Professional Documents

Culture Documents

42 Oil Field Scale in Petroleum Industry

42 Oil Field Scale in Petroleum Industry

Uploaded by

jose rogelio villaseñor gonzalezCopyright:

Available Formats

You might also like

- Studies On Scale Deposition in Oil Industries and Their ControlDocument16 pagesStudies On Scale Deposition in Oil Industries and Their ControlIJIRST100% (1)

- When Glass meets Pharma: Insights about glass as primary packaging materialFrom EverandWhen Glass meets Pharma: Insights about glass as primary packaging materialNo ratings yet

- Glass Case Study and Market StudyDocument57 pagesGlass Case Study and Market StudymintuNo ratings yet

- Dec Exam AnswersDocument17 pagesDec Exam Answersvivivihohoho1No ratings yet

- Design and Construction of Waste Paper' Recycling PlantDocument12 pagesDesign and Construction of Waste Paper' Recycling PlantAhmed Ali100% (1)

- Surface Inorganic Scale Formation in Oil and Gas IDocument12 pagesSurface Inorganic Scale Formation in Oil and Gas IROZANANo ratings yet

- 2 BrasilDocument13 pages2 BrasilmaxjuliNo ratings yet

- IMPROVE EFFICIENCY OF COOLING TOWER BY PASSIVATION Ijariie8796Document6 pagesIMPROVE EFFICIENCY OF COOLING TOWER BY PASSIVATION Ijariie8796KaushalNo ratings yet

- Production Ii PDFDocument235 pagesProduction Ii PDFADARSH KUMARNo ratings yet

- An Introduction To Scaling Causes, Problems and Solutions: NTNU - Institutt For Petroleumsteknologi Og Anvendt GeofysikkDocument23 pagesAn Introduction To Scaling Causes, Problems and Solutions: NTNU - Institutt For Petroleumsteknologi Og Anvendt GeofysikkIman QurbanovNo ratings yet

- Formation Damage and AcidDocument3 pagesFormation Damage and AcidSahito MasroorNo ratings yet

- Vedant Am 2013Document51 pagesVedant Am 2013maría joséNo ratings yet

- Energies: Occurrence and Characterization of Paraffin Wax Formed in Developing Wells and PipelinesDocument23 pagesEnergies: Occurrence and Characterization of Paraffin Wax Formed in Developing Wells and PipelinesMohammed HeshamNo ratings yet

- Cost Saving Case Study Using A Calcium Sulphate Specific AntiscalantDocument10 pagesCost Saving Case Study Using A Calcium Sulphate Specific AntiscalantNaim HossainNo ratings yet

- Scale InhibitorsDocument6 pagesScale InhibitorsgulfengsolutionsNo ratings yet

- Advanced Trends of Shale Inhibitors For Enhanced Properties of Water-BasedDocument7 pagesAdvanced Trends of Shale Inhibitors For Enhanced Properties of Water-BasedSkolastika ErnaNo ratings yet

- 1 s2.0 S0920410521004629 MainDocument16 pages1 s2.0 S0920410521004629 Mainjolugoto1991No ratings yet

- Flocculants and Coagulants NALCO (LIT)Document6 pagesFlocculants and Coagulants NALCO (LIT)Namita AgarwalNo ratings yet

- JCG3382012189 194Document7 pagesJCG3382012189 194ingNo ratings yet

- UOP Extending Molecular Sieve Life Tech PaperDocument7 pagesUOP Extending Molecular Sieve Life Tech PaperOmar EzzatNo ratings yet

- Nandwani 2017Document37 pagesNandwani 2017Alondra Guadalupe Escobar VillanuevaNo ratings yet

- Flocculants and Coagulants NALCO (LIT)Document6 pagesFlocculants and Coagulants NALCO (LIT)AlexisPereiraVásquezNo ratings yet

- Corrosion Inhibitors in The Oil and Gas Industry - 2020 - Saji - Antiscalants and Their Compatibility With CorrosionDocument23 pagesCorrosion Inhibitors in The Oil and Gas Industry - 2020 - Saji - Antiscalants and Their Compatibility With CorrosionNantawat KaekratokeNo ratings yet

- Oajs 02 00054Document8 pagesOajs 02 00054Marcos SilvaNo ratings yet

- C2018-10490Document15 pagesC2018-10490tinovelazquezNo ratings yet

- Efficient Separation of Oil Water Emulsions Compet - 2023 - Journal of EnvironmDocument18 pagesEfficient Separation of Oil Water Emulsions Compet - 2023 - Journal of Environm21chehs.gandhiNo ratings yet

- Universal Correlation For Gas Hydrates Suppression Temperature of Inhibited Systems: I. Single SaltsDocument49 pagesUniversal Correlation For Gas Hydrates Suppression Temperature of Inhibited Systems: I. Single Saltsavula43No ratings yet

- FracturingDocument43 pagesFracturingPrincess OkolomaNo ratings yet

- A Critical Review of Development and Demulsification Mechanisms of Crude Oil Emulsion in The Petroleum IndustryDocument18 pagesA Critical Review of Development and Demulsification Mechanisms of Crude Oil Emulsion in The Petroleum IndustrymirNo ratings yet

- Beneficial Uses of The Produced Water From Palogue Oil Field For Injection To Enhance Oil RecoveryDocument7 pagesBeneficial Uses of The Produced Water From Palogue Oil Field For Injection To Enhance Oil RecoverymuralisunNo ratings yet

- Study of Physiochemical Properties of Sodium Dodecyl Sulphate Surfactant It's Micellization, Oil in Water Emulsification and Industrial ApplicationsDocument6 pagesStudy of Physiochemical Properties of Sodium Dodecyl Sulphate Surfactant It's Micellization, Oil in Water Emulsification and Industrial ApplicationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Experimental - Investigation - of - Crude Oil DesaltingDocument19 pagesExperimental - Investigation - of - Crude Oil DesaltingElbahi DjaalabNo ratings yet

- VEDANTAM-RANADE2013 - Article - CrystallizationKeyThermodynami, KINECTIC Y HYDRODINAMIC ASPECTSDocument51 pagesVEDANTAM-RANADE2013 - Article - CrystallizationKeyThermodynami, KINECTIC Y HYDRODINAMIC ASPECTSVanesa Ramirez CatalanNo ratings yet

- Salt Precipitation and Scale Control in Supercritical Water Oxidation-Part B: Commercial/full-Scale ApplicationsDocument24 pagesSalt Precipitation and Scale Control in Supercritical Water Oxidation-Part B: Commercial/full-Scale ApplicationsOmer Bin HussainNo ratings yet

- Scale Formation PDFDocument16 pagesScale Formation PDFRohit NairNo ratings yet

- Crysytal Growth GelDocument18 pagesCrysytal Growth GelGnana SilviaNo ratings yet

- 1 s2.0 S2405656122000128 MainDocument14 pages1 s2.0 S2405656122000128 Mainorderin aja yukNo ratings yet

- Processes 10 00738 v2Document34 pagesProcesses 10 00738 v2heranNo ratings yet

- Desalting Paper Musleh1Document18 pagesDesalting Paper Musleh1Ahmed Mohamed KhalilNo ratings yet

- Riazi 2Document12 pagesRiazi 2Seyedeh Maryam MousaviNo ratings yet

- SPE 94523 A New Inhibitive Water-Based Fluid: A Completely Cationic SystemDocument8 pagesSPE 94523 A New Inhibitive Water-Based Fluid: A Completely Cationic SystemDaniel Navarro EstradaNo ratings yet

- Research Article Silicate Scales Formation During ASP Flooding: A ReviewDocument13 pagesResearch Article Silicate Scales Formation During ASP Flooding: A ReviewTesis 2019No ratings yet

- Scaling Assessment, Inhibition and Monitoring of Geothermal WellsDocument13 pagesScaling Assessment, Inhibition and Monitoring of Geothermal WellsmuryaspNo ratings yet

- 1 s2.0 S092041052030574X MainDocument10 pages1 s2.0 S092041052030574X MainArunNo ratings yet

- Heliyon: Research ArticleDocument8 pagesHeliyon: Research Articleyeqiang liNo ratings yet

- Grander Technology OverviewDocument12 pagesGrander Technology OverviewanaptdrNo ratings yet

- Scale Problem Oil and GasDocument11 pagesScale Problem Oil and GasMas ChopinNo ratings yet

- Jordan 2008Document18 pagesJordan 2008Nizam NazriNo ratings yet

- Cooling Water TreatmentDocument2 pagesCooling Water TreatmentArun S100% (1)

- Mitigation and Remediation Technologies of Waxy Crude OilsDocument35 pagesMitigation and Remediation Technologies of Waxy Crude OilsChandran UdumbasseriNo ratings yet

- Fines Migration Problems and Treatments 2472 0518 1000123Document4 pagesFines Migration Problems and Treatments 2472 0518 1000123DianaNo ratings yet

- SPE 167632-STU The Trapping Capacity of Nanofluids On Migrating Fines in SandDocument15 pagesSPE 167632-STU The Trapping Capacity of Nanofluids On Migrating Fines in SandLiliana Paipa MontañezNo ratings yet

- Paper Skin DamageDocument11 pagesPaper Skin DamageViridiana SalazarNo ratings yet

- Waterflooding Management Challenges and SolutionsDocument9 pagesWaterflooding Management Challenges and Solutionsartha firmNo ratings yet

- Sumber FileDocument16 pagesSumber FileONes 4686No ratings yet

- Organic-Inorganic Interactions in Petroleum-Producing Sedimentary BasinsDocument7 pagesOrganic-Inorganic Interactions in Petroleum-Producing Sedimentary BasinsNavidNo ratings yet

- Penggunaan Sodium Polyacrylate Untuk Proses Demulsifikasi Minyak-AirDocument6 pagesPenggunaan Sodium Polyacrylate Untuk Proses Demulsifikasi Minyak-AirRahmi Nur Anisah Nasution 2003114489No ratings yet

- QueenDocument15 pagesQueenQunazatulshima BatubaraNo ratings yet

- Paraffin Wax Deposition: (The Challenges Associated and Mitigation Techniques, A Review)Document8 pagesParaffin Wax Deposition: (The Challenges Associated and Mitigation Techniques, A Review)Jit MukherheeNo ratings yet

- Tongyu Zhu 2022. Advances of Microemulsion and Its Applications For Improved Oil RecoveryDocument18 pagesTongyu Zhu 2022. Advances of Microemulsion and Its Applications For Improved Oil RecoverymadadmrdNo ratings yet

- Self-Assembled Supramolecular Architectures: Lyotropic Liquid CrystalsFrom EverandSelf-Assembled Supramolecular Architectures: Lyotropic Liquid CrystalsNo ratings yet

- Katalog Almaz Nefteservis 2022Document88 pagesKatalog Almaz Nefteservis 2022jose rogelio villaseñor gonzalezNo ratings yet

- Resume+Jose+Villaseno+Tech Data, 2023 VCDocument40 pagesResume+Jose+Villaseno+Tech Data, 2023 VCjose rogelio villaseñor gonzalezNo ratings yet

- Metals: An Analytical Model For Stress and Curvature Prediction of A Strip Leveling ProcessDocument18 pagesMetals: An Analytical Model For Stress and Curvature Prediction of A Strip Leveling Processjose rogelio villaseñor gonzalezNo ratings yet

- Operational Risk Management: Reliability Analysis and Proactive Facility MaintenanceDocument3 pagesOperational Risk Management: Reliability Analysis and Proactive Facility Maintenancejose rogelio villaseñor gonzalezNo ratings yet

- 415 120 DB 0001Document30 pages415 120 DB 0001Mustafa AhsanNo ratings yet

- CatTod2015 CO2 To Olefins CatDocument8 pagesCatTod2015 CO2 To Olefins CatSolticiio DiieNo ratings yet

- DESERT Solar CellsDocument2 pagesDESERT Solar CellsAndrew AtotuomahNo ratings yet

- RydAir BPIDocument4 pagesRydAir BPIbhasker sharmaNo ratings yet

- Cambridge IGCSE: Combined Science 0653/51Document16 pagesCambridge IGCSE: Combined Science 0653/51Paca GorriónNo ratings yet

- Evaluation of Factors Affecting Earth Pressures On Buried Box CulDocument593 pagesEvaluation of Factors Affecting Earth Pressures On Buried Box CulMarcus LindonNo ratings yet

- Determination of Specific Gravity: ReferencesDocument26 pagesDetermination of Specific Gravity: ReferencesSagheer AhmedNo ratings yet

- Pricelist Katalog Holymed - Rev JanDocument23 pagesPricelist Katalog Holymed - Rev JanPT.KARYASURYA MULIANo ratings yet

- SPILL CONTROL ENVIRONMENTAL EnglishDocument23 pagesSPILL CONTROL ENVIRONMENTAL EnglishMan NamNo ratings yet

- 5 Ways To Increase Welder EfficiencyDocument18 pages5 Ways To Increase Welder EfficiencyXavier BloombergNo ratings yet

- Katalog ARITA 20199Document68 pagesKatalog ARITA 20199Fresly JayaNo ratings yet

- 42 Sample ChapterDocument8 pages42 Sample ChapterAlex JordanNo ratings yet

- Manganese Oxidation StatesDocument4 pagesManganese Oxidation StatesxbokyxNo ratings yet

- 2222Document3 pages2222ArunNo ratings yet

- Precast EnvelopeDocument70 pagesPrecast Envelopesdutta2591No ratings yet

- Development of A Virtual Wiredrawing Tool For Process Analysis and OptimizationDocument7 pagesDevelopment of A Virtual Wiredrawing Tool For Process Analysis and OptimizationPhani KumarNo ratings yet

- Bhakaro Chautaro PlasterDocument8 pagesBhakaro Chautaro PlasterNaresh YadavNo ratings yet

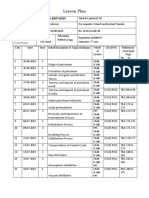

- Lesson Plan: Course Start Date Subject: Code/NameDocument3 pagesLesson Plan: Course Start Date Subject: Code/Nameanon_348923763No ratings yet

- Textbook Ebook Wire Technology Second Edition Process Engineering and Metallurgy Roger N Wright All Chapter PDFDocument43 pagesTextbook Ebook Wire Technology Second Edition Process Engineering and Metallurgy Roger N Wright All Chapter PDFgerald.estrada537100% (9)

- Characteristics of Shear Strength at The Interface Between Two Soil Layers in Ring Shear ApparatusDocument7 pagesCharacteristics of Shear Strength at The Interface Between Two Soil Layers in Ring Shear ApparatusDung2689No ratings yet

- ASTM A27 Steel - A Guide To Choosing The Right Grade - Casting & Foundry ServicesDocument3 pagesASTM A27 Steel - A Guide To Choosing The Right Grade - Casting & Foundry ServicesFrancisco Marin BortoluzziNo ratings yet

- KIO Technical Manual 2016Document34 pagesKIO Technical Manual 2016vuqar0979No ratings yet

- Oxygen and Silver Nanoparticle Aerosol Magnetohydrodynamic Power CycleDocument13 pagesOxygen and Silver Nanoparticle Aerosol Magnetohydrodynamic Power CyclealooNo ratings yet

- Tile Adhesive Heavy-Duty - Allgemeine Bau-Chemie Phil., IncDocument4 pagesTile Adhesive Heavy-Duty - Allgemeine Bau-Chemie Phil., IncRoland CepedaNo ratings yet

- Ansi/Ashrae/Ies Standard 90.1-2013 Envelope: Building Energy CodesDocument72 pagesAnsi/Ashrae/Ies Standard 90.1-2013 Envelope: Building Energy Codessymbo11No ratings yet

- Notes On Applied GeologyDocument35 pagesNotes On Applied Geologyavula43No ratings yet

- Mixtures Compounds PowerpointDocument16 pagesMixtures Compounds PowerpointKimberlyn VelascoNo ratings yet

42 Oil Field Scale in Petroleum Industry

42 Oil Field Scale in Petroleum Industry

Uploaded by

jose rogelio villaseñor gonzalezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

42 Oil Field Scale in Petroleum Industry

42 Oil Field Scale in Petroleum Industry

Uploaded by

jose rogelio villaseñor gonzalezCopyright:

Available Formats

International Journal of Innovative Research in Engineering & Management (IJIREM)

ISSN: 2350-0557, Volume-9, Issue-2, April 2022

https://doi.org/10.55524/ijirem.2022.9.2.42

Article ID IJIR-2245, Pages 288-293

www.ijirem.org

Oil Field Scale in Petroleum Industry

Jinal Patel1, and Ashish Nagar2

1

Research Scholar, Department of Petroleum Engineering, PIT, Parul University, Vadodara, Gujrat, India

2

Assistant Professor, Department of Petroleum Engineering, PIT, Parul University, Vadodara, Gujrat, India

Correspondence should be addressed to Jinal Patel; jnpatel7898@gmail.com

Copyright © 2022 Made Jinal Patel et al. This is an open-access article distributed under the Creative Commons Attribution License, which

permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

ABSTRACT: One of the most important issues in the oil potential directly or indirectly, therefore changes in these

industry is scale formation, which causes a decline in output components affect scale solubility and result in kinetic and

or financial loss. Scale deposits may range in severity from thermodynamic changes in scales formation. Corrosion or

minor to severe. If the scale deposit is allowed to persist, it dissolved gases are two more processes that contribute to the

reduces formation pores, lowers production, and finally creation of scale. Sulfides, as well as other scales such as

blocks the wellbore, resulting in unplanned downtime. carbonates and hydroxides, are affected by H2S and CO2.

Increased deposition results in lower operating efficiency, Scale production is further aided by nucleating places in the

posing a serious problem for the sector. To address the brine systems where scale crystals already are present on the

problem, a more effective management plan is required. equipment's surface. Figure 1 depicts the creation of scale in

Rather of allowing the scale to grow up and then taking a pipe [3], [4].

corrective action, the scale prevention approach should be

applied from the beginning. Descaling is also a costly

technique from a financial standpoint. Methods that can limit

or eliminate the scale deposition technique in the early

phases should be applied so that it does not adhere to the

production should indeed be implemented. The notion of

scale creation must be investigated in order to prevent

making poor corrective decisions that might jeopardize

output. The study considers the establishment of scales and

their implications for the oil sector.

KEYWORDS: Inorganic, Oil Field, Petroleum, Scale

Formation, Scale Deposition.

I. INTRODUCTION

Figure 1: Illustrate the Scale formation in the Layers of the

Inorganic, Organic, or crystal water make up the majority of Pipe

scales. Among the most difficult problems in petroleum

production but even water injections are scale deposit. It is A. Scale Formation or Scales Deposition

caused by the combination of two incompatible fluids in

Aggregation, Crystal Growth, and Agglomeration are the

most cases. When the two fluids interact chemically, these

four stages of the scale creation process. Whenever the brine

mineral precipitates, resulting in scale development. Scale

solution becomes supersaturated with scaling ions, the

deposition begins in the systems when the percentage of salts

aggregation process begins. In solution, these ions clash to

that are generally soluble in natural fluids utilized in the

create ion pairs, which then form micro-aggregates. Inside

treatment during manufacturing and processing surpasses the

the nucleation stages, the micro-aggregates act as nucleation

saturation levels during the treatments. It's a system in which

sites for crystallization, resulting in the development of

the aqueous system is supersaturated with scaling ions and

micro-crystals. These microcrystals grow into bigger

elevated to levels that surpass the solubility of a certain salt

microcrystals, which then fuse together to produce adherent

under ideal circumstances. Scale development is visible and

microcrystals. The agglomeration stage is characterized by

troublesome in systems such as oil well water, slag cooling

the formation of macro-crystals into a scale layer on a

water, boiler water, industrial cooling water, etc.

surface, which eventually results in a scale deposit. The full

Temperature, salinity, pressure, pH, and the kinds of scaling

technique of scale deposition is shown in Figure 2.

ions are all important elements in the scale generation

process [1], [2]. These characteristics impact the scaling

Innovative Research Publication 288

International Journal of Innovative Research in Engineering & Management (IJIREM)

Figure 1: Representing the Scale Deposition Mechanism

B. Types of Scales

Figure 3: Illustrating the Oilfield deposits can be classified in two major categories

These two forms are mutually inclusive, and they tend to to be compatible. It's referred to as incompatible water when

exist in the same system at the same time, which is referred it forms precipitates. The precipitates are unappealing

to as mixed scale. Mixed scales need more severe treatment because they reduce the permeability of producing rocks and

because of their very complicated structure, which makes input wells. They may also play a role in the production and

them difficult to cure and expensive to remediate. deposition of scale in pumps and lines [5]–[7]. When

Supersaturation of any one kind of scale-forming water formation water mixes with other brines, such as injection

owing to physical circumstances under which the water water, mineral deposits termed inorganic scales occur. As a

occurs is the principal cause of oilfield scale deposition as consequence of the mixing changes, which create

shown in Figure 3. It may also happen when two interactions between incompatible ions, the thermodynamic

incompatible waters are mixed together during the and equilibrium states of the reservoir fluids are changed. As

manufacture of well fluids. If water may be combined a consequence, inorganic salts become supersaturated and

without forming insoluble precipitate compounds, it is said precipitate. The most frequent inorganic scales found in the

Innovative Research Publication 289

International Journal of Innovative Research in Engineering & Management (IJIREM)

oil business are carbonates and sulfates; sulfides and Crystal size and number

chlorites are also widespread [8]–[10]. Phosphorus shift

Oilfield fluids contain the ions Ca+2, Ba+2, Sr+2, and Fe+2, Supersaturation level

which produce precipitate in unsuitable waters. Incompatible

waters include sea water, which has a high percentage of the D. Chemistry of the scale’s formation

SO4-2 but a lower content of Ca+2/Ba+2/ Sr+2 and Scale precipitation happens as a result of the mixing of

formation water, or it has a very lower content of SO4-2 but incompatible brine fluids, as well as deviations in external

just a higher proportion of Ca+2/ Sr+2/ Ba+2. Whenever parameters such as temperature, pressure, or pH. The

these two liquids are combined, CaSO4, SrSO4, and BaSO4 precipitation of solids form brines present in producing flow

precipitate. It's also conceivable that liquid waste is harmful systems or reservoirs causes the formation of mineral

to the environment. If waste water is coupled with saltwater crystallographic deposits known as oilfield scales. Minerals

for re-injection, there seems to be a risk of scale formation scale precipitation is driven by changes in brine content and

[10]–[12]. Scale buildup not only slows down production, products, and also pressure, temperature, or PH. The

but it also leads to failure and inefficiency. Excessive scale approaches used to classify the factors of variation are as

development could result in equipment failure. Scale follows:

deposition is a key concern when water injection is used. A drop in pressure or temperature causes the salt's

Deposition can occur in casings flow outlines, tubing, heaters ionic solubility to decrease.

treater, downhole pumps, tank, or even others processing The mixing of two incompatible brines.

apparatus, especially surface facilities. The scales have As the salt content in the brine grows over the

clogged up production processes, machinery, including fluid saturation point, salty precipitation occurs.

stream. Processing equipment failure, alternative downtime, Scale development by any mechanism accumulates over

increased maintenance costs, and a drop in total production time and eventually causes a blockage in the pipeline as well

effectiveness will be the consequences. If machines and as production tube. It should be noted that following water

equipment including instruments fail, workers' safety might injection, scales deposition happens not only in the

well be jeopardised. Biochemical mismatch among possible production tubing but also with the well head or reservoirs.

injecting fluids and reservoir brine causes scale development The production of scales in the injection pipeline is caused

in water flooding techniques. The most common oilfield by dissolved minerals in the water transported by the tubing,

scales are shown in Table 1 [13]–[15]. and the deposition of mineral scales is accelerated by

temperature changes. The major cause for scale development

Table 1: Illustrate the Oilfield scales and its Chemical in production tubing is temperature fluctuation, although a

Formula shift in pressure resulting in fluid or gas phase compositional

changes is another explanation. Because CO2 is liberated

from the water as a consequence of a pressure shift, the pH

of the water changes. The creation of scale at the bottom hole

is caused by the mixing of two incompatible waters and is

unlikely to be altered by temperature changes [16]–[18].

E. Types of mineral scale

There are two types of oilfield scale deposits: pH

independent or pH sensitive scales.

Scale that isn't affected by pH: Barium, Strontium, or

calcium sulphate are the compounds in question. The

sulphate ions in seawater interact with the naturally

occurring Ba+2, Sr+2, or Ca+2 ions in water. These

compounds are likewise just slightly soluble in water, thus

they precipitate out or form solid solutions [19].

Ba+2+SO4-2 BaSO4

Sr+2+SO4-2 SrSO4

Ca+2+SO4-2 CaSO4

C. Factors responsible for scale formation

Pressure increases between the fluids existing in the reservoir pH-dependent scales: Acids soluble carbonates

as well as the dissolved salts during well drilling and (dolomite, calcite, or siderite) or sulfide scales.

production in a hydrocarbon reservoir. After the well is Their structures are shown in the equations below.

completed, the fluid loses its balance, and salts begin to Ca+2 + CO3-2 CaCO3

precipitate. When the soluble limit possible for a single or Fe+2 + S-2 FeS

more components is exceeded, the scale begins to develop. Zn+2 + S-2 ZnS

Scale development is influenced by the following factors: Pb+2 + S-2 PbS

Pressure changes

Temperature shifts

Amount of agitation

Innovative Research Publication 290

International Journal of Innovative Research in Engineering & Management (IJIREM)

F. Mechanism of the scale’s deposition become oversaturated in the generated water. This occurs

Due to the abundance of limestone areas, calcium carbonate, because saltwater has a lot of SO4-2 whereas formation

also known as calcite scale, is commonly discovered in waters include a lot of ions like Ca+2 or Ba+2. Sulphate

oilfield operations. Calcite is the most frequent oil field scale scales including such CaSO4 or BaSO4 occur when these

found at production sites since it is the most stable in terms two precipitates are mixed.

of strength. The reaction that lead to the solids calcium Ca+2(aq) + SO4-2(aq) + 2H2O (l)↔CaSO4.2H2O

carbonates production are follows: (s)

Carbon dioxide first combines with water to form carbonic One of the most harmful scales is barium sulphate. They

acids. cause issues in oilfields such as clogged valves, clogged flow

CO2(g) + H2O (l)↔ H2CO3(aq) lines, and a decline in oil output owing to constraints

This carbon dioxide will continuing to dissociate hydrogen, developed in the production tubing, resulting in millions of

resulting in the formation of additional deprotonated dollars in lost production.

carbonic acids species. The combination of seawater for use as injection water or

H2CO3(aq) + H2O (l) ↔H3O+(aq) + HCO3-(aq) formation water results in the production of barium scale.

H2CO3(aq) + H2O (l)↔H3O+(aq) + CO3-2(aq) Seawater is often high in SO4-2 anions, but deep

There will be a combination of species H2CO3, HCO3-, but subterranean waters are high in ions like Ba+2 or Sr+2.

also CO3-2 in the water mixture. When the condition of any natural fluid is disrupted until the

Carbonate will precipitate in the form of calcium or carbonic solubility limit for one or more of the elements is surpassed,

acids. barium sulphate scales begin to precipitate.

CO3-2(aq) + Ca+2(aq)↔CaCO3(s) Ba+2(aq) (formation water) + SO4-2(aq)

Since, produced water usually contains a carbonic acid and (seawater)↔ BaSO4 (s)

calcium ions, a recombination of these reactions Strontium sulphate scales occurred in oil fields inside the

existence of Barium sulphate scale till recently. SrSO4 scales

Ca(HCO3)2(aq)↔CO2(g) + H2O (l) + CaCO3(s)

act similarly to BaSO4 scales, however they are lower

Water, solid calcium carbonate, and CO2 gas will be in

soluble in water than BaSO4 scales. As a consequence of

balance with calcium or carbonic acids in liquid form.

combining incompatible water or thermodynamic

Calcium sulphate scaling are crystalline but mostly include

conditions, scales development is linked to water injection

calcium and sulphate ions, while they may also contain

processes. So acid resistant scale is broken up using powerful

residues of a variety of other ions. They may produce solid

chelating chemicals that tie up the metallic ions of the scale

solutions when co-precipitated with strontium sulphates. If

inside their closed ring structure. Figure 4 depicts possible

precipitated from oil fluids, it may include trace amounts of

scale creation locations.

silt or wax. Scale deposits are generated when two

incompatible fluids, such as injected saltwater into a

reservoir during effective rehabilitation procedures or

formation water, combine down the well. Scale components

Figure 4: Illustrate the Probable Scale Formation Sites.

Innovative Research Publication 291

International Journal of Innovative Research in Engineering & Management (IJIREM)

Where incompatible water is blended before gas and the necessity for transportation to satisfy that

injection at a surface water injection sit demand, all petroleum and pipeline engineers need exact

Injection wells in which the injected water mixes consumption or scaling data. The Fundamentals of Corrosion

with reservoir formation water. and Scaling for Petroleum or Environmental Engineers will

The injected water disperses formation water provide draughtsman with the quick data they need to work

downhole in the reservoir. on the consistency of usage and scale control improvements,

Downhole in the reservoir, near the producing well, as well as manage scale storage, prevent shortfalls, and

where the injected water and formation water are ensure equipment honesty.

going to meet.

Tubing used in the manufacturing process. III. CONCLUSION

A branching zone at the junction generated diverse A scales statement happens when the arrangements harmony

water. of both the water is disrupted by strain or temperature

In a multi-block zone, when water is generated from variations, broken down gases, or a disparity between

several blocks within the same zone blending water. Scale stores are a common and aggravating

Produced fluids are combined at topside facilities to problem in the oil business, and they may develop in both

extract oil and gas from produced waters, or the creation as well as infusion wells. Scale deposition is one of

pipeline transporting fluids to onshore processing the most serious issues in the oil or gas industry. It not only

facilities. has a negative impact on production, but it also has a

G. Problems caused due to Scale Formation negative impact on formation. The incompatibility of the

waters causes the creation of scale, which causes problems

The formation of scales may occur in the reservoir, surface at the facilities and ultimately leads to production failure.

facilities or deposits may cause Large stores that increase over time, obstructing or degrading

Formation damage liquid circulation through pipelines, valves, siphons, and

Blocking pore throats other similar systems, resulting in substantial declines in

Corrosion under the scale deposits flow rates as well as hardware damage, are referred to as

Instrumental failure scale in the oil business. Rather of allowing the scale to get

Flow meter failure out of control before intervening, the scale prevention

Pump wearing technique should be used from the start. Descaling is also an

Safety valves failure expensive procedure in terms of money. Methods that can

Completion failure by plugging perforations and restrict or remove the scale deposition approach in the early

gravel pack stages should be employed to ensure that it does not adhere

Flow restriction by choking the flow tubing’s to the production. In order to avoid making bad corrective

Reduce oil – water separation efficiency judgments that risk production, the concept of scale creation

must be examined.

II. DISCUSSION

REFERENCES

Scale is a word used in the oil industry to describe large

stores that build up over time or impede liquid flow via [1] _ JPT staff, “An Abrasive Jetting Scale-Removal System,” J.

Pet. Technol., 1998, doi: 10.2118/0598-0082-jpt.

pipelines, syphons, valves, or other equipment, causing

[2] C. Bezemer and K. A. Bauer, “Prevention of Carbonate Scale

crucial production losses as well as hardware damage. Deposition: A Well-Packing Technique with Controlled

Oilfield scale restraints are a method of preventing scale Solubility Phosphates,” J. Pet. Technol., 1969, doi:

from impeding or constraining liquid entry through 10.2118/2176-pa.

pipelines, valves, or syphons used in the oil production and [3] L. Bertero, G. L. Chierici, G. Gottardi, E. Mesini, and G.

transportation process. Scale inhibitors are a kind of Mormino, “Chemical equilibrium models: their use in

specialty chemical that is used to delay or prevent scaling in simulating the injection of incompatible waters.,” SPE

waterways. A store or coating produced on the external layer Reserv. ENGNG., 1989, doi: 10.2118/14126-pa.

of a metal, rock, or other object. Scale may be defined as [4] H. J. Bayona, “Review of well injectivity performance in

Saudi Arabia’s Ghawar field seawater injection program,”

precipitation induced by a synthetic reaction to the surface,

1993, doi: 10.2523/25531-ms.

precipitation caused by material responses, a change in strain [5] A. A. Umar, I. B. M. Saaid, A. A. Sulaimon, and R. B. M.

and temperature, or even a change in the organization of a Pilus, “A review of petroleum emulsions and recent progress

response. The term is also used to denote a thing that is on water-in-crude oil emulsions stabilized by natural

deteriorating. Calcium carbonate, iron sulfide, barium surfactants and solids,” Journal of Petroleum Science and

sulfate, calcium sulfate, iron oxides, strontium sulfate, iron Engineering. 2018, doi: 10.1016/j.petrol.2018.03.014.

carbonate, various silicates, including phosphates but also [6] S. Adham, A. Hussain, J. Minier-Matar, A. Janson, and R.

oxides, or any of a number of insoluble or slightly soluble in Sharma, “Membrane applications and opportunities for water

water combinations are now all common scales. Scale, also management in the oil & gas industry,” Desalination. 2018,

doi: 10.1016/j.desal.2018.01.030.

known as stores, may build up in wellbore tubulars and other

[7] G. Lassalle, S. Fabre, A. Credoz, D. Dubucq, and A. Elger,

downhole components, presenting a major danger to the “Monitoring oil contamination in vegetated areas with optical

well's continuous operation. With the increased use of oil and remote sensing: A comprehensive review,” Journal of

Innovative Research Publication 292

International Journal of Innovative Research in Engineering & Management (IJIREM)

Hazardous Materials. 2020, doi:

10.1016/j.jhazmat.2020.122427.

[8] G. Poi, A. Aburto-Medina, P. C. Mok, A. S. Ball, and E.

Shahsavari, “Large scale bioaugmentation of soil

contaminated with petroleum hydrocarbons using a mixed

microbial consortium,” Ecol. Eng., 2017, doi:

10.1016/j.ecoleng.2017.01.048.

[9] A. S. Abd, E. Elhafyan, A. R. Siddiqui, W. Alnoush, M. J.

Blunt, and N. Alyafei, “A review of the phenomenon of

counter-current spontaneous imbibition: Analysis and data

interpretation,” Journal of Petroleum Science and

Engineering. 2019, doi: 10.1016/j.petrol.2019.05.066.

[10] J. A. Ali, A. M. Kalhury, A. N. Sabir, R. N. Ahmed, N. H.

Ali, and A. D. Abdullah, “A state-of-the-art review of the

application of nanotechnology in the oil and gas industry with

a focus on drilling engineering,” J. Pet. Sci. Eng., 2020, doi:

10.1016/j.petrol.2020.107118.

[11] C. Zou et al., “Formation, distribution, potential and

prediction of global conventional and unconventional

hydrocarbon resources,” Pet. Explor. Dev., 2015, doi:

10.1016/S1876-3804(15)60002-7.

[12] A. V. Lapin, “Classification of threats to the economic

security of the oil industry development,” Mark. Econ.

Probl., 2021, doi: 10.33051/2500-2325-2021-3-148-157.

[13] Z. Tariq, M. Mahmoud, and A. Abdulraheem, “Real-time

prognosis of flowing bottom-hole pressure in a vertical well

for a multiphase flow using computational intelligence

techniques,” J. Pet. Explor. Prod. Technol., 2020, doi:

10.1007/s13202-019-0728-4.

[14] B. Damjanac, C. Detournay, and P. A. Cundall, “Application

of particle and lattice codes to simulation of hydraulic

fracturing,” Comput. Part. Mech., 2016, doi:

10.1007/s40571-015-0085-0.

[15] M. Sagir, M. Mushtaq, M. S. Tahir, M. B. Tahir, and A. R.

Shaik, Surfactants for enhanced oil recovery applications.

2020.

[16] C. Sun, H. Guo, Y. Li, and K. Song, “Recent Advances of

Surfactant-Polymer (SP) Flooding Enhanced Oil Recovery

Field Tests in China,” Geofluids, 2020, doi:

10.1155/2020/8286706.

[17] N. K. Malhotra, “Basic Marketing Research,” Implicit

Measures of Attitudes. 2012.

[18] Z. Huang, H. S. Lee, M. Senra, and H. Scott Fogler, “A

fundamental model of wax deposition in subsea oil

pipelines,” AIChE J., 2011, doi: 10.1002/aic.12517.

[19] S. M. Jokar, D. A. Wood, S. Sinehbaghizadeh, P. Parvasi, and

J. Javanmardi, “Transformation of associated natural gas into

valuable products to avoid gas wastage in the form of

flaring,” J. Nat. Gas Sci. Eng., 2021, doi:

10.1016/j.jngse.2021.104078.

Innovative Research Publication 293

You might also like

- Studies On Scale Deposition in Oil Industries and Their ControlDocument16 pagesStudies On Scale Deposition in Oil Industries and Their ControlIJIRST100% (1)

- When Glass meets Pharma: Insights about glass as primary packaging materialFrom EverandWhen Glass meets Pharma: Insights about glass as primary packaging materialNo ratings yet

- Glass Case Study and Market StudyDocument57 pagesGlass Case Study and Market StudymintuNo ratings yet

- Dec Exam AnswersDocument17 pagesDec Exam Answersvivivihohoho1No ratings yet

- Design and Construction of Waste Paper' Recycling PlantDocument12 pagesDesign and Construction of Waste Paper' Recycling PlantAhmed Ali100% (1)

- Surface Inorganic Scale Formation in Oil and Gas IDocument12 pagesSurface Inorganic Scale Formation in Oil and Gas IROZANANo ratings yet

- 2 BrasilDocument13 pages2 BrasilmaxjuliNo ratings yet

- IMPROVE EFFICIENCY OF COOLING TOWER BY PASSIVATION Ijariie8796Document6 pagesIMPROVE EFFICIENCY OF COOLING TOWER BY PASSIVATION Ijariie8796KaushalNo ratings yet

- Production Ii PDFDocument235 pagesProduction Ii PDFADARSH KUMARNo ratings yet

- An Introduction To Scaling Causes, Problems and Solutions: NTNU - Institutt For Petroleumsteknologi Og Anvendt GeofysikkDocument23 pagesAn Introduction To Scaling Causes, Problems and Solutions: NTNU - Institutt For Petroleumsteknologi Og Anvendt GeofysikkIman QurbanovNo ratings yet

- Formation Damage and AcidDocument3 pagesFormation Damage and AcidSahito MasroorNo ratings yet

- Vedant Am 2013Document51 pagesVedant Am 2013maría joséNo ratings yet

- Energies: Occurrence and Characterization of Paraffin Wax Formed in Developing Wells and PipelinesDocument23 pagesEnergies: Occurrence and Characterization of Paraffin Wax Formed in Developing Wells and PipelinesMohammed HeshamNo ratings yet

- Cost Saving Case Study Using A Calcium Sulphate Specific AntiscalantDocument10 pagesCost Saving Case Study Using A Calcium Sulphate Specific AntiscalantNaim HossainNo ratings yet

- Scale InhibitorsDocument6 pagesScale InhibitorsgulfengsolutionsNo ratings yet

- Advanced Trends of Shale Inhibitors For Enhanced Properties of Water-BasedDocument7 pagesAdvanced Trends of Shale Inhibitors For Enhanced Properties of Water-BasedSkolastika ErnaNo ratings yet

- 1 s2.0 S0920410521004629 MainDocument16 pages1 s2.0 S0920410521004629 Mainjolugoto1991No ratings yet

- Flocculants and Coagulants NALCO (LIT)Document6 pagesFlocculants and Coagulants NALCO (LIT)Namita AgarwalNo ratings yet

- JCG3382012189 194Document7 pagesJCG3382012189 194ingNo ratings yet

- UOP Extending Molecular Sieve Life Tech PaperDocument7 pagesUOP Extending Molecular Sieve Life Tech PaperOmar EzzatNo ratings yet

- Nandwani 2017Document37 pagesNandwani 2017Alondra Guadalupe Escobar VillanuevaNo ratings yet

- Flocculants and Coagulants NALCO (LIT)Document6 pagesFlocculants and Coagulants NALCO (LIT)AlexisPereiraVásquezNo ratings yet

- Corrosion Inhibitors in The Oil and Gas Industry - 2020 - Saji - Antiscalants and Their Compatibility With CorrosionDocument23 pagesCorrosion Inhibitors in The Oil and Gas Industry - 2020 - Saji - Antiscalants and Their Compatibility With CorrosionNantawat KaekratokeNo ratings yet

- Oajs 02 00054Document8 pagesOajs 02 00054Marcos SilvaNo ratings yet

- C2018-10490Document15 pagesC2018-10490tinovelazquezNo ratings yet

- Efficient Separation of Oil Water Emulsions Compet - 2023 - Journal of EnvironmDocument18 pagesEfficient Separation of Oil Water Emulsions Compet - 2023 - Journal of Environm21chehs.gandhiNo ratings yet

- Universal Correlation For Gas Hydrates Suppression Temperature of Inhibited Systems: I. Single SaltsDocument49 pagesUniversal Correlation For Gas Hydrates Suppression Temperature of Inhibited Systems: I. Single Saltsavula43No ratings yet

- FracturingDocument43 pagesFracturingPrincess OkolomaNo ratings yet

- A Critical Review of Development and Demulsification Mechanisms of Crude Oil Emulsion in The Petroleum IndustryDocument18 pagesA Critical Review of Development and Demulsification Mechanisms of Crude Oil Emulsion in The Petroleum IndustrymirNo ratings yet

- Beneficial Uses of The Produced Water From Palogue Oil Field For Injection To Enhance Oil RecoveryDocument7 pagesBeneficial Uses of The Produced Water From Palogue Oil Field For Injection To Enhance Oil RecoverymuralisunNo ratings yet

- Study of Physiochemical Properties of Sodium Dodecyl Sulphate Surfactant It's Micellization, Oil in Water Emulsification and Industrial ApplicationsDocument6 pagesStudy of Physiochemical Properties of Sodium Dodecyl Sulphate Surfactant It's Micellization, Oil in Water Emulsification and Industrial ApplicationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Experimental - Investigation - of - Crude Oil DesaltingDocument19 pagesExperimental - Investigation - of - Crude Oil DesaltingElbahi DjaalabNo ratings yet

- VEDANTAM-RANADE2013 - Article - CrystallizationKeyThermodynami, KINECTIC Y HYDRODINAMIC ASPECTSDocument51 pagesVEDANTAM-RANADE2013 - Article - CrystallizationKeyThermodynami, KINECTIC Y HYDRODINAMIC ASPECTSVanesa Ramirez CatalanNo ratings yet

- Salt Precipitation and Scale Control in Supercritical Water Oxidation-Part B: Commercial/full-Scale ApplicationsDocument24 pagesSalt Precipitation and Scale Control in Supercritical Water Oxidation-Part B: Commercial/full-Scale ApplicationsOmer Bin HussainNo ratings yet

- Scale Formation PDFDocument16 pagesScale Formation PDFRohit NairNo ratings yet

- Crysytal Growth GelDocument18 pagesCrysytal Growth GelGnana SilviaNo ratings yet

- 1 s2.0 S2405656122000128 MainDocument14 pages1 s2.0 S2405656122000128 Mainorderin aja yukNo ratings yet

- Processes 10 00738 v2Document34 pagesProcesses 10 00738 v2heranNo ratings yet

- Desalting Paper Musleh1Document18 pagesDesalting Paper Musleh1Ahmed Mohamed KhalilNo ratings yet

- Riazi 2Document12 pagesRiazi 2Seyedeh Maryam MousaviNo ratings yet

- SPE 94523 A New Inhibitive Water-Based Fluid: A Completely Cationic SystemDocument8 pagesSPE 94523 A New Inhibitive Water-Based Fluid: A Completely Cationic SystemDaniel Navarro EstradaNo ratings yet

- Research Article Silicate Scales Formation During ASP Flooding: A ReviewDocument13 pagesResearch Article Silicate Scales Formation During ASP Flooding: A ReviewTesis 2019No ratings yet

- Scaling Assessment, Inhibition and Monitoring of Geothermal WellsDocument13 pagesScaling Assessment, Inhibition and Monitoring of Geothermal WellsmuryaspNo ratings yet

- 1 s2.0 S092041052030574X MainDocument10 pages1 s2.0 S092041052030574X MainArunNo ratings yet

- Heliyon: Research ArticleDocument8 pagesHeliyon: Research Articleyeqiang liNo ratings yet

- Grander Technology OverviewDocument12 pagesGrander Technology OverviewanaptdrNo ratings yet

- Scale Problem Oil and GasDocument11 pagesScale Problem Oil and GasMas ChopinNo ratings yet

- Jordan 2008Document18 pagesJordan 2008Nizam NazriNo ratings yet

- Cooling Water TreatmentDocument2 pagesCooling Water TreatmentArun S100% (1)

- Mitigation and Remediation Technologies of Waxy Crude OilsDocument35 pagesMitigation and Remediation Technologies of Waxy Crude OilsChandran UdumbasseriNo ratings yet

- Fines Migration Problems and Treatments 2472 0518 1000123Document4 pagesFines Migration Problems and Treatments 2472 0518 1000123DianaNo ratings yet

- SPE 167632-STU The Trapping Capacity of Nanofluids On Migrating Fines in SandDocument15 pagesSPE 167632-STU The Trapping Capacity of Nanofluids On Migrating Fines in SandLiliana Paipa MontañezNo ratings yet

- Paper Skin DamageDocument11 pagesPaper Skin DamageViridiana SalazarNo ratings yet

- Waterflooding Management Challenges and SolutionsDocument9 pagesWaterflooding Management Challenges and Solutionsartha firmNo ratings yet

- Sumber FileDocument16 pagesSumber FileONes 4686No ratings yet

- Organic-Inorganic Interactions in Petroleum-Producing Sedimentary BasinsDocument7 pagesOrganic-Inorganic Interactions in Petroleum-Producing Sedimentary BasinsNavidNo ratings yet

- Penggunaan Sodium Polyacrylate Untuk Proses Demulsifikasi Minyak-AirDocument6 pagesPenggunaan Sodium Polyacrylate Untuk Proses Demulsifikasi Minyak-AirRahmi Nur Anisah Nasution 2003114489No ratings yet

- QueenDocument15 pagesQueenQunazatulshima BatubaraNo ratings yet

- Paraffin Wax Deposition: (The Challenges Associated and Mitigation Techniques, A Review)Document8 pagesParaffin Wax Deposition: (The Challenges Associated and Mitigation Techniques, A Review)Jit MukherheeNo ratings yet

- Tongyu Zhu 2022. Advances of Microemulsion and Its Applications For Improved Oil RecoveryDocument18 pagesTongyu Zhu 2022. Advances of Microemulsion and Its Applications For Improved Oil RecoverymadadmrdNo ratings yet

- Self-Assembled Supramolecular Architectures: Lyotropic Liquid CrystalsFrom EverandSelf-Assembled Supramolecular Architectures: Lyotropic Liquid CrystalsNo ratings yet

- Katalog Almaz Nefteservis 2022Document88 pagesKatalog Almaz Nefteservis 2022jose rogelio villaseñor gonzalezNo ratings yet

- Resume+Jose+Villaseno+Tech Data, 2023 VCDocument40 pagesResume+Jose+Villaseno+Tech Data, 2023 VCjose rogelio villaseñor gonzalezNo ratings yet

- Metals: An Analytical Model For Stress and Curvature Prediction of A Strip Leveling ProcessDocument18 pagesMetals: An Analytical Model For Stress and Curvature Prediction of A Strip Leveling Processjose rogelio villaseñor gonzalezNo ratings yet

- Operational Risk Management: Reliability Analysis and Proactive Facility MaintenanceDocument3 pagesOperational Risk Management: Reliability Analysis and Proactive Facility Maintenancejose rogelio villaseñor gonzalezNo ratings yet

- 415 120 DB 0001Document30 pages415 120 DB 0001Mustafa AhsanNo ratings yet

- CatTod2015 CO2 To Olefins CatDocument8 pagesCatTod2015 CO2 To Olefins CatSolticiio DiieNo ratings yet

- DESERT Solar CellsDocument2 pagesDESERT Solar CellsAndrew AtotuomahNo ratings yet

- RydAir BPIDocument4 pagesRydAir BPIbhasker sharmaNo ratings yet

- Cambridge IGCSE: Combined Science 0653/51Document16 pagesCambridge IGCSE: Combined Science 0653/51Paca GorriónNo ratings yet

- Evaluation of Factors Affecting Earth Pressures On Buried Box CulDocument593 pagesEvaluation of Factors Affecting Earth Pressures On Buried Box CulMarcus LindonNo ratings yet

- Determination of Specific Gravity: ReferencesDocument26 pagesDetermination of Specific Gravity: ReferencesSagheer AhmedNo ratings yet

- Pricelist Katalog Holymed - Rev JanDocument23 pagesPricelist Katalog Holymed - Rev JanPT.KARYASURYA MULIANo ratings yet

- SPILL CONTROL ENVIRONMENTAL EnglishDocument23 pagesSPILL CONTROL ENVIRONMENTAL EnglishMan NamNo ratings yet

- 5 Ways To Increase Welder EfficiencyDocument18 pages5 Ways To Increase Welder EfficiencyXavier BloombergNo ratings yet

- Katalog ARITA 20199Document68 pagesKatalog ARITA 20199Fresly JayaNo ratings yet

- 42 Sample ChapterDocument8 pages42 Sample ChapterAlex JordanNo ratings yet

- Manganese Oxidation StatesDocument4 pagesManganese Oxidation StatesxbokyxNo ratings yet

- 2222Document3 pages2222ArunNo ratings yet

- Precast EnvelopeDocument70 pagesPrecast Envelopesdutta2591No ratings yet

- Development of A Virtual Wiredrawing Tool For Process Analysis and OptimizationDocument7 pagesDevelopment of A Virtual Wiredrawing Tool For Process Analysis and OptimizationPhani KumarNo ratings yet

- Bhakaro Chautaro PlasterDocument8 pagesBhakaro Chautaro PlasterNaresh YadavNo ratings yet

- Lesson Plan: Course Start Date Subject: Code/NameDocument3 pagesLesson Plan: Course Start Date Subject: Code/Nameanon_348923763No ratings yet

- Textbook Ebook Wire Technology Second Edition Process Engineering and Metallurgy Roger N Wright All Chapter PDFDocument43 pagesTextbook Ebook Wire Technology Second Edition Process Engineering and Metallurgy Roger N Wright All Chapter PDFgerald.estrada537100% (9)

- Characteristics of Shear Strength at The Interface Between Two Soil Layers in Ring Shear ApparatusDocument7 pagesCharacteristics of Shear Strength at The Interface Between Two Soil Layers in Ring Shear ApparatusDung2689No ratings yet

- ASTM A27 Steel - A Guide To Choosing The Right Grade - Casting & Foundry ServicesDocument3 pagesASTM A27 Steel - A Guide To Choosing The Right Grade - Casting & Foundry ServicesFrancisco Marin BortoluzziNo ratings yet

- KIO Technical Manual 2016Document34 pagesKIO Technical Manual 2016vuqar0979No ratings yet

- Oxygen and Silver Nanoparticle Aerosol Magnetohydrodynamic Power CycleDocument13 pagesOxygen and Silver Nanoparticle Aerosol Magnetohydrodynamic Power CyclealooNo ratings yet

- Tile Adhesive Heavy-Duty - Allgemeine Bau-Chemie Phil., IncDocument4 pagesTile Adhesive Heavy-Duty - Allgemeine Bau-Chemie Phil., IncRoland CepedaNo ratings yet

- Ansi/Ashrae/Ies Standard 90.1-2013 Envelope: Building Energy CodesDocument72 pagesAnsi/Ashrae/Ies Standard 90.1-2013 Envelope: Building Energy Codessymbo11No ratings yet

- Notes On Applied GeologyDocument35 pagesNotes On Applied Geologyavula43No ratings yet

- Mixtures Compounds PowerpointDocument16 pagesMixtures Compounds PowerpointKimberlyn VelascoNo ratings yet