageCompressor

Original Title

COMP TERMS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCompressor

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views1 pageComp Terms

Comp Terms

Uploaded by

andradajc6Compressor

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

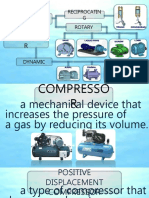

GAS COMPRESSOR a device in which work is DYNAMICS COMPRESSORS

done on the gas to raise its pressure.

Dynamic machines work by mechanically

COMPRESSION changing the velocity of the working fluid.

Trap consecutive quantities of gas in some type Centrifugal compressors the rapidly rotating

of enclosure, reduce the volume, thus impeller accelerates the gas.

increasing the pressure, then push the

-The process flow propagates from axial to

compressed gas out of the enclosure.

radial (perpendicular to shaft centerline) into a

COMPRESSED AIR stationary diffuser converting velocity to

pressure.

Compressed Air is mostly used in operating air

engineer, drive pneumatic tools, cleaning by air Axial compressors the gas flow is accelerated

blast, spray paints, pumping water by air lift, in an axial and peripheral direction by the

manufacture of plastics and other products and rotation of specially shaped blades.

host of other jobs.

- The process flow is parallel to shaft centerline.

Stator blades allow the recovery of velocity to

pressure.

POSITIVE DISPLACEMENT COMPRESSORS

Positive displacements machines work by

mechanically changing the volume of the

working fluid.

Reciprocating compressors the compressing

and displacing element is a piston having a

reciprocating motion within a cylinder.

Sliding Vane compressors are rotary positive

displacement compressors with slotted cylinder

fitted with nonmetallic vanes. As the slotted

cylinder is turned, the vanes slide along the

inner wall of the tube forming regions of

changing volume.

Liquid Ring compressors utilize liquid into the

chamber. Because of the centrifugal force and

the shape of the internal cavity, the liquid forms

an eccentric shape producing regions of

changing volume.

Rotary Lobe compressors Two straight

mating lobed impellers trap the gas and carry it

from intake to discharge

Helical Screw compressors Two intermeshing

rotors compress and displace the gas. The gas

is trapped in the rotor pockets at one end; it is

compressed between the intermeshing rotors

and discharged at the opposite end.

You might also like

- Compressors: Training ManualDocument127 pagesCompressors: Training Manualnazeer_mohd100% (9)

- Philippine Popular CultureDocument18 pagesPhilippine Popular CultureJohn Mark Bugarin100% (4)

- Eng102 Fallacy HandoutsDocument2 pagesEng102 Fallacy Handoutsjeanninestanko0% (1)

- Comp TermsDocument1 pageComp Termsandradajc7No ratings yet

- Gas CompressorDocument6 pagesGas Compressorrandhawa435100% (1)

- Gas CompressorsDocument69 pagesGas CompressorsAqib Khakhi100% (1)

- Compressors - Hassan ElBanhawiDocument14 pagesCompressors - Hassan ElBanhawijesus_manrique2753No ratings yet

- Compressors: Me7313 Industrial Automation and ControlDocument13 pagesCompressors: Me7313 Industrial Automation and ControlNuwan DinushaNo ratings yet

- Types of CompressorDocument19 pagesTypes of CompressorCreative 360No ratings yet

- Centrifugal CompressorsDocument106 pagesCentrifugal CompressorsUmair khan100% (1)

- Department of Mechanical EngineeringDocument16 pagesDepartment of Mechanical EngineeringRishabNo ratings yet

- CompressorDocument9 pagesCompressorYury KunNo ratings yet

- Types of Air CompressorsDocument6 pagesTypes of Air CompressorsJeremiah MalagueñoNo ratings yet

- CompressorDocument26 pagesCompressorChatlyn Kyle ReyesNo ratings yet

- Centrifugal Fan, Blowers and CompressorsDocument41 pagesCentrifugal Fan, Blowers and CompressorsAjejejeNo ratings yet

- Centrifugal CompressureDocument44 pagesCentrifugal CompressureFahim TanvirNo ratings yet

- 200905094-Ppt On Classification of Air CompressorsDocument32 pages200905094-Ppt On Classification of Air CompressorsPrasanna Kumar100% (4)

- Types of CompressorsDocument3 pagesTypes of Compressorsfakedmpp100% (1)

- Compresso R: Positive Displaceme NT Reciprocatin G RotaryDocument15 pagesCompresso R: Positive Displaceme NT Reciprocatin G RotaryjantskieNo ratings yet

- Compressors:: Basic Mechanical EngineeringDocument15 pagesCompressors:: Basic Mechanical EngineeringMelanie Love Pjr Alcantara100% (2)

- Compressor Presentation2005Document30 pagesCompressor Presentation2005lurekalureka100% (2)

- Aim:-To Study Various Types of Compressors Used For Refrigeration Cycle. TheoryDocument8 pagesAim:-To Study Various Types of Compressors Used For Refrigeration Cycle. TheoryAamer MohammedNo ratings yet

- Reciprocating: CompressorDocument12 pagesReciprocating: CompressorAkbar HartawanNo ratings yet

- Gas CompressorsDocument55 pagesGas CompressorsBilal Ahmed80% (5)

- CompressorDocument7 pagesCompressorJohn ValenzonaNo ratings yet

- Air CompressorDocument18 pagesAir CompressorJohn Kris San LuisNo ratings yet

- Compressors Course For EngineersDocument89 pagesCompressors Course For EngineersKhaledAhmedNo ratings yet

- Types of CompressorsDocument2 pagesTypes of Compressorsabuzar12533No ratings yet

- Dynamic CompressorsDocument48 pagesDynamic Compressorsamrutnerlikar75% (4)

- Reciprocating CompressorsDocument105 pagesReciprocating CompressorsMettu Shiva PrakashNo ratings yet

- Compressor - A Short ReviewDocument5 pagesCompressor - A Short Reviewjonayat222No ratings yet

- Gas Compression 3Document45 pagesGas Compression 3THE TERMINATOR100% (1)

- Compressor and Classification of Compressor Operation Industrial UsesDocument4 pagesCompressor and Classification of Compressor Operation Industrial UsesMark StrifeNo ratings yet

- COMPRESSORSDocument29 pagesCOMPRESSORSchdi0% (1)

- A Compressor Is A Mechanical Device That Increases The Pressure of ADocument9 pagesA Compressor Is A Mechanical Device That Increases The Pressure of AParth PatilNo ratings yet

- Gas Compressor Gas: Is A Mechanical Device That Increases The Pressure of A by Reducing Its VolumeDocument3 pagesGas Compressor Gas: Is A Mechanical Device That Increases The Pressure of A by Reducing Its VolumeAnonymous JUOvlONfNo ratings yet

- Compressor and Classification of Compressor Operation Industrial UsesDocument3 pagesCompressor and Classification of Compressor Operation Industrial UsesMark StrifeNo ratings yet

- Classification of CompressorDocument10 pagesClassification of Compressorحسوني المارنزNo ratings yet

- Group # 03 (Eve) Gas Compression SystemDocument25 pagesGroup # 03 (Eve) Gas Compression SystemMALIK ZARYABBABARNo ratings yet

- Compressors in Chilled Water PlantDocument3 pagesCompressors in Chilled Water PlantTangha Muklom KunchaNo ratings yet

- Compressors - Fans & Blowers TrainingDocument107 pagesCompressors - Fans & Blowers TrainingArjun Shantaram Zope100% (1)

- PD CompressorDocument65 pagesPD CompressorMuhammad IrfanNo ratings yet

- What Is A Gas CompressorDocument5 pagesWhat Is A Gas CompressorI AM NOT CHINESENo ratings yet

- Com Blow FanDocument16 pagesCom Blow FanArefin MahinNo ratings yet

- Thmn32e Module 6 - Air CompressorsDocument8 pagesThmn32e Module 6 - Air CompressorsArlos Jhon KempNo ratings yet

- Gas MoversDocument36 pagesGas MoversSupriya bhattacharjeeNo ratings yet

- Reciprocating CompressorDocument95 pagesReciprocating CompressorMuhd RizzuwanNo ratings yet

- Compressor GATE Mechanical EngineerDocument45 pagesCompressor GATE Mechanical Engineersap2279100% (1)

- Compressors - Written ReportDocument17 pagesCompressors - Written ReportJenina Rosa P. LlanesNo ratings yet

- Types of CompressorsDocument23 pagesTypes of Compressorsyash100% (1)

- Aim: To Study Various Type of Compressors. TheoryDocument6 pagesAim: To Study Various Type of Compressors. TheoryAamer MohammedNo ratings yet

- Compressors LectureDocument33 pagesCompressors LectureEric CookNo ratings yet

- Industrial Compressor: Presented byDocument81 pagesIndustrial Compressor: Presented byAmit Kumar JaiswalNo ratings yet

- CompressorsDocument34 pagesCompressorsShanza AsifNo ratings yet

- Air Compressor TermsDocument9 pagesAir Compressor TermsUniversal CollabNo ratings yet

- To Take A Definite Quantity of Air/gas and Deliver It at A Required Pressure. Reciprocating RotaryDocument7 pagesTo Take A Definite Quantity of Air/gas and Deliver It at A Required Pressure. Reciprocating RotaryNishit KumarNo ratings yet

- Centrifugal Compressors: A Seminar ReportDocument32 pagesCentrifugal Compressors: A Seminar ReportGayathri ShastryNo ratings yet

- CompressorsDocument49 pagesCompressorsashishdane100% (2)

- Air CompressorsDocument6 pagesAir CompressorsNaren KumarNo ratings yet

- Relay Based Electropneumatics BucengDocument76 pagesRelay Based Electropneumatics BucengDEATH WISHNo ratings yet

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Decision Trees - 2022Document49 pagesDecision Trees - 2022Soubhav ChamanNo ratings yet

- GalvinDocument9 pagesGalvinІгор ШNo ratings yet

- Certifications To Put On ResumeDocument4 pagesCertifications To Put On Resumeafmgendgzoxmup100% (1)

- Man and SupermanDocument4 pagesMan and SupermanSrestha Kar100% (1)

- 33 Relative and TrueDocument32 pages33 Relative and TrueArun Ketu SethNo ratings yet

- 8 y 9 Sem MATERIAL de ESTUDIO INGLES V Unit V Do You Know Where It Is Unit VI Since WhenDocument12 pages8 y 9 Sem MATERIAL de ESTUDIO INGLES V Unit V Do You Know Where It Is Unit VI Since WhenJoseph MartinezNo ratings yet

- Physics Category 1 9th - 10th Grades SAMPLE TESTDocument4 pagesPhysics Category 1 9th - 10th Grades SAMPLE TESTAchavee SukratNo ratings yet

- Bangalore University: "Student Attendance Management"Document10 pagesBangalore University: "Student Attendance Management"Rohit VilliersNo ratings yet

- A Is For Alienation ArticleDocument4 pagesA Is For Alienation ArticleFamily Court-CorruptionNo ratings yet

- Better Graphics r10 PDFDocument45 pagesBetter Graphics r10 PDFdocsmsNo ratings yet

- Phoenix: February Price ListDocument52 pagesPhoenix: February Price ListDhiman DodhiaNo ratings yet

- Indotech Power Transformers BrochureDocument2 pagesIndotech Power Transformers BrochurenmanjNo ratings yet

- Erection Steel Structure ProcedureDocument15 pagesErection Steel Structure ProcedureOussama Sissaoui100% (2)

- Preventing Maintaince Procedure Froklift HanlerDocument2 pagesPreventing Maintaince Procedure Froklift HanlerAli AlahmaNo ratings yet

- Sol Gel ThesisDocument5 pagesSol Gel Thesiskriscundiffevansville100% (2)

- 4 Process - Analysis - Practice - Problem - SolutionsDocument7 pages4 Process - Analysis - Practice - Problem - SolutionsHEMANT KUMARNo ratings yet

- Cttplus HandbookDocument36 pagesCttplus HandbookgcarreongNo ratings yet

- (Guy - Exton) - Brexit and Game Theory A Single-Case AnalysisDocument9 pages(Guy - Exton) - Brexit and Game Theory A Single-Case AnalysisAmairani IbáñezNo ratings yet

- University of Liverpool India Fellowships ProgrammeDocument6 pagesUniversity of Liverpool India Fellowships ProgrammeShashank BansalNo ratings yet

- CESCDocument4 pagesCESCCarl Rage Cañete YosoresNo ratings yet

- The Heart of Innovation in SPARK - GFRP BridgeDocument8 pagesThe Heart of Innovation in SPARK - GFRP BridgeMysara MohsenNo ratings yet

- mô tả chungDocument34 pagesmô tả chungTuấn Anh NguyễnNo ratings yet

- Blueprint: Freelance RecruitersDocument19 pagesBlueprint: Freelance RecruitersGreenCoffee 24No ratings yet

- Lien 2020Document11 pagesLien 2020Puraghan cahya herawanNo ratings yet

- Practice Test CDocument64 pagesPractice Test CAneri100% (1)

- Cpim BrochureDocument4 pagesCpim BrochureMuhammadNo ratings yet

- Truck Evo Manual FinalDocument28 pagesTruck Evo Manual FinalRodrigo Zuñiga RosselNo ratings yet

- 3D CamDocument16 pages3D CamShin EscaresesNo ratings yet