Professional Documents

Culture Documents

Be - Mechanical Engineering - Semester 6 - 2023 - May - Press Tool Designrev 2019 C Scheme

Be - Mechanical Engineering - Semester 6 - 2023 - May - Press Tool Designrev 2019 C Scheme

Uploaded by

218102Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Be - Mechanical Engineering - Semester 6 - 2023 - May - Press Tool Designrev 2019 C Scheme

Be - Mechanical Engineering - Semester 6 - 2023 - May - Press Tool Designrev 2019 C Scheme

Uploaded by

218102Copyright:

Available Formats

D

CA

25

3D

3

98

A0

Paper / Subject Code: 89425 / Press Tool Design (DLOC)

0A

98

D5

0F

CA

25

1T01436 - T.E.(Mechanical)(SEM-VI)(Choice Base Credit Grading System ) ((R-20-21) (C Scheme) / 89425 - Press Tool Design (DLOC)

3D

A5

98

0

QP CODE: 10028285 DATE: 18/05/2023

0A

98

AA

D5

0F

DE

(3 Hours) Total Marks: 80

25

3D

5

98

C

FA

98

D5

0F

E

D0

43

N.B. (1) Question no. 1 is compulsory.

5

D

A5

98

A2

FA

53

EA

(2) Attempt any three questions out of remaining five questions.

F

E

D0

D

0

43

AD

EA

98

A2

(3) illustrate your answer with necessary sketch wherever necessary.

53

A

EA

0F

3F

3F

D0

8D

(4) Figures to the right indicate full marks.

AD

A

A5

A0

A4

53

E

F9

3F

3F

E

CA

D

50

AD

A

1. Attempt any FOUR of the following : (20)

98

A0

A4

EA

FE

98

0F

F

(a) State the limitations of using press tools.

CA

E

25

03

AD

EA

A5

8

A4

(b) Compare between shaving and trimming die.

0A

98

F9

AA

3F

DE

E

(c) What are the various materials used in press tools and how are these materials

25

50

3D

43

EA

C

A0

FA

A

EA

8

selected?

A

D5

59

3F

0

E

3D

43

(d) What is press tonnage? How it is decided?

AD

EA

98

C

A2

A0

98

EA

Explain why is it necessary to calculate the developed length of the part? 5

0F

(e)

3F

D0

D

A

25

D

A5

EA

98

A4

53

FA

0A

A

0F

DE

59

F

2. (a) Define centre of pressure. Considering a suitable component, explain the steps to (10) D

AE

3D

03

43

A5

98

8C

2

FA

find the centre of pressure.

FE

A

EA

D5

0F

E

59

0

A

(b) Describe with sketch the construction and working of a three stage progressive die (10)

3

AD

03

5

EA

8

A4

C

A2

53

EA

9

considering a suitable example.

98

AA

F

F

AE

3F

D0

8D

50

43

25

AD

8C

A0

53

EA

FE

9

EA

Explain the possible causes of the following defects in bending and also state the (10)

A

3. (a)

0F

3F

59

0

8D

CA

03

AD

precautions to be taken to prevent or minimise these defects:

3D

A

5

4

A2

A

FE

9

AA

98

i) Cracking ii) Warping iii) Marring. Also list the defects in drawn parts.

D5

F

3F

E

E

0

0

03

25

AD

D

EA

8C

5

(b) Discuss methods of feeding the strip/coil material in the press. (10)

98

4

53

A

AA

EA

0A

59

0F

F

DE

8D

03

43

3D

EA

8C

A2

A5

4. (a) Explain with suitable sketches the different methods to reduce cutting force. (10)

A

F9

A

D5

59

3F

3F

D0

DE

A

50

EA

8C

A2

98

A0

4

3

(b) A cup without flange is manufactured by using deep drawing operation. It should

A

EA

A

D5

59

0F

3F

F

D0

have a height of 85 mm and 100 mm outer diameter , and is to be made from 2 mm

3

AD

EA

98

C

A2

A5

0

A4

3

98

AA

thick sheet metal. Determine i) Blank size, ii) Percentage reduction, iii) Number of

D5

0F

3F

D0

DE

AE

25

03

draws, iv) Radius on punches and dies, v) Die clearance, punch diameter and die

5

98

8C

A4

3

EA

FA

A

E

A

D5

0F

opening size at each draw v)Drawing force and blank holding force. The Yield

59

3F

0

AE

D

43

5

98

strength for sheet material is 350 N/mm2. The bottom corner of cup is round having

8C

A2

0

FA

53

EA

E

A

EA

F

59

F

0

radius as 3 R.

8D

A

50

43

AD

EA

C

2

0

53

EA

F9

A

3F

3F

0

D

CA

50

5. (a) Explain the different safety devices used in a press for the safety of operator. (10)

25

AD

3D

98

4

A0

EA

EA

0A

(b) Give reasons for the following: (10)

D5

0F

3F

59

CA

AD

3D

A

i) Correct orientation of grain direction is necessary in arranging the strip layout.

5

98

4

A2

EA

FE

EA

98

D5

0F

ii) Shaving operation is needed after blanking operation.

3F

D0

03

25

AD

A

98

4

iii) Shear is provided on die in blanking operation

53

EA

FE

EA

0A

0F

3F

iv) Clearance is provided on punch in blanking operation.

8D

03

AD

3D

A

A5

4

v) Cutting and non-cutting operations are not combined in one station of

FE

F9

A

EA

D5

3F

E

CA

50

03

progressive die.

AD

A

98

4

EA

FE

98

AA

EA

6. Attempt any FOUR of the following : (20)

0F

3F

25

03

AD

A

8C

Enlist the factors considered while selecting press for a particular application.

A5

(a)

A4

FE

AA

59

3F

(b) Explain the different defects in bent parts.

DE

E

03

EA

8C

A2

A4

(c) Explain overloading of press and how to avoid it.

FA

AA

59

F

D0

(d) What is a load-stroke curve? Describe with different stages during the sheet metal

03

43

EA

8C

A2

53

cutting operation.

AA

EA

59

3F

D0

8D

(e) Explain automatic stock feeding mechanism in a press.

EA

8C

A2

A0

53

59

3F

D0

8D

A

8C

A2

A0

53

9

0F

59

D0

8D

CA

A5

A2

53

F9

98

DE

D0

8D

28285

50

25

3

EA

0A

D5

0F

AD

3D

A43FADEA50F98D53D0A2598CAA03FEAE

A5

98

You might also like

- George Van TasselDocument2 pagesGeorge Van TasselManea SilviuNo ratings yet

- Colloidal Silver Generator InstructionsDocument16 pagesColloidal Silver Generator InstructionsPol ErnNo ratings yet

- Continous Probability DistributionDocument33 pagesContinous Probability DistributionShivani Pandey100% (1)

- Physics Alternative Assessment Task 4Document14 pagesPhysics Alternative Assessment Task 4Alia ShabbirNo ratings yet

- PTD PDF - MergedDocument5 pagesPTD PDF - Merged218102No ratings yet

- Be - Electrical Engineering - Semester 6 - 2023 - May - Energy Storagerev 2019 C SchemeDocument1 pageBe - Electrical Engineering - Semester 6 - 2023 - May - Energy Storagerev 2019 C SchemeHarsh BaswantNo ratings yet

- CA 2023 (Nov)Document5 pagesCA 2023 (Nov)aditikotere92No ratings yet

- Be Electronics and Telecommunication Semester 7 2022 December Mobile Communication System Rev 2019 C SchemeDocument1 pageBe Electronics and Telecommunication Semester 7 2022 December Mobile Communication System Rev 2019 C Schemetejasrabad20No ratings yet

- Css-2019 QPDocument1 pageCss-2019 QPRohit KshatriyaNo ratings yet

- Css 23 MayDocument1 pageCss 23 MayUzair KhanNo ratings yet

- Be - Computer Engineering Ai, DS, ML - Semester 6 - 2023 - May - Data Analytics and Visualization Rev 2019 C SchemeDocument1 pageBe - Computer Engineering Ai, DS, ML - Semester 6 - 2023 - May - Data Analytics and Visualization Rev 2019 C SchemeRohit KshatriyaNo ratings yet

- Be Electrical Engineering Semester 7 2022 December Electrical Power System III Rev 2019 C SchemeDocument2 pagesBe Electrical Engineering Semester 7 2022 December Electrical Power System III Rev 2019 C Schemeishaansingh120208No ratings yet

- Be Mechanical Engineering Semester 6 2023 December Press Tool Designrev 2019 C SchemeDocument2 pagesBe Mechanical Engineering Semester 6 2023 December Press Tool Designrev 2019 C Scheme218102No ratings yet

- Be Information Technology Semester 5 2023 December Software Engineeringrev 2019 C SchemeDocument1 pageBe Information Technology Semester 5 2023 December Software Engineeringrev 2019 C SchemegodizlatanNo ratings yet

- Adsa Pyqs 2023Document1 pageAdsa Pyqs 2023Hacker RanjanNo ratings yet

- Be - First Year Engineering - Semester 1 - 2023 - May - Basic Electrical Engineering Beerev 2019c SchemeDocument2 pagesBe - First Year Engineering - Semester 1 - 2023 - May - Basic Electrical Engineering Beerev 2019c Schemeadityagowda2317No ratings yet

- Be - Mechanical Engineering - Semester 6 - 2022 - December - Heating Ventilation Air Conditioning and Refrigerationrev 2019 C SchemeDocument2 pagesBe - Mechanical Engineering - Semester 6 - 2022 - December - Heating Ventilation Air Conditioning and Refrigerationrev 2019 C SchemeDeepak NamayateNo ratings yet

- Be Electronics and Telecommunication Semester 6 2023 December Electromagnetics and Antennarev 2019 C SchemeDocument1 pageBe Electronics and Telecommunication Semester 6 2023 December Electromagnetics and Antennarev 2019 C Schemeakawm10xNo ratings yet

- Be - Information Technology - Semester 4 - 2023 - May - Engineering Mathematics IV Rev 2019 C SchemeDocument2 pagesBe - Information Technology - Semester 4 - 2023 - May - Engineering Mathematics IV Rev 2019 C SchemeNitish JhaNo ratings yet

- Be - Mechanical Engineering - Semester 5 - 2023 - May - Mechanical Measurements and Controlsrev 2019 C SchemeDocument2 pagesBe - Mechanical Engineering - Semester 5 - 2023 - May - Mechanical Measurements and Controlsrev 2019 C Schemebottomfragger993No ratings yet

- Gender School & SocietyDocument2 pagesGender School & SocietyKavya S R AcharyaNo ratings yet

- Be - Computer Engineering - Semester 7 - 2022 - December - Big Data Analysis Rev 2019 C SchemeDocument2 pagesBe - Computer Engineering - Semester 7 - 2022 - December - Big Data Analysis Rev 2019 C SchemeKDNo ratings yet

- Be - Computer Engineering Ai, DS, ML - Semester 5 - 2022 - December - Web Computing Rev 2019 C SchemeDocument2 pagesBe - Computer Engineering Ai, DS, ML - Semester 5 - 2022 - December - Web Computing Rev 2019 C SchemeSahil SurveNo ratings yet

- Be Mechanical Engineering Semester 5 2023 December Finite Element Analysisrev 2019 C SchemeDocument2 pagesBe Mechanical Engineering Semester 5 2023 December Finite Element Analysisrev 2019 C SchemeaskdeveeNo ratings yet

- Be - Information Technology - Semester 8 - 2023 - December - Blockchain and DLT Rev 2019 C SchemeDocument1 pageBe - Information Technology - Semester 8 - 2023 - December - Blockchain and DLT Rev 2019 C Schemeshitija012No ratings yet

- AIDS Question Paper - RemovedDocument8 pagesAIDS Question Paper - RemovedPriyadarshini ChavanNo ratings yet

- Dmbi 3Document2 pagesDmbi 3Ahmad Raza AnsariNo ratings yet

- Advanced Database Management System Rev 2019meDocument1 pageAdvanced Database Management System Rev 2019meabhiksk4141No ratings yet

- Te Dec 2023Document2 pagesTe Dec 2023siddheshkharat64No ratings yet

- Be - Electrical Engineering - Semester 6 - 2022 - December - Special Electrical Machinerev 2019 C Scheme PDFDocument1 pageBe - Electrical Engineering - Semester 6 - 2022 - December - Special Electrical Machinerev 2019 C Scheme PDFOmkar GuptaNo ratings yet

- 2023 Nov - Constitutional LawDocument2 pages2023 Nov - Constitutional LawAmit SCMNo ratings yet

- Be - Mechanical Engineering - Semester 6 - 2022 - December - Press Tool Designrev 2019 C SchemeDocument2 pagesBe - Mechanical Engineering - Semester 6 - 2022 - December - Press Tool Designrev 2019 C Scheme218102No ratings yet

- Machine Designrev 2019 C SchemeDocument2 pagesMachine Designrev 2019 C Schemehadesg895No ratings yet

- Be - Mechanical Engineering - Semester 7 - 2022 - December - Design of Mechanical System Rev 2019 C' SchemeDocument2 pagesBe - Mechanical Engineering - Semester 7 - 2022 - December - Design of Mechanical System Rev 2019 C' Scheme23 Kaif HakimNo ratings yet

- Be Computer-Engineering Semester-7Document1 pageBe Computer-Engineering Semester-7SaquibNo ratings yet

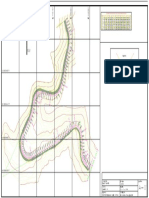

- STA 0+000.00 V 40 KM/H: PT: 0+533.45 TS: 0+631.34Document1 pageSTA 0+000.00 V 40 KM/H: PT: 0+533.45 TS: 0+631.34Alex Jordan Quispe ANo ratings yet

- Technology - Mca Master of Computer Applications - Semester 2 - 2023 - December - Information Security Rev 2019 C SchemeDocument1 pageTechnology - Mca Master of Computer Applications - Semester 2 - 2023 - December - Information Security Rev 2019 C Schemeaffiginia dkharNo ratings yet

- Bench 1F Plan Aug 23 2021 EditedDocument1 pageBench 1F Plan Aug 23 2021 EditedThermms Construction and Development CorporationNo ratings yet

- Bench 1f Plan Aug 23 2021 EditedDocument1 pageBench 1f Plan Aug 23 2021 EditedThermms Construction and Development CorporationNo ratings yet

- IP May 2023 Questio PaperDocument1 pageIP May 2023 Questio Papergpmumbai123No ratings yet

- Be Chemical Engineering Semester 4 2023 May Solid Fluid Mechanical Operationsrev 2019 C SchemeDocument2 pagesBe Chemical Engineering Semester 4 2023 May Solid Fluid Mechanical Operationsrev 2019 C SchemeKW CheahNo ratings yet

- Be - Electronics Engineering - Semester 7 - 2022 - December - Power Electronics Rev 2019 C SchemeDocument1 pageBe - Electronics Engineering - Semester 7 - 2022 - December - Power Electronics Rev 2019 C Schemeshitalmane71No ratings yet

- P2Document1 pageP2manescankaye2No ratings yet

- Commerce Bcom Bachelor of Commerce Semester 5 2023 November Financial Accounting and Auditing Vii Financial Accounting CbcgsDocument14 pagesCommerce Bcom Bachelor of Commerce Semester 5 2023 November Financial Accounting and Auditing Vii Financial Accounting CbcgsRahul MadgundiNo ratings yet

- Data Structures 2Document1 pageData Structures 2kolekarkeshav38No ratings yet

- Be Chemical Engineering Semester 7 2022 December Chemical Engineering Equipment Design Rev 2019 C SchemeDocument3 pagesBe Chemical Engineering Semester 7 2022 December Chemical Engineering Equipment Design Rev 2019 C SchemeMitesh ThakurNo ratings yet

- 2023 Nov - Environmental Laws 60-40Document4 pages2023 Nov - Environmental Laws 60-40Vj AutiNo ratings yet

- Mall Cetakan Shaft MaruisiDocument1 pageMall Cetakan Shaft MaruisiWawan SaputraNo ratings yet

- TE-VI AIDS R-19 ALL CompressedDocument11 pagesTE-VI AIDS R-19 ALL CompressedShubhankar MajgaonkarNo ratings yet

- Be - Information Technology - Semester 8 - 2023 - December - Dloc VI Cloud Computing and Services Rev 2019 C SchemeDocument1 pageBe - Information Technology - Semester 8 - 2023 - December - Dloc VI Cloud Computing and Services Rev 2019 C Schemeaditi palNo ratings yet

- XXMScPart2Analysis2 FourierSeries Oct2022Document2 pagesXXMScPart2Analysis2 FourierSeries Oct2022Ayesha MNo ratings yet

- CNS 2022Document1 pageCNS 2022gpmumbai123No ratings yet

- Be - Computer Engineering Ai, DS, ML - Semester 4 - 2023 - December - Engineering Mathematics IV Rev 2019 C SchemeDocument2 pagesBe - Computer Engineering Ai, DS, ML - Semester 4 - 2023 - December - Engineering Mathematics IV Rev 2019 C SchemeAditya AsabeNo ratings yet

- FM Dec 2022Document2 pagesFM Dec 2022CREATIVE LIFENo ratings yet

- Be Information Technology Semester 5 2023 December Internet Programmingrev 2019 C SchemeDocument1 pageBe Information Technology Semester 5 2023 December Internet Programmingrev 2019 C Schememanujamanav01No ratings yet

- Be Computer Engineering Semester 5 2023 December Internet Programmingrev 2019 C SchemeDocument1 pageBe Computer Engineering Semester 5 2023 December Internet Programmingrev 2019 C Schemerodriguezlillian472No ratings yet

- Iot CNS 10029058Document1 pageIot CNS 10029058Aaditya ChettiarNo ratings yet

- Dw044 p02 MCC Buffer Zone SectionsDocument1 pageDw044 p02 MCC Buffer Zone SectionsMohammed NadeemNo ratings yet

- Bumi Parama Wisesa: ArchitectureDocument3 pagesBumi Parama Wisesa: ArchitectureHafizahNo ratings yet

- Crankshaft CounterweightDocument1 pageCrankshaft CounterweightCốGắngNàoNo ratings yet

- 2023 Nov - Environmental LawsDocument3 pages2023 Nov - Environmental LawsAmit SCMNo ratings yet

- Pyq 1Document4 pagesPyq 1varun.elegeti16629No ratings yet

- 03 Dec 2022 UpDocument1 page03 Dec 2022 Upaaryamankattali75No ratings yet

- Design of Thermal Systems - Stoecker 3rd EditionDocument568 pagesDesign of Thermal Systems - Stoecker 3rd EditionDeep Narula92% (13)

- Manual de Usuario Holiday PcwiDocument12 pagesManual de Usuario Holiday PcwijerrymcflyNo ratings yet

- Oh-Lite®: Single Mode Optical Fibre ITU-T G.652.DDocument2 pagesOh-Lite®: Single Mode Optical Fibre ITU-T G.652.Dhimanshi khivsaraNo ratings yet

- 1.893 3.717 5.57 Tegangan Geser 6.699 7.308 9.743Document6 pages1.893 3.717 5.57 Tegangan Geser 6.699 7.308 9.743theo seoNo ratings yet

- Comparative Analysis Between PI & Backstepping Control Strategies of DFIG Driven by Wind TurbineDocument10 pagesComparative Analysis Between PI & Backstepping Control Strategies of DFIG Driven by Wind Turbinehamza gaNo ratings yet

- Plywood PropertiesDocument55 pagesPlywood PropertiesChandresh ZinzuwadiaNo ratings yet

- Astm D 4221 99 Doble Hidrometro PDFDocument3 pagesAstm D 4221 99 Doble Hidrometro PDFHayatoNo ratings yet

- Autodyn Composite Modeling GuideDocument74 pagesAutodyn Composite Modeling Guidejoesph killerNo ratings yet

- The Jordan Loudspeaker Manual Chapter 5Document2 pagesThe Jordan Loudspeaker Manual Chapter 5Adam PaulNo ratings yet

- Raina M Hill Pe ResumeDocument3 pagesRaina M Hill Pe Resumeapi-233552935No ratings yet

- En 19Document1 pageEn 19Parvee K Nakwal100% (1)

- Design and Analysis of Shrink and Press Fit JointsDocument4 pagesDesign and Analysis of Shrink and Press Fit JointsRajNo ratings yet

- Optimization in Modern Power Systems DTU Course 31765: Lecture NotesDocument48 pagesOptimization in Modern Power Systems DTU Course 31765: Lecture NotesAwol AbduNo ratings yet

- Revision Guide Aiming For 7Document70 pagesRevision Guide Aiming For 7Nayem Hossain HemuNo ratings yet

- Edirisinghe Observations 2022Document9 pagesEdirisinghe Observations 2022Gaut 'SNo ratings yet

- Exp 1Document3 pagesExp 1Mani MaNo ratings yet

- ARIMA Models - Part 1: 8.0 - IntroductionDocument20 pagesARIMA Models - Part 1: 8.0 - IntroductionDadedidoduNo ratings yet

- H-85318-4 TraSys 818Document2 pagesH-85318-4 TraSys 818zouhy0442No ratings yet

- Summative Atomic StructureDocument3 pagesSummative Atomic StructureNovie Mae ReambonanzaNo ratings yet

- Lab Report 08 Applying Non-Destructive Analysis Techniques For Assets Health Assessment Using Predictive Maintenance StrategyDocument8 pagesLab Report 08 Applying Non-Destructive Analysis Techniques For Assets Health Assessment Using Predictive Maintenance StrategyImdad Jalali100% (1)

- Traverse CalculationsDocument6 pagesTraverse CalculationsSteeve SenoNo ratings yet

- Technical DrawingDocument38 pagesTechnical DrawingKinfe MehariNo ratings yet

- The Structural Analysis and Design Methods Considering Joint Bursting in The Segment Lining - TranslatedDocument22 pagesThe Structural Analysis and Design Methods Considering Joint Bursting in The Segment Lining - TranslatedKandousi YassineNo ratings yet

- Pump MixerDocument31 pagesPump MixerPrashant MalveNo ratings yet

- Saros CyclesDocument17 pagesSaros CyclesAmit Desai Predictor100% (3)

- 1 - Review of Compressible FlowsDocument30 pages1 - Review of Compressible FlowsvigneshwaranNo ratings yet