Professional Documents

Culture Documents

Checking of Steel Subgrade For MOL L6 Steel Beam

Checking of Steel Subgrade For MOL L6 Steel Beam

Uploaded by

Heaven ChanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checking of Steel Subgrade For MOL L6 Steel Beam

Checking of Steel Subgrade For MOL L6 Steel Beam

Uploaded by

Heaven ChanCopyright:

Available Formats

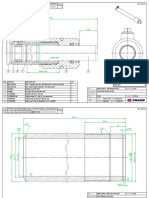

Checking of Steel Subgrade for MOL L6 Steel Beam Rev.

Checking of Steel Subgrade for I-Section 60mm, S355J2 (HKSC 2011, Cls. 3.2)

Proposed Sub-grade J2

o

T27J -20 C

Steel Grade S355

Thickness of Steel, t 60 mm

Nominal Yield Stress 335 N/mm2

o

Tmin 0.1 C

N 2.01

t1 78.2 mm

K (HKSC, Table 3.8), (FPBW -> Welded, Generally) 1

Kt1 78.2 mm >Thickness of Steel, 60mm, OK

Checking of Steel Subgrade for I-Section 40mm, S355J0 (HKSC 2011, Cls. 3.2)

Proposed Sub-grade J0

o

T27J 0 C

Steel Grade S355

Thickness of Steel, t 40 mm

Nominal Yield Stress 345 N/mm2

o

Tmin 0.1 C

N 0.01

t1 52.1 mm

K (HKSC, Table 3.8), (FPBW -> Welded, Generally) 1

Kt1 52.1 mm >Thickness of Steel, 40mm, OK

Checking for Through Thickness Properties to Quality Class Z15, Z25 & Z35

Connection for 40mm Dia Coupler vs >70mm THK Flange with PPBW

According to BS EN 1993-1-10:2005, Table 3.2 21 mm

Za 6 (10 < aeff ≤ 20 mm)

Zb 3 (Partial Penetration Weld)

Zc 15 (Effect Thickness = 60mm) 12.1mm

Zd 0 (Medium Restraint)

Ze -8 (Preheating)

>70 mm

Zed, (Za+Zb+Zc+Zd+Ze) 16 10<Zed<=20, Z15 to be used

Case 2 (Refer Section 6 on Arup Sketch Ref.: SK-ST-1763B dated 18 DEC 2019)

Checking for Through Thickness Properties to Quality Class Z15, Z25 & Z35

Connection to 40mm THK Flange vs 40mm THK Stiffener Plate with FPBW

According to BS EN 1993-1-10:2005, Table 3.2 40 mm

Za 6 (10 < aeff ≤ 20 mm)

Zb 3 (Full Penetration Weld)

Zc 8 (Effect Thickness = 40mm) 20mm

Zd 0 (Low Restraint)

Ze -8 (Preheating) 40mm

Zed, (Za+Zb+Zc+Zd+Ze) 9 No Quality Subgrade to be used

Checking of Steel Subgrade for MOL L6 Steel Beam

Case 3 (Refer Section 6 on Arup Sketch Ref.: SK-ST-1763B dated 18 DEC 2019)

Checking for Through Thickness Properties to Quality Class Z15, Z25 & Z35

Connection for 30mm THK Flange Vs 40mm Stiffener with FPBW

According to BS EN 1993-1-10:2005, Table 3.2 40 mm

Za 6 (10 < aeff ≤ 20 mm)

Zb 3 (Full Penetration Weld) a=20mm

Zc 6 (Effect Thickness = 30mm)

Zd 0 (Low Restraint)

Ze -8 (Preheating)

30mm

Zed, (Za+Zb+Zc+Zd+Ze) 7 No Quality Subgrade to be used

With reference to EN 10164 Table 3.2

For Case 1: Z Ed= 16 Z Rd= 0 (No Subgrade to be used)

For Case 2: Z Ed= 9 Z Rd= 0 (No Subgrade to be used)

For Case 3: Z Ed= 7 Z Rd= 0 (No Subgrade to be used)

Summary of Plate Case 1

Thickness Gr. J Z 60mm

20mm S355 J0 -

30mm S355 J0 -

20mm

40mm S355 J0 -

60mm S355 J2 -

Case 2 Case 3

600x660x40x30 600x660x30x20

BUILT UP I BUILT UP I SECTION

40mm Flange 30mm Flange

40mm Stiffener 40mm Stiffener

Connection for 40mm Dia. Coupler vs > 70mmTHK Flange with

PPBW

2. Connection to 40mm Flange vs 40mm Stiffener with FPBW

3. Connection for 30mm Flange Vs 40mm Stiffener with FPBW

You might also like

- EcDocument35 pagesEcdwifaajust100% (2)

- Shel Lab Water Jacket CO2 Incubator - User and Service ManualDocument30 pagesShel Lab Water Jacket CO2 Incubator - User and Service ManualArte Y MecatrónicaNo ratings yet

- Offshore Structure Design AssignmentDocument26 pagesOffshore Structure Design AssignmentNina GraceNo ratings yet

- DC54D ZDocument4 pagesDC54D ZGustavoNo ratings yet

- Inorganic Chromate-Free Coated Hot-Dip Galvanized Steel Sheet JMDocument2 pagesInorganic Chromate-Free Coated Hot-Dip Galvanized Steel Sheet JMKYAW SOENo ratings yet

- S355J2+N Steel PlateDocument2 pagesS355J2+N Steel PlateAmanNo ratings yet

- TG-X308L TG-X309L TG-X316L TG-X347 TG-X2209: Description and ApplicationDocument1 pageTG-X308L TG-X309L TG-X316L TG-X347 TG-X2209: Description and ApplicationV U P RaoNo ratings yet

- Blind Flange Design For 8", 600#, 15B Service LineDocument2 pagesBlind Flange Design For 8", 600#, 15B Service LineGohar ZamanNo ratings yet

- (Table Size: Larger Than 1500mm X 500mm) (Table Size: Larger Than 1500mm X 500mm)Document2 pages(Table Size: Larger Than 1500mm X 500mm) (Table Size: Larger Than 1500mm X 500mm)solehNo ratings yet

- Metal Coated Structural Steels, EN10346:2015: General Product Description Mechanical PropertiesDocument3 pagesMetal Coated Structural Steels, EN10346:2015: General Product Description Mechanical PropertiesSrikanth SrikantiNo ratings yet

- S235 Low Carbon Manganese Steel - Hillfoot Multi MetalsDocument1 pageS235 Low Carbon Manganese Steel - Hillfoot Multi MetalsIrshad AhmadNo ratings yet

- Chinese Specification For Cast Iron and S. G. IronDocument1 pageChinese Specification For Cast Iron and S. G. IronRahul KhoslaNo ratings yet

- Blind Flange Design For 8", 600#, 15B Service LineDocument2 pagesBlind Flange Design For 8", 600#, 15B Service LineGohar ZamanNo ratings yet

- Problem Input: Particulars UnitDocument43 pagesProblem Input: Particulars UnitChinmay PatilNo ratings yet

- Flat Bracing Design EC3Document1 pageFlat Bracing Design EC3David O'MearaNo ratings yet

- Zincform G300 G300SDocument2 pagesZincform G300 G300SBaziNo ratings yet

- EC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Document7 pagesEC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Dong LINo ratings yet

- Flat Bracing Design EC3Document1 pageFlat Bracing Design EC3David O'MearaNo ratings yet

- European Steel and Alloy Grades: S235JRG2 (1.0038)Document2 pagesEuropean Steel and Alloy Grades: S235JRG2 (1.0038)farshid KarpasandNo ratings yet

- ST 37-2 Steel, ST 37-2 Structure Steel, ST 37-2 Equivalent-Seed SteelDocument1 pageST 37-2 Steel, ST 37-2 Structure Steel, ST 37-2 Equivalent-Seed SteelPeddi Raja MohanNo ratings yet

- Jis G3101 1995Document3 pagesJis G3101 1995Kholer BurgmanNo ratings yet

- Weld Stress CalculationsDocument19 pagesWeld Stress CalculationsMichael WaltersNo ratings yet

- Aço Especial de Engrenagens 20CrMnTiDocument3 pagesAço Especial de Engrenagens 20CrMnTiEdson FelixNo ratings yet

- 01AM - Sample CalcsDocument2 pages01AM - Sample CalcsPrakash SinghNo ratings yet

- Item5 LNT316LDocument1 pageItem5 LNT316LVVan TanNo ratings yet

- Beam DesignDocument2 pagesBeam DesignBilal A BarbhuiyaNo ratings yet

- Mogami W3082Document1 pageMogami W3082djigormNo ratings yet

- Problem Double AnglesDocument3 pagesProblem Double AnglesAnthony SupanNo ratings yet

- En 10025 s235jrg2 SteelDocument2 pagesEn 10025 s235jrg2 SteelsantyagoNo ratings yet

- SN490 B PDFDocument8 pagesSN490 B PDFalextentwentyNo ratings yet

- Durability: Hot Dip Galvanised Steel Sheet & CoilDocument8 pagesDurability: Hot Dip Galvanised Steel Sheet & CoilDin TcmNo ratings yet

- RC Tie Beam DesignDocument8 pagesRC Tie Beam DesignArfel BartianaNo ratings yet

- Datasheet FOXcore 308L T0 DG Cored WireDocument1 pageDatasheet FOXcore 308L T0 DG Cored WireAHRAKNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- RCC DesignDocument39 pagesRCC DesignMariappan .PNo ratings yet

- Technical Performance Data SheetDocument2 pagesTechnical Performance Data SheetAthul T.NNo ratings yet

- Builtup SectionDocument4 pagesBuiltup SectionSuhas MangaloreNo ratings yet

- HotRolledCoil-Gunung Raja PaksiDocument4 pagesHotRolledCoil-Gunung Raja PaksiAbdul JabbarNo ratings yet

- Microsoft PowerPoint - Deloro Stellite Advances in Wear Resistant Alloys and Products PDFDocument56 pagesMicrosoft PowerPoint - Deloro Stellite Advances in Wear Resistant Alloys and Products PDFamitNo ratings yet

- Stiffeners: (MM) (MM) (MM)Document4 pagesStiffeners: (MM) (MM) (MM)Md Ahsanul KabirNo ratings yet

- Chung Hung Steel Corporation: Hot-Dip Galvanized Steel Coil Hot - Rolled Pickled and Oiled CoilDocument16 pagesChung Hung Steel Corporation: Hot-Dip Galvanized Steel Coil Hot - Rolled Pickled and Oiled Coilrahul srivastavaNo ratings yet

- Gaskets - Graphite PDFDocument4 pagesGaskets - Graphite PDFSH1961No ratings yet

- Specification For Galvanized Steel: Raw Material SpecificationsDocument2 pagesSpecification For Galvanized Steel: Raw Material SpecificationsAnonymous aBZfewNo ratings yet

- REINFORCEMENTDocument3 pagesREINFORCEMENTanshdivyNo ratings yet

- MAM STD - B3 - 02 - 17 - 04 - Arc WeldingDocument3 pagesMAM STD - B3 - 02 - 17 - 04 - Arc WeldingMohanrajMJNo ratings yet

- JIS Steel Wires StandardDocument7 pagesJIS Steel Wires StandardPS NguyễnNo ratings yet

- Stroke Tol. +1.8 - 1.6Document4 pagesStroke Tol. +1.8 - 1.6Todor NedyalkovNo ratings yet

- ETABS Concrete Frame Design: ACI 318-19 Beam Section Design (Summary)Document2 pagesETABS Concrete Frame Design: ACI 318-19 Beam Section Design (Summary)dibyacittawirasukmaNo ratings yet

- LPCB Fire Resistant CableDocument2 pagesLPCB Fire Resistant CableArjunNo ratings yet

- Din17100 St37-2 Steel Plate For Carbon SteelDocument2 pagesDin17100 St37-2 Steel Plate For Carbon SteelAnom Manela100% (2)

- CMK2 Series Specifications・How to order・Dimensions (2MB)Document114 pagesCMK2 Series Specifications・How to order・Dimensions (2MB)Moch ChoezainiNo ratings yet

- S355 Low Carbon Manganese SteelDocument1 pageS355 Low Carbon Manganese SteelCarlos LopezNo ratings yet

- DPIS Condura - Prime AMB-Si3N4Document4 pagesDPIS Condura - Prime AMB-Si3N4masonNo ratings yet

- ELECTRODES, Type of Joints, Welding Symbols PDFDocument18 pagesELECTRODES, Type of Joints, Welding Symbols PDFChyawan KumarNo ratings yet

- 93 Qc20 J 414 Inlet NozzleDocument6 pages93 Qc20 J 414 Inlet NozzleHgagselim SelimNo ratings yet

- GFW 625Document1 pageGFW 625amit singhNo ratings yet

- DNO Pred 4 23.03.2018Document14 pagesDNO Pred 4 23.03.2018nemanja micicNo ratings yet

- 23 Feb 2022 Model v9 Beam ForcesDocument2,116 pages23 Feb 2022 Model v9 Beam Forces郑 凯伦 Tey Kai LoonNo ratings yet

- VTA Al99,5Document1 pageVTA Al99,5dmcosta99No ratings yet

- C 4721Document2 pagesC 4721Eileen TylerNo ratings yet

- EndPl MomConn LSDDocument54 pagesEndPl MomConn LSDTony RoseNo ratings yet

- Goldmax, 300 Series, Conformally Coated, X7R Dielectric, 25 - 250 VDC (Commercial Grade)Document19 pagesGoldmax, 300 Series, Conformally Coated, X7R Dielectric, 25 - 250 VDC (Commercial Grade)GillesNo ratings yet

- GWSS 22020 Let 0022Document1 pageGWSS 22020 Let 0022Heaven ChanNo ratings yet

- SKM C55823072014110Document1 pageSKM C55823072014110Heaven ChanNo ratings yet

- Calculation of Signage Connection On FootbridgeDocument94 pagesCalculation of Signage Connection On FootbridgeHeaven ChanNo ratings yet

- SKM C55823072417040Document4 pagesSKM C55823072417040Heaven ChanNo ratings yet

- Comment For FreyssinetDocument1 pageComment For FreyssinetHeaven ChanNo ratings yet

- Comment For AlgaDocument2 pagesComment For AlgaHeaven ChanNo ratings yet

- SKM C55823061410520Document2 pagesSKM C55823061410520Heaven ChanNo ratings yet

- SKM C55823051614420Document1 pageSKM C55823051614420Heaven ChanNo ratings yet

- GBJ17-88 钢结构设计规范 (English Version)Document136 pagesGBJ17-88 钢结构设计规范 (English Version)Heaven ChanNo ratings yet

- ERP Cloud Financials Fusion Cash Management R11 (8) SecurityDocument88 pagesERP Cloud Financials Fusion Cash Management R11 (8) SecurityELOUSOUANINo ratings yet

- (Certificate and Survey Status) : No Certificate Issued by RemarksDocument32 pages(Certificate and Survey Status) : No Certificate Issued by RemarksPankajShukla100% (1)

- UNIT-2Document2 pagesUNIT-2Azra HumićNo ratings yet

- BB 100 CabinetDocument2 pagesBB 100 CabinettinduongNo ratings yet

- BS en 10021-2006Document20 pagesBS en 10021-2006anjanamurthy20060% (1)

- Lab 2Document7 pagesLab 2api-389840384No ratings yet

- Qcadesigner SimuDocument20 pagesQcadesigner SimuSupravatAppaNo ratings yet

- Abb Weather ProofDocument58 pagesAbb Weather ProofEhsan ShaukatNo ratings yet

- LINSEIS Thermal Conductivity v4 CompressedDocument20 pagesLINSEIS Thermal Conductivity v4 CompressedsayarersNo ratings yet

- AITS 2324 FT III JEEM TD SolDocument15 pagesAITS 2324 FT III JEEM TD Soladoranto737No ratings yet

- GATE EE 2014 Solve Paper 1Document34 pagesGATE EE 2014 Solve Paper 1ankitNo ratings yet

- Curriculum Vitae: PersonalDocument10 pagesCurriculum Vitae: PersonalAzhariArdyNo ratings yet

- Java Architecture With 14 Years ExperienceDocument6 pagesJava Architecture With 14 Years Experiencekalicharan13No ratings yet

- Methods of Chemical Analysis of Ferro Alloys. Indian Standard 1962Document73 pagesMethods of Chemical Analysis of Ferro Alloys. Indian Standard 1962Fernando BalseiroNo ratings yet

- IIB WSSecurityDocument65 pagesIIB WSSecuritydiva100% (1)

- Big Data in The Cybersecurity Operations Center: Thomas M. MitchellDocument3 pagesBig Data in The Cybersecurity Operations Center: Thomas M. MitchellBusiness Expert PressNo ratings yet

- AE510 - 03 NACA 0015 AirfoilDocument25 pagesAE510 - 03 NACA 0015 Airfoilasan09No ratings yet

- PredaDoor - NXT - Owners - (8-6-2014) PUERTA RYTECDocument52 pagesPredaDoor - NXT - Owners - (8-6-2014) PUERTA RYTECErikaGaitanGonzalezNo ratings yet

- Arctic Cat Spring ChartDocument2 pagesArctic Cat Spring ChartRobert FenskeNo ratings yet

- Va1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellDocument17 pagesVa1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellKhang TrangNo ratings yet

- 39thv RGVDocument109 pages39thv RGVRajeshYadavNo ratings yet

- Systematic Parametric Design/calculation of The Piston Rod UnitDocument11 pagesSystematic Parametric Design/calculation of The Piston Rod UnitSergio PluchinskyNo ratings yet

- Small Guide To Making Nice Tables: Markus Püschel Carnegie Mellon University WWW - Ece.cmu - Edu/ PueschelDocument16 pagesSmall Guide To Making Nice Tables: Markus Püschel Carnegie Mellon University WWW - Ece.cmu - Edu/ PueschelMonBraveNo ratings yet

- Honda Accord Owners ManualDocument15 pagesHonda Accord Owners ManualSANTOSHANDIAPPA THANEERMALAI A/L KANESAN MoeNo ratings yet

- Vol04 Tab02Document447 pagesVol04 Tab02asssasasNo ratings yet

- 1 - Properties of Plane AreasDocument24 pages1 - Properties of Plane AreasEng Ahmed Abdullah (Engineer)No ratings yet

- LK-1910, LK-1920, LK-1930 emDocument187 pagesLK-1910, LK-1920, LK-1930 emAmila LasanthaNo ratings yet